| Pages:

1

2 |

Nicodem

Super Moderator

Posts: 4230

Registered: 28-12-2004

Member Is Offline

Mood: No Mood

|

|

If you have some primary or secondary amine, or an aniline, you can do a primitive organic test (though I think your tests up to now confirm you got

KOCN anyway). For example, if you disolve aniline in water with one equivalent of HCl and then add the solution of your supposed KOCN you will get a

white precipitate of PhNHCONH2 (which is slightly soluble even in cold water so do not use too diluted solutions of aniline hydrochloride). You can

then recrystallize it and measure its mp to confirm the identity. Since this reaction is generally high yielding you could estimate the approximate

content of KOCN in your product by measuring the yield of N-phenylurea.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

I don't have any amines right now but could, with some effort, make aniline. I do have several amides, however: acetominophen, acetanilide, and

acetamide. Would any of these work?

My 1967 Lange's handbook says that AgOCN solubility is only 0.006g/100g in water. Perhaps this could be the basis for a gravimetric analysis. I do

have a limited amount of AgNO3. Does anyone know if this is a viable method?

(I have qualitatively checked an aqueous solution of my purported KOCN with drops of 0.1M AgNO3. An immediate white ppt forms.)

[Edited on by Magpie]

[Edited on by Magpie]

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

S.C. Wack

bibliomaster

Posts: 2419

Registered: 7-5-2004

Location: Cornworld, Central USA

Member Is Offline

Mood: Enhanced

|

|

If all of the carbonate has been removed with barium nitrate or acetate, then I'd think that you could use lead nitrate or acetate to precipitate

cyanate from this instead if desired.

[Edited on 17-10-2007 by S.C. Wack]

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Yes, thank you. I just tested my KOCN soln with lead acetate soln and did get a white ppt. I would much rather use up my lead (II) acetate

trihydrate than my meager supply of 0.1M AgNO3.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Ciscosdad asked above about any reference material on cyanates. I just stumbled across the best reference material I've seen yet while Googling

"barium cyanate." It is Alfred Henry Allen's 1913 edition of Commercial Organic Analysis, vol VII. This is presented as "Digitized by

Google." I would have copied the internet address but I couldn't figure out how.

[Edited on by Magpie]

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

not_important

International Hazard

Posts: 3873

Registered: 21-7-2006

Member Is Offline

Mood: No Mood

|

|

| Quote: | Originally posted by Magpie

... It is Alfred Henry Allen's 1913 edition of Commercial Organic Analysis, vol VII. This is presented as "Digitized by Google." I would

have copied the internet address but I couldn't figure out how. |

http://www.archive.org/details/allenscommercial07allerich

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Yes, thanks @not_important for the address.

I prepared a larger batch of KOCN using 8g of isocyanuric acid. I then extracted it with the "80% methylated spirit" of the Allen reference. I took

this to mean 80% methanol/20% water, by volume. The KOCN was difficultly soluble but most was picked up by the first extraction of three. As the

solvent began to evaporate small white crystals formed on the walls of the dish. I weighed the crystals and the yield was a surprisingly low 31%

based on the acid charged. Qualitative tests gave very good results, however: strong blue w/Co++, no ppt w/Ba++, and strong "acetic acid smell" with

10% HCl.

I attemtped the quantitative analysis in Allen that is based on Wohler's equation, ie:

AgOCN + 2HNO3 --> AgNO3 + NH4NO3 + CO2

Since I didn't have much 0.1M AgNO3 I only used 0.2g of KOCN. The analysis proceeded well except the results came out way high for some unknown

reason: 0.33g.

As a side note I naively thought that I would have to use an indicator (phenolphthalein) for the final back titration of the excess HNO3 with NaOH.

But it seems the brown Ag2O served to indicate the endpoint quite well.

[Edited on by Magpie]

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

ciscosdad

Hazard to Self

Posts: 76

Registered: 6-2-2007

Member Is Offline

Mood: Curious

|

|

Book

@Magpie and Not_Important

Thanks for the pointer guys.

I'm in the process of downloading it now.

Strangely it does not appear in the google books area as a full view even though its out of copyright. Still, early days yet. I'm holding my breath

waiting for it to trickle down.

|

|

|

ciscosdad

Hazard to Self

Posts: 76

Registered: 6-2-2007

Member Is Offline

Mood: Curious

|

|

Book

The book is down, and you are correct, this is one of the best coverages of the topic I've seen. Nice to be able to read some comprehensive info on

reactions and properties.

I note that this is one of a rather long series, and the others look as good at first glance. Download time!

Thanks again guys.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

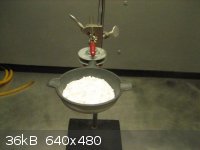

Yesterday I made 4 batches of KOCN. They are small being about 7g each, but only take 10-15 minutes for each one.

