As an alternate way of testing the amount of P formation, perhaps use a phosphorus getter above a glass wool plug. Use something that reacts

completely with gas-phase P, maybe forming a phosphide, but scavenging all the P formed. Mass difference gives a direct reading of yield.

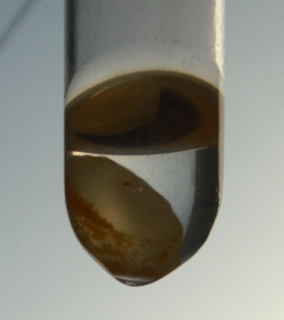

Seeing these samples has spurred some new ideas about additives. Principal are the constituents of soda-lime glass, oxides and carbonates of sodium,

calcium, and magnesium. Looking at the samples leads me to think that the sooner you get into a liquid-phase reaction, the better off the reaction

will be. Lead oxide would lower melting points, but it would reduce along with the phosphorus. I doubt you'd need bulk liquid, but some interfacial

liquid on particle surfaces might be enough.

The other "additive" that comes to mind is a candidate reagent: calcium carbide. It seems to me it would be an excellent oxygen scavenger in this

environment, lower melting points, and provide some mechanical sparging by CO2 production. Wouldn't need much, I'd guess, to be active at

the beginning of the reaction. |