| Pages:

1

2 |

Doped-Al2O3-fusion

Hazard to Self

Posts: 99

Registered: 11-4-2018

Member Is Offline

Mood: Maniacal

|

|

Sodium Thiosulfate Synthesis and Purification

I have been searching the forum for this topic specifically and I came across some threads discussing it, but I haven't found a dedicated thread on

synthesizing Na2S2O3 via the NaOH + S boiling method from start to finish. I've been trying to find experiments with results from anyone with yield

results & pictures...because I need to see pictures to accompany any text that I read.

Here is a method I experimented with a couple times. This post is more the eyeballed lazy approach, as my notes from the first synthesis a couple

months ago are in a notepad upstairs, and I'm not getting them right now. Basically, the purification was done by fractional crystallization and I

don't get into the details of this level of purification. I used ethanol today for the initial precipitation.

The crude basics of making sodium thiosulfate.

Required compounds:

Sulfur

Sodium hydroxide

Distilled water

Everclear (anhydrous ethanol)

Test tube method:

1.) Make normal sodium hydroxide solution and add 10mL of solution to test tube.

2.) Add approximately 1/2 teaspoon of sulfur to start out with.

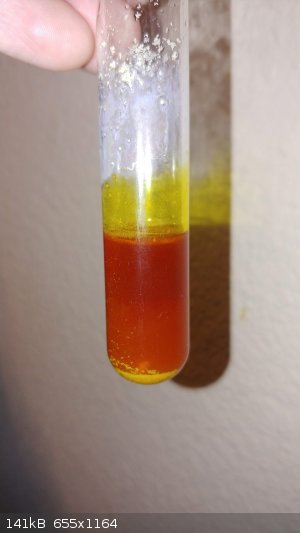

3.) Boil sodium hydroxide + sulfur solution until all the sulfur has dissolved. Add more sulfur if necessary until no more sulfur dissolves. The

solution will be dark red.

4.) Let solution cool, then filter the excess sulfur out.--It's easier if you add 50mL of distilled water to the solution first so that it will be

thin enough to go through the filter paper.

5.) Heat / evaporate water out of solution until crystals begin to form on the stir rod. Let the solution cool.

6.) Poor in an equal amount of ethanol to begin precipitating sodium thiosulfate. It helps to heat the solution up again at this point for a short

while until you see crystals floating on the surface of the hot solution. (I'd veer away from open flames.)

7.) Let the solution cool and filter off the white crystals. <--this is your highly contaminated sodium thiosulfate. It'll be light yellow due to

the polysulfide side products. (i.e. disulfide, trisulfide, tetrasulfide and pentasulfide.)

8.) Recrystallize several times until crystals are colorless/white.

The light yellow colored waste material, as stated, are polysulfides. If you add a bit of hydrochloric acid you can produce hydrogen sulfide which I

hear smells like rotten eggs. I don't have a sense of smell. On that note, hydrogen sulfide is extremely toxic, on par with carbon monoxide, so don't

breathe in the fumes. Due to not having a sense of smell, I created H2S test strips with lead acetate.

I personally used the waste products and added it to some excess hexavalent chromium solution I needed to reduce. The waste product, without a doubt

contained a significant volume of Na2S2O3. It's the chromium solution which prompted me to look into another means of reducing to trivalent form. I

had been using ferrous sulfate previously.

Tips:

Get sulfur powder from garden supply section of hardware store. Pick up some sodium hydroxide drain cleaner as well.--it's 100% sodium hydroxide. The

sulfur will need purified, but this can be done by mixing with distilled water and decanting several times with rinsing. Any remaining impurities can

be removed by recrystallization of the sulfur, using heat and either xylene or toluene. The impurities can also stay in solution as they'll be removed

in the later steps.

I couldn't find anything on how to purify sodium thiosulfate from the sodium hydroxide synthesis method, so I made this procedure up on my own. If it

turns out the white crystallized end product is some nasty unknown chemical, I apologize.--don't use it to treat cyanide poisoning. Buy sodium

thiosulfate instead and throw away the stuff you made.

Another way to get sodium thiosulfate is to go to the pet store and buy dechlorinating solution from the fish section. Be sure it states on the bottle

or look up the MSDS sheet to verify Na2S2O3 is the product. It may be a mix, or have none entirely, so seriously check the ingredients.

You can also buy bucket loads of STS from everywhere online cheaper than water I believe.

[Edited on 16-8-2018 by Doped-Al2O3-fusion]

[Edited on 16-8-2018 by Doped-Al2O3-fusion]

|

|

|

Doped-Al2O3-fusion

Hazard to Self

Posts: 99

Registered: 11-4-2018

Member Is Offline

Mood: Maniacal

|

|

I plan on replying to this thread with much greater detail in the future. I'll leave the humor out as well, which was most likely not noticed to

begin with.

