| Pages:

1

..

44

45

46

47

48

..

68 |

nux vomica

Hazard to Others

Posts: 267

Registered: 18-7-2013

Member Is Offline

Mood: No Mood

|

|

Okay everyone i am up for a bit of fun, I will make another ebw charge and this time try it on a piece of 20mm m/s plate im thinking of 23mm standoff

this time (2xdia) anyone have any other suggestions.

I don't think that my charges are efp but are shaped charges dont know why but you can only go on the results. Nuxy

[Edited on 14-7-2015 by nux vomica]

|

|

|

nux vomica

Hazard to Others

Posts: 267

Registered: 18-7-2013

Member Is Offline

Mood: No Mood

|

|

Pointless post deleted nuxy

[Edited on 15-7-2015 by nux vomica]

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

For 0.6g of copper, density 8.96g/cc :

0.6g / 8.96g/cc = Volume = 4/3 * pi * r^3

r = 0.25 cm

D = 2r = 0.50 cm

edit:

I look forward to your next test. It will be interesting to see how much more penetration you can get out of it.

BTW, math just takes practise, no one is born knowing how to do it, though some do of course have a greater affinity and some have greater ability as

well (not saying I am an expert and yes I make mistakes too). Rework and understand the above calculation a couple of times and then a day or two

later rework it again. If you actually think and follow the process and understand as you are working through it will sink in and you will really know

it. Repetition is a good thing!

A lot of times people are trying to prove a mathematical relation so they tend to latch onto, or force even, anything that looks like a connection

whether or not it obeys the mathematical laws or not (I have been guilty myself). The same sort of thing often happens when detectives decide someone

is guilty before they investigate and a very high percentage of the time they are able to built a strong case against them even when the accused is

innocent (the detectives don't necessarily consciously do it on purpose). The math can be completely wrong and still occasionally end up with the

right number.

[Edited on 15-7-2015 by Hennig Brand]

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

greenlight

National Hazard

Posts: 705

Registered: 3-11-2014

Member Is Offline

Mood: Energetic

|

|

Just found an interesting pdf document about the effects of physical parameter on EFP design.

It has test results on charge weight and height, confining geometry, type of explosive liner thickness and curvature vs. penetration and velocity of

slug.

Just had a quick skim through and noticed: "The charge weight dominant projectile test provides insight as to how changing the charge weight of an

EFP, and resulting head height, affects the flyer formation and production of a dominant projectile. As the charge weight increases, the projectiles

broke apart. As the charge weight decreases, the EFP designs retain more of the initial flyer weight and dominant projectiles are easily

identifiable in the high-speed video."

"As the charge weight increased the projectiles velocity continued to increase. This indicates that there is an optimal charge weight for penetration,

for an EFP with the physical parameters explained in Section 3, of 868 grams. This also indicates that larger charge weights do not improve EFP

performance."

I think what they are saying is that you can increase the charge weight to get more velocity in the slug and more penetration to a certain extent of

peak performance which causes more slug breakup and then it doesn't improve performance from there, the slug just breaks up even more during flight.

Would the height of explosive affect the shape of the slug that is formed making it more or less elongated?

[Edited on 14-7-2015 by greenlight]

Attachment: The effects select physical parameters have on an explosively for.pdf (4.5MB)

This file has been downloaded 669 times

[Edited on 14-7-2015 by greenlight]

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

Very interesting thesis, thanks.

Here is another one regarding EFP penetration of concrete:

Attachment: Impact Effects of Explosively Formed Projectiles on Concrete.pdf (3.9MB)

This file has been downloaded 526 times

And a good one on linear shaped charges as well:

Attachment: Precision Linear Shaped Charge Analysis.pdf (3.7MB)

This file has been downloaded 741 times

[Edited on 15-7-2015 by Hennig Brand]

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

greenlight

National Hazard

Posts: 705

Registered: 3-11-2014

Member Is Offline

Mood: Energetic

|

|

Quite a well done test on the EFP penetration of concrete. Haven't gotten to the linear shaped charge analysis document yet.

