| Pages:

1

2

3

4 |

MineMan

National Hazard

Posts: 998

Registered: 29-3-2015

Member Is Offline

Mood: No Mood

|

|

I still see too main issues. If any monochloride is formed using HCL then it detonated during casting. If any H2S04 is left, it could also detonate

after casting.

|

|

|

Hey Buddy

Hazard to Others

Posts: 384

Registered: 3-11-2020

Location: Bushwhacker Country

Member Is Offline

|

|

It sounds more precarious than it really is, describing the H2SO4 decomposition. I see the H2SO4 issue being entirely avoidable, I believe the

monochloride is known as NHHT in unrelated literature to the source literature inspiring this effort. I suspect NHHT is entirely avoided by gross

excess NaNO2. NHHT explosive decomp also needs to be verified. It may not even be true because these are an obscure family of compounds with only

light attention, mostly Chinese and Russian literature from 80s.

Regardless of the truth of NHHT, whether it is a dangerous possibility, I have been unable to isolate NHHT in literature process. The precipitate of

the Nitrosamine foam is a quality that is only seen in by action of a nitrite, I suspect that there is no NHHT left during these reactions, and the

nitrosamine is a much more strongly favored pathway.

I am at the limitation of my understanding in terms of identifying what the compound is, so at this point I will just attempt to gain some

understanding of the materials comparative performance, and character, and possibly identify any incompatibilities with common materials. Then I will

move on to other materials. There is also a urea based version of this in a process analogous to Keto RDX preparation. There seems to be a bit of

cross over in any of this family of urea/guanidium/hexamine compounds, which makes sense. I have found literature describing preparation route of

Keto RDX in high yield from mannich and nitration reactions between uroptropin and nitroguanidne.

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1339

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: cool.gif

|

|

Your substance still has a long way to go. I look forward to the brisance test results. If it turns out to be more brisantely than PETN, then it will

be a big discovery....

Development of primarily - secondary substances CHP (2015) Lithex (2022) Brightelite (2023) Nitrocelite (2024)

|

|

|

Hey Buddy

Hazard to Others

Posts: 384

Registered: 3-11-2020

Location: Bushwhacker Country

Member Is Offline

|

|

Yield for the previous H2SO4 method is 20.8 g of a bone-dry, fluffy light lemon powder, reminiscent of freeze-dried ice cream. This should correspond

to a 44.8% yield before recrystallization.

I will continue experimenting with dilution/cooling to determine if those points can be pushed up a little bit, but this is satisfactory for a

field-suitable procedure without the use of ice baths or cooling the reagents themselves, simply adding a weight of ice to the reaction mixture. This

44% yield was achieved using whole ice cubes without crushing them, further minimizing processing complication.

I have been recording all of these and will put together a preferred procedure video after some more trial and error to hone efficiency. I will also

test under dosing nitrite in both HCl and H2SO4 versions in order to determine how much of a potential danger residual NHHT presence is upon

deflagration/casting.

Ultimately I will work on a continuous process from guanidium nitrate instead of nitroguanidine. At that point, most of the leg work will be done on

preparing this substance at least enough to describe its preparatory generalities.

Only comparative testing will reveal any suitability of this material, but the prospect of high-performance is "good" based on comparative burning

between TMTN RDX HMX and this substance. The ability to hammer detonate a triazine molecule could be a sign of the character of this molecule

similarly to the hammer detonatable character of Keto-RDX.

This material easily melts inside an 8mm SS detonator body with the body sitting directly on a heat source @110C. The bottom on the steel body was

closed with tape and in experimentation, it's so mobile in melt phase, it can leak through cracks between the scotch tape and SS. It's melt-phase

impact sensitivity is low, perhaps ~10% more sensitive than when solid. It cools and solidifies at a slow speed removing it from heat source. Its

surface hardness is similar to melted sugar but slightly less brittle.

The next step is field tests, I have ordered some lead and located a number of 2.45mm steel strips. My attention is now to prepare some other output

materials for plate/block testing. So far in line up, PETN and ETN, I will prepare some RDX for comparison and for potential input charges will

probably prepare NHN or its zinc analogue and CHP.

