RogueRose

International Hazard

Posts: 1585

Registered: 16-6-2014

Member Is Offline

|

|

Odd precipitate in solution from dissolving gold pins from computer scrap

I have a pile of computer scrap that has hundred's of thousands of gold pins and I thought I would try a small sample of a few pins and try a couple

methods of dissolving the pins leaving the gold behind. The pins I have are the kind from old IDE & SCSI connections and some CAT5 jacks

(female). Some were impossible to remove from the plastic so I chopped up the connector and threw the plastic in with everything else and it's

incredible that there is basically zero damage to any of the plastic.

I've been told that the pins might be a phosphor bronze, they don't seem like copper though they may have some plating. There also was a very small

amount of solder on the pins (maybe 1-2% which could be Sn/Ag or Pb/Sn I'm guessing).

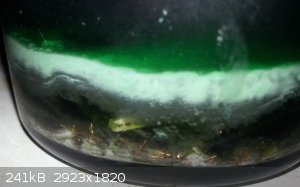

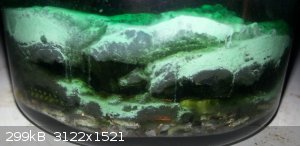

I used 31% HCl & 35% H2O2 with some distilled water and a little heat to begin. When adding the HCl it started to turn yellow pretty quickly and

when the H2O2 was added a green color appeared until it was done dissolving. When things seemed finished (IDK if it was b/c the acid was used up or

all metal was dissolved) but the solution turned from green to blue like a light copper sulfate color and I started getting a grey and light blue

precipitate very similar to what is in the pictures but what is green in the pics was blue. I added a little more HCl (about 5ml - or an additional

~15%) and the solution quickly turned back to green. After that I've allowed it to sit for about a week at room temperature and the result is what is

in the pictures below.

There seems to be 3 layers of precipitate. A white one on the very bottom, a grey "fluffy" layer above that and then the light green layer on the top

which is the stuff that had been blue before the additional HCl was added.

When I added the 5ml HCl I mixed everything up again and it seemed like everything dissolved again into solution. I may have added a little more H2O2

as well.

So I'm trying to figure out what these three layers might be as per chloride salts.

Also, the top view shows a layer of film that keeps growing which sinks and forms the top green layer. I didn't see this happen when the grey

precipitate appeared, I think that happened fairly quickly compared to the top green layer.

Is the solution pulling CO2 out of the air allowing a copper (complex?) to precipitate? Can anyone identify any of the other possible precipitates?

|

|

|

Sulaiman

International Hazard

Posts: 3558

Registered: 8-2-2015

Location: 3rd rock from the sun

Member Is Offline

|

|

AFAIK HCl + H2O2 can dissolve gold !

I don't know what other metals you have but copper, nickel, iron, tin and lead seem common,

none of which are worth recovering - in my opinion.

There is (usually) very little gold on connectors,

opinions will vary but I suggest HCl first, be patient and aggitate the mixture daily.

Decant the liqid to waste disposal.

Rinse thoroughly several times to remove HCl,

Dissolve away the remaining base metals with dil. HNO3

You should be left with mainly gold,

dissolve in Aqua Regia, (do not add excess nitric acid)

filter, add a few drops of H2SO4 to precipitate any lead,

filter, drop the gold out of solution using your favourite reducer (SMB etc.)

then be dismayed at the yield vs. reactants, time, waste disposal and general mess involved.

(I still have one small bottle of black/grey/fluffy sediment in liquid blue/green waste to deal with)

kadriver aka sreetips@YT videos cover almost everything involved.

CAUTION : Hobby Chemist, not Professional or even Amateur

|

|

|

Ubya

International Hazard

Posts: 1232

Registered: 23-11-2017

Location: Rome-Italy

Member Is Offline

Mood: I'm a maddo scientisto!!!

|

|

the white/gray precipitate could easily be lead and/or silver chloride

---------------------------------------------------------------------

feel free to correct my grammar, or any mistakes i make

---------------------------------------------------------------------

|

|

|

Wizzard1

Harmless

Posts: 10

Registered: 13-2-2019

Member Is Offline

|

|

I'm seconding Ag/Pb chlorides.

Also, pins can contain QUITE a few more difficult metals - Nickel, chrome, iridium, silver, lead... Gold extraction around those metals can be a pain.

I might recommend melting down all the pins in a crucible, then making shot and attacking the metal that way. The layers are what slow you down,

significantly. You can also try inquartation with silver, then using mild acids to attack all metals but Au/Ir/Pt, and then traditional purification

from there.

But I usually don't bother with pins - Not worth the hassle.

|

|

|

RogueRose

International Hazard

Posts: 1585

Registered: 16-6-2014

Member Is Offline

|

|

Quote: Originally posted by Sulaiman  | AFAIK HCl + H2O2 can dissolve gold !

