| Pages:

1

..

17

18

19

20

21

..

24 |

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

Here is a picture of the stirrer-hotplate with the 5L erlenmeyer sitting on it, you will need to imagine it in action. Also the bottle holding my 81.5

grams of freshly made Hydrazine Sulfate.

|

|

|

cyanureeves

National Hazard

Posts: 737

Registered: 29-8-2010

Location: Mars

Member Is Offline

Mood: No Mood

|

|

toluene

four times i have done hydrazine sulfate sinthesis,twice using roscoe's method and twice nurd rage. roscoe's method produced a salt that does make a

mirror when mixed with ammonia and silver nitrate but i think i got alot of sodium chloride contamination because it will burn dry but will leave a

black smudge behind. it bubbles over a flame which then burst and release smoke that smell like gunpowder.i cannot get nurd rage's method to separate

in two layers and he recommended using toluene as it was successful for him. my question is would a lacquer thinner with petroleum distillate work as

toluene?paint thinner has some toluene but also MEK and i already added more MEK to my orange solution. thank you. toluene is getting harder to find.

well i googled petroleum distillates and toluene is in the family of petroleum distillates along with napthas,mineral spirits etc...

[Edited on 16-6-2011 by cyanureeves]

|

|

|

cyanureeves

National Hazard

Posts: 737

Registered: 29-8-2010

Location: Mars

Member Is Offline

Mood: No Mood

|

|

well not all petroleum distillates are alike.crown paint thinner has naptha and it pulled out a red oily liquid after i added the sulfuric acid but it

did not salt out. it did however separate easy but i give up on this method of making hydrazine sulfate until i have better reagents. roscoes method

on the other had worked pretty well even with recrystalized urea that was dirty. but when i take out the cold bleach/hydroxide solution and add the

urea/gel then add the heat when the foaming subsides,it gets super hot quick because of the hydroxide activating.do i need to keep adding heat even if

it will maintain at about 185 on its own?i didnt get the solution to deep orange but fluorescent green instead, i made a mirror with the salt o.k. but

want to know what to do because i will be making more. not that i'm eating hydrazine sulfate all day long but it tastes like the rim on a margarita

glass,lime and all.

|

|

|

franklyn

International Hazard

Posts: 3026

Registered: 30-5-2006

Location: Da Big Apple

Member Is Offline

Mood: No Mood

|

|

Studies on the Raschig's Hydrazine Synthesis

www.sdu.dk/media/bibpdf/Bind%2010-19%5CBind%5Cmfm-12-16.pdf

Page 25

It has been shown that on using pure water, pure chemicals, and carefully cleaned

reaction vessels, it is possible to obtain hydrazine yields up to about 46 % of the

hypochlorite in Raschig's hydrazine synthesis, even when no gelatine is added.

Page 32

Fairly good results may also be obtained by addition of carragen. On addition of

a solution of 1 gram of carragen in 100 cc of water to 100 cc of an ordinary

concentration commercial ammonia, followed by an addition of 100 cc of an

approximately 1 molar solution of sodium hypochlorite and by a rapid heating

to boiling etc., hydrazine yields of 48-49% of the hypochlorite could be obtained.

.

|

|

|

cyanureeves

National Hazard

Posts: 737

Registered: 29-8-2010

Location: Mars

Member Is Offline

Mood: No Mood

|

|

made hydrazine sulfate again today and what a difference 10% bleach makes. the hydroxide/bleach mix turned milky when the urea /gelatin was added just

like Hennig Brand's and the precipitate is not salty at all like my other samples. 6% bleach did not give me the froth 10% bleach did. the precipitate

dropped as a gel though because i added too much gelatin but it still dries as crystals. the mirror test with ammonia and silver nitrate may not be

the best test because sodium hydroxide,ammonia and sugar will also make a mirror with silver nitrate.tommorrow i will burn it after it dries

completely

|

|

|

Dr.Bob

International Hazard

Posts: 2656

Registered: 26-1-2011

Location: USA - NC

Member Is Offline

Mood: No Mood

|

|

This discussion reminds me of my youth (a while back now) when I found an ad in Chemical & Engineering News from Olin describing all of the uses

of Hydrazine and offering free samples for testing. So I typed (check wikipedia, they can describe what "typed" means) up a nice letter on some

letterhead that I created for my "company" and requested a sample. Back then, there was no trivial way to verify if a company was real or not, of

course.

