| Pages:

1

..

8

9

10

11

12

..

25 |

franklyn

International Hazard

Posts: 3026

Registered: 30-5-2006

Location: Da Big Apple

Member Is Offline

Mood: No Mood

|

|

Apples and oranges only make a good sangria. Patents are essentially

exclusive business licenses and an article of commerce that inherently

seeks to retain proprietary it's described process or proceedure .

Journals are written for the disclosure of discovery and do not withhold

confidential know how. The later is for fame , the former is for fortune.

.

|

|

|

Douchermann

Hazard to Others

Posts: 117

Registered: 11-10-2005

Location: Illinois, USA

Member Is Offline

Mood: No Mood

|

|

Sorry to bring a thread up from the dead, but would performing the reaction in something other than glass affect it in any way? The reason I'm asking

is because the biggest glass piece I have is a 1000ml flask, and with the foaming, that wont be sufficient. However, I have a 5 gallon (18 liter)

aluminum pot that I could heat quite easily. If the aluminum pot affects it negatively, then I guess a Teflon coated cast iron pot would be out of

the question too, correct?

It\'s better to be pissed off than to be pissed on.

|

|

|

YeOldeImpurities

Harmless

Posts: 8

Registered: 23-12-2007

Location: Europe

Member Is Offline

Mood: D'oh!

|

|

higher yields of hydrazine?

Compounds of manganese (sulfate, chloride of manganese, permanganates...) in hypochlorite/urea/hydroxide reaction work better than gelatine. They give

5-10% higher yields of hydrazine than mixtures with gelatine. --- this I remember from book "The Chemistry of Hydrazine" by Audrieth and Ogg.

In russian book Греков,Отрошко:

"Гидразинометрия" 1981 (Hydrazinometry by Grekov and

Otroshko) is a recipe for making hydrazine sulfate with MnSO4.5H2O instead of gelatine (0,3 grams of MnSO4.5H2O to 15 grams of urea, yield 23 grams of

hydrazine sulfate).

And also something else for increasing yields- in book

Брикун,Козловский,Никит&

#1080;на: "Гидразин и

гидроксиламин и их

применение в

аналитической химии" 1967 (Hydrazine and

hydroxylamine nad their application in analytical chemistry by Brikun, Kozlovskiy and Nikitina) is this: best compounds for protection of

hydrazine/water solutions against oxidizing by air are oxides of calcium, zinc, aluminium and magnesium but the far superior is sulfur in small

amounts. btw there is mentioned a method for producing hydrazine by dry destillation of urea/iron powder at 132-150ºC at atmospheric pressure.

|

|

|

not_important

International Hazard

Posts: 3873

Registered: 21-7-2006

Member Is Offline

Mood: No Mood

|

|

| Quote: | Originally posted by Sauron

I have never seen a prep deleted from Org.Syn....

I don't question that in some text, somewhere, what you are saying may be happening. But I challenge you to show me an example from Org.Syn.

... |

Sorry, missed this reply back when it was done

Not that the actual earlier prep is deleted, but especially in the earlier collected series you would see mention made that XYZ was now commercially

available, and either stated or implied that DIY wasn't worth it.

OS and IS don't change their reprints, the data remains unchanged. However textbooks do drop entries, I've several cases of multiple editions of the

same book where some preparations were dropped and usually new ones added. And before OS was available online, textbooks were more likely to be found

as affordable used books.

