Dan Vizine

National Hazard

Posts: 628

Registered: 4-4-2014

Location: Tonawanda, New York

Member Is Offline

Mood: High Resistance

|

|

Making Element Samples: Lead

Suitable methods for making attractive elemental samples are not easily available in the scientific literature. Development of suitable methods is

often trial and error, and that is especially true of borosilicate ampoules into which a molten metal is introduced.

Some details are universally applicable no matter what metal is used. These include washing the glass with hot, concentrated H2SO4, thorough rinsing

with tap water followed by several rinses with distilled water and air-drying. The glass is then heated with a bushy blue gas flame, while connected

to a vacuum pump, to remove surface water.

But, after that, what works well for one liquid metal often isn't always good for another. The liquid metals that I'm considering here are any that:

a) melt below the softening point of borosilicate glass

b) can react with environmental gases to become discolored or degrade, and thus need protection.

This group includes Na, K, Pb, Sn, Cd, Tl, and Zn.

Ga and In have low enough toxicities, low enough reactivities and interesting enough tactile properties to make sealing in glass unnecessary.

Cs and Rb are largely handled with warm syringes.

Without further discussion, let's consider Pb. I purchased Pb of 99.9% purity and it is stored under argon. When this metal is melted in a 3/4"

diameter borosilicate tube (1.5 mm walls) under UHP argon, it melts to a silvery metal with a gray oxide skin. It first occurred to me that the same

procedure that I used for Na and K would work: form a tube with an ampoule at one end, a place to melt metal at the other and a filtration medium in

between. This gave only fair results compared to Na or K because the solids in the film are fine enough to leak past the stainless steel wool filter.

The metal did not form a smooth even film in contact with the glass. I did observe that most of this film adheres to clean glass when the molten metal

is decanted away. So, I repeatedly melted the Pb in clean glass tubes under argon and then rapidly emptied this tube onto a SS 304 plate. Each time,

the Pb metal that was a bright, shiny silver color was returned to the next tube to be re-melted. After four cycles, three of which are shown below,

the Pb poured out, leaving no grey residue behind. This sample was sealed in an ampoule under vacuum and then re-melted to give a pleasing appearance.

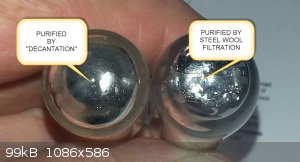

Three of the four decantation tubes are shown, displaying decreasing oxide levels from left to right. A comparison of filtered metal with multiply

decanted metal shows the superior cleanliness of the latter.

This isn't a very scientific post, nor do I expect it to arouse much interest. Hopefully though, somebody, someday, may find this practical knowledge

helpful. As I do the other metals, I'll post similar details for each one. Each one will likely show at least some quirk specific to that particular

metal.

[Edited on 3-1-2017 by Dan Vizine]

"All Your Children Are Poor Unfortunate Victims of Lies You Believe, a Plague Upon Your Ignorance that Keeps the Youth from the Truth They

Deserve"...F. Zappa

|

|

|

AJKOER

Radically Dubious

Posts: 3026

Registered: 7-5-2011

Member Is Offline

Mood: No Mood

|

|

The steel wool is likely more than a filter being that iron is more reactive than lead:

PbO + Fe = FeO + Pb

|

|

|

Dan Vizine

National Hazard

Posts: 628

Registered: 4-4-2014

Location: Tonawanda, New York

Member Is Offline

Mood: High Resistance

|

|

The residence time in the SS wool is a tiny fraction of a second, I doubt that much happens in transit.

The length of the tube is heated, lead is melted in one end, then a quick overhand swing ending near the floor shoots the metal through the plug, and

most importantly, past the pre-made constriction. Any tiny, tiny specks left there result in this:

"All Your Children Are Poor Unfortunate Victims of Lies You Believe, a Plague Upon Your Ignorance that Keeps the Youth from the Truth They

Deserve"...F. Zappa

|

|

|

|