Fery

National Hazard

Posts: 990

Registered: 27-8-2019

Location: Czechoslovakia

Member Is Offline

|

|

azoxybenzene

25,6 g nitrobenzene (0,20 mol)

40,0 g NaOH (1,00 mol)

160 ml methanol

CH3OH + NaOH <-> CH3ONa + H2O

4 C6H5NO2 + 3 CH3ONa -> 2 C6H5-NO-N-C6H5 + 3 HCOONa + 3 H2O

To 500 ml RBF was added 40 g NaOH and 150 ml of methanol, flask swirled, part of NaOH dissolved. Exothermic. To the warm solution was added 25,6 g

nitrobenzene from a beaker and the beaker was washed with 10 ml of methanol which was added to the flask. Liebig condenser was attached to the flask

and the flask was placed on boiling water bath. The reaction mixture was refluxed for 1,5 hours, occasionally swirling the apparatus in hand to

facilitate NaOH dissolution. No boiling stones necessary, at the beginning the NaOH did not dissolve completely and later solid Na2CO3 (NaOH

contaminant) and solid Na formate present. Even after the reflux small pieces of NaOH present.

The content changed color to brown-red.

The flask was cooled in cold water bath and then its content was poured into a beaker containing mixture of 80 g of crushed ice and 80 ml of water and

the content was stirred. The product sucked on Buchner funnel, washed with cold water and air dried.

Yield 19,5 g of crude product. Weak scent of nitrobenzene present.

Small piece of the crude product kept aside (crystallization seeds). The crude product recrystallized from boiling methanol: To the crude product in a

beaker 50 ml of methanol added, the content heated upto boil, product dissolved easily. A little of white undissolved contaminant stayed at bottom.

Filtered quickly through preheated funnel (heated only by hot air on hotplate), beaker and filterpaper washed 2x with 5 ml of hot methanol to minimize

loses.

The solution was then boiled down to 45 ml.

Slowly cooled to room temperature on wooden base (use something which is insulating - maybe not necessary, just to prevent oiling out). When really at

room temperature below m.p. of the product (lit. m.p. of the product is 35,5-36,5 C) a little of previously saved dust of crude product (seeds) added

to start crystallization. The crystallization completed rapidly in 2-3 seconds resembling chain-reaction (slowly started from the only one

crystallization center in the middle and the further the crystals grew from the center the faster growth). Then the mass was put into fridge to +4 C

overnight to continue crystallization.

Vacuum filtered, the product washed on sinter with 10 ml of cold methanol from fridge (+4 C).

Air dried.

Yield 14,7 g = 74 % (theoretical 0,10 mol = 19,8 g), m.p. 34-35 C (lit. 35,5-36,5 C).

The mother liquor and washings (30 ml) boiled down to 10 ml, on cooling to room temperature something only oiled out, added 5 ml methanol (total

volume 15 ml), heated and cooled to room temperature - the same oiling out, no crystals.

For crystallization it seems to be necessary to prepare very pure solution, cool it slowly in new unscratched glass to make it supersaturated (into at

least room temperature or even fridge temperature) and then introduce seeding crystal(s).

http://orgsyn.org/demo.aspx?prep=CV2P0057

arsenite was used for reduction, also dextrose

oxydation of aniline using oxydating agent acetonitrile + H2O2

https://pubs.acs.org/doi/abs/10.1021/jo01062a004

crystalographic structure:

http://scripts.iucr.org/cgi-bin/paper?S1600536807035787

http://publcif.iucr.org/cifmoldb/gui/cifjmol.php?cifid=hg226...

https://library.sciencemadness.org/library/books/gatterman_1...

| Quote: | gatterman_1937.pdf

Azoxybenzenefrom phenylhydroxylamine and nitrosobenzene.—

Phenylhydroxylamine (1 g.) is added to a solution of 1 g.

of nitrosobenzene in 10 c.c. of alcohol. The mixture is shaken

while a few drops of concentrated potassium hydroxide solution

(1 : 1) are added, and is then wanned on the water bath for a few

minutes. The yellowish-red solution thus formed deposits yellow

crystals of the reaction-product when cooled and rubbed with a

glass rod. Since azoxybenzene melts at 36°, it has a great tendency

to separate from a supersaturated solution in the form of an oil.

By recrystallisation from a little alcohol or from petrol ether (retain

a few crystals for inoculation) the compound is obtained as a pale

yellow or almost colourless solid.

|

reactants: 25,6 g nitrobenzene + 40,0 g NaOH + 160 ml methanol

reflux for 1,5 h on boiling water bath

after the reflux

after pouring into mixture of 80 ml of water with 80 g of crushed ice

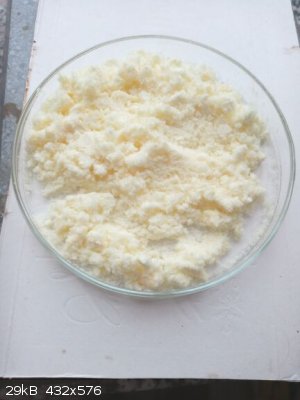

crude product filtered on Buchner funnel and air dried

recrystallization from methanol:

product sucked on sinter

air dried product

mother liquor partially evaporated and cooled down - oiling out

[Edited on 9-8-2021 by Fery]

|

|

|

Fery

National Hazard

Posts: 990

Registered: 27-8-2019

Location: Czechoslovakia

Member Is Offline

|

|

The Erlenmeyer flask from the last picture was put into a freezer to -18 C for 1 hour, second crop of the product crystallized (the bottom oil also

crystallized). The mother liquor was poured off the flask, crystals scraped with glass rod and transferred onto a filter paper, pressed between 2

sheets of the filter paper to remove most of the remaining mother liquor. Air dried. Yield 3,5 g. (so the total yield 14,7 g + 3,5 g = 18,2 g which is

92% of 19,8 g)

this product is very soluble in methanol, maybe worth trying whether light petrolether / pentanes / hexanes wouldn't be more suitable

m.p. not determined, this less pure product will be used in Wallach rearrangement (azoxybenzene + conc. H2SO4 -> 4-hydroxyazobenzene)

|

|

|

|