I don't know what other metals you have but copper, nickel, iron, tin and lead seem common,

none of which are worth recovering - in my opinion.

There is (usually) very little gold on connectors,

opinions will vary but I suggest HCl first, be patient and aggitate the mixture daily.

Decant the liqid to waste disposal.

Rinse thoroughly several times to remove HCl,

Dissolve away the remaining base metals with dil. HNO3

You should be left with mainly gold,

dissolve in Aqua Regia, (do not add excess nitric acid)

filter, add a few drops of H2SO4 to precipitate any lead,

filter, drop the gold out of solution using your favourite reducer (SMB etc.)

then be dismayed at the yield vs. reactants, time, waste disposal and general mess involved.

(I still have one small bottle of black/grey/fluffy sediment in liquid blue/green waste to deal with)

kadriver aka sreetips@YT videos cover almost everything involved. |

I have to agree with this. I had some PCI/ISA and power connector gold fingers that had dissolved off in another batch, all the gold foils were

sunken to the bottom and the entire bottom of the beaker was covered and this was about 3-5 hours after starting the reaction. About 1-2 days later

I'd say 75% of the gold was gone and a small amount of foils was left.

I've seen a lot of videos that say the HCl + H2O2 / O2 can't dissolve the gold, but I tried 2 different times with nothing but gold fingers (not the

phosphor bronze pins) and both times I was impressed with the amount of foils left and then next time I checked the majority of them were gone.

|

|

|

Sulaiman

International Hazard

Posts: 3558

Registered: 8-2-2015

Location: 3rd rock from the sun

Member Is Offline

|

|

First thing to do is to make or buy some Tin(II)Chloride solution.

You really must be able to detect gold ions

(or more importantly, be sure of the lack of gold ions - test your test solution.)

Every time a process produces more than one liquid,

test each with SnCl2 before discarding any

So far I've not managed to make gold disappear, only change character,

its always in there somewhere no matter what dumb things I tried earlier.

Also, gold is so dense that it settles really quickly,

so waiting for precipitation then decanting wastes almost no gold,

whereas filtering always requires further recovery operations.

P.S. my entire hoard of gold powder is 2.7g, over 1g of which was from jewelry,

so my experience is rather limited - so treat my advice accordingly.

[Edited on 23-4-2019 by Sulaiman]

CAUTION : Hobby Chemist, not Professional or even Amateur

|

|

|

RogueRose

International Hazard

Posts: 1585

Registered: 16-6-2014

Member Is Offline

|

|

Quote: Originally posted by Sulaiman  | First thing to do is to make or buy some Tin(II)Chloride solution.

You really must be able to detect gold ions

(or more importantly, be sure of the lack of gold ions - test your test solution.)

Every time a process produces more than one liquid,

test each with SnCl2 before discarding any

So far I've not managed to make gold disappear, only change character,

its always in there somewhere no matter what dumb things I tried earlier.

Also, gold is so dense that it settles really quickly,

so waiting for precipitation then decanting wastes almost no gold,

whereas filtering always requires further recovery operations.

P.S. my entire hoard of gold powder is 2.7g, over 1g of which was from jewelry,

so my experience is rather limited - so treat my advice accordingly.

[Edited on 23-4-2019 by Sulaiman] |

Thanks for the information. I guess I need to buy/make some SnCl2. I wasn't planning on discarding anything until I get things worked out. I

started with much less than 1% of all the gold pins/connectors I have just to see if it is worth it. I'm guessing that the more gold connectors I

have the better cost/benefit ratio for extraction.

I'm wondering if there is a difference with using the HCl + H2O2 (which gets ~150-160F) vs HCl + air bubbling which won't heat up. I'm thinking that

the slower method might not dissolve any of the gold but the other method might?

Also, with all the other chlorides in solution, I'm wondering if those might act as a solvent to the gold just like using hot lead to dissolve gold or

using molten zinc to dissolve aluminum and copper MUCH below their melting points. Also, if there is phosphorus in the bronze, I'm wondering if that

could play a role in the gold fims seemingly dissolving. It's a lot to consider and I'd like to try some very small experiments to test this.

One thing I did notice was I had a very large gold plated power connector (200A) onto which some wires were soldered using 60/40 Pb/Sn solder. The

gold coating was a total of 8" x 1/2" all covered by solder. I removed much of the solder w/ wire wick before dissolving the connector. The other

small fingers w/o solder remained in solution while all that was covered with solder disappeared. IDK if the solder dissolved it (supposedly it needs

to be 600C for lead to dissolve gold, which that never reached, or it was dissolved in the acid. This is one of the more interesting parts of what

I've done so far with this as I thought the solder would be removed w/ the acid but no, all of it was and it happened VERY fast compared to the other

metals in other batches.

|

|

|

|