Klute - 17-1-2010 at 15:37

I had a bunch of veratryl alcohol at hand, and I've been wanting to synthesis veratraldehyde since a long time.

Not having any pur 4-oxo-TEMPO at hand, I can't use it in combination with hypochlorite.

Patent 20090062569 teaches the use of paraformaldehyde and catalytic aluminium isopropoxide to oxidize 3,4-methoxy- subtituted benzylic alcohols

into the corresponding aldehydes with great selectivity and yield. I decided on trying this method.

All glassware used was oven dried prior to use. Toluene was distilled over sodium metal.

A 500mL flask was mounted with a Dean Stark trap, a condenser and a CaCl2 guard.

20g of veratryl alcohol were charged, followed by 250mL toluene. The toluene was heated to reflux, and 25mL distilled off using the Dean Stark, to

ensure proper drying.

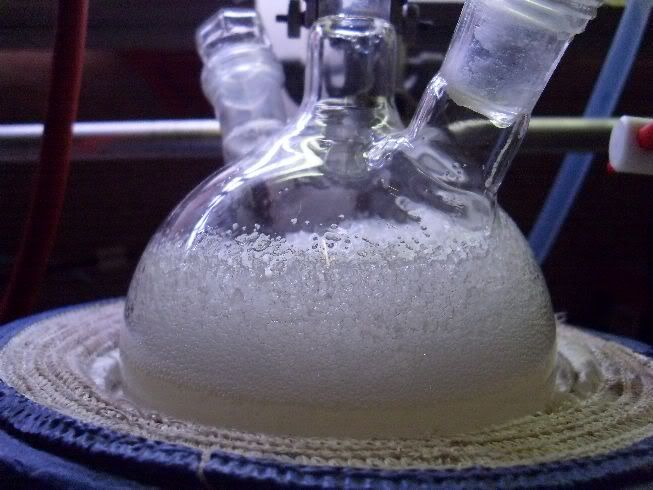

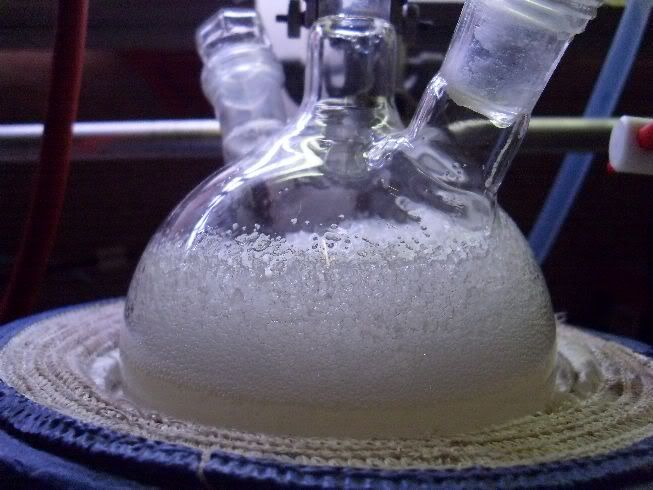

230mg of Al(OiPr)3 were added after cooling the solution. The flask was heated to 100°C, and 10g of paraformaldehyde (dried over NaOH) were slowly

added in portions. This caused foamming, and distillation of the methanol-toluene azeotrope in the trap.

After half the paraformaldehyde was added, a thick gelatinous solid formed. Fresh toluene was added and stirring increased to break up the solid.

The methanol-toluene azeotrope was collected in the trap, which was emptied when full.

The mixture was then refluxed for 2h, at which point it took a yellow color. TLC (20% AcOEt in pet ether) confirmed all the alcohol was oxidized to

the aldehyde.

The mixture was cooled down, added to a 1L seperatory funnel, and 300mL 1N NaOH were added, causing the appearance of a fine white solid (Al2O3).

