| Pages:

1

2

3 |

azulnaught

Harmless

Posts: 6

Registered: 12-9-2014

Member Is Offline

Mood: No Mood

|

|

Made to order PTFE adapters

Any interest in polytetrafluoroethylene (ptfe/Teflon) adapters/parts?

I've had a difficult time finding adapters to join different size glassware in the past and when I do find what I'm looking for, I'm usually not

satisfied with the price (for glass).

So in effort to remedy the situation (and to help pay for my last few semesters of college) I am currently offering any sizes below 29/42, although I

will entertain any special requests for larger sizes.

Here is an example of a reducing adapter going from 29/42 to 24/40:

The seal is good although a little silicone grease is always encouraged, especially when in the presence of a strong vacuum.

I can also add SAE, metric, NPT, and BSPT threads upon request, recesses for gaskets, additional components, or whatever else you need. Don't hesitate

to ask.

Cheers!

|

|

|

Mr. Rogers

Hazard to Others

Posts: 184

Registered: 30-10-2017

Location: Ammonia Avenue

Member Is Offline

Mood: No Mood

|

|

Let me ask first if you're serious about this --

The reason why I ask, is you're not the first person to post PTFE porn and solicit requests here, and then ultimately disappear or back out of the

proposed project.

If you're willing to do this, I need to adapt 24/40 glass to NPT thread, and I need four adapters. But I need to be dealing with a serious person.

I've done business with a few people here, and they all know *I'm* a serious person, ready to do business.

[Edited on 10-2-2019 by Mr. Rogers]

|

|

|

azulnaught

Harmless

Posts: 6

Registered: 12-9-2014

Member Is Offline

Mood: No Mood

|

|

Serious enough to make a prototype in lieu of studying...

The dirty brass push fittings are all I have on hand in eighth inch. However, the dirt helped show the threads so maybe it wasn't a bad choice.

What size or sizes did you want in NPT? I'll try to add some wrench flats as well. The prototype was just to get the process down.

|

|

|

DavidJR

National Hazard

Posts: 908

Registered: 1-1-2018

Location: Scotland

Member Is Offline

Mood: Tired

|

|

How about rotary seals.....

|

|

|

Mr. Rogers

Hazard to Others

Posts: 184

Registered: 30-10-2017

Location: Ammonia Avenue

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by azulnaught  | Serious enough to make a prototype in lieu of studying...

The dirty brass push fittings are all I have on hand in eighth inch. However, the dirt helped show the threads so maybe it wasn't a bad choice.

What size or sizes did you want in NPT? I'll try to add some wrench flats as well. The prototype was just to get the process down.

|

Cool. Here's the deal. There's a bunch of people here that expressed interest in an adapter that will convert a paint can into a disposable flask.

There's demand here for this, and if you can prototype something, you'll definitely have buyers --

The adapter would look like a female 24/40 joint at the top, and have threads just below this, to insert into a hole in a can lid and secure it with a

nut from beneath the lid.

[Edited on 11-2-2019 by Mr. Rogers]

|

|

|

j_sum1

Administrator

Posts: 6218

Registered: 4-10-2014

Location: Unmoved

Member Is Offline

Mood: Organised

|

|

Quote: Originally posted by Mr. Rogers  |

Cool. Here's the deal. There's a bunch of people here that expressed interest in an adapter that will convert a paint can into a disposable flask.

There's demand here for this, and if you can prototype something, you'll definitely have buyers --

The adapter would look like a female 24/40 joint at the top, and have threads just below this, to insert into a hole in a can lid and secure it with a

nut from beneath the lid. |

Oooh Yes!

I want one!

|

|

|

Heptylene

Hazard to Others

Posts: 319

Registered: 22-10-2016

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Mr. Rogers  | Quote: Originally posted by azulnaught  | Serious enough to make a prototype in lieu of studying...

The dirty brass push fittings are all I have on hand in eighth inch. However, the dirt helped show the threads so maybe it wasn't a bad choice.

What size or sizes did you want in NPT? I'll try to add some wrench flats as well. The prototype was just to get the process down.

|

Cool. Here's the deal. There's a bunch of people here that expressed interest in an adapter that will convert a paint can into a disposable flask.

There's demand here for this, and if you can prototype something, you'll definitely have buyers --

The adapter would look like a female 24/40 joint at the top, and have threads just below this, to insert into a hole in a can lid and secure it with a

nut from beneath the lid.

