| Pages:

1

..

39

40

41

42

43

..

66 |

Wizzard

Hazard to Others

Posts: 337

Registered: 22-3-2010

Member Is Offline

Mood: No Mood

|

|

Preliminary on extracting and isolating T-Butyl alcohol from Turbo 108 gasoline additive:

1. Dump contents into large vessel, Let sit for a day or two, the brown muck will settle out. Decant the remaining liquid, then filter it. Dispose of

the brown stuff.

2. Mix liquid with equal parts distilled water. Let sit for 2 hours at RT. 2 layers will form- Clear, and amber (water and alcohols on bottom,

oils/everything else on top)

3. Freeze. The bottom layer will freeze.

4. Pour off the oils, wash the solid ice. You may see some brown muck on top of the ice, and maybe a thin layer of oil below the ice. Dispose of them.

5. Thaw the ice in a clean vessel. Add sodium sulfate as needed- Dry those alcohols! Filter.

6. Partial freezing- Throw clean, thawed alcohols back in the freezer, wait for for some of it to freeze. If you can watch it, it will "snow", then

pause, then the entirety will freeze. Take it out just after it 'snow's. You will have a liquid, and a slush.

7. Put the vessel in the fridge. It will remain as such- Stir, shake, and let it settle. Put it back in the freezer, briefly.

8. Repeat #7. Decant, keep the solids.

This what I have- A very different smelling alcohol, solid so long as it remains in the fridge. My work area is ~28*C now, quite hot! I will be

testing with potassium chromate, and zinc chloride+HCl. My batch was 1/3 of one container, the water and alcohol mix is approximately 50mL. I have a

larger mix processing right now.

I believe I have some great extraction here- Going my TLAR melting point, the smell, and crystal structure!

[Edited on 6-21-2012 by Wizzard]

[Edited on 6-21-2012 by Wizzard]

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Lookin' good.

Remind me again: what;s the point to the sodium nitrate? Salting?

|

|

|

Wizzard

Hazard to Others

Posts: 337

Registered: 22-3-2010

Member Is Offline

Mood: No Mood

|

|

Oh, no, I meant sulfate! It is highly water soluble, and not soluble in alcohols.

And further note- I think my magnesium is the problem... Second batch failed, looks the same as the first batch- White material at the bottom, cloudy

kerosene, no magnesium metal present (or potassium, for that matter).

[Edited on 6-21-2012 by Wizzard]

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

No magnesium present? That sounds impossible. It's gotta go SOMEWHERE

|

|

|

Wizzard

Hazard to Others

Posts: 337

Registered: 22-3-2010

Member Is Offline

Mood: No Mood

|

|

My first experiment turned to brown/amber mess. It's since separeted into a few layers- I guess I will do some analysis. I was using pure (maybe

oxidized??) Mg balls of approx 1mm. The slurry is white, the oils clouded with white, but amber/brown (caused by impurity breakdown in the baby oil).

The kerosene mix is quite clearer, I'll start with analysis of that. I'm using about 30mL of kerosene.

|

|

|

AndersHoveland

Hazard to Other Members, due to repeated speculation and posting of untested highly dangerous procedures!

Posts: 1986

Registered: 2-3-2011

Member Is Offline

Mood: No Mood

|

|

It would be interesting to try to reduce sodium fluoride with aluminum.

4 NaF + Al --> NaAlF4 + 3 Na

I do not think more aluminum could further reduce the NaAlF4

"It will be noted that when aluminum fluoride is in excess to that contained in cryolite (NaF)6Al2F6, aluminum does not reduce sodium fluoride, and on

the other hand, when sodium fluoride is in excess, aluminum does reduce sodium fluoride."

Metallurgical and Chemical engineering, Volume 11, p178 (1913)

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

NaF + 1/3 Al < === > Na + 1/3 AlF3 has an Enthalpy of Reaction (left to right) of ≈ 0.

This would require high temperature and part vacuum/part Argon to distil off the sodium and pull the equilibrium to the right. Molten fluorides:

whooopeyyy!

