Diachrynic

Hazard to Others

Posts: 219

Registered: 23-9-2017

Location: western spiral arm of the galaxy

Member Is Offline

Mood: zenosyne

|

|

2,2'-Bipyridine synthesis

2,2'-Bipyridine is a good ligand and forms many interesting complexes. In this post I want to explore the historically first synthesis of

2,2'-bipyridine. Although the yield is low, I consider this method to be more OTC than the other route using copious amounts of pyridine and

Raney-Ni.[1][2]

Chemicals:

Zinc picolinate

Soluble copper salt (acetate, sulfate)

Sulfuric acid (or another strong acid) and sodium bicarbonate if starch is to be destroyed

Hydrochloric acid

Potassium hydroxide (or sodium hydroxide)

Ethyl acetate (or some other organic solvent to extract)

Part 1 - Copper(II) picolinate:

The first step is to make copper(II) picolinate. While this may not seem OTC, zinc picolinate is used a zinc supplement and can be fairly easily

obtained. Of course it is more convenient to get pure zinc picolinate, but I was only able to get zinc picolinate capsules for cheap.

This part of the procedure is based mostly on a post by Lion850.[4] This was also the only source that contained an estimation for the

solubility of zinc picolinate, which is about 65 g/L in near boiling water according to [4].

I bought 240 capsules containing each 50 mg zinc as the picolinate. This is equivalent to about 70 g of zinc picolinate tetrahydrate. The combined

mass of extracted powder was 117 g. The only other listed component is rice starch.

The starch and the poor solubility of zinc picolinate make hot filtration impossible. The solution is too viscous. Fortunately, there is a trick.

32.00 g of the powder (equal to 19.15 g of zinc picolinate tetrahydrate) was put into a large beaker, 400 mL of water were added as well as 44 g of

14% aq. sulfuric acid. The beaker was covered with a watch glass and boiled for 1 h. Then sodium bicarbonate was used to neutralize the solution to a

pH of about 5-7, about 20 g were required. The starch is now hydrolyzed enough to not impede hot filtration anymore. Using a Büchner funnel, the

solution is vacuum filtered, some insolubles remain on the paper.

From the filtrate some zinc picolinate tetrahydrate is already crystallizing. They are redissolved with heating. To the near boiling solution is added

a saturated hot solution of a copper(II) salt. Both copper(II) acetate[3] and copper(II) sulfate seem to work well for this. A small excess

doesn't seem to hurt. The solution turns a deep blue, and a few seconds later a dark blue precipitate is observed. The solution is left to cool

overnight and filtered the next day.

After drying on air, 16.08 g (93% yield) of the dihydrate salt are obtained. After careful drying on a hotplate at about 200 °C 14.25 g (92% yield)

of, ideally, anhydrous copper(II) picolinate are obtained. The drying process does not seem to affect the color much.

Copper(II) picolinate dihydrate.

Crystals of copper(II) picolinate dihydrate under the microscope. (Image left to right about 15 mm.)

2,2'-Bipyridine test tube/demo version:[5]

If you merely want to see the red iron complex, you can do the following: Place a spatula tip of the copper(II) picolinate (either anhydrous or

hydrated works) in a large test tube and heat it strongly with a propane torch. The salt will melt and bubble and some smoke will escape (fume hood,

pyridine!), but some drops will condense in the colder parts of the test tube. Let the test tube cool to room temperature, then rinse the sides down

with some water and decant or filter from the solid residue. Add a crystal of ammonium iron(II) sulfate hexahydrate to this solution. An intense red

color is immediately observed. The red color is mostly [Fe(bipy)3]2+ and a bit of the terpyridine complex.

2,2'-Bipyridine:[5]

Upfront a WARNING, because the author mentions that besides pyridine, 2,2'-bipyridine, higher

oligopyridines also some HCN is produced, which is very toxic! I was unable to detect any in my experiment, but be warned.

My distillation apparatus consisted from two 15 mm diameter and 11 cm long copper pipe connected with one 90° copper elbow and closed off at one end

with a copper endcap. I used fittings meant for soldering, but just friction fit them together. Ideally, you would braze all but the connection of the

capped pipe to the elbow, so new picolinate can be added after one batch is done. I would also recommend making the still pot shorter. Some blank

copper wire was used to prevent the end cap from falling off. This apparatus was clamped with a metal clamp such that only the now secured end cap

could fall off.

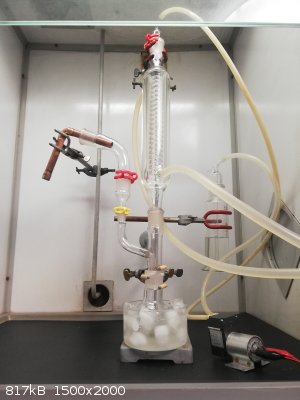

The open copper pipe pointed as deep as possible into a 105° glas adapter which is connected to a claisen adapter on a 100 mL RBF submerged in an ice

bath. On top of the claised adapter was placed a condenser and a gas take off, leading to a 12 V membrane vacuum pump connected to gas washing bottle

containing 5% sodium hypochlorite bleach for HCN destruction. The opening where the copper pipe inserted was also covered with aluminium foil. This is

so as little smoke can escape without passing through the flask and condenser.

The overengineered apparatus. The wire and the foil have not been added yet.

