| Pages:

1

2 |

Tsjerk

International Hazard

Posts: 3022

Registered: 20-4-2005

Location: Netherlands

Member Is Offline

Mood: Mood

|

|

Definitely get some DMF to recrystallize when you go the glutamic acid route.

[Edited on 9-1-2022 by Tsjerk]

|

|

|

DocX

Hazard to Others

Posts: 179

Registered: 22-10-2015

Member Is Offline

Mood: No Mood

|

|

Yes, there is an ongoing research for the needed reagents. I live in one of the most repressive countries on the planet when it comes to odd hobbies

of suspicious nature, so it will take a while.

|

|

|

DocX

Hazard to Others

Posts: 179

Registered: 22-10-2015

Member Is Offline

Mood: No Mood

|

|

So finally I got around to do this.

I thought I'd combine the two methods in the write-ups above with the best yields: pyridine as solvent in the first step (with glutamic acid and

phtalic anhydride), and thiourea + DMF in the second.

I purchased the first reagent, phtalic anhydride, from a seller in Ukraine before the war. The glutamic acid I made myself from commercial Monosodium

Glutamate. I also made the pyridine through decarboxylation of niacin with copper carbonate as catalyst. The DMF and the thiourea were both purchased

from one of the excellent vendors on this site.

1. 14.95 grams of phtalic anhydride in the form of flaky crystals was mixed with the same amount of glutamic acid in a 3-necked RB fitted with a

thermometer and a reflux column. 100 ml of pyridine was added.

And already here I messed up. I had measured up 100 ml of conc HCl and 150 ml of dH2O to use later in the reaction, and in a moment of confusion I

added them both to the flask. I don't want to talk about it.

White smoke was generated when the HCl was added, and the flask was put into a heating mantle in a fume hood.

Temp was raised to 115 C and kept there for 100 mins. When the heat was turned off and the temperature began to decrease, white precipitate was formed

in the solution. PH was checked: 2.

The flask was then kept on an ice bath with stirring for 2 hours, before the precipitate was vacuum filtered and dried.

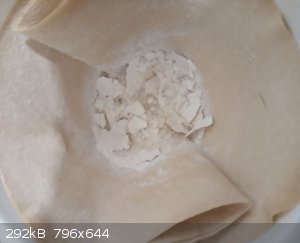

Yield: 17.3 g of white, sparkly crystals, which should be like 64% of theory. Melting point 192-194, to my utter joy.

2. The intermediate N-phtaloyl glutamic acid from above was mixed with 15.3 grams of thiourea in the same 3-necked flask.

50 ml of DMF was added.

The reaction mixture was heated to 167 c and refluxed at this temperature for 1 hour. The smell of sulphur from the thiourea mixed with the smell of

DMF degrading to dimethylamine was really something.

Heating was turned off, and at 110 C 60 ml:s of dH2O was added and refluxed for another 30 minutes.

After cooling, the flask was transferred to an ice bath and kept there under stirring for another 30 minutes, after which the flask was refrigirated

for about an hour.

The greyish-pink precipitate was vacuum filtered and washed with 60 ml of dH2O, then refluxed with 60 ml ethanol for about 20 minutes.

Filtered again, wsshed again with ethanol and water, and then dried. It was now perfectly white and sparkly.

Yield: 12.5 grams.

So I ran the first reaction in a strongly acidic solution by mistake and I was afraid I had ruined it, but the melting point checked out. The second

reaction was textbook though, except for not recrystallising from DMF. The resulting sparkly, free-flowing pristine white powder seemed clean enough

though.

Bioassay was made with 400 mg:s but gave no noticeable effect. So maybe I messed it up anyway?

|

|

|

DocX

Hazard to Others

Posts: 179

Registered: 22-10-2015

Member Is Offline

Mood: No Mood

|

|

My take on the failure to produce a bioactive end product is that I'm actually looking at a crystal mix predominately consisting of phtalamide. I

performed a recrystallisation from DMF which gave me 9.5 g:s in return, but bioassay failed again.

The melting point of phtlamide is like for thalidomide a good bit over 200 C (238 for phtalamide, 270 for thalidomide). I haven't tried the melting

point yet. It's a bit of a hassle for me to do that with these temperatures since I don't have a melting point apparatus yet. But I'll get around to

it.