LL, what is preferred method for CHP? I have seen several routes and would like to know your recommended procedure, please?

[Edited on 10-11-2022 by Hey Buddy]

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1339

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: cool.gif

|

|

Best method for CHP: https://www.youtube.com/watch?v=F94UpYRczkc

Basic laboratory preparation of 5g CHP66 = 4,4g pure dry TACP + 0.3 g pure dry NH4ClO4 + 0.3g hexamine + a few drops of ammonia water ,

concentration is not important cca 10 - 25 %. Important is short drying, maximal 5 minute on hotplate at 40 - 50 C. And close in jar. Stability

(reliable DDT) in close jar cca 6 months. In hermetic cavity is stability without restrict.

(CHP is basically fool-resistant primary compound)

Best way for pure TACP: https://www.youtube.com/watch?v=cfOZfhwKHjg&t=11s

[Edited on 10-11-2022 by Laboratory of Liptakov]

Development of primarily - secondary substances CHP (2015) Lithex (2022) Brightelite (2023) Nitrocelite (2024)

|

|

|

MineMan

National Hazard

Posts: 998

Registered: 29-3-2015

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Hey Buddy  | Yield for the previous H2SO4 method is 20.8 g of a bone-dry, fluffy light lemon powder, reminiscent of freeze-dried ice cream. This should correspond

to a 44.8% yield before recrystallization.

I will continue experimenting with dilution/cooling to determine if those points can be pushed up a little bit, but this is satisfactory for a

field-suitable procedure without the use of ice baths or cooling the reagents themselves, simply adding a weight of ice to the reaction mixture. This

44% yield was achieved using whole ice cubes without crushing them, further minimizing processing complication.

I have been recording all of these and will put together a preferred procedure video after some more trial and error to hone efficiency. I will also

test under dosing nitrite in both HCl and H2SO4 versions in order to determine how much of a potential danger residual NHHT presence is upon

deflagration/casting.

Ultimately I will work on a continuous process from guanidium nitrate instead of nitroguanidine. At that point, most of the leg work will be done on

preparing this substance at least enough to describe its preparatory generalities.

Only comparative testing will reveal any suitability of this material, but the prospect of high-performance is "good" based on comparative burning

between TMTN RDX HMX and this substance. The ability to hammer detonate a triazine molecule could be a sign of the character of this molecule

similarly to the hammer detonatable character of Keto-RDX.

This material easily melts inside an 8mm SS detonator body with the body sitting directly on a heat source @110C. The bottom on the steel body was

closed with tape and in experimentation, it's so mobile in melt phase, it can leak through cracks between the scotch tape and SS. It's melt-phase

impact sensitivity is low, perhaps ~10% more sensitive than when solid. It cools and solidifies at a slow speed removing it from heat source. Its

surface hardness is similar to melted sugar but slightly less brittle.

The next step is field tests, I have ordered some lead and located a number of 2.45mm steel strips. My attention is now to prepare some other output

materials for plate/block testing. So far in line up, PETN and ETN, I will prepare some RDX for comparison and for potential input charges will

probably prepare NHN or its zinc analogue and CHP.

LL, what is preferred method for CHP? I have seen several routes and would like to know your recommended procedure, please?

[Edited on 10-11-2022 by Hey Buddy] |

Just compare to ETN for now. Let’s get basic results fast, if promising we can compare to more.

|

|

|

Hey Buddy

Hazard to Others

Posts: 384

Registered: 3-11-2020

Location: Bushwhacker Country

Member Is Offline

|

|

Good idea. cooking up TACP now. Colors will be violet blue and banana cream yellow. Has SM been using any form factor/load of detonators?

Ive got 8mm Ti, Al, SS and 6mm. What psi are you pressing CHP to in 8 or 6mm surface areas?

What qty of CHP input and standard load output have you tested before in past? If I can try to stick closer to a standard it will be nice and more

comparable.