Several weeks later a wood crate appeared on the doorstep from Olin, with my 1 quart bottle of hydrazine hydrate in it. I used it to make Luminol as

well as a few other experiments from Fieser and Fieser. That used about 10 mls or so, and the rest I eventually donated to the lab I worked in. I

have since used quite a bit of hydrazine in chemistry (pyrazoles, hydrazides, etc) so I guess the ad worked. But that was a very different time.

I think I also got chemicals from DuPont, Monsanto, and a few others that way. Don't think it would work so well now.

Bob

|

|

|

cyanureeves

National Hazard

Posts: 737

Registered: 29-8-2010

Location: Mars

Member Is Offline

Mood: No Mood

|

|

cool thing Dr.Bob. i dont even know what to do with hydrazine sulfate other than make the mirror thing. i also check these posts to see if anyone has

called on me to prove my stuff and i read my own posts and they seem like a diary of a madman to himself.i read up on hydrazine sulfate by that lady

who took it for years and swore by it as a remedy for increasing her appetite. it was said to make one calm and hungry and good thing i dont trust my

hydrazine sulfate or else i'd be a sluggish big fat pig by now.i got so much salt left over that i'm making a chlorate cell but it is all turning back

to green bleach.

|

|

|

franklyn

International Hazard

Posts: 3026

Registered: 30-5-2006

Location: Da Big Apple

Member Is Offline

Mood: No Mood

|

|

Lower Aliphatic Derivatives of Hydrazine

www.dtic.mil/dtic/tr/fulltext/u2/021177.pdf

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

hydrazodicarbonamide or semicarbazide or hydrazine selectively from chlorourea

from page 5 of this thread about the middle of the page

Quote: Originally posted by Rosco Bodine  | The recent discussion about chlorination of NaOH has caused me to remember that this came up once before , and I will have to check my patents , but

IIRC there is a more efficient method for use of chlorination in the synthesis of hydrazine and it involves chlorination of a slurry of urea to form

chlorourea , which is then

reacted with a base like sodium carbonate

or sodium hydroxide to form hydrazine upon heating and hydrolysis . IIRC , there is no need to even make sodium hypochlorite , if you are going to go

the chlorination route , and the yield is better by the chlorourea intermediate . I will see if I can find the patents which reference the method .

GB1063893 Hydrazine or Semicarbazide selectively produced from monochlorourea

Related semicarbazide patents are

US5241117

GB1153483

[Edited on 4-5-2005 by Rosco Bodine] |

This post is also related to the hydrazodicarbonamide thread

http://www.sciencemadness.org/talk/viewthread.php?tid=6729#p... where if found related discussion.

After six years I am now willing to share the file  ....hope no one was in a

big hurry for it . Anyway the prospect for a more direct method to the hydrazine derivative hydrazodicarbonamide in 70% yield is the matter of most

special interest described in US3238226 attached. ....hope no one was in a

big hurry for it . Anyway the prospect for a more direct method to the hydrazine derivative hydrazodicarbonamide in 70% yield is the matter of most

special interest described in US3238226 attached.

If Azide is the intended end product, then attention is called to Example #20 of the patent shows a method for obtaining Semicarbazide as the product

in 90% yield. Byproduct hydrazodicarbonamide is separated by filtering and then byproduct hydrazine is separated by acidifying and filtering

from the more soluble Semicarbazide. This should not require isolation, but could be nitrosated to the Carbamyl Azide and then decomposed by heating

to leave Ammonium Azide in solution. If it was desired or necessary to isolate and purify the semicarbazide prior to nitrosation then acetone could

likely be used to form the semicarbazide addition product for isolation and that could later be converted back to semicarbazide.

The equivalent British patent GB1063893 is also attached.

Also attached are related chlorourea process patents

US5241117

GB1153483

Also here's a little midi or ringtone music trivia posted some years ago

http://www.sciencemadness.org/talk/files.php?pid=42528&a...

Attachment: US3238226_SYNTHESIS_OF_HYDRAZINE_SEMICARBAZIDE_HYDRAZODICARBONAMIDE.pdf (344kB)

This file has been downloaded 2378 times

Attachment: GB1063893 Semicarbazide from Chlorurea.pdf (643kB)

This file has been downloaded 1203 times

Attachment: US5241117 Process for Semicarbazide.pdf (504kB)

This file has been downloaded 2076 times

Attachment: GB1153483 Chlorurea Process for Hydrazine.pdf (170kB)

This file has been downloaded 1598 times

[Edited on 4-8-2011 by Rosco Bodine]

|

|

|

aaparatuss

Harmless

Posts: 41

Registered: 12-7-2011

Location: indepth

Member Is Offline

Mood: questing

|

|

I am still reading this thread in entirety so i apologize in advance

it seems making HS is quite strait forward with even multiple routes to work with.