It seems that a much thicker heavier EFP liner is needed for penetrating concrete.

The liner they are using in the tests is 95.3mm in diameter and 6.35mm thick with a curvature of 22.2mm. Diameter of liner is 95.3mm so the liner

thickness is slightly over 6% of charge diameter which is 101.6mm and even more than 6% of the liner diameter (6% of 95.3=5.718).

It also seems that the proper word for the liner is the "flyer plate".

[Edited on 15-7-2015 by greenlight]

|

|

|

nux vomica

Hazard to Others

Posts: 267

Registered: 18-7-2013

Member Is Offline

Mood: No Mood

|

|

I had a go at penetrating 20mm m/s plate, just couldn't get through though it cracked and bulged the back of the plate.

I had 23mm standoff and I think it was too close as the entry looks smaller than normal and there is hardly any copper spatter on the target 2.5 to 3

times standoff might be a better proposition.

Setup was my standard ebw one ie 1.2 grms etn and firing voltage was 3500v.

Cheers Nuxy.

[Edited on 15-7-2015 by nux vomica]

|

|

|

wodejxc

Harmless

Posts: 2

Registered: 15-7-2015

Member Is Offline

Mood: No Mood

|

|

genie

Wow, this is really a great idea, after I read your post, I feel like all of a sudden interest in science

|

|

|

greenlight

National Hazard

Posts: 705

Registered: 3-11-2014

Member Is Offline

Mood: Energetic

|

|

@Nuxy, thats pretty close to complete penetration by the look of the picture, well done.

I agree about the standoff, I think it would have made it through if you had used 40mm standoff like your last test.

|

|

|

nux vomica

Hazard to Others

Posts: 267

Registered: 18-7-2013

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by greenlight  | @Nuxy, thats pretty close to complete penetration by the look of the picture, well done.

I agree about the standoff, I think it would have made it through if you had used 40mm standoff like your last test. |

I think that 4x or 46mm could be the sweet spot Ive done 40 mm and 50 mm with 10mm plate and they both penertrated well. Nuxy

[Edited on 15-7-2015 by nux vomica]

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

Less standoff would normally produce a larger entry hole, since there is less distance/time for elongation and narrowing of the jet or projectile.

That is a thick piece of steel for the size of the charge that is for sure!

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

nux vomica

Hazard to Others

Posts: 267

Registered: 18-7-2013

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Hennig Brand  | Less standoff would normally produce a larger entry hole, since there is less distance/time for elongation and narrowing of the jet or projectile.

That is a thick piece of steel for the size of the charge that is for sure! |

Ive got over a meter of the 20mm steel flat bar leaning against my bench at work hopefully I wont have to use all of it to get a hole through both

sides.

I agree about the less standoff bigger hole but im wondering if the jet takes longer to focus, the lack of copper splatter is different to the other

shots they had spatter and the hole was nice and round not wonky looking with none ,after all it is a bit of a bastard son, looks like a efp but acts

like a shaped charge.

Cheers nuxy.

|

|

|

nux vomica

Hazard to Others

Posts: 267

Registered: 18-7-2013

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Hennig Brand  | For 0.6g of copper, density 8.96g/cc :

0.6g / 8.96g/cc = Volume = 4/3 * pi * r^3

r = 0.25 cm

D = 2r = 0.50 cm

edit:

I look forward to your next test. It will be interesting to see how much more penetration you can get out of it.

BTW, math just takes practise, no one is born knowing how to do it, though some do of course have a greater affinity and some have greater ability as

well (not saying I am an expert and yes I make mistakes too). Rework and understand the above calculation a couple of times and then a day or two

later rework it again. If you actually think and follow the process and understand as you are working through it will sink in and you will really know

it. Repetition is a good thing!

