Abromination

Hazard to Others

Posts: 432

Registered: 10-7-2018

Location: Alaska

Member Is Offline

Mood: 1,4 tar

|

|

Electrical Ark Furnace Req.

I want to build an electrical ark furnace that runs on a minimal amount of both voltage and ampage. How many volts is required to get an electrical

ark on graphite and how many to achieve temperatures of around 700°C?

Im making mine out of fire brick and graphite electrodes, but need a power source strong enough to get me an ark.

List of materials made by ScienceMadness.org users:

https://docs.google.com/spreadsheets/d/1nmJ8uq-h4IkXPxD5svnT...

--------------------------------

Elements Collected: H, Li, B, C, N, O, Mg, Al, Si, P, S, Fe, Ni, Cu, Zn, Ag, I, Au, Pb, Bi, Am

Last Acquired: B

Next: Na

-------------- |

|

|

WGTR

National Hazard

Posts: 971

Registered: 29-9-2013

Location: Online

Member Is Offline

Mood: Outline

|

|

Quote: Originally posted by Abromination  | I want to build an electrical ark furnace that runs on a minimal amount of both voltage and ampage. How many volts is required to get an electrical

ark on graphite and how many to achieve temperatures of around 700°C?

Im making mine out of fire brick and graphite electrodes, but need a power source strong enough to get me an ark. |

OK, two things:

1. Minimum voltage and current is about 30 volts at 3 amps, in my experience, on 1/8" graphite electrodes that are filed to a blunt point. However,

this is the voltage measured directly across the electrodes. You need a higher voltage power source, closer to about 100-120 DC volts to help

stabilize the arc. What this means is that you can use a 120V DC power supply, and connect to the electrodes through a large power resistor (30 ohms,

300 watt rating, with the resistors submerged in deionized water for cooling). You touch the electrodes together to initiate the arc, and then the

power resistor drops the voltage to around 30 volts across the electrodes while pulling 3 amps. Of course, more current is going to be better, but

I'm giving you my own experiences for minimum values.

2. More importantly though, you don't need an arc furnace to get to 700 degrees. This is a very low temperature, relatively speaking. This is very

easily attainable through electrical heating, barely red heat. Check my signature for a link to an electric furnace that I built. The resistance

wire is very cheap on eBay.

|

|

|

Ubya

International Hazard

Posts: 1232

Registered: 23-11-2017

Location: Rome-Italy

Member Is Offline

Mood: I'm a maddo scientisto!!!

|

|

industrial arc furnaces use a voltage between 400 an 900 volts and pretty much as much current can you supply (44000amps for a medium furnace)

you would need a pretty big transformer, a DIY one from MOTs as Grant Thompson ( The King Of Random) did for example.

the 700°C in the furnace depends on how well insulated it is, an arc can be many thousands of degrees, 700 is nothing compared.

---------------------------------------------------------------------

feel free to correct my grammar, or any mistakes i make

---------------------------------------------------------------------

|

|

|

Abromination

Hazard to Others

Posts: 432

Registered: 10-7-2018

Location: Alaska

Member Is Offline

Mood: 1,4 tar

|

|

Quote: Originally posted by WGTR  | Quote: Originally posted by Abromination  | I want to build an electrical ark furnace that runs on a minimal amount of both voltage and ampage. How many volts is required to get an electrical

ark on graphite and how many to achieve temperatures of around 700°C?

Im making mine out of fire brick and graphite electrodes, but need a power source strong enough to get me an ark. |

OK, two things:

1. Minimum voltage and current is about 30 volts at 3 amps, in my experience, on 1/8" graphite electrodes that are filed to a blunt point. However,

this is the voltage measured directly across the electrodes. You need a higher voltage power source, closer to about 100-120 DC volts to help

stabilize the arc. What this means is that you can use a 120V DC power supply, and connect to the electrodes through a large power resistor (30 ohms,

300 watt rating, with the resistors submerged in deionized water for cooling). You touch the electrodes together to initiate the arc, and then the

power resistor drops the voltage to around 30 volts across the electrodes while pulling 3 amps. Of course, more current is going to be better, but

I'm giving you my own experiences for minimum values.