I still do wonder if using calcium hydrochlorite is a workable approach

but i wonder much more, if one did need anhydrous hydrazine can it be done from the sulfate ??

I have read the literature regarding making the hydrate then distilling under nitrogen of course

It just seems ironic that one would need to make a hydrate to make an anhydrous if you know what a mean

any guidance or creativity would be appreciated

|

|

|

aaparatuss

Harmless

Posts: 41

Registered: 12-7-2011

Location: indepth

Member Is Offline

Mood: questing

|

|

pardon the double post

but i did find

evidence that

. 4. The most effective condition for the reaction is a temperature of 60-65○C. maintained for 20-25 min. 5. The reaction takes place equally

well in either an open or closed container. 6. When calcium hypochlorite is applied in place of sodium hypochlorite, the yield of hydrazine is

increased as much as 17%. 7. The yield of hydrazine is decreased by eliminating the suspension of Ca(OH)2 which results from the use of calcium

hypochlorite. 8. When Ca(OH)2 is added to Raschig process, the yield of hydrazine is raised normally. 9. The fact that some metal ions, such as Cu++,

inhibit the formation of hydrazine was proved. 10. The suspension of Ca (OH)2 acted as a remarkable adsorbent for Cu++ like gelatin. The suspension of

Ca(OH)2 which results from the use of calcium hypochlorite acts as a catalyst, absorbing metal ions, to increase the yield of hydrazine. So I think

that calcium hypochlorite is a more efficient oxidant than sodium hypochlorite in hydrazine syntheses” Journal of the Korean Chemical Society Volume

5, Number 1 (1961)

well i hope my modification using 10% ammonia and calciumhypochlorite solid added slowly to avoid dilution issues with weaker ammonia works out

thanks

nice thread

|

|

|

roamingnome

Hazard to Others

Posts: 363

Registered: 9-9-2006

Member Is Offline

Mood: No Mood

|

|

[img]<a

href="http://books.google.com/books?id=7UE2AQAAIAAJ&lpg=PA1732&ots=mA61dkT8PA&dq=hydrazine%20sulfate%20ammonia&pg=PA1734&ci=114%2C

382%2C836%2C396&source=bookclip"><img

src="http://books.google.com/books?id=7UE2AQAAIAAJ&pg=PA1734&img=1&zoom=3&hl=en&sig=ACfU3U06-mqK7rV-OnbJFuikdqCiS3vH9w&ci=114%

2C382%2C836%2C396&edge=0"/></a>[/img]

for more discourse and details....

[img]<a

href="http://books.google.com/books?id=7UE2AQAAIAAJ&lpg=PA1732&ots=mA61dkT8PA&dq=hydrazine%20sulfate%20ammonia&pg=PA1728&ci=137%2C

91%2C834%2C145&source=bookclip"><img

src="http://books.google.com/books?id=7UE2AQAAIAAJ&pg=PA1728&img=1&zoom=3&hl=en&sig=ACfU3U2HMAkgRl59Nh8BnpEtmbacAeFesQ&ci=137%

2C91%2C834%2C145&edge=0"/></a>[/img]

Journal of the American Chemical Society, Volume 33

|

|

|

Adas

National Hazard

Posts: 711

Registered: 21-9-2011

Location: Slovakia

Member Is Offline

Mood: Sensitive to shock and friction

|

|

What about :

CO(NH2)2 + NaOH ----> HCOONa + N2H4

Is you use too much NaOH, only NH3 will be created. In this process, there will also be some ammonia created along with hydrazine, but it may work.

What do you think?

Rest In Pieces!

|

|

|

ScienceSquirrel

International Hazard

Posts: 1863

Registered: 18-6-2008

Location: Brittany

Member Is Offline

Mood: Dogs are pets but cats are little furry humans with four feet and self determination!

|

|

Quote: Originally posted by Adas  | What about :

CO(NH2)2 + NaOH ----> HCOONa + N2H4

Is you use too much NaOH, only NH3 will be created. In this process, there will also be some ammonia created along with hydrazine, but it may work.

What do you think? |

Urea will hydrolyse slowly to ammonia and carbon dioxide. No hydrazine will be formed at all.

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

It has been a dozen pages back in the thread where freebasing schemes were being discussed and I haven't reviewed this entire thread to be certain,

but I don't think this more recent possible freebasing scheme has been described here in the dedicated hydrazine thread, so I am importing / pasting

from other threads this freebasing hydrazine related information which should have a place here.

