Boffis

International Hazard

Posts: 1836

Registered: 1-5-2011

Member Is Offline

Mood: No Mood

|

|

Preparation of 1,4-Dibromobutane

My previous attempts to prepare this halo-hydrocarbon compound were based on the addition of bromine to a mixture of moist 1,4-butanediol and red

phosphorous. While this worked the small amount of red phosphorous available to me meant that at this small scale the work-up was difficult e.g. the

distillation of 5ml of crude product. To carry out the preparation on a larger scale I decided to try the sodium bromide /sulphuric acid method used

to produce single alkyl halides.

Procedure:

18ml (c 19g) of 1,4-butanediol were added to a solution of 58g of sodium bromide in 55ml of warm water in a 250ml conical flask containing a stir bar.

50ml of concentrate (SG 1.84) sulphuric acid were added, slowly at first as the reaction is strongly exothermic. As more acid was added the reaction,

which is essentially the hydration of sulphuric acid at this stage, become less exothermic and the rate of addition could be increased. The flask was

fairly hot by the time addition was complete but apart from the release of a little hydrogen bromide this is not a problem. If the addition is too

slow the mixture will cool and coarsely crystalline sodium sulphate will crystallize out; though it will dissolve again on heating.

Once all of the sulphuric acid had been added a brown homogeneous solution was formed but as it heats up the mixture begins to turn cloudy and after

about 30 minute brown droplets appear. The solution was refluxed for 4 hours during which time a dark, heavy, oily layer of dibromobutane forms. After

4 hours it was allowed to cool and poured into about 150ml of cold water when a heavy brown oil soon separated. The mixture was transferred to a

separating funnel and allowed to settle until the bulk of the heavy oil had separated. This was run off and the aqueous phase extracted with 30ml of

dichloromethane.

The DCM extract and the original heavy oil were combined and the aqueous layer discarded. The organic layer was washed with 50ml of water, then 50ml

of 5% sodium bicarbonate and finally with 30ml of water. It was dried with anhydrous magnesium sulphate, filtered and distilled. A slightly cloudy DCM

fraction passes over between 40 and 64°C then the temperature rose rapidly but required stronger heating with a Bunsen burner. The 1,4-dibromobutane

was collected between 194 and 200°C as an almost colourless heavy liquid with only a faint halocarbon odour. The dibromobutane fraction was collected

in a pre-weighed beaker, about 20ml were collected weighing 37.01g or about 85% of theory (the exact yield cannot be calculated as the butanediol was

measure out by approximate volume).

Having proved that the process works I intend to carry out a larger scale preparation with accurate weights of reactants and photographs.

|

|

|

DJF90

International Hazard

Posts: 2266

Registered: 15-12-2007

Location: At the bench

Member Is Offline

Mood: No Mood

|

|

Nice work Boffis.

I thought you might be interested to know that there is a preparation of trimethylene dibromide on OrgSyn under the same link I posted in the

Br2 to HBr thread: http://www.orgsyn.org/demo.aspx?prep=CV1P0025

This preparation should be readily adapted for use of 1,4-butanediol as substrate.

|

|

|

Melgar

Anti-Spam Agent

Posts: 2004

Registered: 23-2-2010

Location: Connecticut

Member Is Offline

Mood: Estrified

|

|

You should try this with THF. 1,4 butanediol is somewhat controlled in a lot of jurisdictions, and theoretically THF could react similarly. Never

tried it myself though, it was always just a hypothetical.

The first step in the process of learning something is admitting that you don't know it already.

I'm givin' the spam shields max power at full warp, but they just dinna have the power! We're gonna have to evacuate to new forum software!

|

|

|

AvBaeyer

National Hazard

Posts: 644

Registered: 25-2-2014

Location: CA

Member Is Offline

Mood: No Mood

|

|

Tetrahydrofuran can be converted directly to 1,4-dibromobutane. Here is a reference from my files:

Tetrahydrofuran (72 g., 80 c.c., 1 g.-mol.), b. p. 64-66 C, was added slowly to a cold mixture of hydrobromic acid (50%, 972 g.. 6 g.-mols.) and

concentrated sulphuric acid

(50 c.c.), and the mixture refluxed for 3 hrs. The product was steam-distilled, and the lower layer dried over calcium chloride followed by phosphoric

oxide. Tetramethylene dibromide, thus obtained in 82% yield, had b. p. 198-201 C (Found : C, 22.8 ; H, 3.8 ; Br, 72-35. Calc. for C,H,Br, : C, 22.2 ;

H, 3.7 ; Br, 74.0%).

CHRISTOPHER L. WILSON, Reactions of Furan Compounds. Part II. Fission of the Tetrahydrofuran and the Tetrahydropyran Ring. J Chem Soc 1944 or 1945.

