Boffis

International Hazard

Posts: 1836

Registered: 1-5-2011

Member Is Offline

Mood: No Mood

|

|

The Cannizzaro Reaction

Benzyl alcohol and the Cannizzaro Reaction

For my next act of heresy I’ll turn benzaldehyde into benzyl alcohol and benzoic acid!

I know most SM members seem to spend the lives trying to oxidize benzyl alcohol into benzaldehyde or reduce benzoic acid but for me I don’t use much

benzaldehyde so the gift of a very old bottle of the stuff recently was a bit of a mixed blessing. The bottle was about 100ml in capacity and filled

to just below the cap but still showed evidence of extensive degradation /oxidation with a mass of crystals 5mm deep at the bottom of the bottle. The

contents of the bottle weighed a little over 105g.

However, I do require some benzyl bromide so I thought I would convert the benzaldehyde to benzyl alcohol via the Cannizzaro Reaction as an

intermediate and recovery the benzoic acid from the residue. In theory the Cannizzaro reaction produces equimolar amounts of an alcohol and an acid.

There are two possible variations of this reaction on benzaldehyde, the simple Cannizzaro reaction on benzaldehyde alone and a crossed Cannizzaro

reaction using formaldehyde as the counterpart, the latter being oxidized to formic acid. Since I have more than enough benzaldehyde I decided to us

the simple method as described by Fischer (1).

The reaction is essentially an intra-molecular redox reaction (2) in which one molecule of benzaldehyde is oxidized to benzoic acid while the other is

reduced to benzyl alcohol. In theory this is a general reaction for aldehydes that do not carry an alpha hydrogen on the carbon adjacent to the

aldehyde group (or in the case of formaldehyde carry no carbon atom adjacent to the aldehyde group at all). Interestingly, vanillin

(3-methoxy-4-hydroxy-benzaldehyde) and other o- or p-hydroxybenzaldehydes do not undergo Cannizzaro’s reaction. Under very forcing conditions

vanillin suffers hydrogen loss and then de-methylation to give vanillic acid and protocatechuic acid as the ultimate product (3).

Experimental

A solution of potassium hydroxide was prepared by dissolved 90g of 85% KOH flakes in 60ml of water in a jar with a securely fitting lid of about

400ml capacity. The KOH must be added in two goes; about 40g are added the first time and the solution allowed to cool almost to room temperature

before the remaining 50g is added.

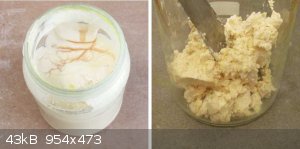

Left) The reagents Right) Initial mayonnaise like mixture

As soon as complete solution was achieved the contents of the bottle, a little over 100ml of crude benzaldehyde, were added to the jar, the lid

secured and then shaken until a homogeneous, mayonnaise-like, emulsion resulted.

Left) The mixture after 14 hours Right) The margarine like product

The jar was set aside to cool and stand for 14 hours. After 14 hours the contents of the jar had set into a cream coloured fudge-like mass. This was

removed from the jar with a spatula into a large beaker and the jar rinsed with 50 ml of water.

Left) Product dissolved in water Right) Extraction with ether

The washings were added to the beaker along with a further 200ml of cold water and a large stir bar. The mixture was stirred cold for about an hour

until all had dissolved and then extracted with 2x 50ml of ether.

Left) Ether extract washed with bisulphite Right) Drying the extract with MgSO4

The ether extracts were combined and treated in the separating funnel with 30 ml of 1M sodium bisulphite solution to remove unreacted benzaldehyde.

After separation of the bisulphite solution the ether was washed with 30ml of water and then dried with magnesium sulphate. The dried extract was

treated with a little decolourising charcoal (about 0.2g) to help remove the aldehyde-bisulphite compound which was very fine. The extract was

filtered through a 3 piece Whatman type filter to give a clear ethereal solution.

