| Pages:

1

..

7

8

9 |

dan.vlad

Harmless

Posts: 31

Registered: 5-11-2017

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by garage chemist  | I completed my new powerful tube furnace. Look here for pictures:

http://www.versuchschemie.de/ptopic,168531.html#168531

You can see that I have successfully taken it to 1300°C (2370°F- thats above the maximum continuous use temp for quartz glass!) already before I put

it into a casing.

As you can see, the construction is ridiculously simple. It can be thrown together and put into use on a single day.

No cements or castable refractories are used.

The core of the furnace is a ceramic tube, 500mm long, 40mm OD, 32mm ID. The ceramic is called "pythagoras" and is good up to 1400°C (some sources

say 1500°C), it is also absolutely gastight (even high-vacuum tight).

14,7m of 1mm Kanthal A1 wire (1,8 ohm per meter, giving about 2000W of power at 230V) is wound onto the tube and covered with a paste of equal parts

MgO (dead-burned magnesia) and Al2O3.

After drying, it is surrounded by two layers of 1400°C aluminum silicate-zirconia 25mm ceramic fiber blankets held in place by wire.

It is put into a 120mm ID sheet metal pipe (the fiber blankets have to compressed somewhat for it to fit into the pipe- a larger pipe would have been

better, but I couldnt find one).

The power is regulated by a thyristor circuit (commercial dimmer module), a 60W incandescent light bulb is put in parallel to the furnace to serve as

a crude indicator of power.

Temperature is measured by a selfmade Type K (Nichrome-nickel) thermocouple connected to a multimeter with a temperature measurement option.

The lifetime of such a thermocouple is limited above 900°C (but can be taken to 1350°C for short periods of time)- a Type S (Pt-PtRh) thermocouple

would be a much better choice, but is very expensive.

I have a 20cm long quartz test tube with ground glass joint that fits into the furnace. This can be used to take substances to temperatures far higher

than what can be reached by a bunsen burner.

Such a tube furnace is able to provide extreme heat for every application in the lab where a gas burner fails miserably.

The prime example for such an application is: SYNTHESIS OF PHOSPHORUS.

I am mostly interested in the production of sulfur trioxide from ferric sulfate in this tube furnace, as well as carbon disulfide from sulfur vapor

and charcoal and ketene from acetone.

[Edited on 25-12-2007 by garage chemist] |

Please repost pics link ,is allready down

Thank you

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Herr garage chemist was a supreme contributor to this forum. Unfortunately, he hasn't posted for several years now. There were no challenges left

for him!

In this thread you will see a picture of my tube furnace in operation, built on his design. If you have any questions, just ask.

[Edited on 25-12-2017 by Magpie]

see: https://www.sciencemadness.org/whisper/viewthread.php?tid=97...

[Edited on 25-12-2017 by Magpie]

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

Bert

Super Administrator

Posts: 2821

Registered: 12-3-2004

Member Is Offline

Mood: " I think we are all going to die. I think that love is an illusion. We are flawed, my darling".

|

|

| Quote: | Please repost pics link ,is allready down

Thank you |

As you look around the web, you'll be more and more frustrated by this. I, too, made the mistake of merely linking to an image or file and parking

images I created on "free" hosting sites, which then changed policy and held them up for ransom, broke down or folded their tent and disappeared with

all member contributions (Yo, E&W? Rhodium?!), etc.

So to share some picture or other file here, I upload the thing TO THIS SITE. Hopefully, it will be available as long as the forum itself is intact.

Rapopart’s Rules for critical commentary:

1. Attempt to re-express your target’s position so clearly, vividly and fairly that your target says: “Thanks, I wish I’d thought of putting it

that way.”