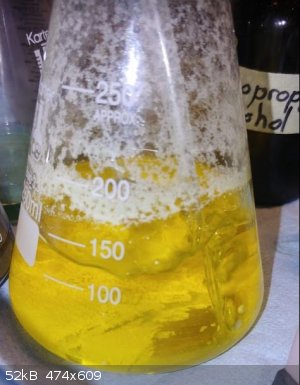

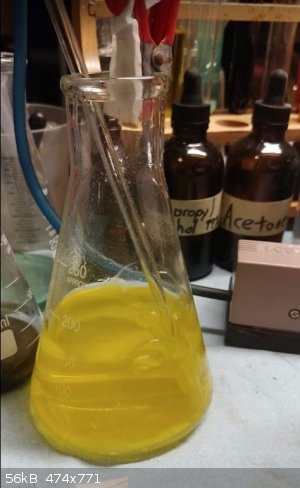

I do have this picture though showing sodium sulfide as the initial precipitate forming. This was pretty much all that precipitated anyhow.

|

|

|

Doped-Al2O3-fusion

Hazard to Self

Posts: 99

Registered: 11-4-2018

Member Is Offline

Mood: Maniacal

|

|

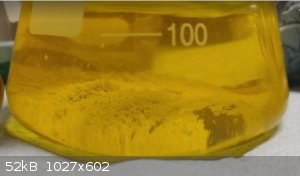

The slower the crystals are grown, the larger and more pure they'll be. They are easily washed off with alcohol and should be recrystallized two or

three more times. I've used both ethanol and methanol successfully. I don't remember if I've ever used isopropanol. I tried acetone on a small

amount and the solution turned really dark reddish brown. It's very clear surprisingly (not turbid), but it's extremely dark. I'll see what it looks

like tomorrow and get a picture.

|

|

|

Doped-Al2O3-fusion

Hazard to Self

Posts: 99

Registered: 11-4-2018

Member Is Offline

Mood: Maniacal

|

|

To be honest, I've not had a chance to proofread anything I've written tonight. My family has been talking my ear off non-stop for over five

hours.--even while writing this reply, I've not looked at the screen.

Step 6 is pretty sketchy and crude. There are a couple of missing steps. The first time I created the sodium thiosulfate I thought it would be much

more basic than what it was, but it had a pH closer to 8.--I think that's why I got such a decent yield of white crystals the first time around.

Today was the first time I've tried alcohols to precipitate anything out.

|

|

|

Doped-Al2O3-fusion

Hazard to Self

Posts: 99

Registered: 11-4-2018

Member Is Offline

Mood: Maniacal

|

|

My overall interest in this method began from watching a YouTube video on synthesizing STS from boiling aqueous NaOH + S.

I thought the "eyeballed chemistry" might spark some comments regarding purifying STS from solution since I'm finding it difficult to come across

others whom have performed this experiment all the way through.

At this time I'm running a modified experiment and I'm going to diligently log my procedures and observations. Posts will follow...

[Edited on 17-8-2018 by Doped-Al2O3-fusion]

|

|

|

Doped-Al2O3-fusion

Hazard to Self

Posts: 99

Registered: 11-4-2018

Member Is Offline

Mood: Maniacal

|

|

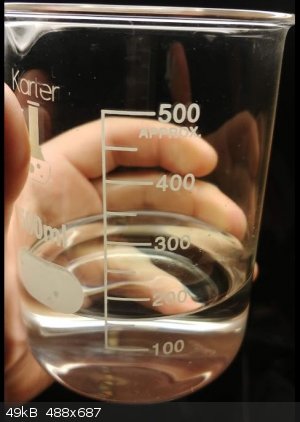

For those that like pictures like I do, here is how my experiment was ruined yesterday morning when I checked on my beakers. This was after I had

removed three large moths already.

|

|

|

Doped-Al2O3-fusion

Hazard to Self

Posts: 99

Registered: 11-4-2018

Member Is Offline

Mood: Maniacal

|

|

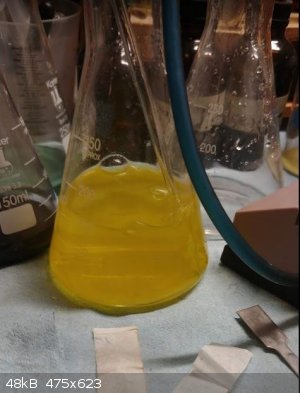

So here I am showing off my novice skills by experimenting with passing pure oxygen through the solution of sodium thiosulfate & polysulfides. I

have no clue if it's working at all or not, but there is about 100mL of dilute H2O2 solution left to drip onto the MnO2, so I'll let it finish just to

see what I come up with.

I came across this article searching "oxidation of polysulfides to thiosulfate".

...on a side note, adding dilute H2O2 to the solution doesn't work as I had hoped. It generates H2S as well as crashing elemental sulfur out of

solution even if the solution remains basic. You can see my lead acetate H2S detector test strip formed lead sulfide immediately.

https://pubs.acs.org/doi/abs/10.1021/ja01328a025?journalCode...

