| Pages:

1

2

3

4 |

chemrox

International Hazard

Posts: 2961

Registered: 18-1-2007

Location: UTM

Member Is Offline

Mood: LaGrangian

|

|

@Ozone: please post the whole apparatus (or I can tomorrow)

"When you let the dumbasses vote you end up with populism followed by autocracy and getting back is a bitch." Plato (sort of)

|

|

|

Ozone

International Hazard

Posts: 1269

Registered: 28-7-2005

Location: Good Olde USA

Member Is Offline

Mood: Integrated

|

|

OK, let's see.

I usually plan the fractionation ahead. The usual, 1 forerun, 1 fraction; two are left for either other fractions or to catch the remainder that comes

over. The header joint is well greased which enables it to be turned easily. You can use collection flasks of various size as you see fit. The spiky

bits on the side of each teat are for the connection of springs which should serve to keep the collector from falling off. I just use Keck clamps.

To the best of my knowledge, the rubber tubing on the bottom of the aspirator serves to "muffle" the water jet coming out of the bottom. This prevents

it from spattering all over the place (from the side *and* when it strikes the bottom of the sink) and making a mess. I've not noticed a difference in

vacuum either way.

OK, I was at a conference all day so I'll put together a sample apparatus for photography tomorrow. [Actually, tomorrow I have day-two of conference

and I am judging science fair thursday. this would have to be done on Friday, then.]

I thought the BSA was a nice touch . .

Moooo,

O3

[Edited on 3-2-2009 by Ozone]

[Edited on 3-2-2009 by Ozone]

-Anyone who never made a mistake never tried anything new.

--Albert Einstein

|

|

|

chemrox

International Hazard

Posts: 2961

Registered: 18-1-2007

Location: UTM

Member Is Offline

Mood: LaGrangian

|

|

You have to grease the shit out of the joint or put a teflon sleave on it. NB there's an inner part not shown that direct condensate to the lowest

"udder." I intended to post the whole apparatus but my camera ran low on batteries. I will post the pic tomorrow to make this very useful piece of

equipment clear to all. BTW this isn't the only kind of glassware that turns on an ST joined under vacuum. McLeod Gauges are often set up that way.

"When you let the dumbasses vote you end up with populism followed by autocracy and getting back is a bitch." Plato (sort of)

|

|

|

crazyboy

Hazard to Others

Posts: 436

Registered: 31-1-2008

Member Is Offline

Mood: Marginally insane

|

|

I have seen these before although it was three pronged. I believe that the "cow" is attached at the end where one would normally put a receiving flask

and at each udder is a small receiving flask. Distill under vacuum and the fraction you distill falls into the receiving flask pointing down. When

another fraction begins to distill over you turn the cow and the fraction is collected in a separate flask.

|

|

|

chemrox

International Hazard

Posts: 2961

Registered: 18-1-2007

Location: UTM

Member Is Offline

Mood: LaGrangian

|

|

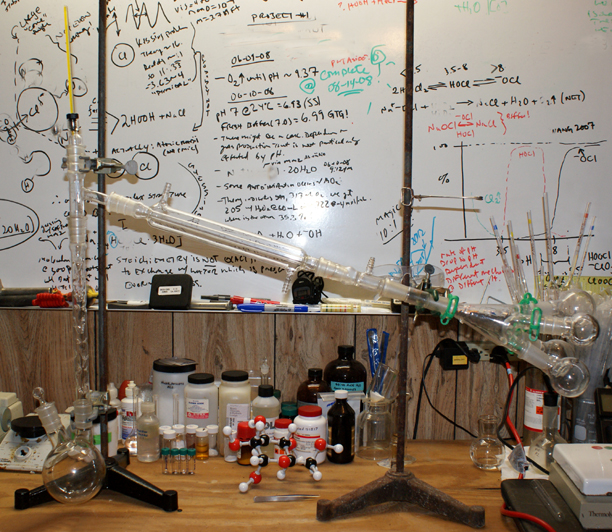

the whole cow setup

"When you let the dumbasses vote you end up with populism followed by autocracy and getting back is a bitch." Plato (sort of)

|

|

|

superman1451

Harmless

Posts: 6

Registered: 7-11-2007

Member Is Offline

Mood: No Mood

|

|

holy cow!