2. More importantly though, you don't need an arc furnace to get to 700 degrees. This is a very low temperature, relatively speaking. This is very

easily attainable through electrical heating, barely red heat. Check my signature for a link to an electric furnace that I built. The resistance

wire is very cheap on eBay. |

Is there a chance that I could damage the wall socket? The graphite acts as a resistor, but when a circuit with only a resistor is completed, a short

occurs. I assume I am simply bad at electrical engineering (I am) and I am wrong?

List of materials made by ScienceMadness.org users:

https://docs.google.com/spreadsheets/d/1nmJ8uq-h4IkXPxD5svnT...

--------------------------------

Elements Collected: H, Li, B, C, N, O, Mg, Al, Si, P, S, Fe, Ni, Cu, Zn, Ag, I, Au, Pb, Bi, Am

Last Acquired: B

Next: Na

-------------- |

|

|

WGTR

National Hazard

Posts: 971

Registered: 29-9-2013

Location: Online

Member Is Offline

Mood: Outline

|

|

The power resistor keeps you from having a short circuit. Anyways, you need DC power, not AC, unless you are using very high voltage. The current

doesn't get interrupted with DC current, so the arc will be more stable at lower voltages and currents. If you use AC, the current gets interrupted

50 or 60 times per second, and the arc will extinguish itself at 120 volts. You'd need over 400 volts to keep an AC arc going, but this is very

dangerous.

Anyway, there are other ways of getting an electric arc going, I'm only suggesting parameters that I have experience with, since you were asking about

the minimum parameters to sustain an arc.

Given the temperature that you want to achieve, I'd suggest building a small electric kiln or tube furnace, or even a small wood-fired furnace. I

built a small wood-fired one out of a few firebricks, and fired it with bits of mesquite charcoal. A hair dryer provided enough air flow to get

things over 1300 degrees inside. I melted all sorts of ceramics and metals in that thing. If you don't mind me asking, what do you need it for?

[Edited on 7-29-2018 by WGTR]

|

|

|

streety

Hazard to Others

Posts: 110

Registered: 14-5-2018

Member Is Offline

|

|

Quote: Originally posted by Abromination  |

Is there a chance that I could damage the wall socket? The graphite acts as a resistor, but when a circuit with only a resistor is completed, a short

occurs. I assume I am simply bad at electrical engineering (I am) and I am wrong? |

What type of resistor are you using? I assume you didn't happen to have a spare 30 ohm power resistor lying around.

Also, when you say a short occurs what are you actually observing?

|

|

|

Abromination

Hazard to Others

Posts: 432

Registered: 10-7-2018

Location: Alaska

Member Is Offline

Mood: 1,4 tar

|

|

Quote: Originally posted by WGTR  | The power resistor keeps you from having a short circuit. Anyways, you need DC power, not AC, unless you are using very high voltage. The current

doesn't get interrupted with DC current, so the arc will be more stable at lower voltages and currents. If you use AC, the current gets interrupted

50 or 60 times per second, and the arc will extinguish itself at 120 volts. You'd need over 400 volts to keep an AC arc going, but this is very

dangerous.

Anyway, there are other ways of getting an electric arc going, I'm only suggesting parameters that I have experience with, since you were asking about

the minimum parameters to sustain an arc.

Given the temperature that you want to achieve, I'd suggest building a small electric kiln or tube furnace, or even a small wood-fired furnace. I

built a small wood-fired one out of a few firebricks, and fired it with bits of mesquite charcoal. A hair dryer provided enough air flow to get

things over 1300 degrees inside. I melted all sorts of ceramics and metals in that thing. If you don't mind me asking, what do you need it for?