I combined the 4 batches with a little remnant from batch 3. I then ran an assay on this combination. The result was 76.6% KOCN. This is consistent

with earlier assays.

Below is a couple of pictures, one of the urea/K2CO3 before heating and the other is the solidified melt fresh out of the heating vessel. The mortar

is about 6" in diameter.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

12332123

Harmless

Posts: 38

Registered: 14-11-2009

Member Is Offline

Mood: No Mood

|

|

If you don't mind me asking, Magpie, how exactly did you assay the cyanate?

I have a batch that I suppose to be sodium cyanate, as mass loss on acidification is roughly consistent with this salt, it hydrolyses with evolution

of ammonia and acidification produces the strong acidic odour of isocyanic acid. I would, however, like to get some idea of purity.

My method uses carbonate and urea, with periodic water additions, and is solid-state and mess free - it is really quite nice and results in a product

that is only very slightly off white.

[Edited on 9-12-2010 by 12332123]

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Please see my procedure "KOCN Assay" in the Prepublication sub-forum.

Let us know what your cyanate assays.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

See attached

US3167387 NaOCN Via DMSO solvated Na2CO3 and Urea

95% yield, reaction at 185C, DMSO can be filtered and recycled.

Attachment: US3167387 Cyanates via DMSO solvated Urea and Carbonate .pdf (404kB)

This file has been downloaded 850 times

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Quote: Originally posted by Rosco Bodine  | See attached

US3167387 NaOCN Via DMSO solvated Na2CO3 and Urea

95% yield, reaction at 185C, DMSO can be filtered and recycled. |

This seems similar to Chinese patent 101412523 which I tried on 11/3/10. I found no joy. The white product produced at 69% yield gave a negative

test result for cyanate using 1M Co(NO3)2.

http://v3.espacenet.com/publicationDetails/biblio?DB=EPODOC&...

I used DMSO and an oil bath. Maybe someone else will have better luck.

[Edited on 10-12-2010 by Magpie]

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

Yes, there was a separate thread where the abstract was posted .....

http://www.sciencemadness.org/talk/viewthread.php?tid=14198&...

but I saw no post about your failed experiment in trying that or a similar method. Keeping us in the dark hmmm, experiment fails ...sshhhh....don't

tell anybody

Ah ha ...now we get to the truth at last  Magpie has been holding out on

us.....keeping a lid, er a watchglass on it, huh. Magpie has been holding out on

us.....keeping a lid, er a watchglass on it, huh.

Note: Moisture is probably the reaction killer, as moisture would favor formation of the cyanurate

and moisture would also favor decomposition by hydrolysis of any cyanate. My educated guess is that the carbonate needs to be anhydrous and the urea

needs to be good and dry also, or else the reaction is poisoned from the start. Here's a link for an extensive article about DMSO properties and

usefulness as a solvent for reactions.

http://www.gaylordchemical.com/bulletins/bulletin105b/Bullet...

It seems odd that this should not work as there are several patents involving a similar concept. Related reactions have been of interest in regards

to methods for producing cyanamide.

There was a thread about using a cyanurate as precursor

for the cyanate formed by depolymerization.

http://sciencemadness.org/talk/viewthread.php?fid=2&tid=...

A patent GB710143 attached says a little about this route, but the stated reaction is an oversimplification of a reaction which has a low temperature

component producing volatile byproducts and a cyanurate salt as a first stage reaction,

followed by a depolymerization of that trimer at or above 400C. There seems to some discrepancy about the temperature range for depolymerization of

any cyanurate which could be an intermediate. Cyanuric acid is the trimer of cyanic acid and the calcium salt requires about 400C, above the melting

point of lead, to depolymerize to the cyanate. The sodium cyanurate salt would likely require a bit higher temperature than 400C, and something like

a lead or a zinc cyanurate salt would probably depolymerize at a bit lower than the 400C for the calcium salt. Heating the cyanate much higher leads

next to the cyanamide, or a cyanide depending upon the atmosphere IIRC.

The lower temperature reactions involving urea would seem to first lead to a cyanurate rather than a cyanate, and this would be confusing to some

analytical methods since the two substances are isomeric, but the cyanurate is the trimer, while the cyanate is the monomer.

Evidently, if the relatively lower temperature methods involving urea under specific conditions do somehow avoid the trimerization to the cyanurate,

using a solvated non-aqueous reaction system is the trick that would make this possible. Of course it cannot be ruled out that possibly a cyanurate

was perhaps gotten and misidentified as the cyanate. I will have to read and compare these reaction

descriptions, but one would hope that bona fide chemists

could tell the difference between the trimer and the monomer before running to throw down a lot of money to file patents.

Attachment: GB710143 Cyanates from Cyanurates.pdf (791kB)

This file has been downloaded 945 times

Actually I am inclined to believe the reaction route using the DMSO does work. Here is a Nippon patent abstract which was renewed, which makes use of

the NH3 byproduct for production of hexamine. Of course it may just be a crafty attempt to keep their formaldehyde from polymerizing

or to break up any polymer already there. We can confirm that urea reacts with alkali carbonates to form NH3, CO2, and H2O, plus some other product

which is either a cyanurate or a cyanate salt of the alkali.