How is that placed on the apparatus?

|

|

|

Ozone

International Hazard

Posts: 1269

Registered: 28-7-2005

Location: Good Olde USA

Member Is Offline

Mood: Integrated

|

|

I'll post a photograph of a whole assembled apparatus tomorrow evening.

That's a big-ass cow, Chemrox! My setup is a little different. Both of my cows, 24/40 125mL and a 14/20 25mL, are male at the header so I have to use

a "gender-bender". I also do not have the drip tube. While nice, and I want one, mine works pretty well just by gravity (it's not as big, though).

Cheers,

O3

-Anyone who never made a mistake never tried anything new.

--Albert Einstein

|

|

|

Sedit

International Hazard

Posts: 1939

Registered: 23-11-2008

Member Is Offline

Mood: Manic Expressive

|

|

Thats a pretty cool setup.

Iv seen little pig adaptors but Iv never seen a cow.

Do you ever have problems with different fractions ending up mixing trace amounts in each other from the sides of the receiver?

|

|

|

Ozone

International Hazard

Posts: 1269

Registered: 28-7-2005

Location: Good Olde USA

Member Is Offline

Mood: Integrated

|

|

Okay, here's the whole thing. I might put up a picture of a rig with a vertical condenser tomorrow.

You are going to get trace amounts anyway (this technique is not perfect). It is still MUCH easier to purify a fraction than the whole mix (even with

the tube, "heart cutting" is difficult).

Cheers,

O3

[Edited on 5-2-2009 by Ozone]

-Anyone who never made a mistake never tried anything new.

--Albert Einstein

|

|

|

Ozone

International Hazard

Posts: 1269

Registered: 28-7-2005

Location: Good Olde USA

Member Is Offline

Mood: Integrated

|

|

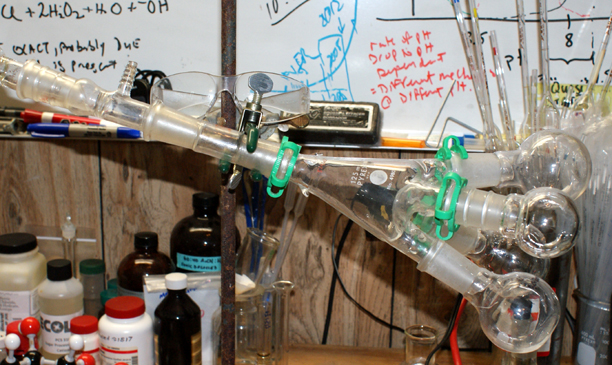

A closeup of the vacuum adapter, gender bender and outfitted cow.

If you look closely at the vacuum adapter, you will see where the tube used to be. The 'bender was a tight fit and eventually, the tube broke off . Bummer. . Bummer.

O3

-Anyone who never made a mistake never tried anything new.

--Albert Einstein

|

|

|

taniya.pinkpower1986

Harmless

Posts: 13

Registered: 3-11-2008

Location: pink island

Member Is Offline

Mood: you know

|

|

Practical Vacuum Distillation

Thanks everyone for such nice pics and good infos........................Now it may sound a little stupid.Can I use a hand vacuum pump like this one

in pic

|

|

|

crazyboy

Hazard to Others

Posts: 436

Registered: 31-1-2008

Member Is Offline

Mood: Marginally insane

|

|

Those are for vacuum filtration not distillation. This thread is about practical vacuum distillation. It's simply not practical to stand a set up

pumping away for hours only to pull a slight vacuum, get carpral tunnel and then have the thing break on you.