A lot of times people are trying to prove a mathematical relation so they tend to latch onto, or force even, anything that looks like a connection

whether or not it obeys the mathematical laws or not (I have been guilty myself). The same sort of thing often happens when detectives decide someone

is guilty before they investigate and a very high percentage of the time they are able to built a strong case against them even when the accused is

innocent (the detectives don't necessarily consciously do it on purpose). The math can be completely wrong and still occasionally end up with the

right number.

[Edited on 15-7-2015 by Hennig Brand] |

Yeh im a bit of a rusher somtimes as they say the devil is in the detail.

Smacked a liner with a hammer till it was reasonably round, you were spot on size with 5mm dia, put it next to the exit hole in the 10mm plate and

it's close to size where the hole flares out .

Cheers nuxy

[Edited on 16-7-2015 by nux vomica]

|

|

|

greenlight

National Hazard

Posts: 705

Registered: 3-11-2014

Member Is Offline

Mood: Energetic

|

|

Just wondering how far you guys insert your detonator into the explosive charge in your EFP's as I found this in one of the pdf's:

"Results of the cap depth test determine that inserting the blasting cap 7.5 cm into an EFP creates a more elongated projectile shape with a higher

velocity than the projectiles produced from the EFP with a cap depth of 2 cm."

I knew centred detonator placement was important but it seem the depth of insertion is also a factor contributing to the final slug shape and

velocity.

|

|

|

nux vomica

Hazard to Others

Posts: 267

Registered: 18-7-2013

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by greenlight  | Just wondering how far you guys insert your detonator into the explosive charge in your EFP's as I found this in one of the pdf's:

"Results of the cap depth test determine that inserting the blasting cap 7.5 cm into an EFP creates a more elongated projectile shape with a higher

velocity than the projectiles produced from the EFP with a cap depth of 2 cm."

I knew centred detonator placement was important but it seem the depth of insertion is also a factor contributing to the final slug shape and

velocity.

|

I don't know about everyone else but with my ebw charges there is no detonator just the 0.1 grm priming charge, so I suppose whole charge is a sort

of detonator main charge. Nuxy

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

It would depend on the size of the charge. I am not sure if what I am doing is correct, but for a 24mm diameter EFP with 20-24mm of explosive head

height I estimate that I have been inserting the blasting cap anywhere from 3-5mm. I try not to insert it too far, with the logic being that I don't

want to interfere with the function of the main charge on the liner too much.

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

nitro-genes

International Hazard

Posts: 1048

Registered: 5-4-2005

Member Is Offline

|

|

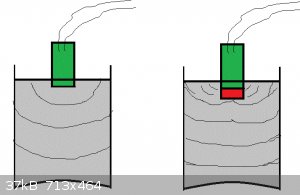

With these charge sizes, it might also help to give the detonator a thick bottom of foam or plastic (about 3mm), and insert it 4-5 mm into the charge,

acting like a sort of a simple waveshaper, helping to "flatten" the shockwave as it hits the liner.

|

|

|

greenlight

National Hazard

Posts: 705

Registered: 3-11-2014

Member Is Offline

Mood: Energetic

|

|

Thanks for that guys.

I think that is why my EFP's before weren't as effective because the explosive height was about 1.5 to 2 x charge diameter.

I also inserted the detonator about 20mm into the main charge as well which is too far.

The pieces of the puzzle are coming together.

From what I have read, the factors affecting EFP performance are:

* Type of explosive

* Confinement strength (casing strength)

* Confinement thickness (casing thickness)

* Flyer/liner thickness

* Flyer/liner diameter

* Flyer/liner radius of curvature

* Flyer/liner material

* EFP casing diameter

* Charge length

* Explosive height

* Charge weight

* Cap/detonator depth

* Standoff from target

Nitrogenes, do you mean a wave-shaper attached to the bottom of the detonator or have a space of explosive between the wave-shaper and the bottom of

the det?