Left) Filtering the charcoal treated extract Right) The acidified residue from the extraction

The pale golden yellow extraction residue, which is mostly potassium benzoate, was brought to a vigorous boil for a few minutes to remove as much as

possible of the volatile organic compounds and cooled a little by diluting to 450ml with cold water. The solution was acidified while still hot by

adding 30% hydrochloric acid until the solution was acid to Congo red paper. Approximately 155ml were required. A creamy white precipitate formed

which rapidly became crystalline.

The washed and dried benzoic acid

The solution was left to stand overnight to cool and crystallise. The crude crystalline benzoic acid was filtered off at the pump and washed several

times with cold water until the washings were no longer acid to Congo red paper, drained with the vacuum and turned out onto a large watch glass to

dry. The final yield of benzoic acid was 77.066g of almost pure white benzoic acid, assuming that the original weight of benzaldehyde was about 105g

this represents a recovery of about 127%. The acid was recrystallized from about 1.8L of water to give 73.10g.

Left) Distilling of the ether Right) Distilling the benzyl alcohol

The clear ether extract was distilled in a 250ml flask in a warm water bath until no more ether distilled off, 70ml were recovered. The residue was

distilled in a small pear shaped flask and the fraction distilling between 199 and 205 C was collected separately. The small amount of low boil

fraction consisted mostly of water and ether and when the distillation was complete about 4ml of amber liquid remained in the flask. This is about the

quantity of liquid required to flood the distillation equipment with vapour and is unrecoverable. The clear distillate of benzyl alcohol weighed

28.10g or about 52% of theory.

The clear benzyl alcohol distillate

Discussion

Fisher does not describe the recovery of the benzoic acid but states that the recovery of benzyl alcohol from benzaldehyde is about 90% of theory

(i.e. about 0.45 moles per mole of benzaldehyde) from freshly distilled benzaldehyde. I used a sample of very old and much degraded/oxidized

benzaldehyde without first purifying it which presumably contains much benzoic acid derived from the oxidation of benzaldehyde by atmospheric oxygen.

This will limit the yield of benzyl alcohol. The total amount of recovered benzoic acid and benzyl alcohol represents a recovery of about 90% of the

total starting material indicating mechanical losses of about 10% which seems to agree with Fisher’s description. This suggests that about a third

of the original benzaldehyde had already oxidized to benzoic acid.

In hindsight it may have been better to have extracted the benzaldehyde with sodium carbonate solution first to remove most of the benzoic acid and

then treat the residue with formaldehyde and KOH in a crossed Cannizzaro reaction to maximise the yield of benzyl alcohol.

Conclusion

While this reaction is not a practical source of benzyl alcohol for most people given that both benzyl alcohol and benzoic acid are more readily

purchasable in most countries than benzaldehyde, it is an interesting reaction never-the-less. In this case it is also an interesting indication of

the amount of atmospheric oxidation that can take place in benzaldehyde. I estimate that the crystalline benzoic acid in the original bottle to be

only 2-3g so it would appear that benzaldehyde can dissolve a large amount of benzoic acid before becoming saturated.

1) E. Fisher; Introduction to the preparation of Organic Compounds; 1909 (book- downloadable)

2) T. A. Geissman; Organic Reactions, vol. 2, p94-113 (book- SM library)

3) I. A. Pearl; Reactions of Vanillin and its derived compounds IV, The Caustic Fusion of Vanillin; JACS; p2180; 1946. (vanillic and protocatechuic

acid).

[Edited on 4-6-2020 by Boffis]

|

|

|

Fery

National Hazard

Posts: 990

Registered: 27-8-2019

Location: Czechoslovakia

Member Is Offline

|

|

Boffis, wow very nice...

According the oxidation of benzaldehyde with air oxygen - when purifying it by distillation it is best to use vacuum distillation after removal of

already present benzoic acid using alkali carbonate.

|

|

|

Pumukli

National Hazard

Posts: 686

Registered: 2-3-2014

Location: EU

Member Is Offline

Mood: No Mood

|

|

Yeah, if those hindsights were just non-existent... :-)

I'm also curious about the crossed Cannizzaro reaction. One day I may try it on vanillin, I have the description of a vanillyl-alcohol preparation

that uses this reaction - if my memory serves well.