2. List any points of agreement (especially if they are not matters of general or widespread agreement).

3. Mention anything you have learned from your target.

4. Only then are you permitted to say so much as a word of rebuttal or criticism.

Anatol Rapoport was a Russian-born American mathematical psychologist (1911-2007).

|

|

|

yobbo II

National Hazard

Posts: 709

Registered: 28-3-2016

Member Is Offline

Mood: No Mood

|

|

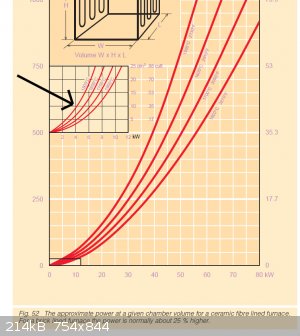

Attempting to make a furnace from Molydbenum Disilicide elements and insulating bricks. These elements can be driven up to 1800C giving a furnace

temp. of around 1700. I will not be going even close to those temperatures. Coming from the kanthal handbook the diagram shows you how much power you

need for a given furnace size. The diagram assumes a wool lined furnace. If you use bricks you must increase power by about 25% to get the same

temperature. For a 10 cubic decimeter oven you need around 4 kW to get 1500C. (arrow on page).

If I were to use a double layer of bricks will I get much higher temperature?

My problem is I have only 2 kW worth of elements. I will have to make a smaller furnace that the 10 (if using single layer of bricks).

How much difference will a second layer of bricks make. I suppose this is not a simple question to answer. Any educated guesses welcome. I am unable

to use heat transfer/modelling software.

TIA,

Yob

[Edited on 8-3-2018 by yobbo II]

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

My educated guess is that you will need 2.6 kW. I will give my assumptions and the derivation tomorrow. I am too tired now.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

for the previous post, here is my analysis:

Assumptions:

1. The furnace is cubical.

2. Standard shaped bricks are used for the walls, floor and ceiling. The brick thickness is 2.25", or 0.0572m, the original wall thickness.

3. Thermal conductivity, k, of the bricks is 1.04 W/m*K.

4. The internal cavity of the furnace is cubic, 0.215m on a side, W1.

5. The internal cavity temperature is 1500°C.

6. Furnace outer surface is 100°C.

7. The original furnace requires a heat source of 5 kW.

8. The furnace is modeled per the example shown in Chapter 3, example 3.39, p.160, of "Engineering Heat Transfer," 2nd ed, by Rathore and Kapuno, jr.

found at books.google.com.

https://books.google.com/books?id=ERtpN94lCOsC&printsec=...

Original furnace ( case 1) computations:

(i) conduction shape factor, S1 = Swall + Sedge + Scorner

w1 =cavity width =cavity length = cavity height = 0.215m.

L1 = wall thickness = 0.0572m.

S1 = 6(0.215m)(0.215m)/0.0572m + 12 (0.54)(0.215m) + 8(0.15)(0.0572m)

=6.311m.

(ii) actual heat loss = 5kW

compute heat loss, Q1, = kS1(delta T) = 1.04(6.311)(1400) = 9.19 kW

For the furnace with a 2nd brick layer:

L2 = 2L1 = 0.430m

shape factor S2 = 6(0.215m)(0.215m)/0.114 + 12(0.54)(0.215)

+ 8(0.15)(0.114) = 3.96

Q2 =1.04(3.96)(1400) = 5.77kW

Using proportions to get the heat loss:

(5.77kW/9.19kW)5 = 3.14kW for the furnace with the added bricks.

[Edited on 8-3-2018 by Magpie]

[Edited on 8-3-2018 by Magpie]

[Edited on 8-3-2018 by Magpie]

[Edited on 9-3-2018 by Magpie]

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

yobbo II

National Hazard

Posts: 709

Registered: 28-3-2016

Member Is Offline

Mood: No Mood

|

|

Thanks alot Magpie.

Another (rather complicated) route to get high heat from the 2 kW worth of Moly Disilicide (super kanthal) might be to place nichrome (super kanthal

A1 say) wire around the 'first layer' of bricks and keep their outside surface at (say) 800C. The second layer of bricks then goes outside this inner

chamber. The moly Disilicide then goes into the inner chamber to put temperature way up.

Is this a crazy idea?

Note: it is easy to mix up Super Kanthal A1 (high spec. 'nichrome' wire) with Super Kanthal (Molybdenum Disilicide)

Yob

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

You are welcome.