It’s also highly off-topic.

|

|

|

Mailinmypocket

International Hazard

Posts: 1351

Registered: 12-5-2011

Member Is Offline

Mood: No Mood

|

|

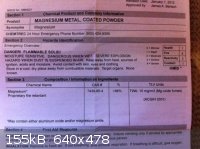

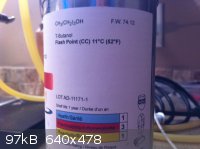

Feeling screwed on Mg

I wanted to try this reaction and ordered some fine Mg and t-butanol...

When I bought the Mg is said nothing about fire retardants...

Take a look at the container...and then look at the MSDS! It seems like they add aluminum and magnesium oxides for fire retardant properties?

I am pissed off that this was not mentioned by the company... Will this work right off the bat for this reaction or should I grind it to expose fresh

surfaces?

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Mailinmypocket  | I wanted to try this reaction and ordered some fine Mg and t-butanol...

When I bought the Mg is said nothing about fire retardants...

Take a look at the container...and then look at the MSDS! It seems like they add aluminum and magnesium oxides for fire retardant properties?

I am pissed off that this was not mentioned by the company... Will this work right off the bat for this reaction or should I grind it to expose fresh

surfaces?

|

Were it says 'coated', that's bad news for this reaction. I would try and get a refund. I bet that stuff wasn't cheap eather, huh?

Removing that coating would be difficult, I think...

|

|

|

plante1999

International Hazard

Posts: 1936

Registered: 27-12-2010

Member Is Offline

Mood: Mad as a hatter

|

|

Iodine in chloroform is commonly used for magnesium activation. I also saw mercuric chloride. But I would use iodine if it was me, immediately use the

Mg after activation. It should work well.

I never asked for this.

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Personally I would put the chances of success somewhat lower. But it's worth a try I guess.

Of course once you've broken into the bottle of Mg and assuming the activation doesn't work, you can kiss goodbye to a refund. Considering problems

with the Mg powder have been common in this thread I wouldn't chance it and would try to source a cleaner grade instead. Decisions, decisions...

Also, we cant a priory exclude the possibility that the stuff might work as such. Certainly if you're gonna keep it try it as it is and see what

happens...

[Edited on 15-9-2012 by blogfast25]

|

|

|

watson.fawkes

International Hazard

Posts: 2793

Registered: 16-8-2008

Member Is Offline

Mood: No Mood

|

|

A fresh

grind should do a lot to ensure reactivity. But since you're going to put the Mg straight into a high-boiling solvent, just grind it in that solvent.

This is straightforward in a ball mill; I don't know what gear you're using. Grinding in solvent helps to exclude oxygen (but doesn't eliminate it),

and greatly reduces any tendency for freshly-ground Mg to become pyrophoric. It's also possible that the coating is actually soluble in the solvent,

in which case you get a double bonus.

|

|

|

Mailinmypocket

International Hazard

Posts: 1351

Registered: 12-5-2011

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by blogfast25  |

Personally I would put the chances of success somewhat lower. But it's worth a try I guess.

Of course once you've broken into the bottle of Mg and assuming the activation doesn't work, you can kiss goodbye to a refund. Considering problems

with the Mg powder have been common in this thread I wouldn't chance it and would try to source a cleaner grade instead. Decisions, decisions...

Also, we cant a priory exclude the possibility that the stuff might work as such. Certainly if you're gonna keep it try it as it is and see what

happens...

[Edited on 15-9-2012 by blogfast25] |

The Mg was 15$, not a huge loss... I just threw it in the order seeing as I was buying t-BuOH anyways.

I performed two experiments, neither of which ending in balls of K.

The solvent I am using is the hypoallergenic baby oil (paraffin) which has been reported to work but I havent been so lucky.

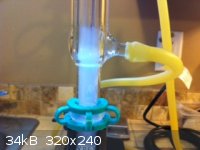

The first experiment I did was using the same setup as Pok, flask in a sandbath at 220c, for four hours. The oil was heated and at first there was

some frothy bubbling (first picture), which subsided once the temp hit 150c or so.. No t-BuOH was added until it reached 200c. I used the timed

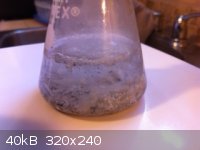

addition, after four hours of boiling there was no sign of K, and no tell tale signs of it when the residuie was added to water (second picture).