I'm planning a second recrystallisation from DMF, and this time basify the solution even more with ammonia to dissolve the phtalamide. We'll see what

my yield will be from that. Probably catastrophic, but right now I just want to get something functional out of this.

If that doesn't work, I have to run with the suspicion that my self-synthesised glutamic acid is faulty somehow. Possibly also the pyridine. In that

case, I will revisit this synth with confirmed, lab grade reagents.

I will make this work.

Also, out of curiosity: how many of you who tried this reaction did a bioassay or a melting point determination of your final yield?

[Edited on 20222222/10/25 by DocX]

|

|

|

Mateo_swe

National Hazard

Posts: 501

Registered: 24-8-2019

Location: Within EU

Member Is Offline

|

|

I will eventually try making some thalidomide, i have all needed reagents except the glutamic acid or glutamine.

But i do have some food-grade monosodium glutamate from the asian store.

I could try either the lower yielding first method or the second method using acetic anhydride or thionyl chloride.

I like DocX´s method above, did you try it again and got it to work?

|

|

|

DocX

Hazard to Others

Posts: 179

Registered: 22-10-2015

Member Is Offline

Mood: No Mood

|

|

No, I haven't gotten round to it yet. I'm waiting for lab grade reagents to try and exclude all the possible impure or faulty ones.

I did try to clean the product I have several times through recrystallisation from DMF, but to no avail.

Also, next time I'll go back to the original patent method using ammonium acetate as a nitrogen donor. I figure it's best to go to the absolute basic

and then work my way from there.

Pyridine + phtalic anhydride + L-glutamic acid in 115 C.

Then Phtaloyl Glutamate + ammonium acetate in PEG400 and a bit of DMF at 160-180 C to get the product. I'll probably run that reaction really long

also, to get good conversion.

As soon as I get something functional out of this I can start elaborating for yield.

This would be an excellent point in life to start meddling with TLC, I guess.

[Edited on 20222222/11/19 by DocX]

|

|

|

SplendidAcylation

Hazard to Others

Posts: 196

Registered: 28-10-2018

Location: Starving in some deep mystery

Member Is Offline

Mood: No one I think is in my tree.

|

|

Preparation of N,N-phthaloylglutamic acid

I have attempted the solvent-free procedure detailed by Tsjerk, I have been successful in the preparation of thalidomide, although my yields were

relatively low.

I have completed a write-up detailing the preparation of the N,N-phthaloylglutamic acid intermediate, it is attached as a PDF.

My yields were consistent with the 54% reported by Tsjerk.

The write-up for the preparation of thalidomide is on its way

Please let me know if I've made any mistakes, or anything, all comments welcome!

Thanks for reading

Attachment: Preparation of N,N-phthaloylglutamic acid by the solvent-free reaction of phthalic anhydride and L-glutamic acid.pdf (52kB)

This file has been downloaded 165 times

[Edited on 21-1-2023 by SplendidAcylation]

|

|

|

Mateo_swe

National Hazard

Posts: 501

Registered: 24-8-2019

Location: Within EU

Member Is Offline

|

|

Very nicely done, SplendidAcylation, good work!

And a good writeup as well with repeated experiments.

Only thing i missed was the final step, you should have included it in the writeup.

But anyway, very nice.

Did you use thiourea in the microwave for the last step as in the paper "Microwave Promoted Synthesis of a Rehabilitated Drug: Thalidomide"?

Also in the paper they use this workup:

The crude RM after microwave irradiation was dissolved in THF and purified by column chromatography on silica gel (THF-hexane, 1:1) to afford a solid

product of (±)-thalidomide (Yield 85%).

Did you use same workup with the column or some other way?

Also, are a fumehood required at this small scale?

I will try repeat your experiment and maybe increase the scale somewhat.

I really like to try a microwave for a reaction and this is the perfect experiment.

Attachment: Microwave Promoted Synthesis of a Rehabilitated Drug - Thalidomide - seijas2001.pdf (31kB)

This file has been downloaded 140 times

[Edited on 2023-1-23 by Mateo_swe]

|

|

|

SplendidAcylation

Hazard to Others

Posts: 196

Registered: 28-10-2018

Location: Starving in some deep mystery

Member Is Offline

Mood: No one I think is in my tree.

|

|

Quote: Originally posted by Mateo_swe  | Very nicely done, SplendidAcylation, good work!