The Na or K cyanurate should be stable against hydrolysis by hot water.

The Na or K cyanate should be vulnerable to hydrolysis

by hot water decomposing as follows:

4KOCN + 6H2O = 2K2CO3 + CO(NH2)2 + (NH4)2CO3

(reaction and other facts about KOCN at following page)

http://www.showa-pk.co.jp/information/cyanate.html

http://v3.espacenet.com/publicationDetails/biblio?FT=D&d...

Abstract of JP 2000119016 (A)

Translate this text

PROBLEM TO BE SOLVED: To obtain a method for producing an alkali metal cyanate, more industrially advantageous than conventional methods for producing

an alkali metal cyanate using a melt solid phase reaction method, providing the alkali metal cyanate in a suitable state as a raw material for

producing a cyanuric acid derivative excellent in purity and preventing formation of ammonium carbonate from ammonium and carbon dioxide produced as

by-products.; SOLUTION: In a method for producing an alkali metal cyanate by reacting an alkali metal carbonate with urea in a reaction solvent under

heating conditions, the whole or the reside after partial condensation of a reaction solvent vapor accompanying ammonium and a carbon dioxide gas as

by-products and discharged from a reactor is brought into contact with formalin ammonium is recovered as an aqueous solution of hexamethylenetetramine

and the reaction solvent trapped in the aqueous solution is recovered and circulated to the reactor

[Edited on 10-12-2010 by Rosco Bodine]

|

|

|

hua xue DIY

Harmless

Posts: 3

Registered: 3-12-2009

Member Is Offline

Mood: No Mood

|

|

Cyanate potassium preparation(KOCN)

Documents: 《The semi-microorganic synthesis (experiment guidance)》

Reagents: potassium ferrocyanide 5g, potessium dichromate potassium 3.8g, 80% ethanol 20ml, ether

Instruments: the gas flame blower, dry pot, iron spoon, 50ml flat bottom flasks, ball cold, glacial water, mortar

Steps: 1, will potassium ferrocyanide, potessium dichromate potassium respectively after dehydration mortar into heat in carefully grinding.

2, the mixture of a position that with an iron spoon in a blowtorch heats. Cannot too close to the flame.

3, black fluffy objects into natural cooling flask, join 20ml ethanol, water bath on heated to boiling, backflow 2h.

4, will clear mixture in a test tube cooling separate out cyanate potassium crystals, filtering, will the mother liquor reversed flasks, heating,

again will clear night poured out cooling exhalation cyanate potassium. Repeat this step 6 ~ 7 times. Cyanate potassium basic extraction was finished.

(i.e., when ethanol cooling no crystallization precipitation)

5, will cyanate potassium with ethanol and washing 2 times, ether 3 times, drying, about 1.5g

(Because my English is not very good, above, there may be some grammar mistakes,please forgive me.)

power

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

No, I made no post as this was just a time-consuming failure. But I see the error of that decision: knowledge of a failure is also of value to the

process of finding the best method by the forum at large.

These patents for low temperature non-aqueous methods are numerous, as you say, and it seems unlikely that they're all not viable. And moisture may

indeed be the culprit. That is one of the beauties of the fusion method. You don't add any water and any genrated is immediately driven off as a gas

at high temperature. Another beauty is that it is very quick. I can make a batch in 15 minutes tops and that includes all the weighing and cleanup.

Compare that to 8 hours at temperature for the Chinese patent. I do purify my urea first by recrystallization in denatured alcohol as my source is

fertilizer containing some rusty prills. And finally, there's the raw material costs: they're dirt cheap. My K2CO3 is pottery grade which is

anhydrous.

I don't know my exact temperatures at fusion of the KOCN. I try to get it just hot enough to keep a good mobile liquid without getting it so hot it

could decompose. The pan never comes close to red heat I don't believe.

I consider any method that comes from ferrocyanides or cyanides to be a form of cheating. To me these are inherently more valuable (or more

energetic) precursors. I prefer to add value to the dirt cheap precursors, when possible. It's more like actually creating something than just

sliding down the energy curve. But in the end I'm not that much of a purist and will do what's necessary.

[Edited on 10-12-2010 by Magpie]

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

With regards to US3167387, the idea of a pure NaOCN product crystallizing out in near quantitative yield from the slowly cooling DMSO has a certain

appeal. How long it would require isn't stated, but appears to be limited by the rate at which the H2O byproduct can be distilled to produce the

elevation in bp for the DMSO. There is by clear inference an elevation of boiling point reported for the DMSO by virtue of the dissolved NaOCN, at the

reaction endpoint of 195C.

|

|

|

| Pages:

1

2 |