smaerd

International Hazard

Posts: 1262

Registered: 23-1-2010

Member Is Offline

Mood: hmm...

|

|

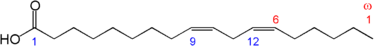

Linoleic Acid -> ... -> Hexanal

I need some help here, so I put this in beginnings instead of organics. I'm not too seasoned with organic chem(seasoned get it har har food chem...).

The goal here is to synthesize/obtain hexanal from oxidation of linoleic acid.

Here is what I do know  . Triglycerides -> hydroperoxides -> short chain

aldehydes via oxidation. {http://www.separationsnow.com/coi/cda/detail.cda?chId=1&id=16241&type=Feature&page=1} . Triglycerides -> hydroperoxides -> short chain

aldehydes via oxidation. {http://www.separationsnow.com/coi/cda/detail.cda?chId=1&id=16241&type=Feature&page=1}

Linoleic acid comprises of ~68% of sunflower oil, or for a more common cooking oil ~21% of canola oil.{http://en.wikipedia.org/wiki/Linoleic_acid}

Simple enough to obtain, possibly hydrolyze, vac distill, or purchase without issue.

(the last link provided in this threads supplies theoretical rxn schemes and lots of information I can't quite all piece together).

Now to the real 'meat' of the issue. I'm trying to understand the entire scope of what is going on here. So as to hopefully obtain a usable quantity

of hexanal. So it goes(correct me if I am understanding this wrong)

1. Linoleic Acid -> 9-hydroperoxides + 13-hydroperoxides via autoxidation

2. 13-hydroperoxide -> hexanal via retroaldolization

3. 9-hydroperoxide -> 2,4-decadienal via retroaldolization

4. 2,4-decadienal -> 2-octenal, hexanal via retroaldolization

{Page 75: Meat science and applications By Y. H. Hui, Yiu H. Hui.

http://books.google.com/books?id=651Zv5hUzyIC&pg=PA75&lpg=PA75&dq=triglyceride+oxidation+hexanal&source=bl&ots=uQQR3uM0dw&sig=

wPj7soKAqym2VjE2i_kR6iy91fw&hl=en&ei=__woTaabCcXflgfYobXpAQ&sa=X&oi=book_result&ct=result&resnum=1&ved=0CBMQ6AEwAA#v=onepa

ge&q=triglyceride%20oxidation%20hexanal&f=false}

so to elaborate further on the actual experimental(here's where I need help).

1. Linoleic acid autoxidation, could occur simply by letting it sit for a few weeks near a window somewhat warm. I would be tempted to put some H2O2

in to provide the free-radicals but I'm not sure if this would change the oxidation products. Photoxidation is an option but it seems impractical

judging on how food spoils on its own.

2. Wouldn't we want to be protonating the hydroperoxide here with a dehydrating acid such as sulphuric?

3,4. Wouldn't the the retroaldolization be catalyzed by water?

Then steam distill the final product to obtain hexanal.

{Food Chemistry By H. -D. Belitz, Werner Grosch, Peter Schieberle : http://books.google.com/books?id=xteiARU46SQC&pg=PA205&lpg=PA205&dq=linoleic+acid+to+hexanal&source=bl&ots=HyNrdMSRrC&sig=wKAI

Go0nrYLco9iu7Pm0jVpm_Zg&hl=en&ei=-gQpTeTaF8aAlAe_uOTXAQ&sa=X&oi=book_result&ct=result&resnum=9&ved=0CFIQ6AEwCA#v=onepage&a

mp;q=linoleic%20acid%20to%20hexanal&f=false}

Thanks to any help sorry this is a mess of a thread and I can hardly carry my own weight here. Been struggling to find grounded information on the

net. The primary focus it seems is how the compound is possibly made when oil spoils, not so much how to make the compound from spoiling oil. Being a

novice this makes it much harder to figure out what exactly going on.