And a good writeup as well with repeated experiments.

Only thing i missed was the final step, you should have included it in the writeup.

But anyway, very nice.

Did you use thiourea in the microwave for the last step as in the paper "Microwave Promoted Synthesis of a Rehabilitated Drug: Thalidomide"?

Also in the paper they use this workup:

The crude RM after microwave irradiation was dissolved in THF and purified by column chromatography on silica gel (THF-hexane, 1:1) to afford a solid

product of (±)-thalidomide (Yield 85%).

Did you use same workup with the column or some other way?

Also, are a fumehood required at this small scale?

I will try repeat your experiment and maybe increase the scale somewhat.

I really like to try a microwave for a reaction and this is the perfect experiment.

[Edited on 2023-1-23 by Mateo_swe] |

Note: Since I wrote this message, I have completed the write-up, however, for continuity, I shall leave the message here anyway.

Thanks!

By " final step" do you mean the microwave synthesis of thalidomide?

I am doing a separate write-up on that, it isn't quite finished yet!

I shall just answer your questions quickly because you will see all the details in the upcoming write-up:

I used urea.

I didn't use the column, I think the product I obtained is fairly pure though.

You definitely don't need a fume-hood, you won't even notice the smell of ammonia at this scale, unless you put your nose up to the test-tube.

Edit: The thalidomide write-up is now complete! It is attached as a PDF.

[Edited on 24-1-2023 by SplendidAcylation]

Attachment: Microwave synthesis of thalidomide.pdf (61kB)

This file has been downloaded 197 times

|

|

|

Mateo_swe

National Hazard

Posts: 501

Registered: 24-8-2019

Location: Within EU

Member Is Offline

|

|

Very nice!

OK, you used urea and not thiourea.

Thiourea is said to give better yields, if you can get some.

Regarding the question if a fumehood is needed, i was thinking about thiourea possible could make it smell a bit, especially if pyridine solvent were

to be tried.

I think i can try this without a fumehood even if thiourea is used, its so small scale.

And i can make a quickfix fume extractor.

I wonder a bit about your yields though, i dont get how you calculated.

In the paper you write 35.5%, 20.0% and 26.7% yields of thalidomide for experiment 1, 2 and 3.

Are those yields based on the N-phthaloylglutamic acid used?

You get more final product in last experiment 3 using less N-phthaloylglutamic acid than in experiment 1 but still get lower yield?

I get

Exp 1

3.9mmol N-phthaloylglutamic acid used, 0.31g(1.2mmol) thalidomide, 1.2/3.9=30.8% yield

Exp 2

3.7mmol N-phthaloylglutamic acid used, 0.25g(0.97mmol) thalidomide, 0.97/3.7=26.2% yield

Exp 1

3.4mmol N-phthaloylglutamic acid used, 0.45g(1.7mmol) thalidomide, 1.7/3.4=51.25% yield

Or do i calculate wrong?

Im a beginner at chemistry so that is a likely explanation.

I will add my experiment here also when its done.

Good work SA

Edit:

Ok i see i calculated on the crude yield, thats why i got better yields.

However, searching for thalidomide solubility i find

Sparingly soluble in methanol, ethanol, acetone, ethyl acetate, butyl acetate, glacial acetic acid.

Very soluble in DMF, dioxane, pyridine.

Practically insoluble in ether, chloroform, benzene.

Sparringly soluble in other alcoholes (no mention of iPrOH though) makes me wonder if another solvent would have been better to use for the

purification step.

Maybee you got better yields than you think.

[Edited on 2023-1-25 by Mateo_swe]

[Edited on 2023-1-25 by Mateo_swe]

|

|

|

SplendidAcylation

Hazard to Others

Posts: 196

Registered: 28-10-2018

Location: Starving in some deep mystery

Member Is Offline

Mood: No one I think is in my tree.

|

|

Quote: Originally posted by Mateo_swe  | Very nice!

OK, you used urea and not thiourea.

Thiourea is said to give better yields, if you can get some.

Regarding the question if a fumehood is needed, i was thinking about thiourea possible could make it smell a bit, especially if pyridine solvent were

to be tried.

I think i can try this without a fumehood even if thiourea is used, its so small scale.

And i can make a quickfix fume extractor.