[Edited on 17-8-2018 by Doped-Al2O3-fusion]

|

|

|

Doped-Al2O3-fusion

Hazard to Self

Posts: 99

Registered: 11-4-2018

Member Is Offline

Mood: Maniacal

|

|

SUCCESS!!!.....(hopefully)

I checked on my experiment yesterday and found that there was a lot of solid material gathering at the bottom of the Erlenmeyer flask which I was

pumping air through the polysulfide solution. I filtered it off and began pumping air again. The solid material that I filtered off looked a bit

like sulfur, only with a green tinge. I think this is more a trick of the lighting as it looks like clear crystals formed over yellow sulfur crystals

under my microscope.

I thought, this could be two things and both indicate a problem. More sulfur is precipitating out from solution which there shouldn't be at this

point, AND, there appears to be sodium sulfide crystallizing on the elemental sulfur. This tells me there is H2S formation, so the pH must have

dropped. This latest batch is actually another do-over which I didn't post about the spill from the last pictures I had posted showing pure oxygen

bubbling through solution. This current batch started out with a pH of approximately 9--which is within the neutral to basic tolerance required to

form thiosulfate. However, this time I'm using outside air rather than generated oxygen.

I'm assuming there is enough carbon dioxide also being pulled into the apparatus and bubbled through the solution to form sodium carbonate and

bicarbonate. The CO2 would add to a slight acidification to the solution bringing the already low basicity of the solution down closer to neutral.

What's more, my pH papers are cheap pH papers which probably have reliability issues much like other cheap pH papers. I'm going to assume that the pH

actually just went to neutral rather than the adjusted drop to 8 during my check. The reported neutral could have been the slightest amount of acid,

we'll say 6.9 for example.

If this polysulfide solution has the slightest drop below the neutral range, it rapidly begins to precipitate elemental sulfur and release H2S. I

tested for H2S production again now that the air was being once again bubbled through the solution. Sure enough, my lead acetate test strip turned

dark indicating H2S formation. I stopped the experiment at this time to investigate what the greenish yellow precipitate was and found what I stated

earlier. I decided the best course of action would be to make the solution more alkaline, so I added 15mL of the remaining sodium hydroxide to the

solution and began the bubbler again.

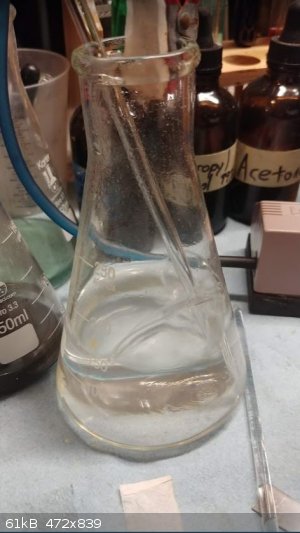

I performed periodic checks and found encouraging results. I'm expecting the solution to become clear because in my mind that's what I imagine should

happen if all the polysuflides are being converted to colorless thiosulfate. If it were to oxidize to much, then I would be getting a white

precipitate with the clear solution due to formation of sodium sulfate. Any of the other sulfides have color from light orange, red, yellow. To

oxidize to tetrathiosulfate would require iodine in a reaction, so as long as I don't let it sit too long, I should get near a 100% yield...at least

theoretically the next time I do this I should. I diminished my yield due to the pH being too low, forming H2S and sodium sulfide which I may be able

to reintroduce into solution, but I'm not going to take my chances for now.

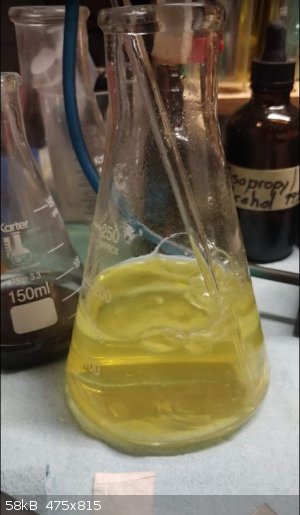

Here are the pictures of everything I just described. You can see the gradual color change to completely clear.

|

|

|

Doped-Al2O3-fusion

Hazard to Self

Posts: 99

Registered: 11-4-2018

Member Is Offline

Mood: Maniacal

|

|

The pH level was between approximately 12 when I made the adjustment yesterday. Today, the pH showed between 10 - 11, so my hypothesis is that the

CO2 coming along in the air line with the oxygen is converting the excess sodium hydroxide to sodium carbonate/bicarbonate.

The very first time I performed this experiment was last winter. I let this whole lab run for a couple weeks to get the crystals I did, so everything

was oxidizing on the solution surface, and I would filter daily or every other day and pull out the crystals to examine. I'd wash them off in ice

cold water, then redissolve into solution to recrystallize once I had accumulated enough crystals. This is also why I have three distinct phases of

crystal structure in my picture showing my past results.

This time around I wanted to do it within two days, or the first 24 hours.

