angeltxilon

Harmless

Posts: 19

Registered: 24-10-2015

Member Is Offline

Mood: No Mood

|

|

Making bionapalm?

The idea is to make ecological and natural napalm (as a personal challenge), or something similar where the prefix "bio-" can be assigned.

At least napalm made from biomass.

This requires the same ingredients as to make normal napalm:

- Gasoline.

- Naphtha-palmitic aluminum soap.

The problem is that, according to the challenge, these two ingredients must be obtained from the transformation of biomass, and not from fossil fuels.

This means that ordinary gasoline does not work, biogasoline is required. And the same criteria is applied to soap.

.

Step 1: get biogasoline.

As I read, it is possible to make gasoline from biomass, but I don't know how to do it at home.

Mentally improvising, I thought of a recipe similar to biodiesel, but replacing vegetable oil (long chain fatty acids) with animal oils (?), Which

contain short chain fatty acids (4-10 carbons).

The underlying logic is that gasoline is composed of short chain hydrocarbons (4-11 carbons), while diesel has longer chain hydrocarbons (with carbon

length close to vegetable fatty acids).

Animal fat, butter, for example, contains significant amounts of butyric acid, caprylic acid and caproic acid (all of these polymerized to form

lipids, of course), among other short-chain fatty acids. These fatty acids, when not polymerized, are somewhat volatile and have unpleasant odors

reminiscent of vomit, cheese, feet, sweat, dirty people and wet dogs.

So the idea is to dissolve caustic soda in wood alcohol (methanol), and mix this solution with animal oils with the hope of producing "biogasoline"

and glycerin.

Getting "distill" animal oils (?), Separating lipids from "non-lipids", is a key step that I don't know how to perform.

.

Step 2: get (bio) palmitic acid and (bio) naphthenic acid.

Palmitic acid is not a difficult ingredient to find (palm oil contains 44%) but it is difficult to separate at the home level, requiring fractional

distillation equipment or something similar.

Getting naphthenic acid from biomass is a real problem, since the most aromatic vegetable oils usually concentrate 4% or less. It is more viable to

synthesize naphthenic acid. Of course, from a naphthenic compound obtained from biomass. I have no idea what to do here.

.

Step 3: make aluminum soap.

Once the previous two (bio) acids have been obtained, new problems now arrive. Aluminum trimethalate, or aluminum alkoxydes, must be manufactured and

reacted with these acids. This, again and at home level, is a problem.

Would it be of any use to make sodium or potassium soap and mix it with aluminum trichloride, with the hope it reacts forming aluminium soap and

sodium/potassium chloride? I do not believe that...

.

Step 4: tasty tasty jelly.

The naphtha-palmitic aluminum biosoap is mixed with biogasoline to finish making the bionapalm. 100% ecological, natural, healthy and renewable

bionapalm (joke).

|

|

|

draculic acid69

International Hazard

Posts: 1371

Registered: 2-8-2018

Member Is Offline

|

|

Should we really go to the trouble of figuring out how to make bio-war weapons.u see we tend to reserve terms like "organic" and "bio" for things that

are going to make us healthier and ethically sourced organic napalm or biologically safe napalm sort of goes against that.

Give it up dude.i doubt your gunna get many serious replies.

|

|

|

Tsjerk

International Hazard

Posts: 3022

Registered: 20-4-2005

Location: Netherlands

Member Is Offline

Mood: Mood

|

|

| Quote: | | Give it up dude.i doubt your gunna get many serious replies. |

Why not? If the idea behind the project would be to do harm, person in question could go to a fuel station, get some gasoline and use that right?

Step 1: you don't have to isolate the oils, you can directly do a trans-esterfication on the fat. The mechanism, I believe, is that glycerol separates

as a layer, driving the equilibrium. This is done all the time when making biodiesel. You only have to separate the layers.

| Quote: | | Getting "distill" animal oils (?), Separating lipids from "non-lipids", is a key step that I don't know how to perform. |

You don't have to distill anything.

Step 2: Is the other 56% content of palm oil a problem? If not just use palm oil. And; naphthenic acid is not aromatic

Step 3: Making aluminium alkoxides is a lot easier than making aluminium chloride (anh.), get some seaweed, sublime the iodine out and use that to

react aluminium foil with an alcohol.

|

|

|

angeltxilon

Harmless

Posts: 19

Registered: 24-10-2015

Member Is Offline

Mood: No Mood

|

|

Making bionapalm B?

This thread is a second part or continuation of the thread https://www.sciencemadness.org/whisper/viewthread.php?tid=15... created two years ago.

In trying to make this "bionapalm" I ran into several problems that I hadn't anticipated.

1. "Biogasoline" made from animal fat does not have the same compounds as natural gasoline.

Natural gasoline contains linear and branched hydrocarbons without oxygen or very rarely with oxygen.

However, this "biogasoline" that I produced was an ester, with quite different organic compounds. This fact (which also occurs with biodiesel) makes

the solubility and effect of aluminum soap different. In addition, the product is hard to light.

2. Eco-friendly aluminum soap is difficult to manufacture if you don't have enough equipment or proper materials.

As a result I don't know if what I got was aluminum soap, but it didn't have the expected effect.