Freebasing of anhydrous hydrazine in alcohol could be a possible usefulness for aluminum amalgam in isopropyl alcohol or magnesium in methanol. This

could certainly be of usefulness in a sodium azide synthesis or for other syntheses where an anhydrous "tincture of hydrazine" is needed. I have

never tried this, so this is offered as a reasonable hypothesis, but now it is definitely on my "to do" list of interesting

experiments.

Also there is an anhydrous double salt of calcium sulfate and sodium sulfate which could also be useful in alternative freebasing schemes for

hydrazine, using a combination of sodium hydroxide and calcium hydroxide. This could also be useful in schemes for forming hydrazine salts such as

the nitrate or perchlorate in aqueous solution by double decomposition schemes.

http://www.sciencemadness.org/talk/viewthread.php?tid=1987&a...

http://www.sciencemadness.org/talk/viewthread.php?tid=874&am...

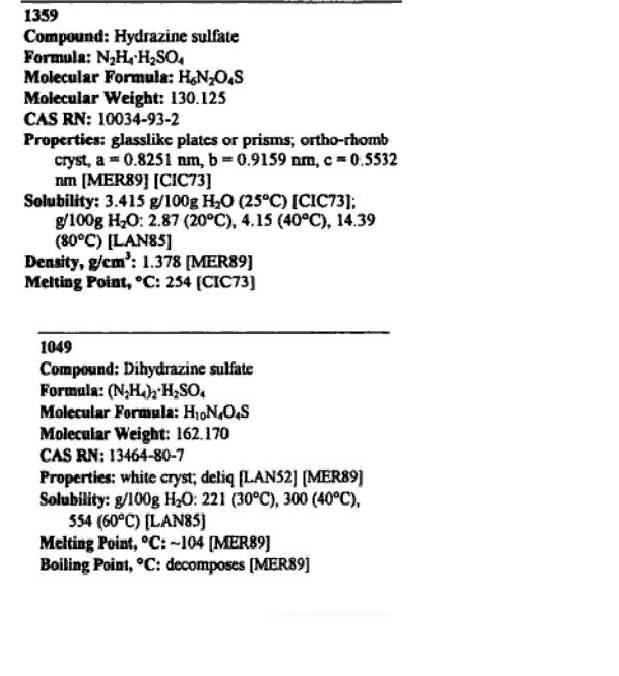

Hydrazine is stable but it is very chemically reactive. Freebasing dihydrazine sulfate does produce byproduct water but only half as much with respect

to the yield of freebased hydrazine as is byproduct water from freebasing hydrazine sulfate. Possibly the extreme solubility of the dhydrazine sufate

is such that a lesser total byproduct water would be involved in freebasing even when a hot aqueous concentrated solution of the dihydrazine sulfate

might be added dropwise to aluminum isopropoxide for the purpose of preparing an anhydrous tincture of hydrazine in isopropanol, which could be

filtered from the byproduct aluminum sulfate. What may be the dangers attendant to such a process I do not know. But it seems like it could be done. I

have never seen this described anywhere so it may be novel. This is not a recommended experiment for a beginning or novice chemist....this would be

more advanced.

http://www.youtube.com/watch?v=axxbIWOge_o Aluminum Isopropoxide video

Hydrazine is stable enough for storing in fuel tanks of spacecraft for months or longer. The descent stage of the Mars lander Phoenix used hydrazine.

Evidently there are adequate methods for long term storage.

http://www.asi.org/adb/04/03/09/hydrazine-info.html

For purposes of synthesis where hydrazine is a needed intermediate, an alcohol solution of hydrazine would likely be prepared and used in the near

term as an intermediate and would not be stored, so stability may not be an issue. And whatever level of hydration is desired could be controlled so

this still seems like a valid experiment, but because of the unknowns it definitely is no benign sort of process.

The differing solubilities of Hydrazine Sulfate and Dihydrazine Sulfate may be exploited to advantage in schemes for freebasing hydrazine in order to

obtain differing states of hydration for the freebased hydrazine. I am posting this in different threads because it is pertinent in all of them.

