I did not read all about this topic, but just wanted to comment that the use of isopropanol is most likely futile. Metal alkoxides containing

alpha-hydrogens are generally not stable up to 200 °C. They tend to decompose via beta-hydride elimination reactions, the rate at which they do so

highly depends on the what metal alkoxide they are. I would expect potassium isopropoxide is not stable at the required conditions. The acetone formed

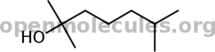

in the decomposition is most likely to blame for the brown-red coloured crap formed via self condensation. On the other hand, t-BuOK is commonly used

as a stable alkoxide at fairly high temperatures, so it might actually be long living at 200 °C as well. Also, tert-butoxides should be much more

soluble in paraffins, which is another reason to stick to tert-butanol or higher homologues. The formation of t-BuOK should be fairly rapid at the

given conditions, especially if Mg is finely divided and/or activated, so I don't think most of t-BuOH escapes, particularly if stirring is used or

heating up is slow.

As to how this redox works, I have no good idea. I don't see how a "2 t-BuOK + Mg <=> (t-BuO)2Mg + 2 K" reaction could ever be favoured on the

right side. Though at least the other part of the cycle, "(t-BuO)2Mg + KOH <=> 2 t-BuOK + Mg(OH)2" makes sense direction-wise. Quite weird.

Anyhow, I would guess the most important factor is the activation of the Mg metalic surface and the quality&mesh of the metal.

|

. Here's a description of my latest attempt:

. Here's a description of my latest attempt: .

.

. I'll try doing as you suggested next time. Boil

off some of the kerosene and maybe even fuse the KOH before I use it.

. I'll try doing as you suggested next time. Boil

off some of the kerosene and maybe even fuse the KOH before I use it.