AvB

|

|

|

Boffis

International Hazard

Posts: 1836

Registered: 1-5-2011

Member Is Offline

Mood: No Mood

|

|

Thanks for the information guys. Actually the reason I choose the diol is precisely because I want to use it up. I originally acquired it from a guy

who was selling various chemicals on ebay. When I went to collect them he asked if I would be interested in any of these (waving his hand over a stack

of boxes). He explained that these were the chemicals he didn't think he could post on ebay; quite a collection. So the diol was just there and it has

sat on the shelf for years without a use. But now my interests in the coordination complexes of thio-ethers has made me look at C2 to C4 length

dithiols as building blocks. I can't find 1,3 propanediol in Europe so I have had to skip the C3 group. A am going to try this with glycol too.

|

|

|

Boffis

International Hazard

Posts: 1836

Registered: 1-5-2011

Member Is Offline

Mood: No Mood

|

|

OK here is a revised procedure on a larger scale with pictures:

Experiment 2

165g of sodium bromide were placed into a 1L conical flask containing a large stir bar and 100ml of water added. The flask was placed on a stirrer

plate and warmed very gently with stirring to help solution of the salt. 55.43g of melted 1,4-butanediol was weighed out into a 100ml beaker and 20ml

of water stirred in to stop it solidifying again. This was added all at once to the flask and the beaker rinses with 40ml of water.

Photo 1; Sodium bromide in the flask and the diluted diol in the beaker

Photo 2; The bromide salt and butanediol solution, the beaker contains sulphuric acid

The flask was stirred without further heating until all had dissolved. 150ml of concentrated sulphuric acid were then slowly added to the stirred

solution, slowly with a dropper at first but after the first 50ml the rate of addition could be increased with additions of up to 5ml at a time

towards the end. The solution turns clear brown and becomes fairly hot and towards the end a little hydrogen bromide escapes.

Photo 3; The clear brown solution after the sulphuric acid addition

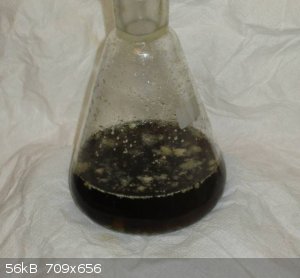

Photo 4; Oily droplets appearing after about 30 minutes refluxing

The solution was heated to boil with constant stirring and then refluxed for 4 hours and then allowed to cool. When almost at room temperature it was

diluted with an equal volume of water. The mixture was allowed to settle overnight in the cold (c 5°C) then most of the upper aqueous layer decanted

into a large separating funnel and extracted with 50ml of dichloromethane; the aqueous phase then being discarded.

The oily lower did not separate cleanly from the aqueous layer as they contained a small amount of dark slimy solid that concentrates at the interface

so the mixture was filtered through a Buchner funnel with glass paper. This greatly improved the sharpness of the subsequent phase separation.

Photo 5; The dark oily layer settling on completion of the reflux

Photo 6; Drying the separated layer with magnesium sulphate

The filtrate was allowed to stand until the phases separated. The oily layer was separated, washed with water, 5% sodium bicarbonate and finally water

again. The aqueous layer was extracted with the earlier DCM extract and then a further 20ml of dichloromethane before being discarded. The DCM

extracts were mixed with the dibromobutane layer and dried overnight with magnesium sulphate.

The clear brown organic layer was distilled in a simple arrangement, a slightly cloudy dichloromethane fraction distilled off between 40 and about

68°C but then distillation ceased: the heat transfer from the hotplate being inadequate to drive off the high boiling butane derivatives. The

hotplate was replaced with a Bunsen burner and a vacuum adapter with a closed receiver were added and the remaining liquid distilled at the lowest

pressure that the water pump could produce. Most of the liquid passed over at 140-142°C but the pressure was unknown. When about 5-7ml of dark

residue was left in the flask the temperature began to rise quickly again and the distillation was stopped. The yield of clear, colourless, heavy

liquid was 102.58g, a little under 60ml, about 77% of theory based on butanediol.

The final distilled product

Discussion

The slightly lower yield of 1,4-dibromobutane in the second experiment may be more apparent than real since the weight of 1,4-butanediol was not

measured in the first experiment. The use of a little less water and a little more sulphuric acid and sodium bromide may improve the yield. The higher

concentration of sulphuric acid reduces the activity of the water in the reaction mixture and since this reaction is an equilibrium reaction drives

the reaction further towards completion. Some preparations using this method use a much higher ratio of sodium bromide or hydrobromic acid to alkohol

but the yield reported don't seem to justify it for such cheap starting materials.

I had the impression that mechanical recovery was better in the second experiment; the filtration of the reaction mixture to remove the small amount

of dark (carbon?) solid greatly improved the cleanness of the separation.

If I run this reaction again I may try recovering the excess bromine in the residue by adding an oxidizing agent (such as manganese dioxide or a

persulphate) and either distilling the bromine or extracting it with DCM.

