"A process developed by Produits Chimiques Ugine Kuhlmana (PcUK), and practiced by Atofina (France) and Mitsubish Gas (Japan) involves the oxidation

of ammonia by hydogen peroxide in the presence of butanone (MEK) and another component that apparently serves as an oxygen-transfer agent. The

reaction is carried out... at at 50degC. The ratio of H2O2/MEK:NH3 used is 1:2:4. Hydrogen peroxide is activated by acetamide and disodium hydrogen

phosphate (117). The mechanism of this reaction involves an activation of the ammonia and hydrogen peroxide because these compounds do not themselves

react (118-121). It appears that acetamide functions as an oxygen transfer agent, [possibly as the iminoperacetic acid, HOOC(=NH)CH3 ], which

then oxidizes the transient Schiff base formed between MEK and ammonia to give give the oxaziridine, with regeneration of acetamide."

(117) U.S. Pat. 3,962,878 (aug. 3, 1976), J.P. Schirmann, J. Combroux, and S. Y. Delavarenne

(118) J.P. Schirmann and S. Y. Delavarenne, Tetrahedtron :ett. 635 (1972)

(119) E. G. E. Hawkins, J. Chem. Soc. C, 2663 (1969)

(120) E. Schmitz, Chem. Ber. 97, 2521 (1964)

(121) Can. Pat. 2,017,458 (Nov. 24, 1990), J.P. Schirmann, J. P. Pleuvry, and P. Tellier (to Atochem)

|

It seems that my visual determination of quantity is not very good

It seems that my visual determination of quantity is not very good

....hope no one was in a

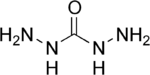

big hurry for it . Anyway the prospect for a more direct method to the hydrazine derivative hydrazodicarbonamide in 70% yield is the matter of most

special interest described in US3238226 attached.

....hope no one was in a

big hurry for it . Anyway the prospect for a more direct method to the hydrazine derivative hydrazodicarbonamide in 70% yield is the matter of most

special interest described in US3238226 attached.