| Pages:

1

2

3

4

5

..

24 |

watson.fawkes

International Hazard

Posts: 2793

Registered: 16-8-2008

Member Is Offline

Mood: No Mood

|

|

I'd guess it's due to variations in the rare earth mineral

sources for the Nd content. I'd be surprised if the purity of Nd in these magnets is higher than technical grade.

|

|

|

MrHomeScientist

International Hazard

Posts: 1806

Registered: 24-10-2010

Location: Flerovium

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by watson.fawkes  | | I'd guess it's due to variations in the rare earth mineral sources for the Nd content. I'd be surprised if the purity of Nd in these magnets is higher

than technical grade. |

I agree with that, but all the vials except the left two were from the same magnets. I probably didn't make that clear enough. After dissolving 4 hard

drive magnets that all looked identical, I heated the solution until some Nd sulfate precipitated. I decanted this to collect the crystals in a vial,

let the solution cool down, and removed any FeSO4 that precipitated. I then heated it again until more crystals dropped out and collected those in

another vial. I repeated this many times and got all the different shades in the picture. So all those colors (except the left two, from another

batch) originated from the same magnets.

|

|

|

MrHomeScientist

International Hazard

Posts: 1806

Registered: 24-10-2010

Location: Flerovium

Member Is Offline

Mood: No Mood

|

|

It's been a long, slow process, but I've finally got more results to post. I tried out the next step in the process, adding the ammonium bifluoride to

the neodymium sulfate, to obtain neodymium fluoride.

The probable reaction for this step is:

Nd<sub>2</sub>(SO<sub>4</sub> <sub>3</sub> +

3NH<sub>4</sub>HF<sub>2</sub> == 2NdF<sub>3</sub> (s) + 3NH<sub>4</sub>HSO<sub>4</sub> <sub>3</sub> +

3NH<sub>4</sub>HF<sub>2</sub> == 2NdF<sub>3</sub> (s) + 3NH<sub>4</sub>HSO<sub>4</sub>

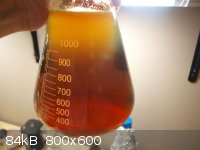

The first step was to dissolve the 2.7g of my first batch of product into 50mL of distilled water. That was the first two vials in my previous post.

I'm still amazed by how different lighting causes the color to change.

The initial Nd-sulfate

Sulfate dissolved in water - from top to bottom: under lab (small) fluorescent tubes, under kitchen (large) fluorescent tubes, and under tungsten

bulbs

According to the above equation, 2.7g of Nd-sulfate requires 1.2g NH<sub>4</sub>HF<sub>2</sub>. This was weighed out and

dissolved in 20mL water, in a plastic container (CAREFULLY, and with maximum precautions). I added this dropwise, slowly, to the sulfate solution. A

very fine, gelatinous off-white precipitate formed. It was pretty neat - a drop would fall into solution, and about 1/2 second later the precip.

appeared. I ended up only adding 13.9mL of the bifluoride solution before additional drops produced no more precipitate. That means that,

interestingly, only 0.83g bifluoride was actually needed to complete the reaction.

<i>EDIT: I apparently made a math error above, and 0.8g of bifluoride was in fact the correct amount that was needed. Score one for

experimentation!</i>

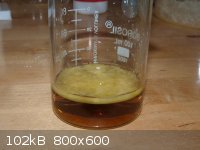

This precipitate was again sensitive to lighting conditions.

Under lab FL lights

Under camera flash

I allowed this to settle for a few days, which compacted it significantly. Then I filtered this through some coffee filters, and let it dry in the

filter paper. I had the solution drip into a beaker of calcium chloride solution, to precipitate out any leftover bifluoride as the insoluble calcium

fluoride.

Strangely, after letting this dry the color had changed to a lime green under the lab fluorescents! It still changes to pink under the tungsten bulbs

though.

The green isn't quite as lime in the picture as it is in person.

The total yield of NdF<sub>3</sub> was 1.7g.