I don't have a chart for the solubility curves, so I borrowed this excerpt via printscreen screenshot, you know sort of ripped it ......sharing is

caring

Attached and linked also is a recent article of interest

regarding the interaction of free hydrazine and CO2 in aqueous medium. There appears to be a similar case

involving solubility difference for the carbonate, where

the monohydrazine "bi"acid, or acid hydrogen salt is low

solubility compared with the more neutral or normal salt

being highly soluble.

http://cbs.ewha.ac.kr/pub/data/2011_15.pdf

There appears to be a discrepancy in identification of what is the formula and composition of the commercial Hydrazine Carbonate 70% solution as is

stated differently by Hummel Croton and VVChem GMBH. I am not sure what to make of this.

http://www.hummelcroton.com/msdspdf/hzco2_m.pdf

http://www.vvchem.com/cas-112/112077-84-6.html

Attachment: Hydrazine CO2 adduct.pdf (1.1MB)

This file has been downloaded 1567 times

[Edited on 26-2-2012 by Rosco Bodine]

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

This is in reply to the mesage below from page 10 of the thread (link)

http://www.sciencemadness.org/talk/viewthread.php?tid=1128&a...

Quote: Originally posted by Formatik  | | Quote: | Originally posted by YeOldeImpurities

Compounds of manganese (sulfate, chloride of manganese, permanganates...) in hypochlorite/urea/hydroxide reaction work better than gelatine. They give

5-10% higher yields of hydrazine than mixtures with gelatine. --- this I remember from book "The Chemistry of Hydrazine" by Audrieth and Ogg.

In russian book Греков,Отрошко:

"Гидразинометрия" 1981 (Hydrazinometry by Grekov and

Otroshko) is a recipe for making hydrazine sulfate with MnSO4.5H2O instead of gelatine (0,3 grams of MnSO4.5H2O to 15 grams of urea, yield 23 grams of

hydrazine sulfate).

And also something else for increasing yields- in book

Брикун,Козловский,Никит&

#1080;на: "Гидразин и

гидроксиламин и их

применение в

аналитической химии" 1967 (Hydrazine and

hydroxylamine nad their application in analytical chemistry by Brikun, Kozlovskiy and Nikitina) is this: best compounds for protection of

hydrazine/water solutions against oxidizing by air are oxides of calcium, zinc, aluminium and magnesium but the far superior is sulfur in small

amounts. btw there is mentioned a method for producing hydrazine by dry destillation of urea/iron powder at 132-150ºC at atmospheric pressure.

|

What yield is that of the theory? Raschig in German patent #198307 says hypochlorite solution and ammonia with lime can get as much as 80 percent of

the theory, and he himself gets 60 to 70 percent in an example. |

The yield of 23 grams Hydrazine Sulfate would be 70.7% based upon 15 grams of urea precursor. What the process described by YeOldeImpurities appears

to be is a slight variant of the attached file which is originally in Russian and this is the English translation attached. It is especially

significant that the increased yield is gotten from a gradual addition scheme for the reaction which allows for a control of the foaming issue. The

"dump in a lump" mass reaction has produced the higher yields generally and that could apply here as well for increasing the yields even beyond 70%

....

but this is speculation and unconfirmed. Scale issue also

seems to be eliminated by the Russian reported technique

in a book which appears to be a student textbook guide for a chemistry course where this and other labs would be

experiments actually performed by students taking the course. I can't recall where I came by this book file or I would credit it. Attached excerpt is

page 139 from my file for the English translation of the Russian textbook

Practical_Inorganic_Chemistry.Vorobyova.O.I_Dunaeva.K.M_Ippolitova.E.A_Tamm.N.S.1987.djvu.rar

An additional item of interest relates to the subsequent post also on page 10 which mentions the Cyanuric Acid salt of Hydrazine mentioned earlier on

page 6 of the thread.

Evidently it may be possible on long refluxing of Hydrazine Cyanurate to produce a good yield of Carbohydrazide which is useful as an intermediate in

synthesis. This has not been confirmed as a practical method, but seems likely to be possible by comparing the earlier Hydrazine Cyanurate patent

GB1073292 with the Carbohydrazide patent US3258485 attached. A variation of the patent process should be possible to make use of Hydrazine Cyanurate

as the precursor since it must be formed in situ as an intermediate in the patent process.

Curiously an identified usefulness for Carbohydrazide nitrate

is as a component of a mixture which may serve as a propellant in ammunition cartridges, operating as a

"liquid gunpowder" substitute for granular gunpowder.

See patent US2970899 attached.

Attachment: Russian Method Hydrazine Sulfate Synthesis.pdf (69kB)

This file has been downloaded 1188 times

Attachment: US3258485 Carbohydrazide via Hydrazine Cyanurate.pdf (118kB)

This file has been downloaded 1476 times

Attachment: US2970899 Liquid Gunpowder Substitute.pdf (242kB)

This file has been downloaded 1995 times

|

|

|

dangerous amateur

Hazard to Others

Posts: 144

Registered: 8-7-2011

Member Is Offline

Mood: No Mood

|

|

Dealing with hydrazine contamination

I'd like to know how you guys deal with the toxic residues after working with hydrazine.