I thought that I was maybe losing the alcohol through the glass tube condenser, and decided to instead try again using a proper water cooled

condenser.

The second attempt was to be heated to the same temp, for the same amount of time, with the same timed addition of t-BuOH. After the very first

addition I saw very small silver dots bobbing around and was overjoyed that it was apparently working! (third picture, hard to see) Once all the

t-BuOH was added the K dots disappeared. I wanted to heat for 4 hours but after 3 hours a white "gel-like" material formed a layer on top of the oil,

it got thicker and thicker so I shut it down.

When I added some of the slag to water though, there were sparks and lilac flames, albeit very small.

Now I am going to try a third time... I am not sure how to go about it though. I think having a proper condenser contributed to my semi success the

second time around, but why there was no coalescence and why the K disappeared midway through is unknown to me. If there was too much t-BuOH the K

would have just stayed in solution as the butoxide, is it possible there was not enough? The reagents used were as follows:

KOH flakes 5g

Mg, fine granules, ground in mortar, 2.4g

t-BuOH 1ml (timed addition)

Could it be the solvent? I know the t-BuOH is pure and good quality(... I wish i had some Shellsol to try, i went to a local art store and picked up

some "odour-free solvent" which contains petroleum distillates, and I can't find an MSDS anywhere. I will test its bp and see if it might fit the

bill.

I also want to try the "one pot" method as mentioned by Blogfast, I am off to try that now and will report back on the results tonight.

[Edited on 15-9-2012 by Mailinmypocket]

***Edit*** Ok, so it has been going for almost 45 minutes, and the oil is somewhat foggy. Previously, the oil stayed clear the whole time and did not

bubble as much. No sign of frothy bubbles during heating up as seen in both previous attempts before the t-BuOH was added. There is no sign of K yet.

The one pot reaction using paraffin oil failed...

So, after heating at 200-220c for four hours, no sign of K

One difference I noticed is that there was no frothing up of the oil during the initial heat-up. It started boiling and producing heavy white mist

which quickly condensed and fell back into the flask, but no froth. After this period it was allowed to boil for about 2 hours, at which point that

white material appeared and started to coat the mg and KOH.

During the last 45 minutes I decided to add a couple very small shaving of fresh mg shaved off an ingot via the top of the condenser. They were very

shiny and clean, added immediately. They gradually darked to almost black as shown in the photo within 15 minutes.

The setup, after injecting 1 ml t-BuOH and getting ready to start heating:

At about 150c the boiling began...

This time there was a white fog that went about 2 inches up the condenser and seemingly was condensing and falling back in. Water? t-BuOH? I didn't

get white fog during both timed additions of the alcohol in previous tries

These pictures taken at 2 hours and 3 hours, respectively, show no formation of K.

[Edited on 15-9-2012 by Mailinmypocket]

[Edited on 15-9-2012 by Mailinmypocket]

[Edited on 16-9-2012 by Mailinmypocket]

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Mailinmypocket:

Very nice write up, thank you.

A few comments. I’m now much inclined to blame the Mg, as you seem to have done everything right and did obtain very small amounts of K. Reported

problems with the magnesium run through this thread like streaks through marble… even though I have some trouble understanding why the coating in

your case appears to be so resistant.

Re. the solvent, Shellsol D isn’t needed: it’s really nothing more than deodorised kerosene (which is what I use). But hypoallergenic baby oil

should work too.

The ‘one pot’ method is unlikely to succeed where the timed addition fails: I didn’t develop this because I thought it would perform

better but because I thought it should work just as well (but easier to execute). Still, it was worth a try.

Since as your set up is very fit for purpose it would be a shame to abandon it now. I see two main possibilities to take it further:

• Change to an uncoated Mg grade

• Try ‘activating’ the current Mg’s surface

I wonder if washing with very dilute HCl (say, 0.01 M) would work. Expose the powder to a small amount of 0.01 M HCl until you get clear reaction (H2

development), then drop everything into alcohol (denaturated ethanol or IPA), then wash metal with clean alcohol to remove traces of acid and dry at

RT. Surely an Mg powder that reacts with very dilute HCl should be suitable for this reaction?

|

|

|

Mailinmypocket

International Hazard

Posts: 1351

Registered: 12-5-2011

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by blogfast25  | Mailinmypocket:

Very nice write up, thank you.