I wonder a bit about your yields though, i dont get how you calculated.

In the paper you write 35.5%, 20.0% and 26.7% yields of thalidomide for experiment 1, 2 and 3.

Are those yields based on the N-phthaloylglutamic acid used?

You get more final product in last experiment 3 using less N-phthaloylglutamic acid than in experiment 1 but still get lower yield?

I get

Exp 1

3.9mmol N-phthaloylglutamic acid used, 0.31g(1.2mmol) thalidomide, 1.2/3.9=30.8% yield

Exp 2

3.7mmol N-phthaloylglutamic acid used, 0.25g(0.97mmol) thalidomide, 0.97/3.7=26.2% yield

Exp 1

3.4mmol N-phthaloylglutamic acid used, 0.45g(1.7mmol) thalidomide, 1.7/3.4=51.25% yield

Or do i calculate wrong?

Im a beginner at chemistry so that is a likely explanation.

I will add my experiment here also when its done.

Good work SA

Edit:

Ok i see i calculated on the crude yield, thats why i got better yields.

However, searching for thalidomide solubility i find

Sparingly soluble in methanol, ethanol, acetone, ethyl acetate, butyl acetate, glacial acetic acid.

Very soluble in DMF, dioxane, pyridine.

Practically insoluble in ether, chloroform, benzene.

Sparringly soluble in other alcoholes (no mention of iPrOH though) makes me wonder if another solvent would have been better to use for the

purification step.

Maybee you got better yields than you think.

[Edited on 2023-1-25 by Mateo_swe]

[Edited on 2023-1-25 by Mateo_swe] |

Yes, although the yields using urea are supposed to be 63% which is still six times better than my yields!

Regarding the solubility in alcohol, yeah, there is a possibility that the isopropanol dissolved some of the product, however, I don't think so,

because:

"These were filtered from suspension, washed twice with 2mL cold water, and dried, yielding 0.25g of off-white powder.

The crude product was extracted with 4g of boiling isopropanol; Once dried, the undissolved product weighed only ~50mg.

A second extraction with boiling isopropanol removed no further soluble impurities, as the undissolved product after the second extraction, upon

drying, still weighed ~50mg."

If the product were significantly soluble in isopropanol, the weight would have decreased from 50mg rather than remain the same.

Of course, my scales aren't 100% accurate, so it's possible the weight might have dropped slightly!

I have been thinking a bit about ways to improve the yield...

It occurred to me that maybe a catalyst could be used to improve the yields; Boric acid is known to catalyze the amidation of carboxylic acids in a

urea melt, which is essentially what we are doing here in this reaction, so maybe boric acid would act as a catalyst here too?

Who knows.

|

|

|

dicyanin

Hazard to Self

Posts: 57

Registered: 29-3-2020

Location: Europe

Member Is Offline

Mood: inquisitive

|

|

Attached is a paper that reports a facile small size (~2-5 grams scale depending on substrate) microwave synthesis of a variety of N-phtaloylamino

acids in good yields.

They prepare an intimate mixture of 10 mmol amino acid and 10 mmol phtalic anhydride in a 100 ml beaker and wet it by adding a small amount of glacial

acetic acid. They cover the beaker with a watch glass and proceed to heat at 1000W for 15-20 minutes in an ordinary household microwave oven (they

used a Panasonic model NN-CD987W). After cooling and adding some methanol, the crude product was filtered, dried and recrystallised from ethanol. They

report yields ranging from 81-100%. Substrates used were glycine, alanine, beta-alanine, L- and DL-valine, 2-aminoisobutyric acid,

S-methyl-L-cysteine, phenylalanine, tyrosine, anthranilic acid, PABA and 4-aminophenylacetic acid.

Given what we know already, glutamic acid should perform in a similar fashion.