[Edited on 7-29-2018 by WGTR] |

I am making a furnace to melt low melting point metals (zinc, aluminum) for some pyro progects. Im making ingots that I can grind to a fine powder it

its sure as hell easier with an ingot than an aluminum can

[Edited on 7-29-2018 by Abromination]

List of materials made by ScienceMadness.org users:

https://docs.google.com/spreadsheets/d/1nmJ8uq-h4IkXPxD5svnT...

--------------------------------

Elements Collected: H, Li, B, C, N, O, Mg, Al, Si, P, S, Fe, Ni, Cu, Zn, Ag, I, Au, Pb, Bi, Am

Last Acquired: B

Next: Na

-------------- |

|

|

WGTR

National Hazard

Posts: 971

Registered: 29-9-2013

Location: Online

Member Is Offline

Mood: Outline

|

|

That's a pretty simple requirement, really. You don't need an arc furnace for that. I've done a small amount of zinc casting using one of these

skillets, and propane as a heat source:

https://shop.lodgemfg.com/skillets-and-covers/3-5-inch-cast-...

I think Academy sells them for camping even. You'll need flux when melting the metal, but that's another matter.

|

|

|

Abromination

Hazard to Others

Posts: 432

Registered: 10-7-2018

Location: Alaska

Member Is Offline

Mood: 1,4 tar

|

|

Borax for flux?

Also there are some future progects I would need an ark furnace for such as refining gold from ore that I found when hiking the other day.

List of materials made by ScienceMadness.org users:

https://docs.google.com/spreadsheets/d/1nmJ8uq-h4IkXPxD5svnT...

--------------------------------

Elements Collected: H, Li, B, C, N, O, Mg, Al, Si, P, S, Fe, Ni, Cu, Zn, Ag, I, Au, Pb, Bi, Am

Last Acquired: B

Next: Na

-------------- |

|

|

Sulaiman

International Hazard

Posts: 3558

Registered: 8-2-2015

Location: 3rd rock from the sun

Member Is Offline

|

|

@Abromination

If you are still having trouble getting your parents to accept your hobby,

setting up an electrical arc furnace is unwise, in my opinion.

Kanthal A1 resistance wire is supposed to work up to 1400oC which is above the m.p. of copper and gold.

For aluminium you can use forced air (bellows/fan/blower etc.) with gas,liquid or solid fuel.

IF you really want to make an electrical arc furnace :

. try to beg or borrow the use of an electric arc welder ... quick, simple, relatively safe.

. if you put a mains-rated electrical heating device

(Infra-red heaters, filament lamps, electric kettle, hot plate, toaster, oven etc.)

in series with the mains, then:

- you can not 'blow' the mains,

the 'worst' case (short circuit) is that the appliance gets its normal full power.

- it will work with a.c. or d.c. (rectified a.c.)

- safer than a diy lash-up of expensive power resistors

THIS WILL PROTECT THE MAINS SUPPLY - NOT YOU !

e.g. 110 Vac supply, 1500 W electric kettle;

short-circuit current = 1500/110 = 13.63 A ... don't use thin wire.

maximum possible usable heating power= 1500/4 = 375 W

There are 'better' methods using transformers and inductance, with or without power electronics,

you could even consider one of the 'zvs' induction heater kits via eBay etc.

but you will need to do a lot of learning to understand such schemes.

P.S. you must shield your eyes from the arc, especially the u.v.

and you will need at least one heatproof gauntlet - or liniment and bandage

[Edited on 29-7-2018 by Sulaiman]

|

|

|

Big Boss

Harmless

Posts: 45

Registered: 17-7-2015

Location: Outer Heaven

Member Is Offline

Mood: No Mood

|

|

Can a MOT be abused to create an arc furnace? The secondary wiring would likely need to be upgraded to a thicker cable, would anything else need to be

modified?

