Keras

National Hazard

Posts: 773

Registered: 20-8-2018

Location: (48, 2)

Member Is Offline

|

|

Sodium chromate from stainless steel and sodium percarbonate

This is a halfway report on something I’m currently trying, given that chromium VI salts are almost impossible to source in Europe (they’re banned

by the REACH directive).

Stainless steel + HCl → (five days to dissolve a spoon) → Mixed solution of Fe (II), Cr (III) and Ni (II) chlorides.

Add NaOH → get a thick goo of mixed hydroxides

Add Sodium percarbonate → the solution immediately turns yellow/brown. After more percarbonate is added, the goo becomes much less viscous, which I

attribute to the change from insoluble Cr(OH)₃ to a soluble Cr (VI) compound, ideally sodium chromate.

I’m still at that halfway house though. Since I don’t have any filtration apparatus at hand, I’m left with a beaker full of rusty stuff which

very slowly decants. Any chance the supernatant water contains Cr (VI) in a usable form that I can make crystals from (my ultimate goal being Chromyl

Chloride for an Etard reaction)?

|

|

|

teodor

National Hazard

Posts: 872

Registered: 28-6-2019

Location: Heerenveen

Member Is Offline

|

|

I did such experiment once (extracting chroumium from stainless steel) but I was not satisfied with the results - I think most of Cr(VI) stays in a

form of iron chromate, not sodium salt.

I would buy Cr metal on ebay to make Cr compounds in case I am unable to buy them.

|

|

|

j_sum1

Administrator

Posts: 6229

Registered: 4-10-2014

Location: Unmoved

Member Is Offline

Mood: Organised

|

|

I have been doing a variety of projects to recycle chromium waste of different kinds and mixed with a range of other stuff.

The simplest route I have found has been precipitation of Cr(OH)3, heating to get Cr2O3, and then fusing with a nitrate salt to obtain dichromate.

Of course, this will not work with iron in the mix.

Extractions and Ire has a yt clip (or 2) where he makes ammonium dichromate beginning with cutlery. After dissolving he oxidises with calcium

hypochlorite and then filters off a solution of calcium chromate. I forget exactly how he converted to the ammonium salt. I do remember the filtration

step being long and painful. And this matches my experience. Cr precipitates can be annoying like that. I have used a large funnel and cotton ball for

filtering. E&I used soft drink bottles converted to funnels and then let it stand for weeks.

I agree that buying Cr or Cr2O3 will greatly simplify your process. If you are not committed to recycling spoons and just want the priduct, then this

will be easier.

|

|

|

j_sum1

Administrator

Posts: 6229

Registered: 4-10-2014

Location: Unmoved

Member Is Offline

Mood: Organised

|

|

Continued...

The liquor you have from the percarbonate treatment will contain some dichromate. But a muddy brown colour suggests to me that there us other stuff in

there as well. That could be Cr(iii), complexes, and impurities of Fe and Ni.

I had a waste container that was similar. I ended up making it alkaline with NaOH and filtering off everything that precipitated. (The residue

evidently contains Cr(iii) since it is a light green colour. It also has a lot of other junk including more chromate, which I won't recover as I know

it will bring a lot of crap with it.)

I am left with 1.5 litres of lemon-coloured solution which contains a lot of sodium chromate and hopefully not too much else. I am unsure how I will

further process this. I may just acidify and use it as is for an oxidant.

It is worth noting that Na2Cr2O7 (and also Na2CrO4) is more than 5 times as soluble as the potassium and ammonium salts. From a concentrated solution

you should be able to precipitate out a desirable solid with a double displacement reaction. There are many options. NH4+ and K+ were my first choices

but you don't get everything. Silver dichromate is also very insoluble but you probably do not want to go that route. Barium chromate will precipitate

easily. Calcium chromate has low solubility and will precipitate somewhat. The solid will dissolve in acid or in plenty of water if you are pricessing

further. These facts may help you to devise a purification route that works for you. One of the first things I did was consult solubility tables for

various chromates, dichromates as well as other salts, copy the information into a spreadsheet and graph some solubility curves. This helped me plan

an approach. (Or, more accurately, eliminate stupid approaches.)

|

|

|

Keras

National Hazard

Posts: 773

Registered: 20-8-2018

Location: (48, 2)

Member Is Offline

|

|

The rationale behind sodium percarbonate is that Cr III should oxidise to Cr VI which is soluble, whereas Fe III and Ni II can’t go that high in

oxidation states and will remain in solid phase under the form of hydroxides or hydroxy-oxides. I didn't take into account that CrO₄ could form

mix-metal compounds with Fe III or Ni II, but I find the probably remote, since most of those ions are already immobilised in their respective

hydroxides.