I am aware that there is a orgsyn procedure on this but it goes beyond my means/home-lab and this seems like much easier/cheaper way to go about it,

if a decent method could be understood. I want to experiment on it, but I fancy knowing whether or not I'm on the right track or not first.

They can do this with enzymes it seems with good success. Looking for a more ochem approach.

http://www.springerlink.com/content/v3410430913t5820/

If you saw this post on another forum I apologize but I don't think anyone is really going to take the time to help me out over there...

Thanks again.

[Edited on 9-1-2011 by smaerd]

|

|

|

Ozone

International Hazard

Posts: 1269

Registered: 28-7-2005

Location: Good Olde USA

Member Is Offline

Mood: Integrated

|

|

I attached the full text of the paper you posted.

Some further infomation can be found here (ricinoleic acid--> heptanal + undecylenic acid).

http://www.sciencemadness.org/talk/viewthread.php?tid=11645#...

I thought this one was really cool, but I got side-tracked and never got around to looking into it. Maybe I'll get to it this time,  . And, this time, it looks like the enzymic route must be examined as well (72% yield

from that mess is OK). . And, this time, it looks like the enzymic route must be examined as well (72% yield

from that mess is OK).

Now then, where to get those enzymes? Ah, here is another route that might get us there using a (crude) enzyme isolate from soybeans (can't upload it,

too big, but it's: Gardner et al. 1991. plant physiol, 97, pp. 1059-1072).

Cheers,

O3

Hmm... The file will not upload? Ah. Crap, it exceeds 2 Mb.

[Edited on 9-1-2011 by Ozone]

Attachment: Marczy et al 2002 Biotechnol. Lett. 24 (20), pp. 1673-1675.pdf (55kB)

This file has been downloaded 443 times

-Anyone who never made a mistake never tried anything new.

--Albert Einstein

|

|

|

smaerd

International Hazard

Posts: 1262

Registered: 23-1-2010

Member Is Offline

Mood: hmm...

|

|

Ah yes I just checked the article(Gardner et al. 1991. plant physiol, 97, pp. 1059-1072) you mention about the crude soybeen isolates. Would love to

entertain this idea if I had a centrifuge and a homogenizer amongst other things.

Interesting never even considered pyrolysis. Haven't done one of those reactions before. Pine rosin as a catalyst? Interesting  . I'll have to do some research but that seems to possibly be the 'quick and dirty'

way to go about it. I bet the clean up stinks, but hey nothing good came easy. . I'll have to do some research but that seems to possibly be the 'quick and dirty'

way to go about it. I bet the clean up stinks, but hey nothing good came easy.

http://www.somaluna.com/prod/pine_rosin.asp(haven't ordered from them cannot vouch)

Good thing there's naturalists out there hehe, if this is actual pine rosin this could be a very affordable experiment.

This is all reminding me how desperately I need to get a fume hood built. Better finish designing that today.

[Edited on 9-1-2011 by smaerd]

|

|

|

spirocycle

Hazard to Others

Posts: 197

Registered: 29-9-2010

Member Is Offline

Mood: No Mood

|

|

What oxidant will you use?

Ozonolysis or swern oxidation should be suitable

cold alkali KMnO4 would work, but give you some of the acid as well, but it would be alot cheaper

|

|

|

smaerd

International Hazard

Posts: 1262

Registered: 23-1-2010

Member Is Offline

Mood: hmm...

|

|

Hmmm I wasn't even thinking of KMnO4 going the pyrolysis route. However, I'm here to play with idea's and experiment, who knows once I get my hands on

some linoleic acid I'm sure to try several different things. KMnO4 is endlessly handy, it's worth a shot. Especially considering I don't have any

oxalyl chloride hanging about for a swern oxidation.

I wonder if a vigreaux column would suffice for the air condenser benzylchloride1 mentions. I'd imagine he left his air condenser unpacked for the

pyrolysis, then packed one for the fractional distillation? If not I need to make another glass-ware run in the near future anyways.