How do you decontaminate your equipment?

Can you rely on the fact that it's getting destroyed by aerial oxigen?

|

|

|

Nicodem

Super Moderator

Posts: 4230

Registered: 28-12-2004

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Nicodem  | | I did a literature search on the topic of the rearrangement of N-haloureas into hydrazines and to my surprise realized that what appeared as a rather

obscure reaction is not that obscure after all. In one instance it was even given a name, the Schestakow rearrangement (or Shestakov; after the author

of the seminal papers). The reaction was found to proceed in three steps, the same ones I mentioned above, that is

N-halogenation/rearrangement/decarboxylation (see J. Am. Chem. Soc., 76, 2572–2574). The N-halogenation reagents most commonly

used are NaClO and NaBrO, but other halogenating reagents can be used as well. The rearrangement of N-chlorourea only occurred when heating under

highly basic conditions (so I was wrong in saying that the reaction might work without using excess NaOH and alkali carbonates are not necessarily

basic enough). Heat is not always used though. The decarboxylation of the so formed N-aminocarbamate salt requires neutralization, so no hydrazine

forms until the final addition of the acid. N,N-Disubstituted ureas also undergo the reaction, so the mechanism appears to be that of a Hofmann

rearrangement and not Favorsky (though this does not prove or disprove that both mechanisms are operating at the same time where possible, which is

however limited only to N-monosubstituted ureas). I could find no examples of rearrangement of N,N’-disubstituted ureas which cannot

undergo a Hofmann rearrangement, but could potentially undergo a Favorsky rearrangement. So either nobody bothered trying the reaction on

N,N’-disubstituted ureas or the rearrangement cannot proceed through a Favorsky-like mechanism. |

In the quoted post I mentioned that I found no examples that would demonstrate the feasibility of an aza-Favorsky mechanistic pathway for the

formation of hydrazines from urea. Today I accidentally stumbled upon articles that indisputably prove that such a pathway is possible. In fact, the

corresponding aza-Favorsky intermediates, the diaziridinones, can be isolated if an N,N'-dialkylurea with bulky alkyl substituents is used (such as

t-butyl; the bulky groups suppress the nucleophilic ring opening reaction). A couple of references:

Organic Syntheses 2009, 86, 315-324. (synthesis of di-t-butyldiaziridinone)

Journal of Organic Chemistry 1969, 34, 2254-2262. (describes the synthesis and chemical properties of diaziridinones, as well as their many ring

opening reactions, including the ones giving hydrazines)

…there is a human touch of the cultist “believer” in every theorist that he must struggle against as being

unworthy of the scientist. Some of the greatest men of science have publicly repudiated a theory which earlier they hotly defended. In this lies their

scientific temper, not in the scientific defense of the theory. - Weston La Barre (Ghost Dance, 1972)

Read the The ScienceMadness Guidelines!

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

Interesting. It has always been reasonably suspected by me that a plurality of possible reaction pathways and mechanisms are possible

from urea leading to hydrazine, semicarbazide, or related products, and/or simultaneously to various possible byproducts and decomposition products of

the reactants, and that dependant upon changes to the reaction conditions a particular pathway may be made favorable for one or another product to

predominate. The observed transient and thermally sensitive color transition in the sodium hypochlorite/urea/NaOH/gelatine reaction mixture as a

waypoint, appeared to be a probable reaction progress milepost color indicator of sorts, showing a visual clue that a hydrazine intermediate is

probably formed. Several years ago I mused about the significance of the color change, observing at one point in the reaction the red orange tea

coloration making my reaction flask temporarily appear to be like a red rubber ball .....reminding me of the song by that name from 1966

http://www.sciencemadness.org/talk/viewthread.php?tid=1128&a...

http://www.youtube.com/watch?v=a9aHrgtf2zY The Cyrkle - Red Rubber Ball

http://www.youtube.com/watch?v=EcdPPd9nEwQ

http://www.youtube.com/watch?v=9nmNKCaOeZk Turn Down Day

Another good one

http://www.youtube.com/watch?v=HUSYj5zq144 The Three Degrees - When Will I See You Again

<iframe sandbox width="622" height="350" src="http://www.youtube.com/embed/HUSYj5zq144" frameborder="0" allowfullscreen></iframe>

|

|

|

Formatik

National Hazard

Posts: 927

Registered: 25-3-2008

Member Is Offline

Mood: equilibrium

|

|

Revisiting my previous attempt of neutralizing hydrazine with bisulfate, this new procedure offered very positive results.