A few comments. I’m now much inclined to blame the Mg, as you seem to have done everything right and did obtain very small amounts of K. Reported

problems with the magnesium run through this thread like streaks through marble… even though I have some trouble understanding why the coating in

your case appears to be so resistant.

Re. the solvent, Shellsol D isn’t needed: it’s really nothing more than deodorised kerosene (which is what I use). But hypoallergenic baby oil

should work too.

The ‘one pot’ method is unlikely to succeed where the timed addition fails: I didn’t develop this because I thought it would perform

better but because I thought it should work just as well (but easier to execute). Still, it was worth a try.

Since as your set up is very fit for purpose it would be a shame to abandon it now. I see two main possibilities to take it further:

• Change to an uncoated Mg grade

• Try ‘activating’ the current Mg’s surface

I wonder if washing with very dilute HCl (say, 0.01 M) would work. Expose the powder to a small amount of 0.01 M HCl until you get clear reaction (H2

development), then drop everything into alcohol (denaturated ethanol or IPA), then wash metal with clean alcohol to remove traces of acid and dry at

RT. Surely an Mg powder that reacts with very dilute HCl should be suitable for this reaction?

|

Thanks! I very much think it is this ridiculous Mg that is the cause of my foul language during the experiments  Perhaps next time I need to order chemicals from them I will ask if they have non-corrosive H2SO4, unreactive sodium

or non flammable CS2. Perhaps next time I need to order chemicals from them I will ask if they have non-corrosive H2SO4, unreactive sodium

or non flammable CS2.

Ive put too much time and energy into this project so it will be a cold day in hell when I give up! I tried activating a small amount of the Mg as per

your suggestion and it seemed to work, the only problem is that the Mg floats and sticks to everything and causes even more annoyance. I tried with

about .1g and got irritated so imagine with ~3g... It does clean it up nicely though.

I remembered a very old Mg firestarter ingot that I have had kicking around for at least 10 years, so out came the drill...

I drilled away at it while having my morning coffee... Very shiny fresh Mg! No random Al/Ca/Mg oxides on those surfaces  (except the outside of the ingot but thats minute) (except the outside of the ingot but thats minute)

Finally, 3 grams of fine turnings, ready to go. I need to do Sunday errands before coming back home and trying this again while enjoying a couple

beers. To minimize any possible oxidation from occurring in the meantime I stored the turnings in a glass bottle, flushed with argon and sealed. Argon

might be overkill for short term storage but I''m trying to rule out all possible sources of failure.

I will report back on the outcome later today!

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

To be fair, that Mg of yours would probably work well in high temperature magnesiothermic reactions.

Yes, floating, I should have thought of that. ‘Cleaning up’ magnesium powder was never going to be that easy.

As regards turnings, it seems mixed results have been obtained with those, so we’ll have to wait and see. Reaction speed should be lower than with

powder. But in my experience these experiments don’t take up to 4 hours because of low reaction speed but because of low speed of potassium

coalescence. A measurement of hydrogen evolution over time I did showed the reduction to have tailed off almost completely after 1 – 1 ½ hour. So

powder/turnings may not make much difference in the grander scheme of things.

|

|

|

Mailinmypocket

International Hazard

Posts: 1351

Registered: 12-5-2011

Member Is Offline

Mood: No Mood

|

|

Well, no luck again! The turnings were very fine, and turned black by the end... But no K after 4 hours. During the whole time I would check every 15

mins but never saw any formation of it. The slag on the bottom was much easier to break apart than previous attempts but showed no water reactivity.

I'll try again as soon as I get the chance and change the Mg once again. I am also maybe going to try some regular kerosene.

The magnesium shavings

Increasing the heat, here at about 160c

After 2.5 hours

After almost 4 hours, getting ready to shut down. Nothing

[Edited on 17-9-2012 by Mailinmypocket]

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Well, I'm lost for words. So many attempts w/o any K: bizarre. When it comes to the magnesium we're overlooking something I think but what???

|

|

|

Mailinmypocket

International Hazard

Posts: 1351

Registered: 12-5-2011

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by blogfast25  | | Well, I'm lost for words. So many attempts w/o any K: bizarre. When it comes to the magnesium we're overlooking something I think but what???

|

I have no clue, it's sort of fun to figure out whats wrong though - the reagents are cheap and the synthesis doesn't require all that much attention,

so it doesn't pain me to do several more runs.