I'm puzzled by the color change. This could be some iron contamination - iron(III) fluoride is listed as a pale green solid, while neodymium(III)

fluoride is listed as purple (though lighting conditions aren't specified). I'd hypothesize that any iron(II) sulfate contamination was initially

reacted into iron(II) fluoride (which is white), then upon exposure to air it converted to iron(III) fluoride (green).

So in conclusion, this appears to have been a success in precipitating the fluoride. Apparently there's quite a bit of iron contamination that I

wasn't aware of. That means that I should probably recrystallize my sulfates to get a more acceptable purity.

Once I process more of my sulfate material into fluoride, I can move on to the final step and (hopefully) get my Nd metal!

[Edited on 9-1-2011 by MrHomeScientist]

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Well done that man! Very interesting...

Good idea also to catch the filtrate in CaCl2.

The iron fluorides are both water soluble, so unless some got 'caught' (occlusion) the iron content of the Nd should actually have decreased further

when precipitating the NdF3.

Can you specify the drying procedure a bit?

Are the ampoules made of glass? Residual moisture could still cause very small (and safe) amounts of HF to attack the glass, if so.

1.7 g of NdF<sub>3</sub> isn’t much of course. To convert it to Nd metal, assuming that’s still your goal, could be tricky. Such small

batches of NdF<sub>3</sub> + Mg are likely to fizzle early because the crucible walls act as a heat sink and stop the reaction it its

tracks, even if you can get it to go initially. I see as only possibility for such a mini-reduction to heat the mixture by heating the crucible with

Bunsen, until reaction starts, then stop heating. You need to protect against fumes!

So far, so good!

|

|

|

Chemistry Alchemist

Hazard to Others

Posts: 403

Registered: 2-8-2011

Location: Australia

Member Is Offline

Mood: No Mood

|

|

I recently dismantled my old play station HDD and took out the 2 small magnets (2.7 grams all up), the magnets have a silverish coating on the actual

magnet, is this nickel or what, when i peel some off the magnet, the under side is shiny, but about an hour later its darkened from the tarnish, could

i just put it in some boiling water? Neodymium Reacts fast with Hot water, and the Iron and Boron dont react with water so can i separate the

Neodymium this way and then separate tthe other 2 a different way?

Fell free to correct me if im wrong

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

CA:

The coating is indeed nickel, you need to peel off as much as you can (demagnetise the magnet first by heating it in a gas flame for a short time).

Nickel really only dissolves in nitric acid.

Dissolving neodymium in water is virtually impossible. Also this material isn't neodymium, it's an alloy (look up 'neodymium magnets'). To dissolve

the magnet you need either fairly strong HCl (20 % or higher) or dilute H2SO4 (at least 20 %). Note that hydrogen will evolve, which is highly

flammable: ventilation is a must and open flames a no-no...

READ the relevant threads before doing ANYTHING ELSE.

|

|

|

Chemistry Alchemist

Hazard to Others

Posts: 403

Registered: 2-8-2011

Location: Australia

Member Is Offline

Mood: No Mood

|

|

So once i have dissolved the magnet in HCl, i have among other things Neodymium Chloride, How do i separate Boron and Iron from this?

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

The boron doesn't dissolve in acid.

To separate the Nd from Fe, see the relevant threads. There are different ways and they're all explained to death in these threads. Use the search

facility and yee shall find.

[Edited on 1-9-2011 by blogfast25]

|

|

|

Chemistry Alchemist

Hazard to Others

Posts: 403

Registered: 2-8-2011

Location: Australia

Member Is Offline

Mood: No Mood

|

|

what if i cant get all the nickel off the magnet? how brittle is the actual magnet, could i crush it with mortar and pastel

|

|

|

Endimion17

International Hazard

Posts: 1468

Registered: 17-7-2011

Location: shores of a solar sea

Member Is Offline

Mood: speeding through time at the rate of 1 second per second

|

|

MrHomeScientist, well done! It's a treat to see the final compound at the end.

Chemistry Alchemist, take some emery paper and start scraping. The scrapings will cling to the magnet, but remove them by pinching with fingers until

they're gone.

|

|

|

MrHomeScientist

International Hazard

Posts: 1806

Registered: 24-10-2010

Location: Flerovium

Member Is Offline

Mood: No Mood

|

|

| Quote: |

Thanks!