Get an aspirator or a vacuum pump.

I have an aspirator but no sink in my workspace so I need to totally rearrange my garage before installing a sink and finally vacuum distilling my

nitric acid that has been in my freezer for the past three months.

|

|

|

chemrox

International Hazard

Posts: 2961

Registered: 18-1-2007

Location: UTM

Member Is Offline

Mood: LaGrangian

|

|

get an aspirator or for a little more money an aspirator pump. Both have their uses. An apsirator pump has a water reservoir and a mechanical pump

that pumps water through internal aspirators. No need to run up the water bill but the e bill suffers a bit.

@O3- ours aren't all that different. I went 250 on the flask for the cow and my receivers are 75 ml with 14/20 joints. I forgot to have him put

spring holders on them so I need some 14/20 Klecks. I like having the flow director with the larger volume cow but at 125 you might not need it. I

like having the white board right there where you work!! I have written on the cabinets and windows and parts of the floor...

I noticed you're using a vigeraux. I saw a dramatic improvement when I started using a Snyder column. The distillation I have planned is for

something that boils around 168/0.3 mm so for that I'm using a short path with a 1" built-in vigeraux. I could show the vacuum station but I don't

want her to despair.

[Edited on 10-2-2009 by chemrox]

"When you let the dumbasses vote you end up with populism followed by autocracy and getting back is a bitch." Plato (sort of)

|

|

|

Ozone

International Hazard

Posts: 1269

Registered: 28-7-2005

Location: Good Olde USA

Member Is Offline

Mood: Integrated

|

|

Yeah, mine's 24/40. I have ~ 1m worth of Snyder ball columns which are very nice to use--but I only really use them for solvent recovery. I find that

it helps to drop some of the solvent into the top of the column (wet the column) prior to use. I suppose I could add a pic of some Snyders tomorrow.

I also have straight wall columns which I pack with steel wool, glass balls, etc. which perform better than the vigreaux. The vigreaux, however...is

easy..and usually works very well. It's a great place to start.

Maybe we should address vacuum manifolds...later.

Nothing like the sound of chattering Snyder columns in the morning!

O3

-Anyone who never made a mistake never tried anything new.

--Albert Einstein

|

|

|

chemrox

International Hazard

Posts: 2961

Registered: 18-1-2007

Location: UTM

Member Is Offline

Mood: LaGrangian

|

|

"Nothing like the sound of chattering Snyder columns in the morning!"

hehehe .. yeah that's the best!

I got a three cock manifold made for $45. I can't understand how Ace and Kontes even, charge so bloody much for those things...even with the high vac

cocks. It probably took the glassblower about 10 minutes. I benefit from the guy (my glassblower) being really busy. When it doesn't make it

impossible to get repairs on short notice that is. Like now. I'm working with a new guy I got through the U. We'll see how he does.

[Edited on 11-2-2009 by chemrox]

"When you let the dumbasses vote you end up with populism followed by autocracy and getting back is a bitch." Plato (sort of)

|

|

|

Engager

Hazard to Others

Posts: 295

Registered: 8-1-2006

Location: Moscow, Russia

Member Is Offline

Mood: Lagrangian

|

|

I use vacuum setup based on rotary oil vacuum pump, it can provide vacuum up to 0.1 mm. Hg. However setups you shown in this topic look somekind

unusual for me.

1. As far as i can see in provided setups nobody uses manometer or other pressure control. Use of pressure control is absolutely essential because

pressure greatly affects boiling points, if pressure in system will be too low, even high boiling liquid can destill off just about room temperature

and there will be great difficulty to condense it even in long condenser cooled by cold water stream. Before preforming vacuum destilation you must at

first select work pressure range such that lower border pressure will provide high enough boiling point of reaction mixture to condense distillate

efficently and high border pressure that allows to destill your mixture with selected heat source (e.g water or oil bath) at acceptable rate while not

allowing destilled substances to undergo thermal decomposition (for example HNO3 is thermaly unstable). Apropriate pressure range can be selected from

vapor pressure / temperature graph for distilled substance.