[Edited on 11-2-2019 by Mr. Rogers] |

I'd add that the thread should be a standard size so that we could connect pipe fittings to glassware too. Pipe fittings can make great high

temperature retorts.

|

|

|

wg48

National Hazard

Posts: 821

Registered: 21-11-2015

Member Is Offline

Mood: No Mood

|

|

azulnaught: I am interested in a 24/40 female to threaded adapter but it will depend on price. Can you give some indication of the price and were you

are so i can estimate the postage. I am in the UK.

Borosilicate glass:

Good temperature resistance and good thermal shock resistance but finite.

For normal, standard service typically 200-230°C, for short-term (minutes) service max 400°C

Maximum thermal shock resistance is 160°C

|

|

|

happyfooddance

National Hazard

Posts: 530

Registered: 9-11-2017

Location: Los Angeles, Ca.

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by j_sum1  | Quote: Originally posted by Mr. Rogers  |

Cool. Here's the deal. There's a bunch of people here that expressed interest in an adapter that will convert a paint can into a disposable flask.

There's demand here for this, and if you can prototype something, you'll definitely have buyers --

The adapter would look like a female 24/40 joint at the top, and have threads just below this, to insert into a hole in a can lid and secure it with a

nut from beneath the lid. |

Oooh Yes!

I want one! |

Lol. We all want one (even though I get by with teflon tape)!

azulnaught: check out this thread if you haven't already, and especially the post from markx at the bottom of the first page.

[Edited on 2-12-2019 by happyfooddance]

|

|

|

azulnaught

Harmless

Posts: 6

Registered: 12-9-2014

Member Is Offline

Mood: No Mood

|

|

DavidJR:

What type? For a rotary evaporator, a motor, or rotary vane vacuum pump?

Heptylene:

'Standard' is a little ambiguous as it depends upon your geographical location which may differ from mine (U.S.). Did you have a specific size in mind

or a picture of what you would like to connect?

wg48:

$30 plus shipping for 24/40 with internal threads. If you or anyone else wants multiple then the price will be less per unit. I see your location is

set as Scotland - I'm unfamiliar with the pipe threading standards for each country but I'm assuming it is British Standard Pipe Thread Tapered (BSPT)

for most countries outside the U.S. Not an issue, I just want to make sure that what I send will be compatible with your locally available materials.

For those interested in the paint can lid attachment:

I will gladly start working on this project although it will take a little time to complete as my only real free time to play is late nights and on

weekends.

|

|

|

happyfooddance

National Hazard

Posts: 530

Registered: 9-11-2017

Location: Los Angeles, Ca.

Member Is Offline

Mood: No Mood

|

|

My bad, I meant to link this thread in my previous post: http://www.sciencemadness.org/talk/viewthread.php?tid=100197

|

|

|

DavidJR

National Hazard

Posts: 908

Registered: 1-1-2018

Location: Scotland

Member Is Offline

Mood: Tired

|

|

I would also possibly be interested in a paint can to glassware adapter of some description.

I mean for a rotary evaporator. I have DIY-ed a rotovap using an off-the-shelf PTFE stirrer bearing and fluoropolymer tubing, but it's not ideal.

See here: https://www.youtube.com/watch?v=MGEMQTo0t2g

I think what I want would have a 24/29 cone and a smallish spherical ball joint thing, which would form the vacuum seal against a standard glass

spherical socket. I'd 3d-print some sort of bracket to hold the glass tubing with the socket pressed against the ptfe ball joint.

Or maybe it'd be better to have both mating surfaces be PTFE to take advantage of the low coefficient of friction. I'm not sure what the best way to

do this is.

[Edited on 13-2-2019 by DavidJR]

[Edited on 13-2-2019 by DavidJR]

|

|

|

wg48temp9

National Hazard

Posts: 761

Registered: 30-12-2018

Location: not so United Kingdom

Member Is Offline

|

|

Quote: Originally posted by azulnaught  |

wg48:

$30 plus shipping for 24/40 with internal threads. If you or anyone else wants multiple then the price will be less per unit. I see your location is

set as Scotland - I'm unfamiliar with the pipe threading standards for each country but I'm assuming it is British Standard Pipe Thread Tapered (BSPT)

for most countries outside the U.S. Not an issue, I just want to make sure that what I send will be compatible with your locally available materials.