Procedure:

317.51g NaHSO4 (95% pure, assumed to be the monohydrate) was fully dissolved with stirring in 800mL tap water. Temperature was between 20-25 C. Then

99.44g of 35% aq. N2H4 was dumped into the aqueous bisulfate under stirring. The temperature now went from 23 C to 43 C, but the reaction is

completely mild and entirely not violent. Then 85.17g of 31% HCl acid was stirred in, where no temperature change was seen. This was let stand until

it cooled down to 24.5 C which took about 90 minutes. Then about 425mL of liquid was decanted into a container and let stand for 10 minutes, this was

then decanted to a volume of 100mL and this poured back into the original mixture. 20mL of decanted liquid was used to rinse the container and also

put back into the original mixture. Now the mixture was filtered. And washed the hydrazine sulfate and the filter with tap water (temp. 24 to 25 C)

using the following three portions from first to last: about 45mL, 50mL, 60mL. The filtered solid was then mildly strained (some 100mL liquid

removed). And then air dried in a warm area for 3 days. Yield: 130.835g hydrazine sulfate (92.56% theory).

Purity tests.

The chloride content was approximated using 0.250g sulfate in 200mL distilled water, about 25 mL strong aq. AgNO3 and distilled water wash (20mL), the

precipitate was not really measurable so that the amount was even likely below 0.005g (scale minimum), and chloride content is maximally around 0.90%

NaCl. But it is possible to be even less like 0.5% NaCl or below. The lowest amount of Cl- possible is around 0.08 to 0.1% NaCl. The sodium content

was approximated by solvating some part of 11.750g of the hydrazine sulfate in 100.00g distilled water at 24.5 C. The amount that was solvated was

about 3.320g. Loss by decantation was very low, maybe 20mg. Solubility of N2H6SO4 in H2O is reported in the lit as 3.302% at 25 C according to Weise

(Z. anorg. Ch. 94 [1916] 80,86). Purity is around 99%+. Some more testing would be good to further confirm, but purity is very satisfactory.

Discussion:

If more hydrochloric acid is used this can readily precipitate sodium salts alongside the hydrazine sulfate, the purity of the product shows the

addition of hydrochloric acid was ideal. The addition of hydrochloric acid in those amounts bumped the yield up by an estimated 14%. Washing with

distilled water instead of tap water should increase purity of the final product more. According to the previous reference p. 79, hydrazine sulfate is

insoluble in alcohol so it can be used to dry it quicker. Warm air and temperatures can dry it, but heating hydrazine sulfate with strong heat can

cause explosion under the formation of sulfur (Ber. 20, 1633).

The yield seen here was about the same when aqueous hydrazine was neutralized with dilute sulfuric acid. Although the yield can also be increased by

the sulfuric acid neutralization by boiling down and crystallizing, and evaporating to dryness, this is more laborious and the small amount not really

worth the effort in the small scale.

In the end, sodium bisulfate is much more preferable for neutralizing hydrazine. The reaction of aqueous hydrazine and diluted aqueous sulfuric acid

is extremely violent and requires very long slow addition, during which time significant amounts of hydrazine also evaporate and can expose one to the

fumes.

Speculating in the preparation of hydrazine like from the Raschig process, etc. one can readily use NaHSO4 to form hydrazine sulfate also, however the

sulfate shouldn't be used straight away, the solution should first be neutralized with hydrochloric acid, then the sodium bisulfate added. Though the

additional sodium salts could decrease yield somewhat.

Neutralizing aqueous hydrazine is useful for obtaining a much more stable, less reactive, and less toxic material in the form of one of its salts.

[Edited on 3-9-2012 by Formatik]

|

|

|

ANFO_

Harmless

Posts: 6

Registered: 22-10-2012

Member Is Offline

Mood: No Mood

|

|

I'm completely new here, but I've been lurking on this thread for a while now. Hopefully my first post isn't too retarded

I'm just wondering: what is the best way to reclaim pure hydrazine hydrate from the Hoffman rearrangement?

The reaction produces sodium carbonate as well as hydrazine, and I want to isolate the hydrazine solution from the carbonate without distilling it.