My goal now is to reproduce this experiment one more time using my corrected mistakes and procedure adjustments, and produce something near 100%

yield. From the research I performed, it seems formation of all polysulfides to thiosulfate is inevitable under the right conditions. I think so

long as you start out with a high enough pH (minimum pH10), high yeilds can be achieved easily enough. Just add excess sodium hydroxide to raise the

pH and add about 50mL more H2O, or a total of 150mL in a 250mL Erlenmeyer. Acid and H2S and SO2 formation are all your limiting reactants, in that

you want zero percentage to form, else the experiment will fail since we're not purposely generating H2S to bubble through sodium sulfite solution.--a

totally different process.

My process as this is what I gathered from the YouTube Video which gave very little information other than eyeballing an experiment. As stated before,

I really wanted to see what kind of results could be achieved using only this eyeballed style of approach. I replicated it the best I could and

thought up additional steps to take to purify and reduce/eliminate wasteful byproducts.

Now, if anyone has any input into this experiment, now is the time to place your thoughts. My goal is to never come here asking others to tell me how

to do something. My goal is to learn safely on my own (I'll take safety tips at any point in a thread I run), but I'm not looking for input on how to

run the experiment. That's no different to me than asking everyone "What's the answer?" I want to find that out at minimum prove something is

feasible, and I hope for great/respectable yields. Then once I'm done with that, I come to my conclusion if I can move onto another project or save a

re-do for another day because it was successful enough on the latest round to comfortable place on the backburner, having a good idea what needs

revisited, readjusted and implemented for better future results.

So, Please feel free to chime in on any input you may have on things I could have done better from known examples, or your educated ideas such as

laterally similar reactions. Was the pure oxygen method better or was regular atmosphere the better option since the results look so great at this

time? My concerns are unnecessary buildup of carbonates, despite having a percentage of carbonates present as a pH buffer which would have prevented

the first major issue on this last time around. I don't see any evidence that if the pH is set too high, thiosulfates won't be formed, but I also

don't see any data indicating tetrathiosulfates & sulfates won't be generated. Monitoring to keep the pH between 10 - 12 while the product is

dark orange, then between 9 - 10 when clear.

I'm going to begin evaporating off the excess water so that any lower salts may precipitate from solution first. (i.e. sodium sulfate, sodium

carbonate/bicarbonate, etc.) Then I can form the (med growth rate) thiosulfate crystals (tetrahedral) and rinse them with freezing water. I'll

redissolve in solution and recrystallize into evenly grown, symmetrical and large crystals. I'll get some of the solid purified crystal and save it

to help purify the runnoff waste from rinsing and solution waste products which still contain thiosulfate. I save and recycle everything I create in

my lab. That's why my learning appears slow. I just don't constantly report on all the work I do in purifying aluminum, copper, chromium, nickel,

bismuth, gallium iron oxides and all the transition metal salts. In fact this is the reason I wanted to create my own thiosulfate in the firstplace.

I wanted to reduce haxavalent chromium to trivalent, then I found other uses for it in my iron disulfide crystal synthesis experiment.(synthetic

pyrite)--I'm aiming for microscopic since I have a good microscope. Using my microscope to see things I created is no different to me than holding it

in my hand.

Anyhow, I'm back off to bed or maybe clean up a bit, and prep for my next experiments.

I'll post more on the progress later on.

NaOH + S --> Na2S2O3 x 5

|

|

|

Doped-Al2O3-fusion

Hazard to Self

Posts: 99

Registered: 11-4-2018

Member Is Offline

Mood: Maniacal

|

|

I'm feeling very proud of myself right now. If not pride, then excitement. I'm very happy with this result. This is what I predicted should happen

if I convert a very good yield of thiosulfate from the polysulfide solution. I should end up with a clear as water solution after oxidizing the

polysulfides in a high pH solution. It freaking worked to this point. Now I only need to crystallize the final product and perform some tests. I

would love, I'd be honored, to have someone repeat my experiment to validate or invalidate my results. There is no right and wrong in validation

results. There's just correct or incorrect. I'll learn from mistakes and new observations and move on. That's winning and I want to win.

[Edited on 20-8-2018 by Doped-Al2O3-fusion]

|

|

|

wg48

National Hazard

Posts: 821

Registered: 21-11-2015

Member Is Offline

Mood: No Mood

|

|

My thoughts are why not add the H2O2 directly to the the NaOH + S solution or probably better the other way round?

Judging by the colour of your NaOH + S solution there is too much sulphur in there. Do you need poly sulphides ? Sorry but I do not know the ideal

stoichiometry. Try to determine the stoichiometry from a balanced equation.

If your oxygen bubbles are reaching the surface approximately the same size, reduce the oxygen rate and add a fine tip or sinter to the end of the

bubblier tube and use a long tall and narrow flask. perhaps add a balloon to the out let so you can swirl the flask and see how quickly the oxygen is

absorbed

Sorry if you have already covered the above I only skimmed through your posts.

Borosilicate glass:

Good temperature resistance and good thermal shock resistance but finite.

For normal, standard service typically 200-230°C, for short-term (minutes) service max 400°C

Maximum thermal shock resistance is 160°C

|

|

|

Doped-Al2O3-fusion

Hazard to Self

Posts: 99

Registered: 11-4-2018

Member Is Offline

Mood: Maniacal

|

|

I haven't been nearly as clear as I would have liked to have been on this entire thread. I began this experiment based on a YouTube video I watched

using this method. I'll link it to this post.