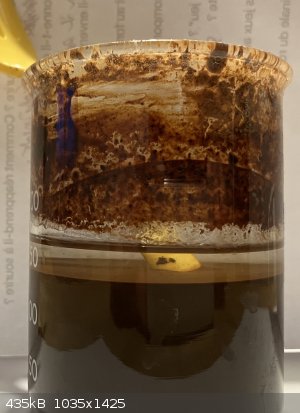

The major problem that I face right now is that after letting the solution decant for almost two days, I’m left with a very narrow upper layer of

what appears to be just water (with probably sodium hydroxide and carbonate in it), but there is absolutely no trace of yellow or orange colour as I

was expecting from Cr VI (see attached picture). I might have to add more sodium percarbonate, I suspect most of the oxygen has been absorbed by the

iron. In any case, there’s definitely no soluble Cr III left, that’s for sure.

Also, I have recently received a ceramic Büchner funnel with a pack of assorted glass-fibre based filters, so I’ll be using that to filter the

solution, given that I don’t want to clog my sintered filters with hydroxide particles.

[Edited on 7-4-2023 by Keras]

|

|

|

Johanson

Harmless

Posts: 39

Registered: 23-3-2023

Member Is Offline

|

|

1. What SS are you starting with? The 300-series contains Ni, while 400-series does not. That's the first question. If you're just starting with a

piece of scrap metal off the shop floor, it's probably 304SS (cheap) or maybe 316SS (expensive). But there are many other alloys, and some do not

contain any Ni at all.

2. You stated you added NaOH until you "got a thick goo". I don't even know what that means in english. What was the pH at that point? All 3 of these

metals precipitate at different pH's. In fact, that's one way you could try to separate them.

3. Okay, so turn them into their Cl salts like you did. Then *carefully* add NaOH (or other base) to selectively ppt them.

4. Just trying to brainstorm here, but sulfide precipitation is another well-known approach used in the water treatment industry. Bubble H2S into the

soup, and selectively ppt them as the sulfide. I'm just throwing out ideas, here.

5. Use selective ion exchange. Pretty complicated, but this is another separation technique used in removal of heavy metals from wastewater streams.

6. Just buy Cr metal online.

7. Just start with 400-series SS. That eliminates the Nickel, anyway.

That's just my 25 cents worth

|

|

|

j_sum1

Administrator

Posts: 6229

Registered: 4-10-2014

Location: Unmoved

Member Is Offline

Mood: Organised

|

|

That is an ugly looking sediment you have there, Keras. I agree, there seems to be no Cr(vi) dissolved. Which suggests that it is in the precipitate

somehow.

One thing to note is that Cr forms a range of complexes with peroxide. That is probably what you have. I don't know where you go in identifying or

separating. I decided to avoid peroxide after a little (ok, a lot) of experimentation. My mixture behaved in unpredictable ways and I was never sure

what state my chromium was in. This is partly how I came to have my waste container of Cr with so much other junk in it.

Sodium percarbonate is an adduct of sodium carbonate and H2O2. I don't think it is the best oxidant for your purpose.

Where to from here? Here us my recommendation.

Worth testing the liquid. Boil off a small portion and see if there are any transition metals in the residue. Unlikely, but worth checking.

Filter the sludge. It will take a while. Plastic soft drink bottle cut down should give you a funnel of sufficient volume. Cotton ball will be ok as a

filter.

I would wash and filter again to reduce sodium salts present. Painful, but I think worth it.

Dry thoroughly. At higher temperatures you should convert some hydroxides to oxides. You should also eliminate any peroxide.

Perform some tests at test tube scale to find a route to.separate Cr from Fe and Ni and leave it in Cr(vi) oxidation state. This will probably involve

digestion in acid again and re-oxidation.

Or, dispose of the mess and start again.

|

|

|

j_sum1

Administrator

Posts: 6229

Registered: 4-10-2014

Location: Unmoved

Member Is Offline

Mood: Organised

|

|

Here is my effort.