I was thinking that maybe hydrolysis of the ketazine could work for this, but that might mean putting another unwanted compound in the solution. Or

can the hydrazine sulfate be turned back into hydrazine hydrate without producing any soluble salts?

|

|

|

Random

International Hazard

Posts: 1018

Registered: 7-5-2010

Location: In ur closet

Member Is Offline

Mood: Energetic

|

|

Quote: Originally posted by ANFO_  | I'm completely new here, but I've been lurking on this thread for a while now. Hopefully my first post isn't too retarded

I'm just wondering: what is the best way to reclaim pure hydrazine hydrate from the Hoffman rearrangement?

The reaction produces sodium carbonate as well as hydrazine, and I want to isolate the hydrazine solution from the carbonate without distilling it.

I was thinking that maybe hydrolysis of the ketazine could work for this, but that might mean putting another unwanted compound in the solution. Or

can the hydrazine sulfate be turned back into hydrazine hydrate without producing any soluble salts?

|

Ketazine with sulfuric acid proved to be the best method as I recall.

|

|

|

Vargouille

Hazard to Others

Posts: 380

Registered: 16-4-2012

Member Is Offline

Mood: No Mood

|

|

Has anyone tried the Peroxide Process?

I found a US patent claiming a 86.74% yield with proportions of H2O2:MEK:NH3 of 1:2:3.43, with a "working solution" comprised of three parts acetamide, 1.8

parts ammonium acetate, 0.033 g Na2HPO4, and 1.77 g EDTA, disodium salt (1 part representing 0.35 moles in the example given). It may be significant

that the ammonia was gaseous, and H2O2 was 69.27%, although it says that aqueous ammonia and 30% H2O2 are acceptable. Ullmann's says that some sort of

catalyst is required, though, or else the reaction will be too slow.

|

|

|

AndersHoveland

Hazard to Other Members, due to repeated speculation and posting of untested highly dangerous procedures!

Posts: 1986

Registered: 2-3-2011

Member Is Offline

Mood: No Mood

|

|

Here is an interesting excerpt taken from D. Todd, in R. Adams, ed., Organic Reactions, Vol. 4, John Wiley & Sons, Inc., New York, 1948,

Chapt. 8. "Hydrazine and its Derivitives" :

| Quote: |

"A process developed by Produits Chimiques Ugine Kuhlmana (PcUK), and practiced by Atofina (France) and Mitsubish Gas (Japan) involves the oxidation

of ammonia by hydogen peroxide in the presence of butanone (MEK) and another component that apparently serves as an oxygen-transfer agent. The

reaction is carried out... at at 50degC. The ratio of H2O2/MEK:NH3 used is 1:2:4. Hydrogen peroxide is activated by acetamide and disodium hydrogen

phosphate (117). The mechanism of this reaction involves an activation of the ammonia and hydrogen peroxide because these compounds do not themselves

react (118-121). It appears that acetamide functions as an oxygen transfer agent, [possibly as the iminoperacetic acid, HOOC(=NH)CH3 ], which

then oxidizes the transient Schiff base formed between MEK and ammonia to give give the oxaziridine, with regeneration of acetamide."

(117) U.S. Pat. 3,962,878 (aug. 3, 1976), J.P. Schirmann, J. Combroux, and S. Y. Delavarenne

(118) J.P. Schirmann and S. Y. Delavarenne, Tetrahedtron :ett. 635 (1972)

(119) E. G. E. Hawkins, J. Chem. Soc. C, 2663 (1969)

(120) E. Schmitz, Chem. Ber. 97, 2521 (1964)

(121) Can. Pat. 2,017,458 (Nov. 24, 1990), J.P. Schirmann, J. P. Pleuvry, and P. Tellier (to Atochem)

|

[Edited on 5-2-2013 by AndersHoveland]

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

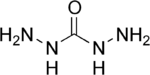

carbohydrazide ( diaminourea )

attached is more of interest about carbohydrazide mentioned above in my post 26-02-2012

Carbohydrazide forms metal complexes whose oxy-acid salts are energetic materials

related post in Exotic Primaries - Complex Salts

http://www.sciencemadness.org/talk/viewthread.php?tid=1778&a...

franklyn mentions that carbohydrazide is also known as diaminourea ( DAU )

http://www.sciencemadness.org/talk/viewthread.php?tid=15455&...

Attachment: THE CHEMISTRY OF CARBOHYDRAZIDE AND THIOCARBOHYDRAZIDE.pdf (850kB)

This file has been downloaded 9461 times

Attachment: Explosives Based on Diaminourea (carbohydrazide).pdf (240kB)

This file has been downloaded 1171 times

[Edited on 22-3-2013 by Rosco Bodine]

|

|

|

| Pages:

1

..

17

18

19

20

21

..

24 |