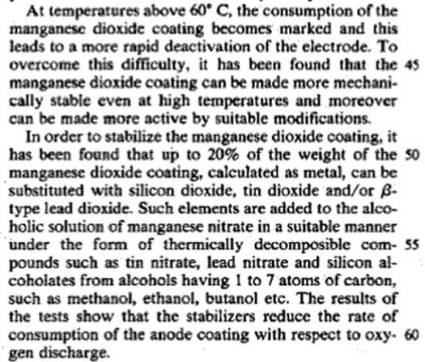

BTW Hubert is still running in the KClO3 cell, I will have to call it a day soon though, as I'm getting a bit sick of it. It's been running continuously for 42 days (1008 hours) now. Every few days I scoop out KClO3 and add some more KCl (a bit like running a ginger beer plant). The electrical characteristics are very, very slowly degrading. I think if you put on 20 coats of MnO2 and kept the current density to 50 mA/cm^2 it would just about run forever ...

...when they get

...when they get