ThePKWonder

Harmless

Posts: 5

Registered: 6-4-2020

Member Is Offline

|

|

Oxalate Stain Removal from Stainless Steel Question

Hello SM!

I'm pretty new here, and I'm trying to stay conscious of forum etiquette, and I welcome any constructive criticism. I have created this new topic

after having searched and not found an existing one covering this specific question:

How can insoluble oxalates be removed from stainless steel?

Brief background: I am having trouble removing stains from stainless steel flatware (irony noted), which I presume has calcium oxalate as a major

component. In an attempt to remove red iron stains, and without thinking things through enough, I dissolved an arbitrary amount of oxalic acid in tap

water and left some pieces of the flatware soaking in it for a few days. A white precipitate developed, which in retrospect may be calcium oxalate due

to the hardness of my tap water. During the soaking, I observed slow gas formation on the metal surfaces. After removing and rinsing the flatware, I

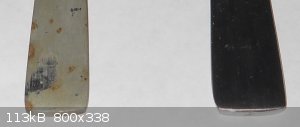

was left with surface staining which is well represented by the piece at the left of the image below. A piece of flatware not soaked in the oxalic

acid tap water solution is shown to the right. It is pretty apparent that there’s still ferric iron present, but the main stain is now an off white

layer.

Now, I'm thinking that the off white staining/layer probably consists of some sort of insoluble oxalate(s), maybe calcium from the tap water.

Comparing the solubilities from Wikipedia, it looks like calcium oxalate is 19 times less soluble in water than calcium carbonate!

I found a reference which discusses dissolving calcium oxalate using EDTA, with increasing dissolving ability with increasing EDTA concentration and

with increasing pH:

https://pubmed.ncbi.nlm.nih.gov/3102759/

So, I tried soaking a sample of the stained flatware in a solution of tetra sodium EDTA (with a measured pH of about 10) for about a week, but I got

no noticeable removal of the stain. I then added sodium carbonate to the solution, with a resultant pH of 13 to 14, and even with that high pH, the

stain shows little to no improvement after a few days. This surprises me because the reference claimed dissolution of a bulk piece (2 mm) of calcium

oxalate in a 0.03 M solution of EDTA at a pH of 7.5 within 48 hrs. My solution was both more concentrated and at a higher pH, and so by the logic of

the reference, should have fared even better.

It is quite possible that I am missing something obvious here. Perhaps a different approach is needed, like using an acid stronger than oxalic acid?

Or maybe I need to oxidize the oxalate anions to CO2 somehow? Or maybe the stain layer is not even an oxalate at all?

I would love to hear any ideas about identification of and dissolution of insoluble oxalates.

|

|

|

Maurice VD 37

Hazard to Self

Posts: 66

Registered: 31-12-2018

Member Is Offline

|

|

If I summarize your observations, you started by trying to remove red iron stains from stainless steel. These red iron stains are probably rust.That

is the first surprise. How can rust appear on stainless steel ? Are you sure that this steel is stainless ?

Then you dipped your metallic pieces in a solution of oxalic acid in tap water. Of course this solution will soon be cloudy. But I don't think this

cloud will make a deposit on steel. Why should it ? The deposit will slowly gets deposited on the ground of the flask.

I think the deposit observed on our pieces is due to the reaction of oxalic acid on the metal. The white deposit is probably made of ferrous oxalate

produced by the slow reaction of oxalic acid on iron.

The reaction could be : Fe + H2C2O4 --> FeC2O4 + H2. And indeed, iron oxalate is a greyish insoluble substance. Furthermore you had observed some

gas formation on the metal surface. This is Hydrogen H2.

There is no sign of ferric ions, despite your opinion. If some ferric should appear somewhere, it should be quickly reduced ion ferrous ions by the

oxalic acid.

So your left sample is steel covered by ferrous oxalate. I don't know how to explain what the piece at right is so black. You did not mention what you

did with it. You simply say that this piece was not soaked in the oxalic acid. But what was its fate ?

|

|

|

ThePKWonder

Harmless

Posts: 5

Registered: 6-4-2020

Member Is Offline

|

|

response to Maurice:

Hi Maurice, thanks for the thoughts!

First off, to address a couple of your questions, I believe the original red iron stains are from the hard tap water from my house's well. The lab

analysis I've had done has reported that it contains 0.610 mg/L of iron. I think the way this kind of iron stain forms on surfaces from hard water is

as follows: the small amount of iron dissolved in the hard water is present as Fe[II]. Since the pH is pretty much neutral, the counter ions are

hydroxide. Fe[II] hydroxide has a slight solubility in water, high enough to keep the small amount of iron in solution. When the tap water is used,

oxygen from the air oxidizes the Fe[II] ions to Fe[III] ions, and due to Fe[III] hydroxide having a much lower solubility than Fe[II] hydroxide at

neutral pH, the Fe[III] then gradually precipitates in very small amounts as insoluble stains on surfaces where the tap water is in frequent contact

over long time scales. (I think the precipitated Fe[III] is in the form of Fe(O)(OH), ferric oxyhydroxide, and/or Fe2O3, ferric

oxide.) If I have this right, then this explains why the 'rust' stains appeared on my stainless flatware: it came from the tap water, not actually

from corrosion of the stainless steel.

As for the appearance of the piece at the right of the picture, it looks black just from the light and camera angle, where the metal is reflecting a

relatively dark background. In person it is typical shinny stainless steel metal. I used this angle because it gave the best contrast to show the

white stain.

I think you've got a good line of thinking regarding the deposit: the oxalic acid behaved as a strong acid and reacted with the metal, releasing

hydrogen. So, as you suggest, the stain is probably a reaction product of the oxalic acid and the metal, which being stainless steel, consists of at

least iron and chromium, and possibly some nickel as well.

So, the deposit is likely some combination of iron, chromium, and nickel oxalates, probably of their lowest common oxidation states, due to the

reducing nature of oxalic acid.

So, now I need to think about what conditions would make these oxalates soluble, or convert them into soluble substances, while also not excessively

attacking the stainless steel.

Some ideas to look into off the top of my head are

- pyrolysis of the transition metal oxalates to the free metals and their oxides, pickling the samples in HCl to remove bulk metal oxides, and then

repassivation of the SS with nitric acid

- trying to form the complex ion salts (like potassium ferrioxalate K3[Fe(C2O4)3]), if those would be

more water soluble, by heating the samples in a basic solution of KOH and H2C2O4 (essentially a solution of

K2C2O4 with excess KOH)

I'll give this more thought and reading, and I'll report back.

|

|

|

macckone

International Hazard

Posts: 2159

Registered: 1-3-2013

Location: Over a mile high

Member Is Offline

Mood: Electrical

|

|

use a power buffing wheel (regular sized or dremel).

Oxalic acid is a poor choice.

You likely etched the surface.

The only thing you can do is buff it out.

Vinegar is usually used to remove rust.

It is much less reactive with the metal.

Naval jelly is also used to remove rust.

It is a mixture of phosphoric acid.

Rust Out is also a good choice. It won't etch stainless steel.

The best method of removing iron oxylate is LOTS of water or abrasive removal ie. buffing.

|

|

|

|