Anyway, good work as always, thanks for the article!

|

|

|

Fery

National Hazard

Posts: 990

Registered: 27-8-2019

Location: Czechoslovakia

Member Is Offline

|

|

Pumukli, cool, then pls post your method or at least the description of the preparation. I have almost 100 g of common vanilline (methoxy) as well 500

g of ethyl vanilline (ethoxy) in stock and also 2 L of formaldehyde which could not be stored for long time as it itself undergoes Cannizzaro so its

concentration degrades though it is stabilized with methanol since manufacturing. I have little of paraformaldehyde too (I should order more of it as

it is more stable than 40% formaldehyde solution in water). I ordered the ethoxy from a shop selling icecream manufacturing substances and devices

because of more powerful scent than the methoxy, it was quite cheap and the purity of food grade is quite high and I like to sniff if. I have also

commercial vanillic acid in stock which has interesting pleasant scent too (hard to describe, mixture of somewhat vanilla + cacao + coffee). I do not

drink coffee at all but I love cacao as well vanilla ice cream is my preferred one. I wonder the scent of vanillyl alcohol, it should be worth of

trying it in reality. I would prefer the crossed Cannizzaro with methoxy vanilline + formaldehyde to obtain as much of vanillyl alcohol as possible.

From ethoxy I would very likely try common Cannizzaro to obtain both ethoxyvanillyl alcohol as well ethoxyvanillic acid, from alkaline water mixture

after the reaction the alcohol should be extracted with some organic solvent which I do not yet know which one exactly and the acid should stay solved

in water as a salt (Na / K salt depending which hydroxid used for the reaction).

So far I found this:

https://sci-hub.tw/https://pubs.acs.org/doi/pdf/10.1021/jo01...

the pdf attached here too

Attachment: pearl1947.pdf (433kB)

This file has been downloaded 279 times

|

|

|

Fery

National Hazard

Posts: 990

Registered: 27-8-2019

Location: Czechoslovakia

Member Is Offline

|

|

A lot of vanillin landed in my lab yesterday so I would like to further investigate Cannizzaro reaction with it. Could crossed Cannizzaro with

formaldehyde maybe go favorably via creation of phenol formaldehyde resins? Direct Cannizzaro allegedly does not run and there is necessity to add

fluffy Ag prepared as in the above pdf. Could someone highly theoretically skilled explain why it shouldn't undergo direct Cannizzaro reaction without

Ag catalyst (unlike benzaldehyde where it runs flawlessly and no need of Ag catalyst)? Have the -OH or -OCH3 groups a negative effect on the

Cannizzaro reaction or do they just favor a reaction into phenol formaldehyde resin? I had an idea to close reaction mixture (vanillin + conc. sol of

KOH) into a jar with a lid and put it into a pot with water and that at the wood stove for the whole winter, just adding evaporated water into the pot

and see whether something reacted when the winter ends when I stop burning wood in that stove (that could be 1000 h of reaction at T 100 C if

hydroxide won't eat through the whole glass wall of the jar). And maybe second jar with crossed Cannizzaro (vanillin + conc. sol. KOH + 38%

formaldehyde).

Obtaining vanillic acid could be easier by oxidation with KMnO4 or Na2Cr2O7. I'm more interested in vanillyl alcohol (every lab method uses NaBH4 for

the reduction which is not available to masses). If that long term experiment fails, there is a method with 82,5% yield in the above pdf (crossed

Cannizzaro catalyzed by fluffy Ag).

|

|

|

TriiodideFrog

Hazard to Others

Posts: 108

Registered: 27-9-2020

Member Is Offline

|

|

Nilered has a video about the Cannizzaro reaction.

https://www.youtube.com/watch?v=qEBC204WTKs

|

|

|

zed

International Hazard

Posts: 2277

Registered: 6-9-2008

Location: Great State of Jefferson, City of Portland

Member Is Offline

Mood: Semi-repentant Sith Lord

|

|

Vanillyl Alcohol?

I've read papers extolling the virtues of the MPV, for such transformations

Heat the Aldehyde, under pressure with a great excess of Isopropyl Alcohol. High yields!

I might have left a reference, somewhere in the archives. I'll go check on that............

|

|

|