[Edited on 25-1-2018 by Boffis]

|

|

|

Boffis

International Hazard

Posts: 1836

Registered: 1-5-2011

Member Is Offline

Mood: No Mood

|

|

Experiment 3

I have just completed the work up on a repeat of the above experiment but using a molar equivalent (44.30g) of tetrahydrofuran but the same weight of

acid and sodium bromide. I dissolve the sodium bromide in just 100ml of water with warming and added the THF. The latter did not mix as the diol had

and since it is highly volatile I added the reflux condenser immediately and then added the acid fairly rapidly from a dropping funnel through the

reflux condenser. So much heat is generated that the mixture can be made to reflux steadily without heating at first but powerful stirring is

essential. After all of the conc. sulphuric acid had been added (about 10-12 minutes) the mixture was refluxed with external heat for 5 hours then

cooled a little and diluted with 200ml of water then cooled to room temperature (this is to stop the sodium sulphates from crystallising out). The

whole reaction mixture was filtered through a fine glass frit and then separated in a funnel. After removal of the heavy organic layer the aqueosu

residue was dilute with 200ml of water and then extracted with 50ml of dichloromethane.

The organic phases were combined, washed with 2 x 100ml of 4% sodium bicarbonate and then 100ml of water. The organic phase was a little cloudy so was

dried overnight with magnesium sulphate and then distilled, initially at atmospheric pressure to remove the dichloromethane and then under aspirator

vacuum. The product distilled over under a steady but unknown pressure at between 128 and 134 C. The yield of water clear, mobile but dense

1,4-dibromobutane was 110.81g or about 83% of theory.

It would appear therefore that tetrahydrofuran and 1,4-butanediol are completely interchangeable in this react. Slightly less water was used in this

run than in the previous runs and this along with improved handling skills probably may accounts for the better yield rather than tetrahydrofuran

being an inherently better substrate. Only 30ml of dichloromethane was recovered.

I hope these notes are useful to someone else.

|

|

|

Dr.Bob

International Hazard

Posts: 2656

Registered: 26-1-2011

Location: USA - NC

Member Is Offline

Mood: No Mood

|

|

Great writeup. I have heard of THF acting as 1,4-butanediol, but have not tried this reaction. But I have found if you want to make 1,4-butanediol

by mistake, just let BH3 in THF sit at room temp (or higher) for few days. If you use that BH3-THF for a reaction, your product will be grossly

contaminated with 1,4-butanediol once you work it up and evaporate the THF.

|

|

|

Boffis

International Hazard

Posts: 1836

Registered: 1-5-2011

Member Is Offline

Mood: No Mood

|

|

Does anyone know if it is possible to produce butadiene gas by say dropping 1,4-dibromobutane into say aqueous NaOH or ethanolic KOH?

Also how soluble is it in organic solvents like ether, petroleum ether, THF etc.?

|

|

|

LearnedAmateur

National Hazard

Posts: 513

Registered: 30-3-2017

Location: Somewhere in the UK

Member Is Offline

Mood: Free Radical

|

|

Doesn’t that just convert it back into butanediol through nucleophilic substitution? OH- + R-X -> R-OH + X-. I think you’d have better luck

dehydrating your butanediol with concentrated sulphuric acid at high temperatures, like how ethene is made from ethanol; I’m sure there’d be a way

to minimise THF formation (forgot that you’d get that as a significant product) like through higher temperatures or a catalyst. Or there might be

some way to convert intermediary THF to butadiene too?

[Edited on 28-2-2018 by LearnedAmateur]

In chemistry, sometimes the solution is the problem.

It’s been a while, but I’m not dead! Updated 7/1/2020. Shout out to Aga, we got along well.

|

|

|

Boffis

International Hazard

Posts: 1836

Registered: 1-5-2011

Member Is Offline

Mood: No Mood

|

|

@LearnedAmateur; that's basically my reason for asking the question. I notice that some aliphatic halide seem to undergo substitution while others,

particularly aromatic substitute ones, loose hydrogen halide. I was wondering if someone with a better grasp of theoretical chemistry could offer

enlightenment!

I like the idea of sulphuric acid dehydration but like you say THF might form first and being rather volatile boil off before it can react further.

Treating the 1,4-dihalide might give THF too though.

|

|

|

vibbzlab

Hazard to Others

Posts: 241

Registered: 6-11-2019

Member Is Offline

Mood: Always curious

|

|

Synthesis of 1,4 dibromobutane from THF

I know it's very late response for the thread. But this should be helpful for someone searching the synthesis of 1,4 dibromobutane using THF and HBr.

The synthesis was adapted from Vogel's textbook of practical organic chemistry.

1,4 Dibromobutane synthesis

https://youtu.be/TzJvJrxxG4g

Amateur chemist. Doctor by profession

Have a small cute home chemistry lab.

Please do check out my lab in YouTube link below

This is my YouTube channel |

|

|

j_sum1

Administrator

Posts: 6218

Registered: 4-10-2014

Location: Unmoved

Member Is Offline

Mood: Organised

|

|

Thanks Vibbzlab. I found your video on yt and enjoyed it.

Very accessible procedure. And you got a good yield.

|

|

|