[Edited on 11-11-2022 by Hey Buddy]

[Edited on 11-11-2022 by Hey Buddy]

|

|

|

underground

National Hazard

Posts: 696

Registered: 10-10-2013

Location: Europe

Member Is Offline

|

|

You can get an idea about performance by checking the density when it is casted. The better the density the better the performance

For comparison

ETN 1.72

PETN 1.77

RDX 1.82

HMX 1.91

[Edited on 11-11-2022 by underground]

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1339

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: cool.gif

|

|

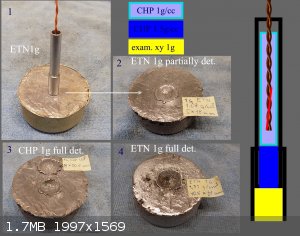

Professionals usually test 1.00 g of the substance under investigation. The smaller cavity is 6/8mm x 50mm. Which is the basic detonator for the

substance under investigation. The examined material is in a cavity of 8/10 x 22 mm. Aluminum brick gives the most accurate results. But for initial

tests, a lead brick is enough. Which provides good indicative results. Lead is easy to cast again and again. In the first test (examination of ETN 1g)

there was an incomplete detonation. Reason unknown. (fig. 1+2) During the examination of CHP 1g, a complete detonation occurred. (fig. 3) During the

second test of ETN 1g, a complete detonation occurred. (Fig. 4) For standardization and comparison, the most important result is in Fig. 4. Thus the

crater cca dia. 20 x deep 10 mm. The basic detonator contains highly compressed CHP with a density of 1.45 - 1.6 g/cm3, 250 - 300mg.

The rest of the detonator is filled with CHP with a low density of 0.8 - 1g/cc. The total charge of the basic detonator is usually 1g - 1.2g CHP.

Development of primarily - secondary substances CHP (2015) Lithex (2022) Brightelite (2023) Nitrocelite (2024)

|

|

|

Hey Buddy

Hazard to Others

Posts: 384

Registered: 3-11-2020

Location: Bushwhacker Country

Member Is Offline

|

|

Quote: Originally posted by underground  | You can get an idea about performance by checking the density when it is casted. The better the density the better the performance

For comparison

ETN 1.72

PETN 1.77

RDX 1.82

HMX 1.91

[Edited on 11-11-2022 by underground] |

I've had a rough time with density. I have measured with erratic results. It needs a large-mass volume displacement measurement to get a solid

average. I just measured a sample right now. 1.83 g/cm^3, I've gotten higher and lower. This sample had some air bubbles. It needs a good 10g melt

cast displacement measurement. I may do it another time. (To be more concise, because of nature of displacement meas., 1.83 is the minimum it could

be, pretty sure it's >1.83g/cm^3 due to air in sample fluffing number)

[Edited on 11-11-2022 by Hey Buddy]

[Edited on 11-11-2022 by Hey Buddy]

|

|

|

underground

National Hazard

Posts: 696

Registered: 10-10-2013

Location: Europe

Member Is Offline

|

|

So most likely its performance will be better than RDX at high density. Its OB is similar to RDX and HMX. If you achieve similar density of HMX i am

sure it will perform like HMX.

Edit: From its chemical structure i could say that it may be a bit more dense than RDX but close to RDX. I believe it will perform a bit better than

RDX at its max density.

Edit2. Something more interesting will be the reaction between NQ and HEX to obtain 2-nitriminohexahydro - 1,3,5 triazine then nitrate it to obtain

2-nitrimino tri-nitro 1,3,5 triazine, which is like your EM but with 3 more oxygen molecules. It will have a greater density and OB. It will be like

keto-RDX but with the NQ structure instead of NU structure. NQ based keto-RDX wont have the disadvantage of decomposition with moisture like NU based

keto-RDX. I have always wondering if keto-RDX can be made with NQ instead of NU and this proves that it can be made. The procedure of making keto-RDX

can be followed but using NQ instead of NU will result a NQ based keto-RDX. Very interesting. NQ based keto-RDX will have the same performance as HMX

without the decomposition disadvantage the classic keto-RDX got. I am sure the nitration of NQ based keto-RDX can be made with mixed acids. Holy

grail?