Or am I good to just create a kiln with firebrick with graphite electrodes on either side and strike a constant arc? There has to be more to it than

that

[Edited on 29-7-2018 by Big Boss]

Kept you waiting, huh?

|

|

|

WGTR

National Hazard

Posts: 971

Registered: 29-9-2013

Location: Online

Member Is Offline

Mood: Outline

|

|

For zinc, I use:

28% Li2CO3

28% Na2CO3

28% K2CO3

16% NH4Cl

Percentages are based on mass.

This seems to give a good low-melting point flux.

|

|

|

MJ101

Hazard to Self

Posts: 82

Registered: 14-6-2018

Member Is Offline

Mood: Always Sunny

|

|

Take a look here.

https://www.ebay.com/itm/2Pcs-1000V-50A-Metal-Case-Single-Ph...

This, in conjunction with an autotransformer (also called a Variac) should work. You can get a 20 A variac from ebay too.

https://www.ebay.com/b/Autotransformers-Variacs/181930/bn_16...

Choose the most beefy one that you can afford.

Also, if you're worried about tripping the breaker, then make sure to use a heavy duty Air Conditioner outlet.

Now here's the disclaimer:

The DC output of a bridge rectifier in this configuration can be Lethal! When I was in the trades, we used to call them "tech killers".

When working with high voltage or high current, it's always best to keep one hand in your pocket.

Also, make damn sure that you're wearing decent shoes, especially if you're "shop" has a cement floor. (NO SNEAKERS!)

You might want to filter the DC output. I recommend capacitor filters.

Capacitors in series behave just like resistors in parallel.

See here: https://www.allaboutcircuits.com/textbook/direct-current/chp...

Don't forget the bleeder resistors.

http://www.completepowerelectronics.com/bleeder-resistor-bas...

Now take a look at the thread that WGTR posted, and that will give you pretty much everything else you need to build it.

Best of luck, and be careful.

[Edited on 29-7-2018 by MJ101]

|

|

|

wg48

National Hazard

Posts: 821

Registered: 21-11-2015

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Big Boss  | Can a MOT be abused to create an arc furnace? The secondary wiring would likely need to be upgraded to a thicker cable, would anything else need to be

modified?

Or am I good to just create a kiln with firebrick with graphite electrodes on either side and strike a constant arc? There has to be more to it than

that |

Yes but because of the negative or very low resistance of the arc you need a ballast to limit the arc current.

The ballast also helps to start the arc and stabilize it. The ballast is simply an impedance in series with the arc to limit the current. It can be a

resistance or better an inductance which will not waste power.

If you goggle something like “arc welder from MOTs” you should find lots of such projects and even some with no obvious ballast. Some use the

resistance of the mot windings and the carbon rods as the ballast which I do not recommend.

I will try to find a reasonably sensible one for you

Borosilicate glass:

Good temperature resistance and good thermal shock resistance but finite.

For normal, standard service typically 200-230°C, for short-term (minutes) service max 400°C

Maximum thermal shock resistance is 160°C

|

|

|

Abromination

Hazard to Others

Posts: 432

Registered: 10-7-2018

Location: Alaska

Member Is Offline

Mood: 1,4 tar

|

|

Quote: Originally posted by WGTR  |

For zinc, I use:

28% Li2CO3

28% Na2CO3

28% K2CO3

16% NH4Cl

Percentages are based on mass.

This seems to give a good low-melting point flux. |

Why lithium carbonate?

I have plenty but why?

List of materials made by ScienceMadness.org users:

https://docs.google.com/spreadsheets/d/1nmJ8uq-h4IkXPxD5svnT...