The solutions I could have adopted (but did not adopt) were the following:

1. Manufacture gasoline by the Fischer-Tropsch method, using any biomass or plastic as a base... which is beyond my capabilities at my current level.

2. For potassium soap: buy some ready-made aluminum alkoxide, or laboratory-quality iodine... I was lazy and stingy.

...

So I have reformulated the experiment. Initially, it was based on an old napalm formula. Today's napalm (napalm B or supernapalm, longer-burning) is

made by dissolving certain organic polymers in gasoline.

At home, a substitute for napalm B can be made by dissolving polystyrene in gasoline.

In this case, since bionapalm B is being manufactured, the idea would be to dissolve an equivalent non-petroleum-derived polymer in a fuel mixture

with an octane rating similar to gasoline.

Since my biogasoline failed (it didn't turn out to be what I expected) and since I'm not going to spend hundreds of dollars to build a dangerous

machine to synthesize oil or naphtha from plastic and biomass, my idea was to mix various renewable organic liquids, among which which vegetable oil,

turpentine and ethanol (http://www.sciencemadness.org/talk/viewthread.php?tid=158958).

The logic is that vegetable oil comes from seeds, white spirit from resinous woods, and ethanol from sugar fermentation, so they would be "ecological"

and therefore valid for bionapalm.

The mixture would initially consist of 70% ethanol, 10% turpentine and 20% sunflower oil. Ethanol is insoluble in oil, but both are soluble in white

spirit. The mix would have an octane rating similar to commercial gasoline.

I haven't put the mixture into practice yet, so it might be the case that they don't dissolve. If that happens, you would have to increase the

percentage in turpentine.

The last thing that would be needed is a polymer similar to polystyrene that dissolves in some of the components of the mixture and that can be

manufactured using chemical products derived from biomass.

I don't know which is the best candidate for this.

[Edited on 10-10-2022 by angeltxilon]

|

|

|

Elemental Phosphorus

Hazard to Others

Posts: 184

Registered: 11-11-2016

Location: Is everything

Member Is Offline

Mood: No Mood

|

|

I thought this was an interesting idea and I was back home for a little bit so I decided to take a crack at this.

For a solvent, I would think that turpentine would be superior to ethanol by quite a bit (although it's a lot more expensive) - it should release

about twice the energy on a volume/volume basis.

Ethanol's combustion releases 22.77MJ/L (with water in the gas phase). I couldn't find an enthalpy of combustion for turpentine, but I found one for

isoprene, which turpentine is a dimer of, and that is 44.08MJ/kg, or at turpentine's density of 0.86g/cc, about 38MJ/L.

Also, acetone can also be a biological product, it is made in some cases by ABE fermentation instead of by the cumene process.

At any rate, my mixture consisted of equal parts by volume turpentine, acetone and vegetable oil. The components all mixed completely and easily,

which was interesting, but the mixture was quite homogeneous.

I am not really sure why it would be necessary for the octane of a napalm solvent to be similar to that of gasoline, since it's not going to be used

in an engine, I would imagine knock resistance isn't particularly important.

For my polymer, I just used styrofoam at this time because I couldn't think of anything organic which I had at hand. Natural rubber would be the most

obvious choice to me; it was dissolved in gasoline and used in incendiary bombs before the invention of napalm (in fact, IIRC, napalm was invented

because during WW2 the Japanese took over most of the world's rubber plantations and a new type of incendiary was needed).

Being an isoprene polymer and knowing it can dissolve in gasoline, I think an acetone-turpentine-oil mixture ought to be able to dissolve it.

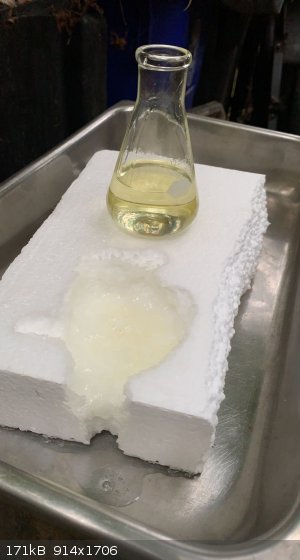

Here is my mixture of acetone and vegetable oil with turpentine being added:

And here is the mixture burning on top of a piece of wood. From what I could tell, it burned with more or less the same intensity and characteristics

of polystyrene dissolved/jellied with gasoline.

[Edited on 18-10-2022 by Elemental Phosphorus]

|

|

|

Texium

|

Threads Merged

18-10-2022 at 08:41 |

Texium

Administrator

Posts: 4508

Registered: 11-1-2014

Location: Salt Lake City

Member Is Offline

Mood: PhD candidate!

|

|

No reason to start a new thread. Better to keep it consolidated.

|

|

|

Lionel Spanner

Hazard to Others

Posts: 163

Registered: 14-12-2021

Location: near Barnsley, UK

Member Is Offline

|

|

Ethyl cellulose is a biologically derived oil-soluble polymer - at high enough concentrations it'll thicken and 'jellify' an organic solvent.

|

|

|

|