The polysuflides are oxidized easily by air, so that is the reason for the polysulfides. It's not efficient to target the thiosulfate right away.

Let sitting in open air do the work for you.

https://www.youtube.com/watch?v=dSWr8NUrk4A

It was not clear in the video the amounts used, nor the reasons for the details of the procedure steps. It also doesn't get into extracting any

thiosulfate, nor what yield could be obtained with this method. I decided to go on a journey to find out, what all does it really take for this

method to work efficiently enough to be a valid means of synthesis. Was it enough to eyeball a procedure as shown in that video, and to what end?

I first ran the experiment to where the video concludes.--so I have this dark red solution with excess sulfur floating around--now what? (there was no

reason as to why--but I found a reason why during my research. I'll be making a very detailed post about why the extra sulfur is important. I

believe the excess sulfur needs to be there because of the formation of sodium sulfide, the sulfur can act as a buffer in the formation of other

products, so it's a limiting reactant.--I think that's the term. S has to replace one of the O bonds to form thiosulfate rather than tetrasulfide. I

have the document on my upstairs laptop describing the benefit to forming thiosulfate with excess sulfur. It's either in the one I linked regarding

oxidizing polysulfides to thiosulfate. The other article I read was a research paper on hydrothermal synthesis of sulfides and the role thiosulfates

play. There was some information there which I was able to use for my advantage as it was a disadvantage in the formation of certain minerals.

Something like that.

I'll try the addition of hydrogen peroxide again now that I know to use an even high pH. That would be the quickest way, but bubbling plain air was

really fast overnight.

[Edited on 20-8-2018 by Doped-Al2O3-fusion]

|

|

|

Doped-Al2O3-fusion

Hazard to Self

Posts: 99

Registered: 11-4-2018

Member Is Offline

Mood: Maniacal

|

|

Day 3:

2g NaOH

4g S

10mL H2O

performed boiling NaOH + S

performed all previous steps up to adding to 100mL of H2O, checking pH and raising it between 10 - 12

final clear solution has a pH approx 9.5

Boil NaOH solution adding S until it all dissolves in test tube. It's best to have a few crystals that won't dissolve and leave them in the solution.

Add the test tube contents to 100mL of H2O + 1.4g NaOHaq (should be pH between 10 - 12, don't let it drop below 10 until it's light yellow.)

Bubble air through solution until it turns clear.--pH should be between 9 - 11.

This is the point I'm at. I had actually filtered the solids out before bubbling air in again. I threw in a tiny bit of elemental sulfur to interact

with any sodium sulfide in solution. The excess sulfur can always be mechanically filtered out before crystallizing.

|

|

|

Doped-Al2O3-fusion

Hazard to Self

Posts: 99

Registered: 11-4-2018

Member Is Offline

Mood: Maniacal

|

|

Quote: Originally posted by wg48  | My thoughts are why not add the H2O2 directly to the the NaOH + S solution or probably better the other way round?

Judging by the colour of your NaOH + S solution there is too much sulphur in there. Do you need poly sulphides ? Sorry but I do not know the ideal

stoichiometry. Try to determine the stoichiometry from a balanced equation.

If your oxygen bubbles are reaching the surface approximately the same size, reduce the oxygen rate and add a fine tip or sinter to the end of the

bubblier tube and use a long tall and narrow flask. perhaps add a balloon to the out let so you can swirl the flask and see how quickly the oxygen is

absorbed

Sorry if you have already covered the above I only skimmed through your posts. |

I appreciate your feedback a great deal. I've give this a try. I'll just make sure the pH is higher this time around before adding the H2O2 since

last time it formed a fair amount of H2S quickly. The pH of the solution became too neutral and had to have been dipping into the acidic range. That

will drop your S and generate a bunch of H2S.

|

|

|

wg48

National Hazard

Posts: 821

Registered: 21-11-2015

Member Is Offline

Mood: No Mood

|

|

I think increasing the pH is equivalent to reducing the polysulphide ie more NaOH for a given amount of sulphur is the same as less sulphur for a

given amount NaOH.

Unless it take heat and significant time for the poly to react with extra NaOH.

You could also try cooling the reagents and adding the H2O2 slowly, heat tends to decompose the H2O2 before it reacts. Note that you can flush/purge

some H2S out of a Na2S solution.

[Edited on 20-8-2018 by wg48]

Borosilicate glass:

Good temperature resistance and good thermal shock resistance but finite.

For normal, standard service typically 200-230°C, for short-term (minutes) service max 400°C

Maximum thermal shock resistance is 160°C

|

|

|

Doped-Al2O3-fusion

Hazard to Self

Posts: 99

Registered: 11-4-2018

Member Is Offline

Mood: Maniacal

|

|

Quote: Originally posted by wg48  | I think increasing the pH is equivalent to reducing the polysulphide ie more NaOH for a given amount of sulphur is the same as less sulphur for a

given amount NaOH.