[Edited on 12-11-2022 by underground]

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1339

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: cool.gif

|

|

The tested substance of this fiber should create more precise edges of the hole in the steel plate (2.45 mm) than the hole on the right. That is, with

an internal diameter of the cavity of 6 mm and 300 mg of the investigated substance. I recommend assigning your substance some comprehensible

(working) abbreviation. For example: Guanex, Guahex, Guanite, Hexamite, Hexagun. It looks like foam, so: Foanit, Foamit, Fluffynit. A pile of ice is

used, so: Icelit, Icenit. (It will be the holy grail when we see the first holes)

Development of primarily - secondary substances CHP (2015) Lithex (2022) Brightelite (2023) Nitrocelite (2024)

|

|

|

Hey Buddy

Hazard to Others

Posts: 384

Registered: 3-11-2020

Location: Bushwhacker Country

Member Is Offline

|

|

Quote: Originally posted by underground  |

Edit2. Something more interesting will be the reaction between NQ and HEX to obtain 2-nitriminohexahydro - 1,3,5 triazine then nitrate it to obtain

2-nitrimino tri-nitro 1,3,5 triazine, which is like your EM but with 3 more oxygen molecules. It will have a greater density and OB. It will be like

keto-RDX but with the NQ structure instead of NU structure. NQ based keto-RDX wont have the disadvantage of decomposition with moisture like NU based

keto-RDX. I have always wondering if keto-RDX can be made with NQ instead of NU and this proves that it can be made. The procedure of making keto-RDX

can be followed but using NQ instead of NU will result a NQ based keto-RDX. Very interesting. NQ based keto-RDX will have the same performance as HMX

without the decomposition disadvantage the classic keto-RDX got. I am sure the nitration of NQ based keto-RDX can be made with mixed acids. Holy

grail?

[Edited on 12-11-2022 by underground] |

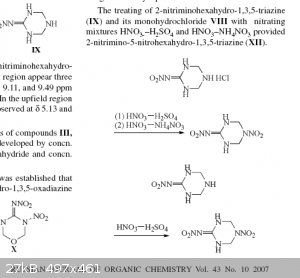

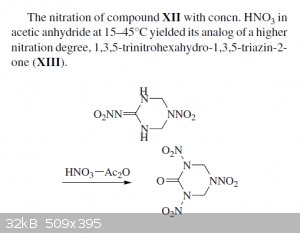

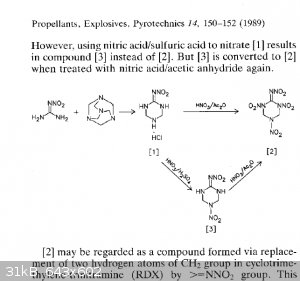

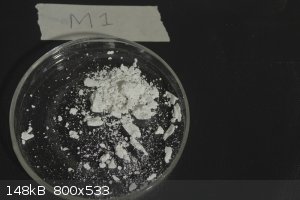

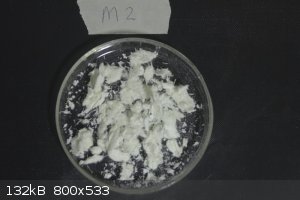

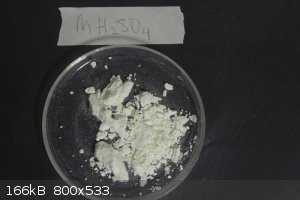

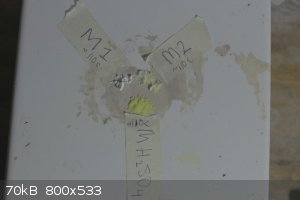

See images for result of higher nitrations of NHHT. It appears to have reversion to oxadiazines or an almost Keto-RDXlike material depending on

concentration and combination of HNO3/H2SO4/Ac2O.

IMO "holy grail" is accessibility, simple processing and high performance combined. This is the reason I think this compound should be known.

Melt-cast, with cheap less-hazardous materials and a low intensity synthesis procedure. High performance is the only box to tick, then IMO, it could

be considered by some to be a "Holy Grail".

There are complications. The combination of complications make this a slow work load to examine. It's not as simple as just loading up a test sample

and detonating it. This is where I could use help. If anyone would like to help, I could use assistance and confirmations.

Im waiting on a shipment of lead for block tests, but there are a few issues.