--------------------------------

Elements Collected: H, Li, B, C, N, O, Mg, Al, Si, P, S, Fe, Ni, Cu, Zn, Ag, I, Au, Pb, Bi, Am

Last Acquired: B

Next: Na

-------------- |

|

|

wg48

National Hazard

Posts: 821

Registered: 21-11-2015

Member Is Offline

Mood: No Mood

|

|

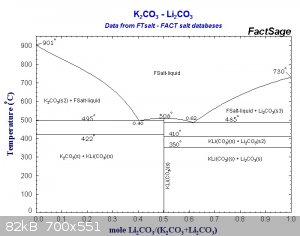

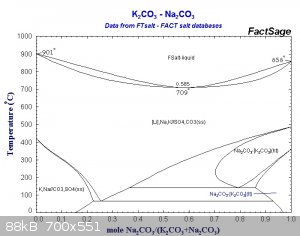

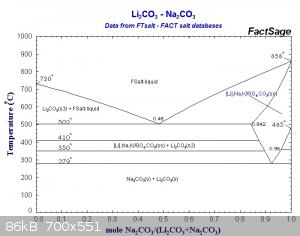

The three carbonates probably form a eutectic melting at a lower temperature than any of the carbonates on their own.

Borosilicate glass:

Good temperature resistance and good thermal shock resistance but finite.

For normal, standard service typically 200-230°C, for short-term (minutes) service max 400°C

Maximum thermal shock resistance is 160°C

|

|

|

WGTR

National Hazard

Posts: 971

Registered: 29-9-2013

Location: Online

Member Is Offline

Mood: Outline

|

|

From http://www.crct.polymtl.ca/fact/documentation/FTsalt/FTsalt_...

All three together:

https://www.researchgate.net/publication/235439109_The_Therm...

I knew that lithium salts can depress the melting point when mixed with other salts, so I just looked around for a good binary or ternary mixture.

Maybe there is something better out there, but I had some zinc to melt, and what I found seemed good enough. I threw in some ammonium chloride since

that is a common additive in aggressive fluxes, and most of it sublimates anyway.

|

|

|

markx

National Hazard

Posts: 645

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

Quote: Originally posted by Big Boss  | Can a MOT be abused to create an arc furnace? The secondary wiring would likely need to be upgraded to a thicker cable, would anything else need to be

modified?

Or am I good to just create a kiln with firebrick with graphite electrodes on either side and strike a constant arc? There has to be more to it than

that

[Edited on 29-7-2018 by Big Boss] |

A MOT is usually not designed for long duty cycles as would be encountered by the operation of an arc furnace. The original secondary winding

(dangerous high voltage!) has to be removed and a suitable replacement installed on the core. Also a MOT tends to work with high losses due to

inefficient coupling. There are not enough turns on the primary winding to achieve decent operation and power transfer efficiency. As a result the

transformer will overheat quite quickly and cooling the system will become a serious challenge. I remember from the days of trying to build a 5V power

source for electrosynthesis using a MOT with the original primary in tact and a rewound secondary....it was robust, but consumed 120W of power while

idling with the secondary circuit disconnected from the cell. All of that 120W was dissipated as waste heat in the massive core and overheating was a

serious trouble. So long story short: not a good choice for a constant duty power supply.

For small arc furnace a stick welder is probably the most reasonable choice of power supply. Contemporary inverter type stick welders have become

quite cheap and accessible and they have proper safety circuitry to deal with shorts and overcurrent situations. Trying to build something comparable

on your own accord needs a strong knowledge in power electronics design and in my opinion would be a waste of time.

Exact science is a figment of imagination.......

|

|

|

Big Boss

Harmless

Posts: 45

Registered: 17-7-2015

Location: Outer Heaven

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by markx  | Quote: Originally posted by Big Boss  | Can a MOT be abused to create an arc furnace? The secondary wiring would likely need to be upgraded to a thicker cable, would anything else need to be

modified?