I can rule out that the set up itself is good, the t-BuOH is high quality and I did get evidence of elemental K once which means the coated Mg must

work to some extent.

This leaves me with one question: Is it the Mg or is it the solvent? I know this liquid paraffin baby oil has been said to work, but how well? I've

read this whole topic but aside from Nurdrage mentioning it works, nobody seems to have specified how well it works and how consistent the results

are...

If anyone has tried with this baby oil, have they had problems? How successful were the results? Was the coalescence good or just okay?

Otherwise I am inclined to think that the Mg is to blame, but seeing as the oil is the only variable that has not changed during this whole time I'm

wondering if it is the culprit somehow. I don't want to go and order some expensive reagent grade Mg if it isn't absolutely the cause of my problems!

More experiments are in order, that's for sure. I think I will try pure kerosene this week and see where that takes me with both the purchased Mg and

the freshly shaved Mg.

If that doesn't work I am going to try cleaning and activating the Mg with the procedure you suggested as it did produce clean magnesium. To avoid the

"floating problems" I encountered during a test I will put the Mg powder into a loose leaf tea steeper and dunk that under some dilute HCl. That way

it wont float everywhere and can be cleaned by shaking it around under some ethanol.

That is a last resort attempt but might be worth trying, fun times!

[Edited on 17-9-2012 by Mailinmypocket]

|

|

|

watson.fawkes

International Hazard

Posts: 2793

Registered: 16-8-2008

Member Is Offline

Mood: No Mood

|

|

It's clear (to me, at least) that the geometric arrangement of the solid reagents is critical to the success of the reaction. The initial failure to

make this reaction work used stirring, and nothing happened. After following this thread since Pok first reported success, it seems to me one of the

necessary elements is intimate solid-solid contact between KOH and Mg. To maximize this contact, both reagents should have reasonably high surface

area and be intimately mixed together. On the other hand, t-butanol needs to be able to flow into the interstices between reagents, so very fine

powders don't work as well. Relying upon diffusion alone leads to a low reaction rate. I don't recall if anyone has tried it, but a schedule of

shaking for a few seconds every few minutes would seem to balance mixing t-butanol with the solvent with close contact of the solid reagents.

Another technique would be to use a thistle tube under the condenser to introduce the t-butanol reflux underneath the solid reagents. When the

condensate falls on the top surface of the solvent, it would seem not to penetrate very far into the solid charge below before it evaporates again.

Reflux of t-butanol is only going to be useful if it comes into contact with the solids during its reflux cycle. Perhaps using just enough solvent to

cover the solid charge would be adequate.

Passivisation of the Mg seems also to be an issue. Dehydrating the KOH in hot solvent before adding the other reagents would seem to be beneficial.

As for mechanism, it seems that there's some kind of short-range intermediary at play. I don't know what causes the short range. A combination of

short lifetime and low diffusion speed would cause this effect. There might be other mechanisms to consider.

|

|

|

Mailinmypocket

International Hazard

Posts: 1351

Registered: 12-5-2011

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by watson.fawkes  | It's clear (to me, at least) that the geometric arrangement of the solid reagents is critical to the success of the reaction. The initial failure to

make this reaction work used stirring, and nothing happened. After following this thread since Pok first reported success, it seems to me one of the

necessary elements is intimate solid-solid contact between KOH and Mg. To maximize this contact, both reagents should have reasonably high surface

area and be intimately mixed together. On the other hand, t-butanol needs to be able to flow into the interstices between reagents, so very fine

powders don't work as well. Relying upon diffusion alone leads to a low reaction rate. I don't recall if anyone has tried it, but a schedule of

shaking for a few seconds every few minutes would seem to balance mixing t-butanol with the solvent with close contact of the solid reagents.

Another technique would be to use a thistle tube under the condenser to introduce the t-butanol reflux underneath the solid reagents. When the

condensate falls on the top surface of the solvent, it would seem not to penetrate very far into the solid charge below before it evaporates again.