I believe there are ionic versions being rendered here between the two methods of using HCl, which if it is producing ionic members would be a

chloride variant, and H2SO4 is rendering a sulfate. I think the sulfate version is higher yielding but the product does not exhibit the same qualities

as HCl version, crystal structure, melting point, density, and most importantly workability or pourability in melt phase seem different. At least,

that is what I think I am dealing with here. It is difficult for me to say for sure, but they appear to decompose differently when heated with the HCl

being the preferred variant for castability and burn profile. It could also be a free-ion version that is the preferable one.

Of course if ionic variants are what is being produced here, that inevitably begs for a nitrate crystallized from dilute ~40% NA. But at this point

that is a digression until it can be determined which version is the excellent melt castable version.

In conclusion, my methods beginning this effort are simple because I am unexperienced in development of energetics, and so I am learning by the seat

of my pants. However this inexperience has left me to make errors in failing to foresee the complications and increased work load of multiple ionic

members, and so I have not kept a good enough record, nor kept proper separation of all of the samples, because I have operated under the assumption

that they were all identical. They are not identical.

Unfortunately, this realization has made this effort a little frustrating and slower than I prefer. And so, I am now circling wagons and have ordered

a bucket of nitrite and a propane heater for the lab because it is now turned cold. I am prepared to see how far I can get in this effort alone, but

help would be welcome. Particularly in locating the excellent melt cast version.

At this point I am now trying to reproduce and isolate three versions: Chloride, Sulfate and free-ion versions, in order to identify which is best at

melt cast. There is also possibility that my judgement is wrong, and there is not ionic versions, and the differences in character of samples is due

to some other factor.

edit: For underground see third image. Decomposes @ 50 C, but zero OB.

NHHT or the hexahydro HCl is claimed 9000 m/sec @ 1.8 g/cc but claimed to detonate without melting @ 102 C. Hexahydro (NHHT) might be a good ddt

candidate.

[Edited on 12-11-2022 by Hey Buddy]

[Edited on 12-11-2022 by Hey Buddy]

|

|

|

Hey Buddy

Hazard to Others

Posts: 384

Registered: 3-11-2020

Location: Bushwhacker Country

Member Is Offline

|

|

Quote: Originally posted by Laboratory of Liptakov  | The tested substance of this fiber should create more precise edges of the hole in the steel plate (2.45 mm) than the hole on the right. That is, with

an internal diameter of the cavity of 6 mm and 300 mg of the investigated substance. I recommend assigning your substance some comprehensible

(working) abbreviation. For example: Guanex, Guahex, Guanite, Hexamite, Hexagun. It looks like foam, so: Foanit, Foamit, Fluffynit. A pile of ice is

used, so: Icelit, Icenit. (It will be the holy grail when we see the first holes)

|

lol. FDX- frustratingly developed explosive

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1339

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: cool.gif

|

|

F - fastest

D - detonatable

X - stands for variable unknown composition.....

OK....FDX is good acronym

[Edited on 12-11-2022 by Laboratory of Liptakov]

Development of primarily - secondary substances CHP (2015) Lithex (2022) Brightelite (2023) Nitrocelite (2024)

|

|

|

Hey Buddy

Hazard to Others

Posts: 384

Registered: 3-11-2020

Location: Bushwhacker Country

Member Is Offline

|

|

Well, lead arrived in mail and bought a heater, designed experiment to further test potential ionic species of material. TACP is all ready for

hexamine. 8x22 output casings are cut, cases are loaded with melt cast ETN. Fresh nitric acid in still. Wife mad. Too much science. have to stop for

now.

edit:

hanging out at computer. I've spent a lot of time in the last couple of weeks analyzing hundreds of energetic molecules, determining their valances

and oxygen balance etc. one of the tools I use is this online molecular analysis map https://www.webqc.org/mmcalc.php

I just realized that theoretically desirable explosives can be quickly visually analyzed by examining their atomic percent as a pie chart.

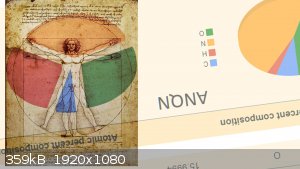

Ive made this graphic to give an example of what I mean.