There's also changes in reagents across time. In the organic world it was typical to see an old method be dropped for one using a more exotic reagent

but giving higher yields and/or more easily isolatable product. Over in the inorganic world an example in 'practical' books was in the preparation of

HBr; first the SO2 and H2S routes disappeared, leaving just the red phosphorus method, then the preparation was dropped entirely as HBr became an easy

to obtain reagent. But nowadays an amateur experimenter may not be able to purchase HBr, not unlikely for liability issues, not able to buy

phosphorus because of legal restrictions, and thus be looking for those old alternatives that don't get mentioned in modern books.

|

|

|

not_important

International Hazard

Posts: 3873

Registered: 21-7-2006

Member Is Offline

Mood: No Mood

|

|

| Quote: | Originally posted by Douchermann

Sorry to bring a thread up from the dead, but would performing the reaction in something other than glass affect it in any way? The reason I'm asking

is because the biggest glass piece I have is a 1000ml flask, and with the foaming, that wont be sufficient. However, I have a 5 gallon (18 liter)

aluminum pot that I could heat quite easily. If the aluminum pot affects it negatively, then I guess a Teflon coated cast iron pot would be out of

the question too, correct? |

The metal pot might react with the alkali, the non-stick coating if new should be OK.

|

|

|

len1

National Hazard

Posts: 595

Registered: 1-3-2007

Member Is Offline

Mood: NZ 1 (goal) - Italy 1 (dive)

|

|

| Quote: | | There are often good reasons why, even for perfectly good ideas, some vital details are left out of patent descriptions. Most notably it makes it more

difficult for someone to pirate the idea. |

Maybe, but this strikes me as a very dangerous thing to do. If someone subsequently reinvents this 'omission' and makes the procedure work, the

patent holder has a good chance of getting no royalties.

|

|

|

franklyn

International Hazard

Posts: 3026

Registered: 30-5-2006

Location: Da Big Apple

Member Is Offline

Mood: No Mood

|

|

About - higher yields of hydrazine ?

Welcome YeOldeImpurities

Very intriguing references , particularly the last about distillation , although

that may pose an explosion risk similar to distillation of H2O2. Iron normally

interferes with hypochlorite processes. By the way, this can't be right,

it's not stoichiometric -

0,3 grams of MnSO4.5H2O to 15 grams of urea, yield 23 grams of hydrazine sulfate

Please post more details if you can, transactions here are in english, few

can read cyrillic. As you see the postings tend to deviate into side issues

unrelated to the main thread. Don't be put off by this, consider starting

another thread of your own.

.

|

|

|

YeOldeImpurities

Harmless

Posts: 8

Registered: 23-12-2007

Location: Europe

Member Is Offline

Mood: D'oh!

|

|

Hi Franklyn, here is an approximate translation from that book: Add concentrated solution of 0.3g of MnSO4.5H2O to 60ml of cooled NaOH solution of

density 1.37-1.38. At 0 degrees of celsius add 15g of urea, then cool the solution to -7 degrees. Then gradually add 125ml of NaClO solution cooled to

-3 degrees. Do not allow to rise the temperature of the solution over +10 degrees. When NaClO was added, let it stand for 10 minutes. Then heat the

solution gradually, 2 degrees per 1 minute in water bath to +63-65 degrees. Then allow to cool to room temperature and add the solution gradually to

stirred 140ml of 50% H2SO4. Do not allow to rise the temperature over 40-50 degrees. Then cool to +22-25 degrees and filter out the crystals of

hydrazine sulfate and wash them three times with 10 ml of water and dry. Yield 23 grams (70% of the theoretical).