Reflux of t-butanol is only going to be useful if it comes into contact with the solids during its reflux cycle. Perhaps using just enough solvent to

cover the solid charge would be adequate.

Passivisation of the Mg seems also to be an issue. Dehydrating the KOH in hot solvent before adding the other reagents would seem to be beneficial.

As for mechanism, it seems that there's some kind of short-range intermediary at play. I don't know what causes the short range. A combination of

short lifetime and low diffusion speed would cause this effect. There might be other mechanisms to consider. |

After my most recent attempt I think this may be my problem! I was getting frudtrated with the baby oil making a waxy "skin" and foam on top of the

mixture after an hour or so and it's viscosity seemed to increase as time went on. I started looking for a new solvent and found some odorless

paraffin based lamp oil. It is much less viscous and I think I got the first signs of K balls!

I tried again, using the HCl activation of the Mg granules as suggested above by Blogfast. The solvent had no initial frothing as with the baby oil

and I saw the beginnings of what i am sure was K particles as I have never seen small globules dancing around in the solvent.

I used the timed addition of t-BuOH and after the first addition is when the suspected K appeared, as I continued to add the alcohol they disappeared

and the Mg went darker and bubbling slowed right down.

I am now thinking that the Mg is passivating earlier on and the continued addition of t-BuOH is turning any existing K into the butoxide as the Mg is

not available to react with it.

I will try, yet again today, but instead I will dehydrate the KOH under the oil first. Then I will let it cool down to RT, add some freshly activated

Mg and mix it in well, and then run the reaction.

After the first addition of t-BuOH, the Mg still has a silvery appearance.

A close up of the above photo shows the small particles that appeared.

After all the t-BuOH was added you can see the Mg is dark and there are no particles whatsoever in the solvent. The slag did not react with water

whatsoever either.

|

|

|

elementcollector1

International Hazard

Posts: 2684

Registered: 28-12-2011

Location: The Known Universe

Member Is Offline

Mood: Molten

|

|

I noticed someone ordered tetralin a while up. What was your source?

Elements Collected:52/87

Latest Acquired: Cl

Next in Line: Nd

|

|

|

Mailinmypocket

International Hazard

Posts: 1351

Registered: 12-5-2011

Member Is Offline

Mood: No Mood

|

|

I wasn't the person in question but I did purchase some a few years back from Cole-Parmer.

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

According to 'nurdrage' tetralin is by far the best reaction medium. For one, the K floats in it, thereby greatly facilitating coalescence. IIRW, his

total reaction time with tetralin was only about 1 hour. He's the one who ordered and used it. Very hard to obtain for private individuals and quite

expensive too.

[Edited on 21-9-2012 by blogfast25]

|

|

|

elementcollector1

International Hazard

Posts: 2684

Registered: 28-12-2011

Location: The Known Universe

Member Is Offline

Mood: Molten

|

|

Well, I had emailed an Instructables contributor some time ago (over a year) about the synthesis of tetralin he mentioned on NurdRage's potassium

metal page on Instructables. To my surprise, he replied a few days ago, sharing this:

| Quote: | High molecular weight hydrocarbons like decane are often available as fuels, for example, C14-C16 are available as some varieties of "lamp fuel"; -

slightly lower hydrocarbons are found in "stove fuels"; -- you have to look at a brand, then find the msds.

To make tetralin, one uses one mol of naphthalene to about 1/2 mol of sodium metal. The first ring reduces much faster than the second ring, unless

you use a catalyst like platinum. You will need about two mols of ethanol in the mixture. Add the naphthalene and bring to reflux. Add the sodium

metal slowly (and carefully, it's flammable as are the ethanol, hydrogen, and products) and don't add more sodium until the first portion has reacted.

Wash the result with water, this gets rid of the sodium hydroxide and ethanol, then fractionally distill. The boiling points are far enough apart

that the separation is fairly easy. |

Ironically, one needs sodium metal to make this, but it's well worth it for this useful solvent from a fairly simple procedure of reflux and

fractional distillation. (Okay, maybe not "fairly simple" for the home chemist, but still, better than nothing.)

Elements Collected:52/87

Latest Acquired: Cl

Next in Line: Nd

|

|

|

| Pages:

1

..

39

40

41

42

43

..

66 |