Look at all the molecules on the left stack. I separated the pie chart divisions so you can see the pie proportions but also see the negative space.

All the explosives on the left have a similar proportion which is highlighted by the negative space which sort of looks like an upside down divinci

with carbon between the legs and he's holding up the nitrogen in the air. Although the molecules on the right are also high performance, they are not

really exceptional, and their upside down divincis have their legs and arms uneven, they are about to drop the nitrogen or throw it in the air and

they are kicking to one side or about to do the splits. This analogy is silly, but, I have performed this examination on many molecules. So far it has

been incredibly consistent.

[Edited on 13-11-2022 by Hey Buddy]

[Edited on 13-11-2022 by Hey Buddy]

lol

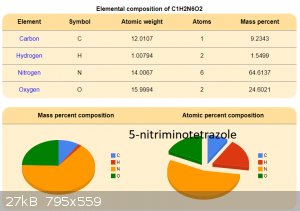

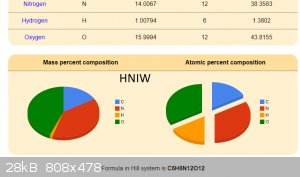

this geometry expression appears to hold true regardless of structure. For example, ANQN is a nitrate with partially ionic bonding that is totally

different than HMX for example as molecule. It's also true for radically different conformations of molecules like this 5-nitriminotetrazole, which is

reported at over 10,000m/s and a tetrazole structure. Instances where it doesnt hold true are in cases like cubanes. but it does hold true for cage

structures like HNIW. I suspect The divinci shape expresses geometrically the ratio of the end state of valances in total composition.

[Edited on 13-11-2022 by Hey Buddy]

|

|

|

Herr Haber

International Hazard

Posts: 1236

Registered: 29-1-2016

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Laboratory of Liptakov  | The tested substance of this fiber should create more precise edges of the hole in the steel plate (2.45 mm) than the hole on the right. That is, with

an internal diameter of the cavity of 6 mm and 300 mg of the investigated substance.

|

Sorry to ask I just want to make sure. What did you use in 300mg amount that punched such neat holes in 2.45mm steel ?

The spirit of adventure was upon me. Having nitric acid and copper, I had only to learn what the words 'act upon' meant. - Ira Remsen

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1339

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: cool.gif

|

|

Left is from 300mg ETN, right hole is from 300mg Cu8 or Li 8 from thread LL8...http://www.sciencemadness.org/talk/viewthread.php?tid=158259

against 2 mm construction steel

Development of primarily - secondary substances CHP (2015) Lithex (2022) Brightelite (2023) Nitrocelite (2024)

|

|

|

Hey Buddy

Hazard to Others

Posts: 384

Registered: 3-11-2020

Location: Bushwhacker Country

Member Is Offline

|

|

Update:

Back in lab again looking for the most desirable species of NTNT also looking for potential dangers. There appear to be several NTNT species that melt

cast, both the sulfate and HCl melt, but they appear to melt at slightly different windows and with a different character, either this is indicative

of ionic species or there is enough of a difference in crystal morphology to cause differences in melt character, apparent decomp temp etc. There are

at least two possible species from HCl so far, depending on conditions.

Tonight I am isolating NHHT (the dreaded monochloride). I suspect it's already been located in an indirect route, but not sure yet. If it is NHHT, it

has not detonated at the reported 102C which is part of why I'm uncertain because that is a characteristic it would be easily identified by. I have

also found report from Metelkina of a ~170mp on NHHT with no mention of explosive decomp. This conflicts with other reports so it is something that

has to be explored through to see if a compound can be formed that will detonate on melt cast. Not sure how far to take it before preparing procedure

but at minimum the variations need to be identified between HCl and H2SO4 so that a continuous process can be developed for H2SO4 method or H2SO4

avoided entirely and simply accepting lower yield HCl method. After NHHT is positively found then I will go back to applicable H2SO4/HCl methods and

attempt to under nitrosate to simulate that mistake and learn about its results.