[rquote]The iron fluorides are both water soluble, so unless some got 'caught' (occlusion) the iron content of the Nd should actually have decreased

further when precipitating the NdF3. |

That's interesting, I must have missed that. I can try washing the product with water a few times and see if that helps. Looks like it's only slightly

soluble though.

I waited a few days after taking the picture of the precipitate under water to allow it to settle, and it compacted to about 1/3 of that volume. Then

I decanted most of the liquid through my filter paper, let that run through, and then poured out the rest that held the precipitate. Since it was so

gelatinous, it took quite a while to stop dripping. I left everything alone for another few days, and when I came back it had turned green. So, it was

very moist and exposed to air. Once it was dry, it had compacted even further and is now a nice powder.

Quote: Originally posted by blogfast25  | | Are the ampoules made of glass? Residual moisture could still cause very small (and safe) amounts of HF to attack the glass, if so.

|

Yes they are - unfortunately that's all I have. But I do have quite a few, so it's fine if I frost a couple up. Thanks for the tip though, I'll keep

that in mind.

Quote: Originally posted by blogfast25  | 1.7 g of NdF<sub>3</sub> isn’t much of course. To convert it to Nd metal, assuming that’s still your goal, could be tricky. Such small

batches of NdF<sub>3</sub> + Mg are likely to fizzle early because the crucible walls act as a heat sink and stop the reaction it its

tracks, even if you can get it to go initially. I see as only possibility for such a mini-reduction to heat the mixture by heating the crucible with

Bunsen, until reaction starts, then stop heating. You need to protect against fumes!

So far, so good!

|

Indeed. Nd metal is still my goal, for my element collection (and the achievement of making it myself!). I remember you mentioning that small

'thermites' were difficult to work with, thanks for the excellent explanation of why. I have a ton of material to work with - see the picture of that

huge brick of magnets a coworker gave me - so the plan is to process those and make more of the fluoride before moving on. That's whats taking so

long; the magnets take ages to dissolve, and separating the sulfates is also time-intensive. I hope to use labor day weekend for more experimenting!

|

|

|

MrHomeScientist

International Hazard

Posts: 1806

Registered: 24-10-2010

Location: Flerovium

Member Is Offline

Mood: No Mood

|

|

It doesn't matter if you can't get all the coating off. When I was doing it I found that it can be really tenacious. All you want to do is expose the

actual magnet material to the acid - the more nickel you remove, the faster the reaction will go since more surface area is available. Any leftover

nickel just won't react.

Try smashing the magnets yourself (after demagnetizing), they are very brittle. Grinding might be possible, but it'll be a chore and is really

unnecessary since you're dissolving in acid anyway. I just broke mine into chunks.

I'd also recommend you read this whole thread and others about neodymium (do a forum search) - a lot of your questions can be answered there.

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Mr Home Scientist:

My experience with thermites is that 20 g batches of mixture are 'viable', i.o.w. can be lit the usual way (here just Mg ribbon should get it

going) and will burn completely through. Yield of obtained metal does increase with batch size but 20 g should be ok for pilots (you DON'T want to put

all your eggs in one basket, considering the effort it takes to get the NdF3). Anything below 20 g may become more problematic.

Your NdF3 will also need to be bone-dry: drying at 200 C or more should do it. Moist powder is difficult to light and can lead to porous slag and poor

metal separation.

[Edited on 1-9-2011 by blogfast25]

|

|

|

MrHomeScientist

International Hazard

Posts: 1806

Registered: 24-10-2010

Location: Flerovium

Member Is Offline

Mood: No Mood

|

|

It's been a while, but I finally have time to start work on this again. I got very busy at work and haven't been able to do hardly any hobby chemistry

for a few months.

I last left off at dissolving 5 large Nd magnets (about 200g worth) in acid, to make about 1.5 liters of "magnet soup." That's been sitting for a

couple months, and it looks like a lot of the iron has oxidized to insoluble brown iron(III) sulfate.