2. I don't see boiling capilary in your setups, and this is very strange, because it's absence makes vacuum destillation unstable and even dangerous.

Under reduced pressure gasses that are dissolved in reaction mixture quickly escape from reaction mixture and seed gas bubbles esential for stable

boiling no longer form - liquid can easily become overheated. This is absolutely inacceptable because overheated liquid mixture sooner or later will

boil up with great violence, it can jump over to condenser outlet and in some cases even explosive boil up is possible (heat explosion). To solve this

problem a boiling capilary is used in vacuum setups, this is thin glass tubbing with very small hole in the end that is passed almost to the bottom of

distilation flask, then system is evacuated it passes stream of small air bubbles from atmosphere witch aid phase chance and allow liquid to have

stable boiling. This additional air inlet is also used to fine tune pressure by means of gas valve connected to the top of the inlet capilary.

3. I don't see any trap devices between vacuum outlet and vacuum pump. If you are using water stream vacuum pump if pressure in water system will

suddenly change water from the pump can easily jump into distillate flask and cause some nasty chemical reactions (especialy if destilled substances

react violently with water). If you are using oil vacuum pump some uncondensed fumes can reach pump oil and dissolve in it to lower maximum vacuum, or

if fumes are aggressive they can react with oil or corrode parts of vacuum pump. In usual setups there are trap flasks between vacuum outlet and

vacuum pump. In case of water stream pump trap serve as emergency drain in case of water stream pressure fluctuations, and in case of oil pumps this

trap flask is usualy strongly cooled (for example with solid CO2) to freeze any vapours not condensed by condenser and not allow them to enter pump

oil or leave evacuated system.

[Edited on 22-3-2009 by Engager]

|

|

|

Gruson

Harmless

Posts: 30

Registered: 22-10-2005

Location: Southern Netherlands

Member Is Offline

Mood: Creating!

|

|

Since I intend vacuum distilling and use of a rotary evaporator with an oil pump as well (<1mbar), I was wondering if I could replace the dry

ice/acetone cold trap with an 60 cm graham condensor. (water on the outside) This would be cooled with an refrigerated circulator bath, this one http://www.capovani.com/dp/cat/107/63160/iinfo.cfm?LCl=986&a... to be more precise. It would be running with water/EG at -5 till -8 degrees

celcius. Is this sufficient to prevent solvent from reaching the pump oil? The rotavap/liebig cooler would also be cooled with this temperature.

It could be that the purpose of your life is only to serve as a warning to others.

|

|

|

Lambda-Eyde

National Hazard

Posts: 857

Registered: 20-11-2008

Location: Norway

Member Is Offline

Mood: Cleaved

|

|

That all depends on what you intend to distill. Look up a graph on the BP of the solvent with pressure plotted in, and cross-check that with the

temperature of the condensing water and the efficiency of your condenser.

|

|

|

Panache

International Hazard

Posts: 1290

Registered: 18-10-2007

Member Is Offline

Mood: Instead of being my deliverance, she had a resemblance to a Kat named Frankenstein

|

|

Quote: Originally posted by Gruson  | | Since I intend vacuum distilling and use of a rotary evaporator with an oil pump as well (<1mbar), I was wondering if I could replace the dry

ice/acetone cold trap with an 60 cm graham condensor. (water on the outside) This would be cooled with an refrigerated circulator bath, this one http://www.capovani.com/dp/cat/107/63160/iinfo.cfm?LCl=986&a... to be more precise. It would be running with water/EG at -5 till -8 degrees

celcius. Is this sufficient to prevent solvent from reaching the pump oil? The rotavap/liebig cooler would also be cooled with this temperature.

|

Remember that although something may be well below its boiling point for a given pressure it still may have some, even significant, vapour pressure

and as such will eventually end up in your pump.