|

|

|

franklyn

International Hazard

Posts: 3026

Registered: 30-5-2006

Location: Da Big Apple

Member Is Offline

Mood: No Mood

|

|

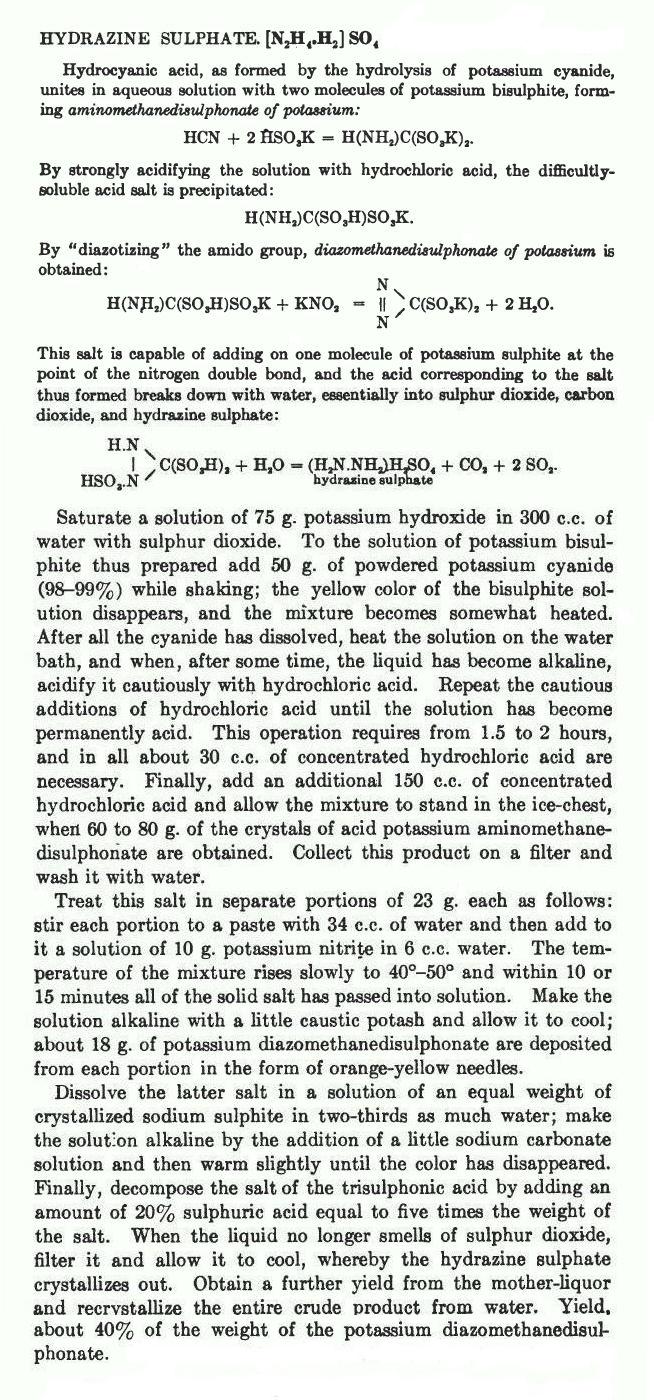

NH2NH2 from KCN, KHSO4, KNO2

Laboratory Methods of Inorganic Chemistry

Heinrich Biltz, Wilhelm Biltz

http://books.google.com/books?id=1gkNAAAAYAAJ&pg=PA215&a...

From prep 122 on page 158

|

|

|

Mason_Grand_ANNdrews

Hazard to Self

Posts: 63

Registered: 19-1-2006

Location: New Berlin City !!

Member Is Offline

Mood: crabby

|

|

Excuse to write the text into this, it is my second time to write down that. I`ve sitting down, hove some nice ideas and my editor was killed by what

you have now 5 minutes to hold. I thkink - it was ""never mind""

I hope it is somewhat for the "balconery" chemistry to get hydrazine.

Prepare two saturated solutions of 4 mol ammonium chloride and 0.5 mol of sodium chloride. Combine the solutions in a beaker in an salt ice bad to

minimum 0 degrees centigrade (ammonium) nitrate ice bad is better when you have) that it not will react anytime. A third solution of 6 mol of 25 %

ammonium hydroxide is chilled to 0 degrees centigrade and combined with the first mixture in an distiller and put on an distiller by stirring it with

an teflon rod.

Step one:

Heat the mix over many hours to the lowest bp of all the liquids

(water 101 degrees centigrade) and put the condenser in an ice bad by connecting the equipment to an disstillation equpment and an simple vacuum pump

or an electircal when you have. The distilled liquid is collected in an chilled beaker of ammonium nitrate

ice and connectect to a new eqiupment.