It's tough to see, but there's bits of it floating around in there and a large fluffy mass at the bottom of the flask.

Anyways tonight I tried out the oxalate separation method on a sample of this, just to see how it went. I started with 20mL of magnet solution and

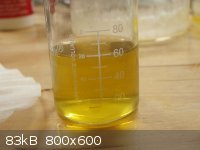

made a dilute solution of 5g oxalic acid dihydrate in 80mL of water. Oxalic is on the left.

Slowly adding this to the magnet solution immediately yielded a very compact yellowish precipitate that floated at first, but after stirring quickly

settled to the bottom.

After adding 20mL of the oxalic acid solution, no more precipitation was observed. This corresponds to 1.25g worth of oxalic acid dihydrate used. This

was then filtered off. Here is the leftover solution, which has turned very yellow. Encouragingly, it shows no color change in different lighting,

suggesting nearly all the Nd has been separated out.

The precipitate also looks distinctly yellow under lab fluorescents, but changes back to pink (with a yellow tinge) under tungsten bulbs.

Now the yellow color suggests to me that some iron(II) oxalate is contaminating my Nd oxalate. Perhaps when it's dry and weighed, I'll try dissolving

the iron back into solution? I do like how quick and effective the separation of Nd from Fe appears to be. Much easier than the repeated cooling and

heating cycles I've been doing to separate the sulfates, especially with the amount of solution I now have to process.

So assuming this is indeed NdOx (and that I can remove the iron impurities likely present), where do I go from here? I was thinking calcine it to

Nd<sub>2</sub>O<sub>3</sub>, then react with sulfuric or hydrochloric acid to get it into solution, then precipitate it back

out as NdF<sub>3</sub> with my ammonium bifluoride. Does this sound reasonable?

Thanks for any feedback. I hope to really get moving on this project soon.

|

|

|

DerAlte

National Hazard

Posts: 779

Registered: 14-5-2007

Location: Erehwon

Member Is Offline

Mood: Disgusted

|

|

Re this thread, see also my earlier posts on RE metals Ce, Nd, Sm:

http://www.sciencemadness.org/talk/viewthread.php?tid=12934#...

http://www.sciencemadness.org/talk/viewthread.php?tid=8758&a...

All references I have seen say Nd sulphate is red and Sm is light yellow, Ce white (colourless); and these were the colors I got. All these sulphates

are very difficult to dissolve at 0C, the most soluble point. Once dissolved, heating to 100C usually will precipitate them. Better crystals can be

obtained by slow evaporation.

Regards, Der Alte

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

@Mr Home scientist:

If your iron hadn’t been completely converted to Fe (III) then your Nd oxalate precipitate is likely to be contaminated with insoluble Fe (II)

oxalate (yellow). Check the mother solution with K3Fe(CN)6 for Fe2+ presence (it gives Turnbull’s blue with Fe2+, quite a sensitive test).

Now try adding 9 % (or better) H2O2 to the mother solution to oxidise any remaining Fe2+ to Fe3+. Do this VERY SLOWLY, aliquot by aliquot, cooling if

needed, as it’s highly exothermic and effervescent. You can also use nitric acid, if preferred. Then simmer gently for a bit to get rid of excess

H2O2. Cool and then repeat what you did and compare colours.

If your current Nd2Ox3 really is contaminated with FeOx, I think I know a trick to get the latter out of there… A very small amount of

Nd2Ox3 I precipitated recently looked just plain white to me, to be honest. I might publish a photo here…

Der Alte: thanks for the links. My Nd2(SO4)3 was more like a salmon-pink colour…

The trouble with the oxalate route is that Nd2Ox3 is so damn insoluble (Ksp = 1.3 x 10<sup>-31</sup> , so that once you’ve obtained it there’s a ‘what now?’ moment. You can fire it to Nd2O3 but that’s pretty

insoluble too. So, shortly I’ll be making some ‘magnet soup’ too and I think I’ll ‘go sulphate’, to be honest… , so that once you’ve obtained it there’s a ‘what now?’ moment. You can fire it to Nd2O3 but that’s pretty

insoluble too. So, shortly I’ll be making some ‘magnet soup’ too and I think I’ll ‘go sulphate’, to be honest…

But I wonder also if use could be made of a lesser known Fe (III) complex, FeOx<sub>3</sub><sup>3-</sup> (ferrioxalate

or trioxaloferrate (III) anions) which has a complexation constant of Kf = 2 x 10<sup>20</sup>.