I really appreciate the help guys.

|

|

|

DJF90

International Hazard

Posts: 2266

Registered: 15-12-2007

Location: At the bench

Member Is Offline

Mood: No Mood

|

|

Swern oxidation on an alkene? I don't think so... And oxidative cleavage of alkenes requires acidic KMnO4. Alkaline conditions (pH>8)gives the

1,2-diol - which brings me onto my point...

Lemeiux-Johnson oxidation using a modified protocol (cat. KMnO4, NaIO4) could work nicely, and you'd possibly get malonaldhyde as a byproduct! Not

bad!

The mechanism occurs in two parts - first, the syn-dihydroxylation of the alkene occurs via the cyclic manganate ester. This is hydrolysed under the

conditions to give the 1,2-diol, which will react selectively with the periodate - giving oxidative cleavage to two aldehydes, via a cyclic periodate

ester. Mechanisms are readily available online. The protocol I recall used catalytic KMnO4, but if its cheaper than the periodate (which was used as

stoichiometric oxidant), then a molar equivalent of each per double bond would be satisfactory I suspect. Dont forget to add the base though (KOH is

typical).

[Edited on 9-1-2011 by DJF90]

[Edited on 9-1-2011 by DJF90]

|

|

|

smaerd

International Hazard

Posts: 1262

Registered: 23-1-2010

Member Is Offline

Mood: hmm...

|

|

Ah yea primary/secondary alcohols only for the swern woops.

Very interesting idea about the Lemeiux-Johnson oxidation I would have never came up with that one(well maybe in a few years  )! Sodium periodate preparation looks simple enough so long as I can get my hands on

some HNO3 for recrystalization. I might have to try that out first actually. )! Sodium periodate preparation looks simple enough so long as I can get my hands on

some HNO3 for recrystalization. I might have to try that out first actually.

|

|

|

DJF90

International Hazard

Posts: 2266

Registered: 15-12-2007

Location: At the bench

Member Is Offline

Mood: No Mood

|

|

I'm certain Woelen has the preparation on his webpage. I dont recall HNO3 being needed.

|

|

|

spirocycle

Hazard to Others

Posts: 197

Registered: 29-9-2010

Member Is Offline

Mood: No Mood

|

|

My bad on those suggestions, I'm obviously not thinking too clearly

What about OsO4/IO4-

probably quite expensive though.

on you suggestions of KMnO4/NaIO4, why even add the iodate?

isnt permanganate usually powerful enough to oxidize to the acid?

why not just control the temperature carefully with the permanganate alone?

|

|

|

DJF90

International Hazard

Posts: 2266

Registered: 15-12-2007

Location: At the bench

Member Is Offline

Mood: No Mood

|

|

OsO4/NaIO4 is the original Lemieux-Johnson procedure. As OsO4 is terribly toxic and out of reach for most of us here, I suggested KMnO4 in its place

(as I had seen a protocol which also does so). KMnO4 will oxidatively cleave alkenes to aldehydes/ketones under acidic conditions but then the

aldehyde product is at risk and I suspect it is more easily oxidised than the alkene itself. Using the procedure stated, KMnO4 poses less of an issue

due to the alkaline conditions, and the periodate is a selective oxidant for the cleavage of vicinal diols.

|

|

|

Random

International Hazard

Posts: 1018

Registered: 7-5-2010

Location: In ur closet

Member Is Offline

Mood: Energetic

|

|

What's the mechanism behind this? Would dry distillation of linoleic acid isolated from sunflower oil along with pine rosin catalyst yield hexanal?

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

For a local supply of rosin check your music store and sports supplies store. It is used on violin bows and in baseball (for bat gripping and

possibly pitching), to increase friction.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

Random

International Hazard

Posts: 1018

Registered: 7-5-2010

Location: In ur closet

Member Is Offline

Mood: Energetic

|

|

http://en.wikipedia.org/wiki/1-Octen-3-ol

Here it is written that by oxidative breakdown of linoleic acid that is produced. How to actually get the biggest yield of 1-octen-3-ol from linoleic

acid?

|

|

|