Unless it take heat and significant time for the poly to react with extra NaOH.

You could also try cooling the reagents and adding the H2O2 slowly, heat tends to decompose the H2O2 before it reacts. Note that you can flush/purge

some H2S out of a Na2S solution.

[Edited on 20-8-2018 by wg48] |

I just made another 10mL batch and had to create a dilute H2O2 solution of approximately 6%. I slowly added it in a small amount at a time allowing

the solution to cool. This seemed to help eliminate sodium sulfate and sulfur from crashing out of solution. The pH is high, so I haven't observed

any H2S or SO2 fumes as well.

I'll see how that one does and I'll do another larger batch with improvements to the process.

Thanks again for your input.

|

|

|

fusso

International Hazard

Posts: 1922

Registered: 23-6-2017

Location: 4 ∥ universes ahead of you

Member Is Offline

|

|

What if you perform the reaction in another solvent that either the thiosulphate or (poly)sulphide is insoluble? will that enhance separation?

|

|

|

wg48

National Hazard

Posts: 821

Registered: 21-11-2015

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Doped-Al2O3-fusion  |

I just made another 10mL batch and had to create a dilute H2O2 solution of approximately 6%. I slowly added it in a small amount at a time allowing

the solution to cool. This seemed to help eliminate sodium sulfate and sulfur from crashing out of solution. The pH is high, so I haven't observed

any H2S or SO2 fumes as well.

|

Hopefully you did not observe any effervescence suggesting that the H2O2 did not decompose releasing oxygen to flush/purge out H2S and leaving it to

oxidise the sulphur.

As side note you can use the polysulphide solution to sulphide coat copper by dipping copper into it, with possibility of making a rectifier perhaps

even a transistor see http://jes.ecsdl.org/content/87/1/275.abstract

Here is the full paper

Attachment: CuSrectifier.pdf (1.7MB)

This file has been downloaded 269 times

[Edited on 20-8-2018 by wg48]

Borosilicate glass:

Good temperature resistance and good thermal shock resistance but finite.

For normal, standard service typically 200-230°C, for short-term (minutes) service max 400°C

Maximum thermal shock resistance is 160°C

|

|

|

Doped-Al2O3-fusion

Hazard to Self

Posts: 99

Registered: 11-4-2018

Member Is Offline

Mood: Maniacal

|

|

Quote: Originally posted by wg48  | Quote: Originally posted by Doped-Al2O3-fusion  |

I just made another 10mL batch and had to create a dilute H2O2 solution of approximately 6%. I slowly added it in a small amount at a time allowing

the solution to cool. This seemed to help eliminate sodium sulfate and sulfur from crashing out of solution. The pH is high, so I haven't observed

any H2S or SO2 fumes as well.

|

Hopefully you did not observe any effervescence suggesting that the H2O2 did not decompose releasing oxygen to flush/purge out H2S and leaving it to

oxidise the sulphur.

As side note you can use the polysulphide solution to sulphide coat copper by dipping copper into it, with possibility of making a rectifier perhaps

even a transistor see http://jes.ecsdl.org/content/87/1/275.abstract

Here is the full paper

[Edited on 20-8-2018 by wg48] |

I didn't observe any effervescence, however I think the H2O2 was still too strong and converted the solution to sodium sulfate instead of the

thiosulfate I was aiming for.

I ran a test on both of the solutions, one which I bubbled air through and the other solution I used the 6% H2O2 to oxidize the polysulfides. I

placed a piece of copper in the solution which was oxidized by bubbling air through and it immediately starts to turn the surface of the copper black.

The solution that I used the H2O2 actually cleans the tarnish off the copper which I did not expect.

I created another batch of polysulfides today and I'm currently bubbling air through the solution. I diluted the solution with distilled water to

double the amount of surface area that the air can bubble through. It's become a little less turbid during the last hour. I'll probably need to

continue bubbling air through the solution for a few days at least. In the meantime, I'm purifying more sulfur since I've run out of my current

supply of purified crystals.

...perhaps chilling the solution in an ice bath would resolve the issue of over-oxidizing to sodium sulfate. I'm bound and determined to figure this

out. It's a lot more difficult than creating typical transition metal salt crystals. I've created STS before, but the circumstances were different

than now. The first time I created STS crystals was during the cold months of winter and I gathered the crystals that formed gradually over three

weeks as the solution evaporated. I then recrystallized the product several times to get really pure samples.

[Edited on 22-8-2018 by Doped-Al2O3-fusion]

|

|

|

RogueRose

International Hazard

Posts: 1585

Registered: 16-6-2014

Member Is Offline

|

|

This may be a little off topic but have you ever worked with ammonium thiosulfate? I am thiking about getting some from a local supplier but it is in

solution (~40% I think) which is fairly high. The problem is that I think it decomposes at low temps (wiki says it starts at 50C) and decomposes upon

boiling at ~300F. I'd rather have it in crystal form if possible so I am thinking about trying to evaporate under vacuum though IDK if even that is

enough if it starts to decomp at 50C (I'm guessing NH3 is evolved).