The copper still is filled with about 2-3 g of dry copper picolinate at a time (note that Blau[5] recommends working in 1 g batches in

small glass retorts, I am deviating here), then closed and heated with two propane torches at once. The goal is to heat the salt as hard and fast as

possible. Soon smoke begins to pour out of the copper pipe and within 1-2 minutes it is done. A tarry distillate is obtained. The still is left to

cool, then disassembled and the residue scraped out with a spatula. This is fairly easy to do and a brittle brown solid with a glassy feel to it is

left behind. This is repeated until all copper picolinate is processed.

The tarry distillate.

During this distillation HCN was tested for both with sodium carbonate + sodium picrate solution soaked on wet filter papers (positive if it turns

from yellow to red) and wet Fe(II)/Fe(III) soaked filter papers (should turn blue from Prussian Blue), but at no point either test was positive.

A solution of 7 g of 37% HCl and 30-40 mL water was used to rinse the angle piece and the claisen adapater out (taken off, all open joints capped,

shaken with the acid, then poured out), which was then added to the main liquid. White smoke was observed, the pH of the solution was strongly acidic

(0-1 with pH paper). The condenser was practically clean, although a single drop of brown liquid had collected in the gas take off on top of the

condenser.

Again, no HCN could be detected, but the literature mentiones it! If any were present it will be released in this step.

In the fume hood the solution was then boiled for 30 minutes, first in the flask, then in a crystallizing dish. Any HCN should now be expelled.

Now a solution of 6 g KOH and 8 g of water was added. The pH was strongly basic.

The solution was distilled with a capped claised adapter (used for steam distillation later) at a mild membrane vacuum of 200-250 mbar. (The use of

vacuum is based on Orgsyn.[1]) The solution seemed to foam somewhat, and about 10-15 mL of distillate were collected at 62-64 °C. This

should contain most of the pyridine along some 2,2'-bipyridine. According to Blau[5] some more 2,2'-bipyridine can be recovered from this,

but for time reasons I haven't done this, but I have kept the solution.

Then the residue is steam distilled at atmospheric pressure, and the water is resupplied via a dropping funnel on the claisen adapter. Again, some

foaming occurs, so the distillation is monitored closely.

In the initial distillate shiny colorless crystals form - 2,2'-bipyridine is only soluble at about 5 g/L.[6] It is recommended to collect

until the distillate only gives a very slight red coloration to Fe(II) salts. But I just collected about 100-120 mL of distillate and called it good

enough.

2,2'-Bipyridine crystallizing from the first steam distillate.

The only very slightly yellow distillate is extracted with 50 mL of ethyl acetate in three portions (so about 15 mL each). The separation of ethyl

acetate is much improved by dissolving a few spoons of sodium chloride in the solution. After the last extraction basically no red color is formed

between the water phase and Fe(II) salts.

The ethyl acetate is slowly evaporated and on the molten residue is pulled a vacuum several times in order to drive off the solvent. The residue

easily crystallizes of cooling.

Finally 0.63 g (9% yield) of a slightly yellow solid is obtained. The literature yield for this preparation is 17%, but I am not sure if this is meant

on a weight basis or on a molar basis.[5]

Final 2,2'-bipyridine. It looks less yellow in person.

The melting point was measured to be 60-67 °C, which is disappointly broad and somewhat low. The literature value is 69.5 °C.[5]

It can be recrystallized from very dilute ethanol,[5] but because I had so little at hand I didn't do this.

A small amount is dissolved in some water and some crystals of ammonium iron(II) sulfate hexahydrate are added (my Fe(II) source throughout this

preparation) - an intense red color is observed.

Tris(bipyridine)iron(II) cations in solution.

A bit of the residue in the stillpot, after buffering with some acetic acid, gives an even more intense red color with Fe(II), which is due to small

amounts of terpyridine.

Literature:

[1] - W. H. F. Sasse, Org. Synth. 1966, 46, 5, https://doi.org/10.15227/orgsyn.046.0005

[2] - Chemiolis, YouTube 2022, "Making 2,2'-Bipyridine and its Ruthenium Complex", https://www.youtube.com/watch?v=kkqECgHcZZY

[3] - H. Weidel, Ber. Dtsch. Chem. Ges. 1879, 12, 1989, https://doi.org/10.1002/cber.187901202207

[4] - Lion850, Sciencemadness 2021, "Metal picolinates", tid=157748#pid663345

[5] - F. Blau, Monatshefte für Chemie 1889, 10, 375, https://doi.org/10.1007/BF01516447

[6] - F. Blau, Monatshefte für Chemie 1898, 19, 647, https://doi.org/10.1007/BF01517438

we apologize for the inconvenience

|

|

|

Dr.Bob

International Hazard

Posts: 2656

Registered: 26-1-2011

Location: USA - NC

Member Is Offline

Mood: No Mood

|

|

Great writeup and photos. This brings up memories of my undergraduate days, when I worked in a heterocyclic lab a few years and made pyridine

complexes much like terpyridine and such, as well as some more polar ones. Got my first X-ray structure of a copper complex with one, got lucky

enough to grow big crystals of it. (back then you need big crystals to get anX-ray structure, now they can work with tiny ones in comparison. But

your yields are good for such a painful route.

|

|

|

Boffis

International Hazard

Posts: 1836

Registered: 1-5-2011

Member Is Offline

Mood: No Mood

|

|

Hi Diachrymnic, nice write up once again and I like your make-shift retort from copper pipe and fittings.

But is this really an easier method, even for amateurs, that the Raney nickel route? I appreciate that Raney nickel is not always readily available

(the last lot I bought was from the Ukraine ): ). Could you use precipitated nickel like a Urushibara type ppt instead of Raney nickel?

|

|

|

|