For those interested in the paint can lid attachment:

I will gladly start working on this project although it will take a little time to complete as my only real free time to play is late nights and on

weekends. |

Azulnaught: Thanks for the reply. Sorry that price and shipping is too high for me but thanks for the offer.

[Edited on 13-2-2019 by wg48temp9]

I am wg48 but not on my usual pc hence the temp handle.

Thank goodness for Fleming and the fungi.

Old codger' lives matters, wear a mask and help save them.

Be aware of demagoguery, keep your frontal lobes fully engaged.

I don't know who invented mRNA vaccines but they should get a fancy medal and I hope they made a shed load of money from it.

|

|

|

Mr. Rogers

Hazard to Others

Posts: 184

Registered: 30-10-2017

Location: Ammonia Avenue

Member Is Offline

Mood: No Mood

|

|

What's the status on the adapters? I want four.

|

|

|

azulnaught

Harmless

Posts: 6

Registered: 12-9-2014

Member Is Offline

Mood: No Mood

|

|

Mr. Rogers:

What size pipe (NPT) threading do you require for the adapters? 1/8" and 1/4" will work without any modification. It would need to be a little longer

than what is pictured above for 1/2" female threads. Let me know so I can get these finished for you. All 24/40 joints correct?

|

|

|

azulnaught

Harmless

Posts: 6

Registered: 12-9-2014

Member Is Offline

Mood: No Mood

|

|

DavidJR:

Your rotatory evaporator looks good. I can't tell from the video but what are the dimensions (or joint size) of the 3-way adapter you are using and of

the straight glass tubing that is rotating? I'm thinking that two pieces, one on the receiving end of the 3-way adapter and one connected to the

turning glass tubing would be the easiest way to solve the problem.

It seems to have a decent flow rate though, even with your current set up. Lithium grease is a decent lubricant for PLA parts which might help cut

down on noise some if it's not already lubricated in some manner.

|

|

|

Loptr

International Hazard

Posts: 1347

Registered: 20-5-2014

Location: USA

Member Is Offline

Mood: Grateful

|

|

I would also be interested in a paint can adaptor.

"Question everything generally thought to be obvious." - Dieter Rams

|

|

|

DavidJR

National Hazard

Posts: 908

Registered: 1-1-2018

Location: Scotland

Member Is Offline

Mood: Tired

|

|

Quote: Originally posted by azulnaught  | DavidJR:

Your rotatory evaporator looks good. I can't tell from the video but what are the dimensions (or joint size) of the 3-way adapter you are using and of

the straight glass tubing that is rotating? I'm thinking that two pieces, one on the receiving end of the 3-way adapter and one connected to the

turning glass tubing would be the easiest way to solve the problem.

It seems to have a decent flow rate though, even with your current set up. Lithium grease is a decent lubricant for PLA parts which might help cut

down on noise some if it's not already lubricated in some manner. |

All of the joints are 24/29.

For now, I have stopped using that weird 3 way adapter and replaced it with a different adapter, which is a straight tube with a cone and socket, and

a hose barb on the side. A short piece of PVC tubing goes over the hose barb and over the fluoropolymer tubing.

The stirrer bearings have an O ring that gets compressed against the 7mm tubing. It has chewed up a couple of O-rings though, even though i tried

putting a bit of grease on them. I think the issue is that the tubing is not actually PTFE and instead is some other polymer which has a significantly

higher coefficient of friction. I actually just received some actual PTFE tubing to try, but unfortunately I can't because the spinning glass tube

part cracked while in use...

|

|

|

Mr. Rogers

Hazard to Others

Posts: 184

Registered: 30-10-2017

Location: Ammonia Avenue

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by azulnaught  | Mr. Rogers:

What size pipe (NPT) threading do you require for the adapters? 1/8" and 1/4" will work without any modification. It would need to be a little longer

than what is pictured above for 1/2" female threads. Let me know so I can get these finished for you. All 24/40 joints correct?

|

I'm agnostic WRT to the NPT size, as long as the top portion is a standard joint size like 24/40 or 24/29. Other people want to adapt jointed

glassware to pipe fittings. If you make the adapter like this, you can potentially satisfy the needs to of two audiences. I'm in the "paint can"

category.

|

|

|

Mr. Rogers

Hazard to Others

Posts: 184

Registered: 30-10-2017

Location: Ammonia Avenue

Member Is Offline

Mood: No Mood

|

|

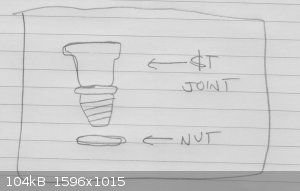

Here's my high-tech diagram I did in AutoCAD. The "nut" should be a standard metric 6-point size. It would probably end up at around 19mm given the

24mm size of the top portion.

