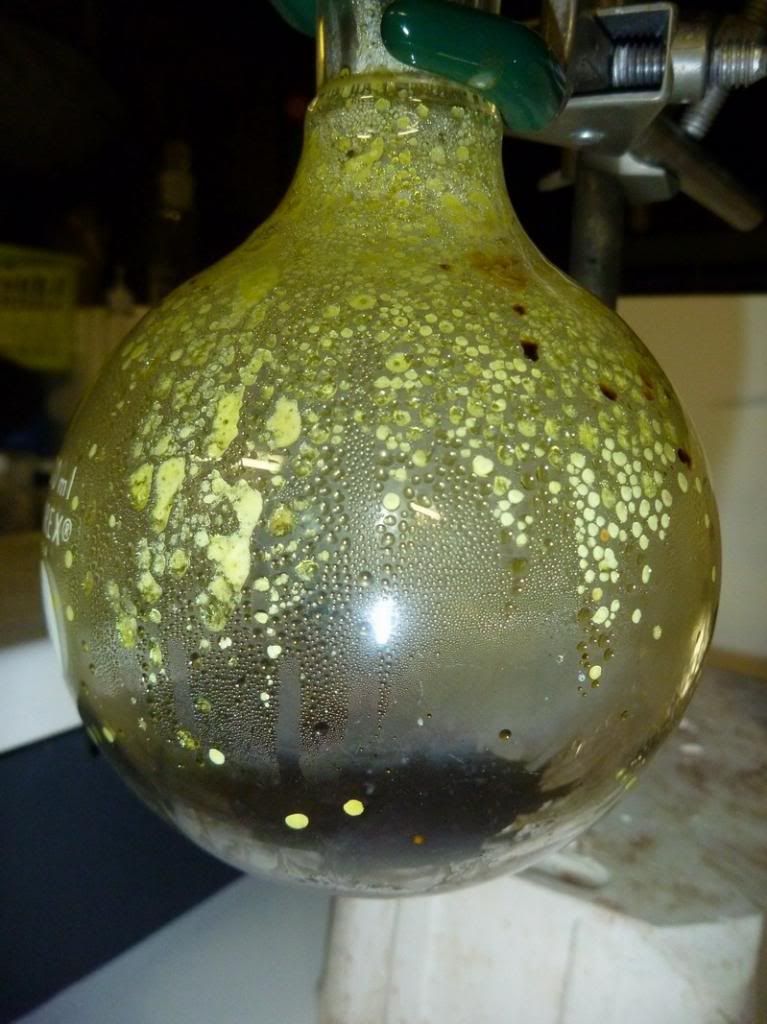

At - 278 and 280 o C a fast weight loss is observed in Cu(nic), and

Cu(isonic), respectively. The overall weight loss is in agreement with the

stoichiometry

5 Cu(NC5H4CO2)2(s) + 5 Cu(s) + 10 CO2(g) + 8 NC5H5(g) + N2(g) + 10 C(s)

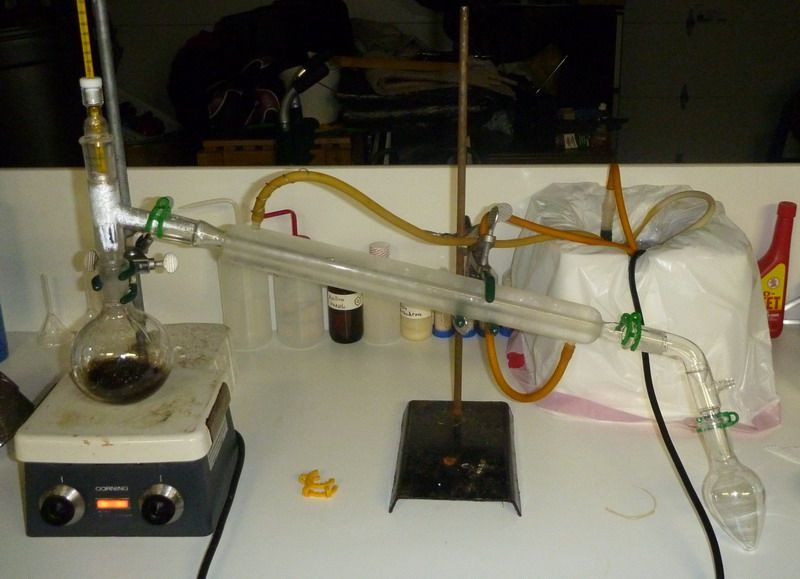

Carbon dioxide was detected as the main gaseous product through the

formation of BaCO, upon bubbling the released gases in aqueous Ba(OH),,

and this was confirmed by IR spectroscopy of the evolved gases. Pyridine is

also formed and partially condenses; it can be identified both in the gas and

condensed liquid through IR spectra. |