Pressed NTNT in caps to structural cap failure with no detonation. Melting directly into a cap or vessel requires homogenous heat conduction on

vessel, or a larger mold, in small mass melts air pockets form where some material cools while other material melts when melted inside a casing. it's

cold in my lab now so direct melt casting has resulted in the latter I'v found melting it then breaking the melt casting to grains, then pressing the

high density grains seems to work pretty well.

EDIT: also almost forgot, the geometry analysis from the post above was driving me crazy trying to figure out why HNIW would comply, it should not,

then I realized the program rearranged that molecules CHNO profile so that the colors are not corresponding correctly, HNIW as a cage molecule does

not comply with this, which is further helpful because its as expected. It seems some smart kids could deep -dive and make a geomoetry analysis tool

that would reveal character of energetic materials or unknown or undiscovered energetic compounds at a glance.

[Edited on 15-11-2022 by Hey Buddy]

[Edited on 15-11-2022 by Hey Buddy]

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1339

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: cool.gif

|

|

For example, it is much easier for ETN to create a melt as a 1mm layer. Leave to cool. Break apart on pieces 10x10 mm. Crush slowly on a 2x2 mm sieve.

Then press cold into the cavity. This achieves high densities. It is almost always 1.7g/cc.

I bow to tenacity and diligence on a new substance. I see at least 3 preparation methods emerging. If it were me, I would press the first batch into a

detonator and detonate it against the sheet metal. And if the results showed a high brizance, then only then would I deal with a better method of

preparation. But that's just my opinion, nothing more.

[Edited on 15-11-2022 by Laboratory of Liptakov]

Development of primarily - secondary substances CHP (2015) Lithex (2022) Brightelite (2023) Nitrocelite (2024)

|

|

|

Hey Buddy

Hazard to Others

Posts: 384

Registered: 3-11-2020

Location: Bushwhacker Country

Member Is Offline

|

|

LL, I am not concerned with the number of ways of preparation so much. I'm concerned with firstly someone popping off NHHT trying to cast this and

secondly forming a slightly different compound using the same reagents, then complaining about the material when it could in fact be a different

material.

My hope is a little bit can be learned about possible mis-preparation ahead of time to identify which compound is the target compound and how to

confirm the correct one. Im not entirely even sure I know which one is best I just know at minimum two come from HCl and another comes from H2SO4 (it

appears). It may be that they all detonate with acceptable performance.

Plus, if I'm slow, it's only because I dont know what I'm doing. The plan so far is to collect all possible samples can be produced, keeping track of

which preparation they came from, then when they are catalogued, melt test them all in a single test, then press them all and compare them too when

detonating.

In preparation for detonation, lead and steel strips are secured. 6061 Al stock for is enroute. Now I need to come up with something to detonate them

with. It appears you have done a lot of the photographed tests of materials on SM using CHP in the past, so I'm attempting that. But I have never used

this CHP. It's a bit slow, I need to get CHP made correctly, and tested so as to not waste NTNT samples on misfires.

I attempted to prepare a large batch of CHP for all comparative testing, but I didnt understand the unique ammonation properties of the CHP, I assumed

erroneously that it was analogous to a traditional pyrotechnic first fire, so I didn't follow the procedure with hydration by NH4OH. Lesson learned. I

have now prepared some TACP properly, CHP and tests are next in that part of the effort. When CHP detonations are achieved to the same performance as

previous tests, then I will immediately begin firing all of these samples.

Rest assured, firing tests are coming soon, but this is about as fast as I can go working with these new materials. --I don't think there will be any

issues with its performance as an HE in general, the only question is how well it melts, and if it benchmarks above RDX or if it would out perform

K-6. I suspect it will outperform HMX due to it's higher nitrogen relative percentage and its low hydrogen content. If it melts easily without

complications of decomposition over wide melting conditions, then its usefulness is very good. If it out performs RDX, but does not melt well, then it

is good, but not really excellent. If it outperforms HMX and melts, it is grail that is full of holes. Some of these micro reactions I've done on

testing have produced NTNT in about 7 minutes total from reagents added to filtering. It's very fast. Regardless, I will photograph it all and you

will know if it is good or not so good.

2nd picture is 500 mg NTNT sample in 8x22 casing pressed to case failure. I guess it will serve as the dead press test.