Sodium thiosulfate seems to be much easier to work with and can be made by addition of NaOH to the ammoium Thiosulfate and then easily dried. As per

wiki, addition of ammonium sulfate will convert the sodium thiosulfate back into ammonium thiosulfate (along with Na2SO4 precipitate) and then states

that it can then be re-crystalized from here. So it seems odd that the ammonium thiosulfate made this way can be re-crystalized but the original

can't. Maybe there is something missing in the Wiki, not a huge leap in logic there, and I'd like to give it a try to see if it works.

Is there an use for potassium thiosulfate over sodium? I've seen thiocyanate in Na/K/NH3 salts, but haven't seen the K salt of thiosulfate. Any

reason for this, or is there any benefit or use for it?

Sorry if this is a slight hi-jacking, but it does have to do with the topic in a round about way.

Also as a side note, I've found the ammonium thiosulfate is usually available at farm & feed/seed stores, mine has it in liquid at very good

prices (gallon quantities though - less expensive if they fill your jugs!)

|

|

|

Doped-Al2O3-fusion

Hazard to Self

Posts: 99

Registered: 11-4-2018

Member Is Offline

Mood: Maniacal

|

|

Quote: Originally posted by RogueRose  | This may be a little off topic but have you ever worked with ammonium thiosulfate? I am thiking about getting some from a local supplier but it is in

solution (~40% I think) which is fairly high. The problem is that I think it decomposes at low temps (wiki says it starts at 50C) and decomposes upon

boiling at ~300F. I'd rather have it in crystal form if possible so I am thinking about trying to evaporate under vacuum though IDK if even that is

enough if it starts to decomp at 50C (I'm guessing NH3 is evolved).

Sodium thiosulfate seems to be much easier to work with and can be made by addition of NaOH to the ammoium Thiosulfate and then easily dried. As per

wiki, addition of ammonium sulfate will convert the sodium thiosulfate back into ammonium thiosulfate (along with Na2SO4 precipitate) and then states

that it can then be re-crystalized from here. So it seems odd that the ammonium thiosulfate made this way can be re-crystalized but the original

can't. Maybe there is something missing in the Wiki, not a huge leap in logic there, and I'd like to give it a try to see if it works.

Is there an use for potassium thiosulfate over sodium? I've seen thiocyanate in Na/K/NH3 salts, but haven't seen the K salt of thiosulfate. Any

reason for this, or is there any benefit or use for it?

Sorry if this is a slight hi-jacking, but it does have to do with the topic in a round about way.

Also as a side note, I've found the ammonium thiosulfate is usually available at farm & feed/seed stores, mine has it in liquid at very good

prices (gallon quantities though - less expensive if they fill your jugs!) |

No worries on anything you stated/asked in your reply. Working with thiosulfate(s) in general is on topic here. Any compound pertaining to

thiosulfate is relevant because the chemical reactions are usually similar in some regard for classes of compounds (i.e. sulfate, suflide,

thiosulfate, etc.)--especially between sodium & potassium.

The only reason I'm hell bent on creating sodium thiosulfate is due to my quest to synthesize iron disulfide in my autoclave. From my previous

experiment, my tests don't disprove my results. I would love 3rd party verification. There is only so much my personal chemical supply and

microscope can prove for some compounds.

I've really only concentrated my efforts on sodium thiosulfate due to the material(s) availability. I will most likely attempt working with potassium

thiosulfate just to see how that works out. I've got around five pounds of potassium hydroxide. I'm a novice when it comes to chemistry, as I

entered the hobby from metallurgical efforts to electroplate various transition metals. My experience with chemical reactions has always been more

dependent on tracking pH and other observations rather than stoichiometry.--I'm trying to become more disciplined and ditch my bad habits.

I'll look into the other thiosulfate compounds. I know I can obtain sodium thiosulfate much cheaper than anything I've made so far. I've actually

got some in the form of aquarium dechlorinating products.

|

|

|

Doped-Al2O3-fusion

Hazard to Self

Posts: 99

Registered: 11-4-2018

Member Is Offline

Mood: Maniacal

|

|

I found this patent which describes products created by boiling sulfur in sodium hydroxide solution. This at least gives me some solace in the

struggle I'm having acquiring a good yield.

https://patents.google.com/patent/US2705187A/en

I think my aim of disproportionately producing polysulfides, then oxidizing gently by bubbling oxygen through the solution to form the thiosulfate is

my best bet.

It appears from the research I've conducted so far, sodium sulfide won't oxidize to thiosulfate but the polysulfides will. Oxidizing with hydrogen

peroxide creates sodium sulfate. My experiment observations indicate this information to be fairly accurate. I'm by no means a chemistry

professional or super genius, so there's that as well.

(*edit--I found contradicting information on that assumption in another patent utilizing a PTFE coated carbon catalyst. https://patents.google.com/patent/US4024229A/en?q=C01B17%2f3... -- I'm continuing research.)