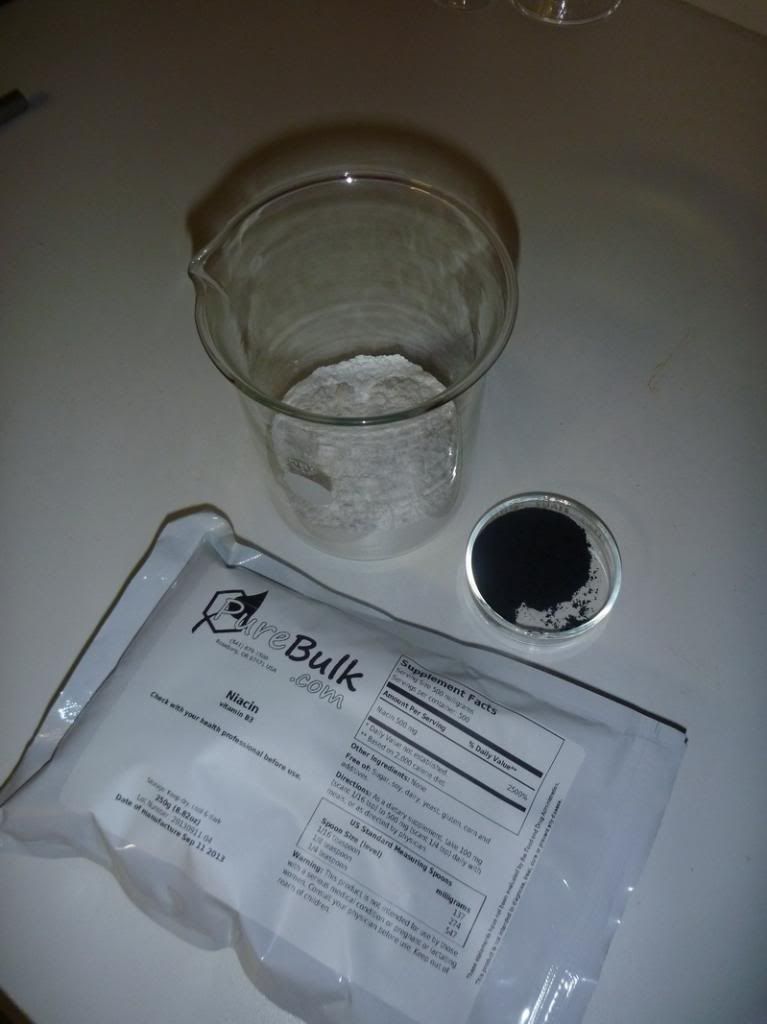

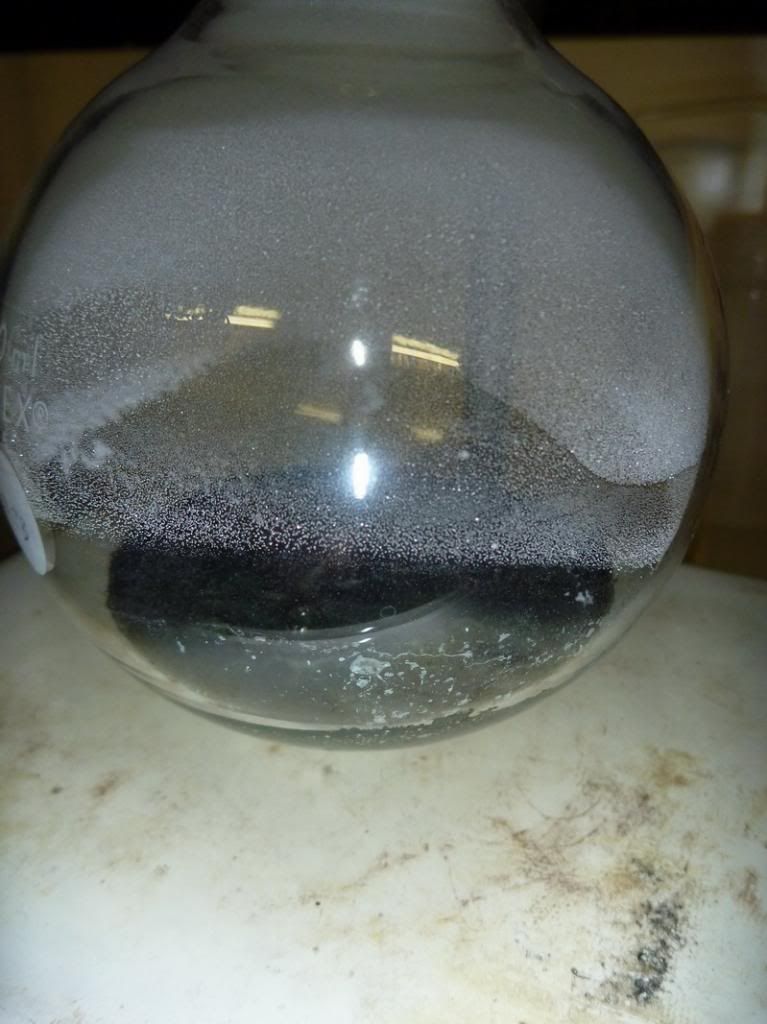

), it is remarkable that the residue can be removed from the flask with ease! Its just a shame that niacin is so expensive. I do think that

with sufficient copper chromite "catalyst" the reaction can be scaled up somewhat so long as the niacin precursor can be economically obtained.

), it is remarkable that the residue can be removed from the flask with ease! Its just a shame that niacin is so expensive. I do think that

with sufficient copper chromite "catalyst" the reaction can be scaled up somewhat so long as the niacin precursor can be economically obtained.