[Edited on 15-11-2022 by Hey Buddy]

[Edited on 15-11-2022 by Hey Buddy]

|

|

|

MineMan

National Hazard

Posts: 998

Registered: 29-3-2015

Member Is Offline

Mood: No Mood

|

|

Can you just do a crude test. Seems insane to have this detailed discussion without any brisance test. Even shattering from a copper tube buried in

sand will tell us much. But just put it on a plate of steel

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1339

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: cool.gif

|

|

Thanks for the extensive explanation. For first and reliable tests, I recommend using 200 mg of ETN. And as the primary substance SA-DS 200mg. Both

can be manually pushed in 6mmdiameter of steel cavity. Convincing the whole world of amazing properties without a single proof sounds

untrustworthy. I'll wait for the test results.......

Development of primarily - secondary substances CHP (2015) Lithex (2022) Brightelite (2023) Nitrocelite (2024)

|

|

|

Hey Buddy

Hazard to Others

Posts: 384

Registered: 3-11-2020

Location: Bushwhacker Country

Member Is Offline

|

|

Im sorry guys.

I was satisfied with a general report about the existence of the substance. That was not good enough. I expounded. That was not enough. I was not

concerned about the requests, but I want to fit in so I complied.

Then mineman wrote

" it can explosive the whole batch during melt casting!???"

and I imagined kids blowing themselves up and I felt bad about that. So I started to look at it more to see if I could blow myself up on a micro scale

to simulate and catch those pitfalls. Then mineman wrote,

"If any monochloride is formed using HCl then it detonated during casting. If any H2S04 is left, it could also detonate after casting."

^He said it was an "issue". So I was then determined to overcome this challenge and safely avoid those potential issues. In doing so, I learned there

are at least three variations that can form from using HCl and at least one that can form from H2SO4. They all have different characteristics on

burning and melting. To determine all this required at least 15 syntheses. One of them is NHHT whose literature procedure is two and a half days.

And I make no claim on the compound, other than that it should have Vd between 7800 and 9500, and *should be over 9000. If it's not around or above

9,000m/s something will be very wrong with either the literature or the molecule is incorrect. I mention all of these variations because I dont want

someone to prepare the incorrect compound then claim I am sloppy or drunk (which i am). --But look at these compounds! These first two are from the

identical reagents and the only difference is reaction temperature, they are both energetic but mp is different, color is different, they burn with

different color flame and gas. Maybe it will be more accurate during testing the new explosive material if it is positive the compound being loaded

into the test cap is correct? Or you could just synth it and blow some up if you have everything else ready. Its a very simple synth. I am not ready.

I have no primary prepared right now and I thought I should use what you guys are using for comparative testing which seems to be LL's CHP, so that's

what I've been trying to make and get to detonate while concurrently running all of these development tests. It's a lot of work and I asked for help,

no one offered to help (which is fine), I have only been able to hammer detonate CHP so far and have not been able to detonate it in a cap yet. So I

currently have no primary, i'm considering just synthing some lead azide. Im still trying, not giving up, im just not that fast, I'm sorry.

|

|

|

MineMan

National Hazard

Posts: 998

Registered: 29-3-2015

Member Is Offline

Mood: No Mood

|

|

I wrote those things because I don’t want someone blowing up firings melt cast because of sulfuric acid in the crystals.

You do fit in. You may not have noticed but you actually revived this forum which was pretty much dead. You have done great investigative work.

We’re just impatient because it seems so damn promising.

The CHP works, every time. If you get the grain sizes even remotely close.

Standard tests are great. But we can also tell a lot from 1 melt cast gram in a tube placed on scrap steel. Or burying a 6mm copper tube in a 5 gallon

bucket of sand and collecting the fragments.

You have done insane work, but everyone here wants a 9kms melt cast…. So you must deliver. Then we can be business buddies  and hopefully find a way to use your invention. and hopefully find a way to use your invention.

Also, invite your wife into the garage with a little lab coat role play so she is more willing of your project  )) ))

PS. If I sound insane it’s just the genius in me

[Edited on 16-11-2022 by MineMan]

|

|

|

| Pages:

1

2

3

4 |