Or am I good to just create a kiln with firebrick with graphite electrodes on either side and strike a constant arc? There has to be more to it than

that

[Edited on 29-7-2018 by Big Boss] |

A MOT is usually not designed for long duty cycles as would be encountered by the operation of an arc furnace. The original secondary winding

(dangerous high voltage!) has to be removed and a suitable replacement installed on the core. Also a MOT tends to work with high losses due to

inefficient coupling. There are not enough turns on the primary winding to achieve decent operation and power transfer efficiency. As a result the

transformer will overheat quite quickly and cooling the system will become a serious challenge. I remember from the days of trying to build a 5V power

source for electrosynthesis using a MOT with the original primary in tact and a rewound secondary....it was robust, but consumed 120W of power while

idling with the secondary circuit disconnected from the cell. All of that 120W was dissipated as waste heat in the massive core and overheating was a

serious trouble. So long story short: not a good choice for a constant duty power supply.

For small arc furnace a stick welder is probably the most reasonable choice of power supply. Contemporary inverter type stick welders have become

quite cheap and accessible and they have proper safety circuitry to deal with shorts and overcurrent situations. Trying to build something comparable

on your own accord needs a strong knowledge in power electronics design and in my opinion would be a waste of time. |

I've decided I'm going to stick with kanthal wire instead, I don't know enough about electronics to be able to handle high voltages safely, plus I

don't need really high temperatures.

Kept you waiting, huh?

|

|

|

Sulaiman

International Hazard

Posts: 3558

Registered: 8-2-2015

Location: 3rd rock from the sun

Member Is Offline

|

|

Good Choice

Quick notes;

. mains voltages are hazardous

. maximum achievable temperature will be determined almost entirely by

electrical power input and thermal insulation

|

|

|

Abromination

Hazard to Others

Posts: 432

Registered: 10-7-2018

Location: Alaska

Member Is Offline

Mood: 1,4 tar

|

|

How might I go about making a crucible?

I do not want to have to buy one, and preferably would like to avoid having to pay a lot for materials to build it with. Chances are, I probably have

a lot of the cheaper stuff in my lab.

List of materials made by ScienceMadness.org users:

https://docs.google.com/spreadsheets/d/1nmJ8uq-h4IkXPxD5svnT...

--------------------------------

Elements Collected: H, Li, B, C, N, O, Mg, Al, Si, P, S, Fe, Ni, Cu, Zn, Ag, I, Au, Pb, Bi, Am

Last Acquired: B

Next: Na

-------------- |

|

|

WGTR

National Hazard

Posts: 971

Registered: 29-9-2013

Location: Online

Member Is Offline

Mood: Outline

|

|

Well, I've made a few small ones in the kiln that I have linked in my signature. They're a mix of Grog, A.P Green Fireclay, and OM4 ball clay.

The ball clay is about 10% by weight, just enough to add plasticity to the clay body and make everything stick together without falling apart. The

fireclay is for high temperature strength, about 50-60% total, and grog is merely pre-fired fireclay that has been smashed into powder. The grog adds

porosity to the clay body (makes it more user-friendly to fire without it exploding from chemically-combined moisture), and helps minimize shrinkage

during firing. Typically you use as much grog as possible. It's normal to practice with different compositions until you get what you want.

You'll need to practice wedging the clay to get it properly mixed and get the clay particles oriented well enough to give you a workable clay. Then

you can form your crucible and fire it.

https://www.youtube.com/watch?v=A8eEMTgW7u8

I have experience melting only small amounts of metal in clay crucibles, a pound or less. You have to be darn well sure that if that crucible breaks,

that molten metal isn't going to splash on you or pool around your feet on the ground. For large pours I've seen people wear metalized aprons, face

shields, metal covers over their shoes, and to stand on a grill that is spaced above the ground, such that molten metal can flow through it in case of

accidents.

If your going to pour several pounds of low melting point metals, if it were me I'd use a small metal skillet over an open flame.

|

|

|

mysteriusbhoice

Hazard to Others

Posts: 473

Registered: 27-1-2016

Member Is Offline

Mood: Became chemistry catboy Vtuber Nyaa

|

|

to make an arc furnace power supply, all you need is 2 mots rewired to about 30 volts secondary under oil to prevent it from overheating and bursting

into flames.

|

|

|

Texium

|

Thread Moved

27-11-2023 at 12:29 |

|