The trick would be to obtain the ‘magnet soup’ with iron as ferric ions, then adding a sufficiency of K<sub>2</sub>Ox and excess

oxalic acid. This should the complex the ferric ions to ferrioxalate complex, while precipitating the Nd as oxalate, with near perfect separation.

Some have reported difficulties with straight ferric oxalate crystallising out, thereby making separation difficult, this trick could circumvent that

from happening.

Some work on ferrioxalate here:

http://www.sciencemadness.org/talk/viewthread.php?tid=17831

[Edited on 25-10-2011 by blogfast25]

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Scanning my old Holleman (‘inorganic Chemistry’) for a few more useful clues on RE chemistry, I came across a notion I’ve not seen posted on

this forum yet.

Holleman claims that lanthanum, cerium, praseo- and neodymium salts can be separated from the others because the former are insoluble in saturated

K2SO4, due to the formation of double sulphates (RE alums?)

I decided to put that to the test with my NdCl3 stock solution (est. about 1 M) by saturating about 2 ml in a test tube with K2SO4. Sure enough, a

thick precipitate of presumably (Nd,K)n(SO4)m resulted. This was washed and then excess KOH was added to the slurry with a bit of water. The

precipitate became fluffier at once. I heated it for a bit to ensure the supposed conversion to Nd(OH)3.nH2O was complete, then cooled and washed and

decanted about 3 times.

The moment of truth: the precipitate dissolves effortlessly and without heat in a couple of ml of 36 % HCl.

So this would appear to provide another oxalate free route: saturate the solution of ‘neomagnet chloride’ with K2SO4, filter and wash the filter

cake with sat. K2SO4, then convert the alleged double sulphate with strong alkali hydroxide to Nd hydroxide, wash profusely with hot clean water.

|

|

|

MrHomeScientist

International Hazard

Posts: 1806

Registered: 24-10-2010

Location: Flerovium

Member Is Offline

Mood: No Mood

|

|

Blogfast25,

I tried out your hydrogen peroxide suggestion, and my oxalate came out looking very nice! I also used your idea of testing for iron(II) with potassium

ferricyanide - the mother solution has a strong positive test (lots of immediate blue). I tested small amounts during the addition of peroxide, and

stopped adding it when the test only showed a faint blue, which still took a few minutes to appear. Writeup follows.

I again started with 20mL of 'magnet soup' and made up a roughly 9% H<sub>2</sub>O<sub>2</sub> solution by diluting 2mL of 28%

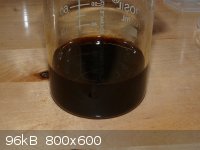

peroxide to 6mL. Peroxide is on the left. I ended up making another 6mL of this and using all of that as well.

I added this dropwise, and it rapidly heated up with lots of bubbling. The solution quickly turned very dark brown, almost black.

I then left to go eat dinner, and when I came back it had changed color to brown! I imagine this is iron(III) sulfate coming out of solution? I tried

filtering it but it didn't clear it up at all (coffee filters probably aren't good enough).

I decided to press on anyway. I heated it for a short while to decompose the peroxide (as suggested). I then used the rest of my oxalate solution I

made for the previous test plus 50mL more of a new batch, for a total of 110mL of solution or about 6.9g worth of oxalic acid. This one took

<u>much</u> more oxalic acid to complete. I would add some, the precipitate would form just like last time, but on stirring it would

promptly redissolve. The solution first cleared of the brown precipitate and returned to a light brown color (darker than the original solution), then

ended up lime green once the Nd finally started precipitating out. I filtered this off and collected it. Here's a comparison between the two methods -

the stuff from my previous post is on the left.