Attachment: facile microwave method for preparation of N-phtaloylamino acids__al-hazimi2012.pdf (519kB)

This file has been downloaded 23 times

sic transit gloria mundi

|

|

|

dicyanin

Hazard to Self

Posts: 57

Registered: 29-3-2020

Location: Europe

Member Is Offline

Mood: inquisitive

|

|

recrystallisation and resolution of thalidomide polymorphs

In crystallography, polymorphism describes the phenomenon where a compound or element can crystallize into more than one crystal structure. Racemic

thalidomide is dimorphic, the existence of two polymorphic phases is discussed in the following papers :

Reepmeyer et al., J. Chem.Soc. Perkin Trans. 2, 1994, p 2063-2067, DOI: 10.1039/P29940002063

Caira et al., J. Chem. Crystallography 1994, vol 24, nr 1, p 95-99, DOI: [10.1007/BF01665353

Carini et al., Int. J. Pharmaceut. 2009, vol 372, p 17-23, DOI: 10.1016/j.ijpharm.2008.12.034

(The existance of a third form was alluded to in the Caira et al. 1994 paper, but later retracted.)

The two forms are characterised in terms of their different X-ray diffraction patterns, infrared spectra and intrinsic dissolution properties. The

more recent of these three papers, "Solid state evaluation of some thalidomide raw materials" (Carini et al. 2009) investigated six

commercially available sources of thalidomide and concluded that there was a lack of homogeneity due to differences related to crystalline

constitution, crystal habit and intrinsic dissolution rate of the samples analysed, suggesting that none of the known processes used to produce

thalidomide are capable of producing a pure polymorph.

It is well known that physical properties such as dissolution behavior can affect bioavailability, which can affect the required dose of a

formulation. It is important that pure, stable, crystalline forms are used in pharmaceutical preparations as conversion from a form showing greater

dissolution and better bioavailability to a less soluble form can potentially have disastrous consequences. The phenomenon is well-known with racemic

modafinil, where no less than six different anhydrous polymorphic phases exist (of which four are stable), in addition to a monohydrate.

The attached patent WO2011154739 includes two purification methods that can resolve the crystalline phases of racemic thalidomide in either its alpha-

or beta-form with high polymorphic purity through a solvation-desolvation process.

α-thalidomide

10 g of crude thalidomide was dissolved in 50 ml DMSO with gentle heat. This solution was slowly added, with good stirring, to 170 ml methanol at a

temperature of 45-50°C. The mixture was kept at that temperature with stirring for a further 50 minutes, then slowly cooled to 40°C and filtered.

The solids were washed with methanol and collected through vacuum filtration. Finally the solid pure product was dried to a constant weight under mild

vacuum (~100 mmHg) at a temperature of 50-55°C to give the alpha-form of thalidomide as white to off-white solid.

Yield = 8-8.5 g (~85%)

β-thalidomide

10 g crude thalidomide was dissolved in 60 ml DMF and heated at 70-75°C for 2 hours. The solvent was removed by distillation under reduced pressure

(80-100 mmHg) at a temperature of 65-70°C. To the residual mass, acetone was added to produce a slurry, which was stirred for 2 hours. The slurry was

then filtered and washed with additional fresh acetone. The solid was then dried to a constant weight under mild vacuum (80-100 mmHg) at 55-60°C to

give the beta-form of thalidomide as a white to off-white solid.

Yield = 9.5 g (95%)

Attachment: thalidomide polymorphisms_WO2011154739.pdf (2MB)

This file has been downloaded 11 times

sic transit gloria mundi

|

|

|

dicyanin

Hazard to Self

Posts: 57

Registered: 29-3-2020

Location: Europe

Member Is Offline

Mood: inquisitive

|

|

my results

L-Glutamic acid was prepared from Ajinomoto MSG, according to the procedure outlined on the OrgSyn page (note 4) with the use of activated carbon for high purity.

N-phthaloyl-DL-glutamic acid was prepared by heating an intimate mixture of phthalic anhydride and L-glutamic acid in an oil bath as outlined in the

post by Tsjerk earlier in this thread.

Experimental

5.25 g N-phthaloyl-DL-glutamic acid and 1.55 g thiourea was dissolved in 20 ml warm methanol. This solution was poured into a porcelain dish and the

methanol evaporated in a well-ventilated area with the aid of a hairdryer. The dish was then further dried in a stream of hot air (70°C). The solids

were finely ground using mortar and pestle, and placed in a large (25 x 200 mm) borosilicate test tube, the top of which was plugged with a ball of

toilet paper.

The bottom sides of the test tube were gently heated with a hot air gun until the powder at the side just started to melt. The tube was then placed in

a porcelain cup in the microwave oven (600W) and heated in short bursts of 10-30 seconds. The contents started to melt, bubble, water vapour and gases

evolved, which judging from the smell included ammonium sulfide. For that reason in between the short bursts of heating the test tube was taken

outside, the paper wad removed, and the foul smelling volatiles released. This was repeated until the liquified contents became orange in colour.