For most common solvents this is not really problematic as your can bleed them from your oil easily enough (assuming a vane pump here). Especially if

using a fully synthetic vac pump oil. However for distillations of more reactive substances you really want to avoid any contamination into your pump

and -8 ain't gonna cut it even for moderate vacuums. That is why the dry ice cold finger is standard good practise, however its annoying for the home

experimenter because you must have the dry ice around and it has this silly habit of subliming away and warming up the earth.

I posted recently in relation to small domestic benchtop ice cream makers being an excellent alternative to the dry ice cold finger. They run

continuously (i leave mine on all week), sit at around -38 and negate the need for the consumable dry ice. I just fill mine with ethanol and immerse

the trap into it.

|

|

|

Gruson

Harmless

Posts: 30

Registered: 22-10-2005

Location: Southern Netherlands

Member Is Offline

Mood: Creating!

|

|

That is an excellent idea. I presume you have the icemaker with built-in compressor? Which type exactly? (I believe you have a "Nemox"?) I can get my

hands on dry ice, but that would be a 70 km drive. Okay for one particular synthesis, but I was looking for a solution on the long term. Does ethanol

has the heat capacity needed for efficiently cooling the cold trap?

It could be that the purpose of your life is only to serve as a warning to others.

|

|

|

Panache

International Hazard

Posts: 1290

Registered: 18-10-2007

Member Is Offline

Mood: Instead of being my deliverance, she had a resemblance to a Kat named Frankenstein

|

|

Quote: Originally posted by Gruson  | | That is an excellent idea. I presume you have the icemaker with built-in compressor? Which type exactly? (I believe you have a "Nemox"?) I can get my

hands on dry ice, but that would be a 70 km drive. Okay for one particular synthesis, but I was looking for a solution on the long term. Does ethanol

has the heat capacity needed for efficiently cooling the cold trap? |

The reason i leave it on all week is it has about a 20min warm-up time (ha funny to describe it as this) before it is at it lowest temperature. This

solution is not as good as dry ice obviously, but many more times convenient and permanent. I use ethanol because i have it and didn't want to use any

solvents potentially aggressive to the polymers of the unit, whatever they may be. If your unit is fully cooled it works fine.

|

|

|

Globey

Hazard to Others

Posts: 183

Registered: 9-2-2009

Member Is Offline

Mood: No Mood

|

|

A great OTC method I've adapted uses a Reynolds Handi-Vac, hand held vacuum pump, and have had decent results. Not the same as my carbon vane, but it

seems to be able to deal with the organic vapors so far, and is handy and easy to grab real quick. Maybe not for critical sensitive work, but surely

to speed things along which otherwise are slow, but not necessarily all that heat sensitive without it.

|

|

|

marksev1

Harmless

Posts: 26

Registered: 16-3-2009

Member Is Offline

Mood: No Mood

|

|

What about the crushed ice with calcium chloride hexahydrate in ratio 2:3, i read that it achieves temp. about -40 degrees celsius...would that be

sufficient (for example for DCM)? And also calcium chloride is quite cheap.

[Edited on 7-4-2009 by marksev1]

|

|

|

Shingoshi

Harmless

Posts: 49

Registered: 20-4-2008

Location: Salem, Oregon

Member Is Offline

Mood: No Mood

|

|

Would this be the right thread to ask questions about boiling butane (or ammonia) from water using Mazzei Injectors? I can start a new thread if I

need to. I want to know if such aspirators are capable of the task?

Here's the information on these injectors:

http://www.mazzei.net/products/injector_info.htm

Shingoshi

|

|

|

not_important

International Hazard

Posts: 3873

Registered: 21-7-2006

Member Is Offline

Mood: No Mood

|

|

Is your goal to purify the water, or to recover the butane/ammonia?

For simply removing the gas, bubbling air through the water might do the job, use a packed column with counterflow of air and water.

|

|

|

| Pages:

1

2

3

4 |