[Edited on 23-8-2018 by Doped-Al2O3-fusion]

Another document to checkout related to sodium sulfide oxidation:

https://www.jstage.jst.go.jp/article/jcej1968/13/4/13_4_331/...

[Edited on 23-8-2018 by Doped-Al2O3-fusion]

**another edit**

Another interesting document to read:

https://www.degruyter.com/downloadpdf/j/znb.1986.41.issue-12...

[Edited on 23-8-2018 by Doped-Al2O3-fusion]

|

|

|

wg48

National Hazard

Posts: 821

Registered: 21-11-2015

Member Is Offline

Mood: No Mood

|

|

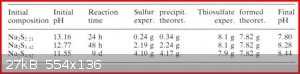

The last document of your last post appears to be most useful. It gave the following results of oxidation:

That strongly suggests that only the 2.2S polysulphide (almost stoichiometric wrt to the thiosulphate) is required, anymore sulphur (S3.4) slows the

oxidation significantly.

So the to produce crude thiosulphate (not contaminated with sulphate) you should start with NaOH and gas with H2S to produce NaS2.2. The H2S can be

produced by boiling oil and sulphur. Then oxidation to thiosulphate and filtering to remove the sulphur. Perhaps using air probably with the CO2

scrubbed out.

Yes H2O2 oxidation my not have the same result as diatomic oxygen.

[Edited on 24-8-2018 by wg48]

Borosilicate glass:

Good temperature resistance and good thermal shock resistance but finite.

For normal, standard service typically 200-230°C, for short-term (minutes) service max 400°C

Maximum thermal shock resistance is 160°C

|

|

|

Doped-Al2O3-fusion

Hazard to Self

Posts: 99

Registered: 11-4-2018

Member Is Offline

Mood: Maniacal

|

|

Quote: Originally posted by wg48  | The last document of your last post appears to be most useful. It gave the following results of oxidation:

That strongly suggests that only the 2.2S polysulphide (almost stoichiometric wrt to the thiosulphate) is required, anymore sulphur (S3.4) slows the

oxidation significantly.

So the to produce crude thiosulphate (not contaminated with sulphate) you should start with NaOH and gas with H2S to produce NaS2.2. The H2S can be

produced by boiling oil and sulphur. Then oxidation to thiosulphate and filtering to remove the sulphur. Perhaps using air probably with the CO2

scrubbed out.

Yes H2O2 oxidation my not have the same result as diatomic oxygen.

[Edited on 24-8-2018 by wg48] |

Yep. I'm glad I found that document. I didn't have a chance to review it thoroughly before my last check on it yesterday when I got home from work. I

found it was producing a fair amount of H2S and the pH had dropped to around 8 according to my crappy universal test strips. It also appeared to have

more elemental sulfur in the test tube than the night before. I added some more sodium hydroxide solution to raise the pH again, but I'm probably

going to send a text message to my wife to just unplug the air pump.

Thanks for pointing out that specific info from that document. I really don't think "eyeballing" this synthesis is going to be possible at all. I

definitely agree that oxygen instead of regular air would probably work better. I think if the solution were much more diluted with distilled water

like I had done previously would also be of benefit since I seemed to have had better results. I just wanted to see how the 50% concentrate would work

out. It might also make sense for me to add 5x as much water to form the pentahydrate since this is also something I did on previous runs.

My goal was definitely to prove how well the caustic soda + sulfur method would work as described in that YouTube video I posted the link to

previously. That crude solution does work great for polysulfide formation which is ideal for my hydrothermal synthesis of iron disulfide, but too much

of a hassle.

|

|

|

Doped-Al2O3-fusion

Hazard to Self

Posts: 99

Registered: 11-4-2018

Member Is Offline

Mood: Maniacal

|

|

I forgot to include a couple of things in my last reply, one of which was pretty cool to find out through a surprise observation.

First, I noticed in one of the documents I posted links to, that it mentioned sodium hydroxide readily reacts with sulfur exothermically to produce

sodium sulfide.--I read that on a conference call I was on yesterday for work, so it's possible that I read something wrong there, but I'm pretty sure

I did a double-take and re-read that paragraph. I would think that's not possible without external heat applied. I've got to find that paragraph.

Second thing. I saw that sulfide will react with elemental sulfur in solution to produce polysulfides. I didn't think much into it until my wife

sent me a picture of my test tube earlier this morning. I'm at the office and I forgot to check before leaving the house this morning. I noticed in

the picture she sent that there was no visible sign of free elemental sulfur in the solution, and there was quite a bit that had accumuled last I

checked. I had added more sodium hydroxide to the solution yesterday to increase the pH, but it wasn't that much.--certainly not enough to dissolve

all the sulfur which I last observed.

So the sulfur which had accumulated at the bottom of the solution and above the solution clung to the wall of the test tube is gone.--at least as far

as I can tell from her picture. I'm very interested to check it out once I'm home this evening.

[Edited on 24-8-2018 by Doped-Al2O3-fusion]

|

|

|

| Pages:

1

2 |