Step 2:

Hold the distillate under cold conditons below 0 degrees centigrade and connect it to an new disstillation equipment with two mol of 25 % HCl in the

condenser. The condenser is chilled with an sligh ammonium nitrate ice bad and the yieded liquid is transferd into a new beaker by collecting this

to a new disstillation equipment.

Step 3:

Prepare an ""condenser"" with 2,5 mol of 25 % HCl and connect this to the chilled distiller by step two and over a few hours rise the temperature of

the distillate to over 190 degrees centirade and remove the most of the water if you can. The stuff is dryed by placed it to an easy filter paper and

hang it over an mix of magnesium sulfate powder and the water is removed over al lot of days.

Soo, i hope this is an real alternative to some hard to get stuff and what you can get from nothing. I`ve to much trunken but i hope it helps.

Money is fare away besides - but i`m an illusian.

By the way, the hydrazinedihydrochloride what the synth. calculated by me is dryed over concentrated sodium hydoxyde or something stuff wath is

hycroscopic. I mean it works when the slick is placed into an filter and dryed over concentrated H2SO4 by connecting a vacuum pump to the

flask !

I hope it sometime easy or correct, some hints will help.

It`s very pity that i`ve no lab more that a few years, it more

than an feeling. Maybe someone can this test if it work - i hope.

[Edited on 4-3-2008 by Mason_Grand_ANNdrews]

Every love is a little inspiration - every day is

a new live !

|

|

|

Formatik

National Hazard

Posts: 927

Registered: 25-3-2008

Member Is Offline

Mood: equilibrium

|

|

| Quote: | Originally posted by YeOldeImpurities

Compounds of manganese (sulfate, chloride of manganese, permanganates...) in hypochlorite/urea/hydroxide reaction work better than gelatine. They give

5-10% higher yields of hydrazine than mixtures with gelatine. --- this I remember from book "The Chemistry of Hydrazine" by Audrieth and Ogg.

In russian book Греков,Отрошко:

"Гидразинометрия" 1981 (Hydrazinometry by Grekov and

Otroshko) is a recipe for making hydrazine sulfate with MnSO4.5H2O instead of gelatine (0,3 grams of MnSO4.5H2O to 15 grams of urea, yield 23 grams of

hydrazine sulfate).

And also something else for increasing yields- in book

Брикун,Козловский,Никит&

#1080;на: "Гидразин и

гидроксиламин и их

применение в

аналитической химии" 1967 (Hydrazine and

hydroxylamine nad their application in analytical chemistry by Brikun, Kozlovskiy and Nikitina) is this: best compounds for protection of

hydrazine/water solutions against oxidizing by air are oxides of calcium, zinc, aluminium and magnesium but the far superior is sulfur in small

amounts. btw there is mentioned a method for producing hydrazine by dry destillation of urea/iron powder at 132-150ºC at atmospheric pressure.

|

What yield is that of the theory? Raschig in German patent #198307 says hypochlorite solution and ammonia with lime can get as much as 80 percent of

the theory, and he himself gets 60 to 70 percent in an example.

|

|

|

Formatik

National Hazard

Posts: 927

Registered: 25-3-2008

Member Is Offline

Mood: equilibrium

|

|

| Quote: | Originally posted by Rosco Bodine

GB1073292 Hydrazinium Cyanurate

This is another means of precipitating a slightly soluble hydrazine salt which may be freebased by NaOH . |

There are also other hydrazonium salts which might be worth trying. Although the oxalate is soluble, hydrazonium hydrooxalate N2H5HC2O4 is said to

result from estimated amounts of oxalic acid and N2H5OH, and these crystals are barely soluble in cold water: 2.02 g per 100 g H2O at 22.5 deg.