[Edited on 26-2-2019 by Mr. Rogers]

|

|

|

draculic acid69

International Hazard

Posts: 1371

Registered: 2-8-2018

Member Is Offline

|

|

If you could fabricate a fitting/stopcock that turns a coke bottle into a separatory funnel that would be something I've been dreaming about for 20

years.ive come close to this by drilling a hole thru the lid and screwing in a 4mm inline tap valve.it works great except chloroform dissolves the

plastic tap.xylene ethyl acetate and toluene were fine but chloroform is a no-go.an all teflon piece would be the holy grail of turning a coke bottle

into a separate funnel.

Also another bottle idea is to have a dreschel attachment made that would turn any glass lemonade bottle into a gas wash/scrubber bottle.

If either of these are possible I'll definitely buy some.

[Edited on 27-2-2019 by draculic acid69]

|

|

|

andy1988

Hazard to Others

Posts: 135

Registered: 11-2-2018

Location: NW Americus ([i]in re[/i] Amerigo Vespucci)

Member Is Offline

Mood: No Mood

|

|

azulnaught: In the distant future I'm interested in some custom FEP, PTFE, & PEEK parts for a contraption in a paper, but I need to work through

some other stuff first. I hope you are enjoying your courses!

Quote: Originally posted by DavidJR  |

For now, I have stopped using that weird 3 way adapter and replaced it with a different adapter, which is a straight tube with a cone and socket, and

a hose barb on the side. A short piece of PVC tubing goes over the hose barb and over the fluoropolymer tubing.

The stirrer bearings have an O ring that gets compressed against the 7mm tubing. It has chewed up a couple of O-rings though, even though i tried

putting a bit of grease on them. I think the issue is that the tubing is not actually PTFE and instead is some other polymer which has a significantly

higher coefficient of friction. I actually just received some actual PTFE tubing to try, but unfortunately I can't because the spinning glass tube

part cracked while in use...

|

DavidJR did you see this rotovap design? Uses a PTFE Standard Stopper, but the threads filed down and a channel dug for the o-ring. And a high torque motor to

"overcome the friction the vacuum puts on the rotary joint". What do you think of it?

[Edited on 27-2-2019 by andy1988]

|

|

|

draculic acid69

International Hazard

Posts: 1371

Registered: 2-8-2018

Member Is Offline

|

|

Azalnaught could you replicate this in teflon?

It is a 4mm inline tap valve for aquarium /garden irrigation.

it does not need to be as small but under 1cm wide for the threads.

Can this be done?

[Edited on 27-2-2019 by draculic acid69]

[Edited on 27-2-2019 by draculic acid69]

|

|

|

DavidJR

National Hazard

Posts: 908

Registered: 1-1-2018

Location: Scotland

Member Is Offline

Mood: Tired

|

|

Quote: Originally posted by andy1988  |

DavidJR did you see this rotovap design? Uses a PTFE Standard Stopper, but the threads filed down and a channel dug for the o-ring. And a high torque motor to

"overcome the friction the vacuum puts on the rotary joint". What do you think of it?

|

Yes, I have seen that. I'm concerned about gluing a tube into PTFE as PTFE is nearly ungluable. I also thought that maybe an unmodified stirrer

bearing could work given that it's designed to seal onto a PTFE shaft - you just need a PTFE tube instead. Like i said, I've got some real PTFE tubing

to replace the not-PTFE tubing which should hopefully work better. But i'm waiting on a replacement glass tube thing since it broke.

The motor i'm using is capable of a fairly decent torque.

|

|

|

Mr. Rogers

Hazard to Others

Posts: 184

Registered: 30-10-2017

Location: Ammonia Avenue

Member Is Offline

Mood: No Mood

|

|

Still want this, and I like the Sep funnel adapter idea too.

Someone do this -- there's a ready-made audience here.

|

|

|

| Pages:

1

2

3 |