| Quote: |

| Originally posted by Barium Steve, which substrate have you tried nickel boride on? |

Not allowed to say

I'd much rather use Zn/H+ any day...

I'd much rather use Zn/H+ any day...

| Quote: |

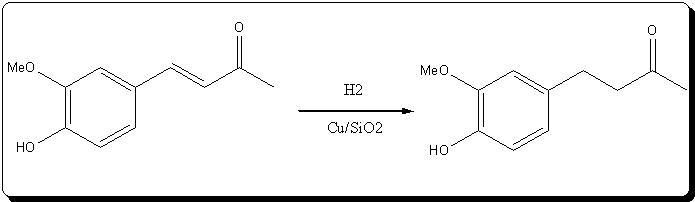

) or you're using a DEhydrogenation catalyst for hydrogenation?

) or you're using a DEhydrogenation catalyst for hydrogenation?| Quote: |

| Quote: |

I'd much rather use Zn/H+ any day...

I'd much rather use Zn/H+ any day...| Quote: |

| Quote: |

| Quote: |

| Quote: |