Hydrazonium subhydrophosphate N2H5H3P2O6 made by neutralizing hypophosphoric acid with N2H5OH against methyl orange and addition of the same amounts

of hypophosphoric acid. This salt is even less soluble, 1.5 g per 100 g H2O at room temperature. Compared with the hydrosulfate, the solubilities are

for 100 g H2O: 2.794 g at 20 deg, 3.302 at 25 deg., 6.538 at 50 deg., 12.580 at 80 deg., etc. which solubility is also decreased by acids.

Another idea is hydrazonium pyrosulfite (N2H5)2S2O5 which is made by leading so much SO2 into N2H5OH soln. until it turns yellow, this evolves

considerable heat. Allowing this to stand in a vaccum or in an SO2 atmosphere, or by precipitating with alcohol causes it to crystallize. The salt

also oxidizes easily to sulfate. I bubbled SO2 into a small amount of a weeks old reacted liquor solution of urea to test this, the solution got warm

from bubbling and eventually was very barely yellow, and let the solution stand in a closed container for a few hours. At the bottom there was a small

amount of glittering, glancing white crystals. Best to try on larger scale, but I would say using the hydrosulfate is more advantageous.

|

|

|

franklyn

International Hazard

Posts: 3026

Registered: 30-5-2006

Location: Da Big Apple

Member Is Offline

Mood: No Mood

|

|

Syntheses of some N-substituted hydrazines by the anhydrous chloramine process

S R Jain and D Chappella

Proceedings, Indian Academy of Science

Chemical Science Journal , Vol 95 , pp 381 - 389

October 1985

Attachment: N-substituted hydrazines by anhydrous chloramine.pdf (1.9MB)

This file has been downloaded 1435 times

|

|

|

DeAdFX

Hazard to Others

Posts: 339

Registered: 1-7-2005

Location: Brothel

Member Is Offline

Mood: @%&$ing hardcore baby

|

|

hmmm here is a patent discussing the usage of Ca(OCl)2 as a chlorine source as opposed to NaOCl. I skimmed over the patent a little bit but it certainly does

seem interesting. Is their any real benefit in using the ketazine process over the Olin Raschig process?

[Edited on 9-8-2008 by DeAdFX]

|

|

|

mbrown3391

Hazard to Others

Posts: 133

Registered: 2-9-2006

Member Is Offline

Mood: No Mood

|

|

Hydrazine from Acetone, Ammonia and Bleach

1. 2 CH3-C=O-CH3 + 2 NH3 + NaOCl --> CH3-CH3-C=N-N=C-CH3-CH3 + NaCl + 3H2O

2. CH3-CH3-C=N-N=C-CH3-CH3 + 2 H2O --> H2N-NH2 + 2 CH3-C=O-CH3

Has anyone tried this method of preparing Hydrazine?

|

|

|

Sauron

International Hazard

Posts: 5351

Registered: 22-12-2006

Location: Barad-Dur, Mordor

Member Is Offline

Mood: metastable

|

|

Post your referencess for this putative reaction. At present it appears at best incomplete and unlikely.

Sic gorgeamus a los subjectatus nunc.

|

|

|

chemoleo

Biochemicus Energeticus

Posts: 3005

Registered: 23-7-2003

Location: England Germany

Member Is Offline

Mood: crystalline

|

|

He's referring to the ketazine process, the industrial method of preparing hydrazine.

http://en.wikipedia.org/wiki/Ketazine_process

I seem to remember looking into this, does it perhaps apply high pressure? Somehow I must have concluded at the time that it is not easily possible

for the amateur. I don't have my references here, so maybe someone else can help on the details.

Never Stop to Begin, and Never Begin to Stop...

Tolerance is good. But not with the intolerant! (Wilhelm Busch)

|

|

|

Sauron

International Hazard

Posts: 5351

Registered: 22-12-2006

Location: Barad-Dur, Mordor

Member Is Offline

Mood: metastable

|

|

Pretty much what I meant by "incomplete and unlikely"

I have seen acetone cyanohydrin reacted with ammonia, then coupled to the substituted hydrazine, then oxidized to AIBN, the radical initiatyor. But,

using that approach then expecting to end up reversing it, keeping the N-N bond while cleaving two C-N bonds?