And here's a comparison of the Nd salts under lab fluorescents (left) and tungsten bulb (right). The sample from this test is on the bottom, and the

one from my previous post is on top.

As you can see, the color is <i>much</i> nicer this time around. I'm sure you were correct in saying some iron(II) oxalate was

contaminating my other sample. I really like how pure white the bottom vial (from this run) looks! It sounds like it matches your own observations.

I ended up with 1.2g of Nd<sub>2</sub>Ox<sub>3</sub> this time, and 1.7g last time. I optimistically imagine the extra mass

from last trial was the iron contamination.

Quote: Originally posted by blogfast25  | The trouble with the oxalate route is that Nd2Ox3 is so damn insoluble (Ksp = 1.3 x 10<sup>-31</sup> , so that once you’ve obtained it there’s a ‘what now?’ moment. You can fire it to Nd2O3 but that’s pretty

insoluble too. So, shortly I’ll be making some ‘magnet soup’ too and I think I’ll ‘go sulphate’, to be honest… , so that once you’ve obtained it there’s a ‘what now?’ moment. You can fire it to Nd2O3 but that’s pretty

insoluble too. So, shortly I’ll be making some ‘magnet soup’ too and I think I’ll ‘go sulphate’, to be honest… |

The idea here is to obtain the oxalate, heat it to decomposition to the oxide, then react this with acid (either sulfuric or HCl) to make the Nd

soluble again. Then, this can be reacted with my bifluoride as per the original plan to get NdF<sub>3</sub>. So solubility shouldn't be an

issue, unless you see a problem with this strategy?

Quote: Originally posted by blogfast25  | | So this would appear to provide another oxalate free route: saturate the solution of ‘neomagnet chloride’ with K2SO4, filter and wash the filter

cake with sat. K2SO4, then convert the alleged double sulphate with strong alkali hydroxide to Nd hydroxide, wash profusely with hot clean water.

|

I like this idea too, I'll give that a try soon. Thanks for doing some extra research on this! That's interesting to me because I just recently got

started with another project trying to make alum from coke cans, so it's neat to see double salts here too.

For this route, once I've obtained Nd(OH)<sub>3</sub> would it be possible to react that with bifluoride to get

NdF<sub>3</sub>? I'm not sure if it would work all that well since the hydroxide is also insoluble. Seems like no matter what separation

technique is used, I'd want my Nd in a soluble form before moving on to the next step.

The reason I'm looking at alternative separation techniques, by the way, is because of the volume of solution I have. In order to squeeze out all the

Nd from my magnet soup, I've had to run the solution through 5 or 6 heating and crystal collecting cycles. That takes ages, and it will be very

tedious to do that for so much liquid. It'd be nice if I could just mix in some oxalic acid or potassium sulfate and see immediate and total

separation. I feel like these would yield higher overall purity too, considering the different colors I got from different crops of crystals from the

same solution (see one of my earlier posts). I suppose that could be more or less solved by a recrystallization, though.

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

MrHomeChemist, I know you’re a physicist but now it’s official: you’re also a chemist!

This is great work.

A few comments.

The ferrioxalate method is a little ‘hairy scary’ in the sense that both times I’ve made this complex it appeared touch and go as to whether the

conversion to complex will proceed. In actual fact it simply takes enough oxalate/oxalic acid for it to happen, that’s all. Keep adding oxalate

slowly, with time between additions, keeping hot until the red turns green.

The red precipitate (pict. 3) MUST be ferric oxalate: ferric sulphate is too soluble to precipitate like that and ferric hydroxide can mathematically

be shown to be too insoluble to re-enter solution as ferrioxalate. So it must be Fe2Ox3. In the actual synth. of K3FeOx3 oxalate is added to yellow

FeOx, then peroxidised: it turns red/brown. On adding extra oxalic acid eventually the complex forms over an interval of a few seconds.

In your salts comparison, aren’t you comparing sulphate with oxalate? That would be an unfair comparison: we know that because of Nd’s ‘dangling

f-electrons’ Nd salt colours are affected by the type of anion.