[Edited on 16-7-2015 by greenlight]

|

|

|

nitro-genes

International Hazard

Posts: 1048

Registered: 5-4-2005

Member Is Offline

|

|

Like this (forgive my terrible drawing skills):

So the red colour representing some 3 mm piece of low density inert material, flattening the shockwave.

|

|

|

nux vomica

Hazard to Others

Posts: 267

Registered: 18-7-2013

Member Is Offline

Mood: No Mood

|

|

I am a bit more happy with the results of the 20mm plate test now I have cut the plate in half I got 16mm depth with 2.5mm dia at the bottom of the

hole .

I added a picture showing the cut plate after I sprayed crack detection fluid on then developer to show things better.

Dont know whether to go up another 5 mm or try 46 mm now. Nuxy

[Edited on 17-7-2015 by nux vomica]

|

|

|

nux vomica

Hazard to Others

Posts: 267

Registered: 18-7-2013

Member Is Offline

Mood: No Mood

|

|

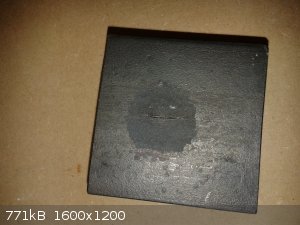

Ebw shaped charge video

I took a video of one of my shaped charges going off since it was a bright day and not raining, l protected my phone with a piece of 2mm stainless

steel sheet with a 10mm hole drilled in it to just let the lens be exposed I don't know the mathematical odds of a splinter hitting the lens at 4

meters away but I thought it must be minute .

And no I don't know how I would explain to my wife how my phone got a hole through it .

The video charge is ebw fired at the end of 7 m coax at 3500 v using my standard s/s rivnut with 1.2 + 0.1 etn, copper liner and 35mm standoff,

target is 20mm plate.

Plate in photo is the target i will cut at work to check penetration.

Cheers nuxy.

Attachment: 20150718_121734_001.3gp (8.4MB)

This file has been downloaded 823 times

[Edited on 18-7-2015 by nux vomica]

|

|

|

nux vomica

Hazard to Others

Posts: 267

Registered: 18-7-2013

Member Is Offline

Mood: No Mood

|

|

I just redid the 35mm standoff again because I wasn't happy with the result [12mm] and bingo I got a full penetration through 20mm of steel , I spent

a little more time assembling everything and I got the best looking penetration yet, nice and straight and narrowing to 1.75 mm which is the dia of

the pin sticking through the target.

It was standard ebw charge fired at 3500v through 7m coax.

Cheers nuxy.

[Edited on 22-7-2015 by nux vomica]

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

Nice result! That is a lot of steel penetrated for such a small charge! I also watched your video above, which was interesting. I noticed from the

video that you seem to be doing your explosive testing in a more suitable location than I have been. Probably not something to be emulated, but I have

been taking 20 or 30 paces off my back door step before setting up a test. Of course where I am is very rural with no close neighbors.

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

nux vomica

Hazard to Others

Posts: 267

Registered: 18-7-2013

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Hennig Brand  | | Nice result! That is a lot of steel penetrated for such a small charge! I also watched your video above, which was interesting. I noticed from the

video that you seem to be doing your explosive testing in a more suitable location than I have been. Probably not something to be emulated, but I have

been taking 20 or 30 paces off my back door step before setting up a test. Of course where I am is very rural with no close neighbors.

|

Yeah I didn't think I was going to make It through at one stage so maybee 35mm standoff is the sweet spot for these small charges.

I realize how lucky you are because were semi rural till 10 years ago now suburbia is everywhere new estates taking over a lot of the farmland . its getting harder to find quiet spots all the time. . its getting harder to find quiet spots all the time.

cheers nuxy.

|

|

|

nux vomica

Hazard to Others

Posts: 267

Registered: 18-7-2013

Member Is Offline

Mood: No Mood

|

|

Cut the 20mm steel plate that I got full penertation in half looks even better than I thought 3mm dia to 16mm depth then narrowing to 1.75mm for a

small amount of etn it sure does some work.

Rod in pic is 1.6 dia.

Cheers Nuxy

|

|

|

| Pages:

1

..

44

45

46

47

48

..

68 |