Sounds like a job for some supercatalyst and harsh conditions.

Of course he could ask Rosco about urea -> hydrazine.

Sic gorgeamus a los subjectatus nunc.

|

|

|

ScienceSquirrel

International Hazard

Posts: 1863

Registered: 18-6-2008

Location: Brittany

Member Is Offline

Mood: Dogs are pets but cats are little furry humans with four feet and self determination!

|

|

It is definitely a practical approach on an industrial scale.

http://www.atsdr.cdc.gov/toxprofiles/tp100-c4.pdf

However if one is making small amounts of hydrazine in the lab then the classic approach is quite adequate and there are good recipes that if you

follow them faithfully will produce a good yield.

|

|

|

kmno4

International Hazard

Posts: 1495

Registered: 1-6-2005

Location: Silly, stupid country

Member Is Offline

Mood: No Mood

|

|

Oxidation NH3 with NaOCl is standar procedure for making N2H4.

Reaction with acetone has also application for making pure hydrazine salts. But for hydrolysis 30% H2SO4 is using. All these you can find (in

russian) in work of Kariakin and Angielov.

Besides, there is HYDRAZINE thread.

|

|

|

tapira1

Hazard to Others

Posts: 168

Registered: 9-10-2006

Location: Here!!!

Member Is Offline

Mood:

|

|

NaClO + NH3

This works beautiful. The product may be crystallized as the sulfate

|

|

|

kilowatt

Hazard to Others

Posts: 322

Registered: 11-10-2007

Location: Montana

Member Is Offline

Mood: nitric

|

|

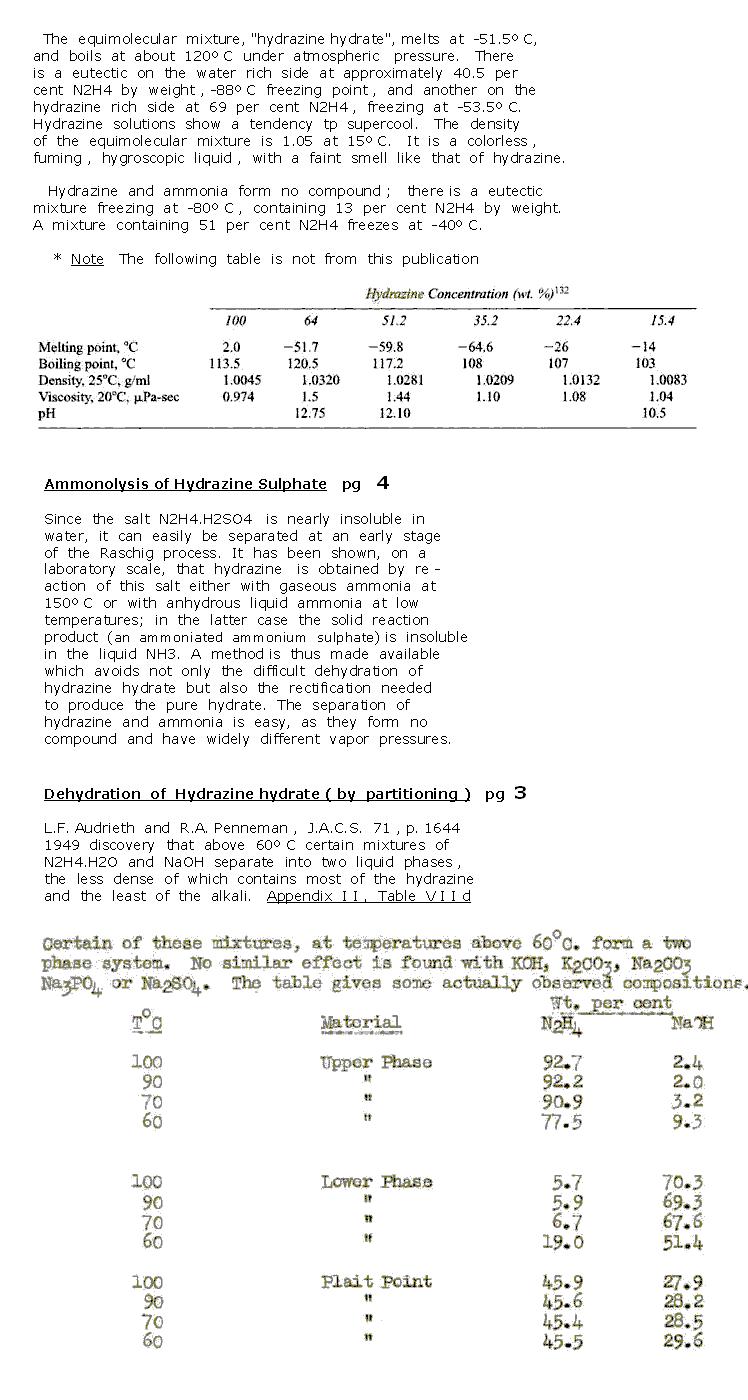

I did some poking around tonight, and it occurred to me that you could likely crystallize anhydrous hydrazine from any aqueous form significantly

exceeding 27% molar (40% w/w) at low temperature. I don't have a full phase diagram, but the eutectic is 27% molar N2H4 and freezes at 193°K. I

believe hydrazine hydrate (64% N2H4) begins to freeze at something like -50°C to -60°C. Thus, with dry ice it should be possible to crystallize an

amount of anhydrous hydrazine from hydrazine hydrate, leaving a liquid depleted to just over 40% N2H4. The diluted liquid could then be re-distilled.

Probably not the most efficient method, but it is interesting anyhow, and perhaps quite suitable for the lab.

The mind cannot decide the truth; it can only find the truth.

|

|

|

chloric1

International Hazard

Posts: 1136

Registered: 8-10-2003

Location: GroupVII of the periodic table

Member Is Offline

Mood: Stoichiometrically Balanced

|

|

Patent literature

Well, I read some patents that talk about the ketazine reaction. Although acetone would suffice, the product is water soluble and would be difficult

to separate under normal conditions. The patents I am thinking of uses MEK instead because mekazine is insoluble. This can be hydrolysized by

heating with strong acid at atmospheric pressure. A reflux setup here would probably be best here. The ketazine can be hydrolysized with plain

water. IIRC, it was at 250 C and 10 atm. This sounds bad but a heavy walled stainless tube with a bleed off valve might work. I seem to remmeber

they even described the pressure reactor. This would be dangerous but set up your workspace like an explosive bunker and you shoudl be OK.

Just remeber your cheap plastic soda bottle is good to like 8 or 9 atms!!

Fellow molecular manipulator

|

|

|

franklyn

International Hazard

Posts: 3026

Registered: 30-5-2006

Location: Da Big Apple

Member Is Offline

Mood: No Mood

|

|

@ kilowatt

Interesting idea , but I think if you resort to temperature extremes

there are other methods perhaps better that become available also.

This reference contains data of interest , excerpts are seen below

An Assessment of Hydrazine, Hydrazine Hydrate and

Liquid Ammonia as fuels for Rocket Propulsion

K. A . Cooper & L. A. Wiseman - 1949

http://www.dtic.mil/cgi-bin/GetTRDoc?AD=ADA474005&Locati...

|

|

|

User

Hazard to Others

Posts: 339

Registered: 7-11-2008

Location: Earth

Member Is Offline

Mood: Passionate

|

|

Destroying hydrazine

Iam planning to throw myself on the hydrazine synthesis (Urea+hypo).

Can anyone tell me how it could destroy hydrazine(hydrate/sulfate) in a worst case scenario.

Grtz user.

|

|

|

| Pages:

1

..

8

9

10

11

12

..

25 |