Yes, Nd oxalate fires to Nd2O3 (allegedly at about 700 C) and the calcined oxide will dissolve in hot, concentrated sulphuric acid (but not in conc.

HCl, I would think). It just adds another step, that’s all. That’s why I’ll be testing the pot. sulphate double salts idea. I should be back in

the race soon!

Very good question about reacting the Nd(OH)3 with bifluoride. I’ve been pondering that myself. Only the solubility products (Ksp) of both

substances allows to make a judgement. In short, if Ksp,hydroxide > Ksp,fluoride, then conversion should be possible. I have no value for

Ksp,fluoride and was planning on re-dissolving the hydroxide back to chloride first, just to be sure.

Volumes? Blimey, you really are thinking like a chemist now. Sure, when processing larger batches, volumes that need to be processed can be

prohibitively large!

Al cans to alum? I know the text you’re referring to. Works very well. A bit boring though (done it myself). Spice it up by scaling up a bit. Double

salts can be quite interesting.

[Edited on 27-10-2011 by blogfast25]

[Edited on 27-10-2011 by blogfast25]

|

|

|

plante1999

International Hazard

Posts: 1936

Registered: 27-12-2010

Member Is Offline

Mood: Mad as a hatter

|

|

Very nice Synth. of NdF3 here. From wath I read you are planning to reduce it to Nd the element , how are you planning to do that , in wath condition?

I never asked for this.

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by plante1999  | | Very nice Synth. of NdF3 here. From wath I read you are planning to reduce it to Nd the element , how are you planning to do that , in wath condition?

|

Magnesiothermic reduction with magnesium powder:

NdF3 + 3/2 Mg === > Nd + 3/2 MgF2

Very similar to thermite. All thermochemical calculations show that enough heat will be generated to exceed the MP of MgF2 (and of course the MP of

Nd). It's similar to the industrial reduction of UF4 with Mg for the production of metallic uranium.

Aluminothermy (on the oxide) doesn't work here because of the high HoF of Nd2O3. And AlF3 is far too volatille...

|

|

|

MrHomeScientist

International Hazard

Posts: 1806

Registered: 24-10-2010

Location: Flerovium

Member Is Offline

Mood: No Mood

|

|

Blogfast25: Thanks so much for your support! That really brought a smile to my face

Some clarification on two points:

Quote: Originally posted by blogfast25  | | The red precipitate (pict. 3) MUST be ferric oxalate: ferric sulphate is too soluble to precipitate like that and ferric hydroxide can mathematically

be shown to be too insoluble to re-enter solution as ferrioxalate. So it must be Fe2Ox3. In the actual synth. of K3FeOx3 oxalate is added to yellow

FeOx, then peroxidised: it turns red/brown. |

Actually, that picture was taken <i>before</i> adding any oxalic acid. I added the peroxide to the mother solution until it barely tested

positive any more for iron(II), then went to eat dinner, and upon returning it had changed to that brown color. I heated it for a few minutes, and

only then added the oxalic acid. So that photo should only have iron(III) and Nd salts in it.

Quote: Originally posted by blogfast25  | | In your salts comparison, aren’t you comparing sulphate with oxalate? That would be an unfair comparison: we know that because of Nd’s ‘dangling

f-electrons’ Nd salt colours are affected by the type of anion. |

No, those final two pictures are both Nd oxalate. The top vial in both pics is the yield from my post before that one (where I just added oxalic acid

to the mother solution) and the bottom vial is the yield from this last trial. The photo on the left is both samples under fluorescent lighting, and

the photo on the right is under a regular tungsten bulb. The sample on top is undoubtedly contaminated with some yellow iron(II) oxalate, whereas the

one on bottom from this latest trial looks much better.

Quote: Originally posted by blogfast25  | | Very good question about reacting the Nd(OH)3 with bifluoride. I’ve been pondering that myself. Only the solubility products (Ksp) of both

substances allows to make a judgement. In short, if Ksp,hydroxide > Ksp,fluoride, then conversion should be possible. I have no value for

Ksp,fluoride and was planning on re-dissolving the hydroxide back to chloride first, just to be sure. |

That seems like the safest way to me. Even if the hydroxide does directly react, it may be hard to distinguish the two compounds. When I made the

fluoride it looked quite fluffy too, so you may not be able to tell when the reaction is complete.