That should work.

I tried to calculate the wall thickness for a loss of 2kW directly but the shape factor calculation broke down, so can't do this.

[Edited on 9-3-2018 by Magpie]

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

Geocachmaster

Hazard to Others

Posts: 146

Registered: 5-3-2016

Location: Maine, USA

Member Is Offline

Mood: Corroded, just like my spatulas

|

|

I just built a tube furnace which is capable of reaching 1100 C.

The heart of the furnace is an alumina tube, 25/20/200 mm (OD, ID, length). This cost me about $15. Around it I wrapped around 100 turns of 22 gauge nichrome wire, which took

around 8 meters. Cost of nichrome was $2. Then I painted on two thin layers of high heat mortar. The first was just enough to keep the wire in place, the second a little thicker and covered all the exposed wire completely. I

bought a 10 ounce tube of the mortar but only used ~5% of it, for a cost of $0.25. While letting it cure, I cut a section of 4 inch duct slightly

shorter than 200 mm. I also cut some caps for the duct out of aluminum flashing (adding holes for power and the tube itself in the middle). I already

had these materials, but they would cost ~$5 to buy. I then wrapped the tube with a ceramic fiber blanket. It took about one square foot of 1/2 inch

thick ceramic fiber to make a good fit. This was rated to 1300 C and cost $3.50. The final part was putting everything together with a couple of large

hose clamps ($3).

Total cost: $28.75

The insulation works well, it only takes ~80 watts to maintain the temperature at 1100 C. The outside gets hot but it's not too bad, especially

considering how hot the interior is.

|

|

|

yobbo II

National Hazard

Posts: 709

Registered: 28-3-2016

Member Is Offline

Mood: No Mood

|

|

Some MoSi2 on ebay at the moment. Hard to come by and expensive. You can get them from china but min. order is 10 pieces (about 1000 bucks).

https://www.ebay.co.uk/itm/MoSI-2-heating-element-Kanthal-Su...

I have nothing to do with the seller btw.

Finished my (rather temporary) furnace. It has two Molydbenium Disilicide elements in it (about 2.2kW worth).

The internal volume is about three standard bricks with 1/3 of the space occupied by the moly d elements.

It is powered by a 200 amp welder (buzz box) and a large variac, I think the variac is about 25 or 30 amps. The welder puts out the usual 50 and 80

volts (open circuit) in relation the the earth terminal which is in series with the internal inductor (current selector) . I ignored the earth and

wired the mold d's between the 50 and 80 volt terminals which give about 20 volts or so at full load (about 200 amps is max. for my elements).

The set up works well enough as long as the variac is used as an autotransformer. I had to wire the mains in (230V) to a tap 'up' the variac

transformer a bit so that it output from zero to 260 volts or so.

The furnace is double bricked. The outside gets warm but you could keep your hand on it. It goes up to 1200C easily enough and will go more if

necessary. At 1100C the power in is about 2kw with 100 amps and 19.8 Volts.

The s type thermocouple and the k type disagree regarding temperature by about 60C.

To measure current I am using a microwave transformer as a current transformer. The HV winding's are removed and the high current line is put through

one of the lamination slots. This gives and output current of 175mA for 100 Amps in and 360mA for 200Amps. The mA are measured on the mains input

(now the output) of the transformer using a MM. I believe you need to be careful with current transformers (ct) as they can give a nasty shock.

Perhaps this one is even dangerous. The ct was calibrated using a known resistance in the line.

Now for some steam!!!

Yob

[Edited on 13-5-2018 by yobbo II]

|

|

|

yobbo II

National Hazard

Posts: 709

Registered: 28-3-2016

Member Is Offline

Mood: No Mood

|

|

Hi

Lidl. Are selling zirconia blade chef knives for a few bucks.

They might be usable as very high temperTure elements.

See ernesto ceramic chefs knife

Yob

|

|

|

Texium

|

Thread Moved

19-11-2023 at 09:51 |

| Pages:

1

..

7

8

9 |