The tube was allowed to cool down and the contents inside solidified. When still warm to the touch (but not hot) 30 ml methanol was added, which

caused the solids to break up easily. After filtration, washing with cold methanol and air drying 1.60 g (33%) thalidomide was obtained.

Thoughts & remarks

The yield is indeed slightly better than when urea is used, but I don't know if that is worth dealing with the stench evolved. It did bring back

pleasant memories of childhood, when we used to buy 'stink bombs' which were glass ampoules with an ammonium sulfide solution inside. Once we

shattered one under our feet inside the driving bus on a school trip, I distinctly remember a raging busdriver and inadequate ventilation on the bus,

we had to suffer the foul atmosphere equally as our classmates but thought that was worth the joke.

Anyway it's the same substance, and I suspect in about the same amounts as in such a stink bomb ampoule. On this scale I don't think it's dangerous

with adequate ventilation, but it's not very pleasant either and such odor could certainly draw attention. Something to consider.

Recrystallisation

1.60 g crude thalidomide was dissolved in 8 ml DMSO with gentle heating. In a roundbottom flask fit with condensor, placed in a warm water bath on a

hotplate/magnetic stirer, was placed 30 ml methanol and the contents were heated to 45-50°C. With good stirring the thalidomide in DMSO solution was

added dropwise to the methanol, and after addition the solution obtained was left stirring at that temperature for 50 minutes.

Contents were then poured into a beaker, flask washed with 10 ml methanol and added to the beaker. On cooling to room temperature crystals started to

appear. The beaker was then placed into the freezer for 2 hours, and a mass of fine needle-shaped crystals had formed, which were filtrated and washed

with cold methanol.

after air-drying 0.91 g thalidomide (presumably as the alpha form) were obtained, 57% yield based on the crude thalidomide

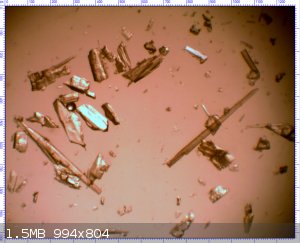

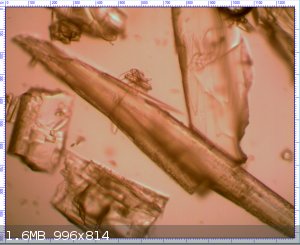

A preparation of the recrystallised thalidomide crystals was made for viewing under the microscope. The following pictures were taken at 40x, 100x and

400x magnification respectively.

[Edited on 3-4-2024 by dicyanin]

sic transit gloria mundi

|

|

|

dicyanin

Hazard to Self

Posts: 57

Registered: 29-3-2020

Location: Europe

Member Is Offline

Mood: inquisitive

|

|

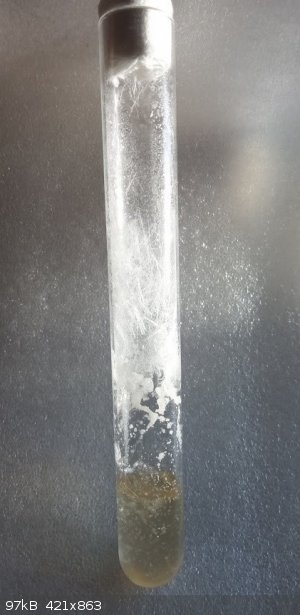

An intimate mixture of 5 grams phthalic anhydride and 5 grams L-glutamic acid (finely ground together in a mortar with pestle) in a large (23 x 200

mm) test-tube was heated in an oil bath at 145-150°C for 30 minutes. Here's a picture taken from the post-reaction mixture cooled to room temperature

:

At the bottom the melt turned into a glassy solid, this is chiefly our product N-phthaloyl-DL-glutamic acid. There are still some white particles

present through the mix, consisting of the precursor products.

Same for the white crust on the sides of the tube above that, this is because the volume of the powder mixture is about twice that of the melt.

Then above that you see large pretty needles of phthalic anhydride that sublimated from the mixture, and water droplets formed during the reaction.

sic transit gloria mundi

|

|

|

| Pages:

1

2 |

|