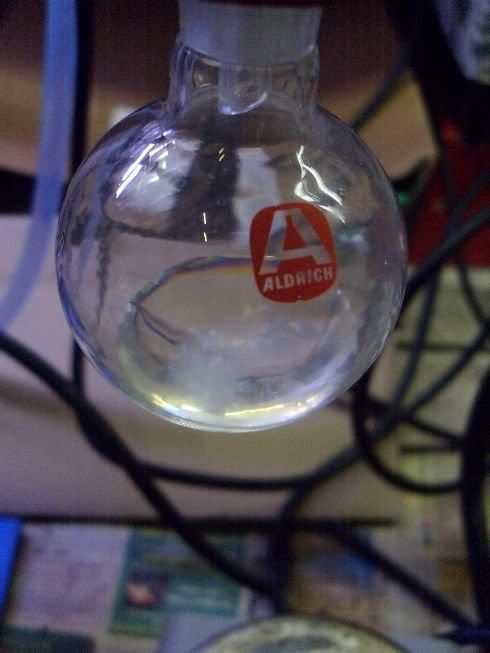

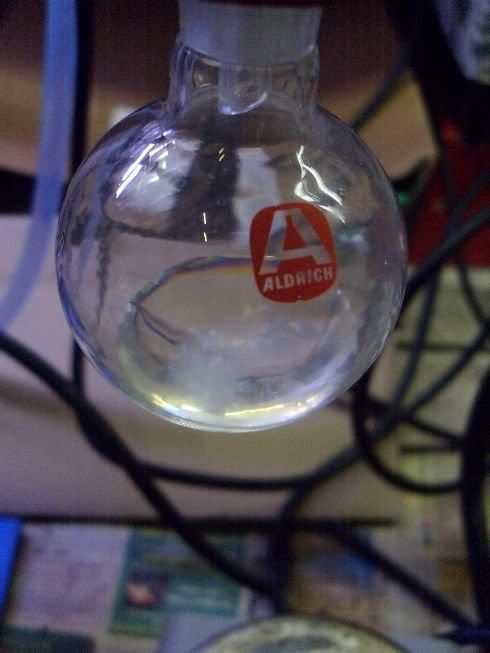

The toluene layer was seperated, and washed with brine before drying with Na2SO4. The toluene was then removed under vacuum. The residu was transfered

to a micro-distillation setup, the rest of the toluene removed under vacuum, and the aldehyde distilled. The aldehyde started cristallizing in the

receiver.

The aldehyde was obtained in a 89% yield after distillation. This method works very well, and is fairly easy to take out.

The addition of the paraformaldehyde needs to be done under 100°C because of the vigorous foamming that takes place as soon as the solid is added.

Carefully heating up the solution after addition causes alot of foamming.

Some solid Al2O3 is present in the extract, and precipitates when the toluene is removed. It is not a trouble for the distillation of the aldehdye

however.

It is essential that the setup is dry, aswell as the solvent. Presence of water desactivates the catalyst.

The methanol formed by reduction of the paraformaldehyd is removed to displace the equilibrium.

See my preparation of the catalyst in the corresponding thread:

Preparation of solid Al(OiPr)3.

smuv - 18-1-2010 at 18:51

Nice work and good write-up Klute.

What do you think the " thick gelatinous solid formed" after the addition of 1/2 of the paraformaldehyde is? Some polyoxymethylene?

[Edited on 1-19-2010 by smuv]

Klute - 19-1-2010 at 19:19

THanks Smuv!

Well, i'm not 100% sure, but I think it's the complex of veratryl alcohol and paraformaldehyde, or methanol, considering it redissolved after a

moments heating.. Not sure what else it could be..

DJF90 - 19-1-2010 at 20:21

Great work as always Klute. I find the use of paraformaldehyde to effect the oxidation very intriguing indeed, and if I ever attempt an oppenheimer

oxidation this will likely be the method I use.

Have you considered trying the Meerwein Ponndorf Verley reduction on an aldehyde or ketone? It would be interesting how yields compare in the opposite

direction (albeit a different substrate unless you want to reclaim your veratryl alcohol), and it'd be likely you'd have to use isopropanol or

cyclohexanol to effect the reduction.

One use of the Oppenheimer/MPV equilibrium is to effect a change in the stereochemistry of a hydroxy group in some substrates.

Klute - 19-1-2010 at 23:28

Using the reverse conditions will be quite interesting, but I simply don't have any substrate I'd like to reduce! I'm more into preparing aldehdyes

and ketones ratehr than reducing them

Anyway, I will be re-doing this reaction, because I botched my glycidate ester synthesis with old hydrolyzed NaOMe, serves me right to try and skip

the preparation of fresh methoxide! I didn't use all the veratraldehyde, but I will be needing more for the phenylbutanone synthesis..

Rattata2 - 31-1-2010 at 03:30

How does it smell?

Klute - 31-1-2010 at 04:46

Very nice! A very subtle vanillin-like, with scents of almonds..