Quote: Originally posted by blogfast25  | | Al cans to alum? I know the text you’re referring to. Works very well. A bit boring though (done it myself). Spice it up by scaling up a bit. Double

salts can be quite interesting. |

Yeah it was quite simple and is looking great so far. I'm just waiting for my solutions to evaporate down a bit more before collecting the crystals.

I'd never seen it done before so I thought it would be fun to try. I also thought it would be neat to have a big single alum crystal and say it used

to be a soda can! That would boggle the minds of many of my friends

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by MrHomeScientist  |

Actually, that picture was taken <i>before</i> adding any oxalic acid. I added the peroxide to the mother solution until it barely tested

positive any more for iron(II), then went to eat dinner, and upon returning it had changed to that brown color. I heated it for a few minutes, and

only then added the oxalic acid. So that photo should only have iron(III) and Nd salts in it.

No, those final two pictures are both Nd oxalate. The top vial in both pics is the yield from my post before that one (where I just added oxalic acid

to the mother solution) and the bottom vial is the yield from this last trial. The photo on the left is both samples under fluorescent lighting, and

the photo on the right is under a regular tungsten bulb. The sample on top is undoubtedly contaminated with some yellow iron(II) oxalate, whereas the

one on bottom from this latest trial looks much better.

|

Oh well, ‘Bang goes my theory’. The brown solution was essentially strong FeCl3 and on cooling something like a ferri hydroxichloride must have

precipitated, due to high concentration. Presumably aided by the low pH that was then able to get complexed with the oxalate to the trioxaloferrate

anion.

So both photos are Nd2Ox3, huh? Crickey, the second run clearly gives a cleaner product. It’d be great to compare them to a sample obtained with

potassium sulphate as a precipitant. It does also seem to confirm that with an excess Fe the oxalate based method (without complexing) may not have

the right resolution to achieve full separation between these elements.

It might be useful to pool all your samples together for a final purification.

Re. these alum crystals: as long as you know that growing large, near perfect ones is a labour of love!

|

|

|

MrHomeScientist

International Hazard

Posts: 1806

Registered: 24-10-2010

Location: Flerovium

Member Is Offline

Mood: No Mood

|

|

While trying to figure out what exactly Nd2Ox3 decomposes into so I could do some stoichiometry, I came across this interesting little side note at

the end of a short article on neodymium chloride (from 1901, found here ):

| Quote: | | I may finally add that I have been able to isolate the [Nd] metal itself by the action of sodium on the anhydrous chloride. |

That's all the detail he goes into, but it does sound interesting. I know you have the chloride blogfast- got any sodium? The vague word 'action'

makes me wonder what all is actually involved. Making it anhydrous may also be difficult.

Quote: Originally posted by blogfast25  | | Oh well, ‘Bang goes my theory’. The brown solution was essentially strong FeCl3 and on cooling something like a ferri hydroxichloride must have

precipitated, due to high concentration. Presumably aided by the low pH that was then able to get complexed with the oxalate to the trioxaloferrate

anion. |

Remember I used sulfuric acid here, so all that should be in the mother solution at this point is Nd2(SO4)3, Fe(SO4), and Fe2(SO4)3. No chloride

involved!

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Reduction of anh. NdCl3 with sodium is probably possible but you'll get Nd sponge riddled with NaCl: hard to separate because Nd is very reactive.

Also: hard to get a lump of metal, unless you heat the assembly strongly, vacuumed and backfilled with low pressure Ar. Above my paygrade... Anhydrous

NdCl3: heat the hydrate in inert armoshere, mixed intimately with an excess of NH4Cl or heat hydrate in a stream of pure, dry HCl.

For Mn, reduction of the anh. dichloride dissolved in molten KCl with Mg, At the end the crucible is then heated to above the MP of Mn and a puddle of

the metal then forms. Could work for NdCl3 too...

|

|

|

| Pages:

1

2

3

4

5

..

24 |

|