Beginning with mixed liquor of Cr waste and failed recycling attempts involving bleach, Ca(OCl)2, peroxide and I can't remember what else. Cr

evidently in mixed oxidation states. No iron or nickel, but plenty of other cations.

Mixture was filtered while acidic. Then the liquor made basic with excess NaOH to precipitate. Filtering has been happening for a week.

Filtrate contains Cr2O3 and white solids. There is still some chromate in there which can be washed out. But I suspect too much other stuff will come

with it to make it worthwhile.

If you followed a similar procedure you should be able to filter out Ni and Fe oxides / hydroxides.

|

|

|

Keras

National Hazard

Posts: 773

Registered: 20-8-2018

Location: (48, 2)

Member Is Offline

|

|

Quote: Originally posted by Johanson  | 1. What SS are you starting with? The 300-series contains Ni, while 400-series does not. That's the first question. If you're just starting with a

piece of scrap metal off the shop floor, it's probably 304SS (cheap) or maybe 316SS (expensive). But there are many other alloys, and some do not

contain any Ni at all.

2. You stated you added NaOH until you "got a thick goo". I don't even know what that means in english. What was the pH at that point? All 3 of these

metals precipitate at different pH's. In fact, that's one way you could try to separate them.

3. Okay, so turn them into their Cl salts like you did. Then *carefully* add NaOH (or other base) to selectively ppt them.

4. Just trying to brainstorm here, but sulfide precipitation is another well-known approach used in the water treatment industry. Bubble H2S into the

soup, and selectively ppt them as the sulfide. I'm just throwing out ideas, here.

5. Use selective ion exchange. Pretty complicated, but this is another separation technique used in removal of heavy metals from wastewater streams.

6. Just buy Cr metal online.

7. Just start with 400-series SS. That eliminates the Nickel, anyway.

That's just my 25 cents worth

|

Hey,

first of all, I do have chromium oxide (from which I intend to make a bit of Chromyl Chloride later today), so this is more an effort to help with

other people or an eventual refilling.

You’re right about Cr(OH)₃ forming first, then iron and finally nickel hydroxide. I didn't really pay attention to the K of the different

reactions until I watched the video of this guy. The video is in French (we were, last time I talked to him, neighbours). He uses bleach to oxidise Cr III to Cr VI and

seems, after a lot of filtration / washings / changes of pH get a good 66% yield of calcium chromate from his starting 18/0 stainless steel.

I started from a 18/10 stainless steel, so there’s definitely 10% Ni in my goo. My idea was to precipitate everything and then to selectivity

re-solubilise chromium by: 1. adding extra sodium hydroxide that converts Cr(OH)₃ into the (more) soluble [Cr(OH)₆]³⁻ complex; and 2. use an

oxidant to turn insoluble Cr III hydroxide into a soluble Cr VI compound, reckoning that neither Fe nor Ni are (a priori) able to undergo such changes

and would be left behind as insoluble hydroxides.

I also bore in mind that: 2 CrCl₃ + 10 NaOH + 3 H₂O₂ → 2 Na₂CrO₄ + 6 NaCl + 8 H₂O

I didn't measure the pH. At home, in my flat, I have only minimal equipment. My lab is located in my mother's cottage, which is very convenient, with

plenty of space outside and an outhouse to store all the stuff. That being said, I could’ve brought back a reel of pH paper. Will do that this

weekend.

Since I have some pure CrCl₃ left, I’ll try and see what happens when sodium hydroxide and then percarbonate is added to it. That could give a

good insight into what's happening to my ‘goo’

And j_sum, thanks for the suggestions. I’ll experiment with different methods and see if I can get anything out of this messy mixture.

[Edited on 8-4-2023 by Keras]

|

|

|

Keras

National Hazard

Posts: 773

Registered: 20-8-2018

Location: (48, 2)

Member Is Offline

|

|

Update: I suspected the problem was that Fe II had somehow ‘eaten up’ all the percarbonate before Cr III had a chance to turn to Cr VI. So I kept

adding more percarbonate. Something odd is that addition of percarbonate results in bubbling and frothing, which I think is oxygen: probably one of

the ion in solution catalyses the decomposition of hydrogen peroxide, much like manganese dioxide does. Anyway, after addition of a liberal, yet

unweighted quantity, I proceeded to filtration and miracle! (It’s Easter) I got a yellow liquid coming through with much difficulty (even under the

greatest vacuum I could achieve with my water aspirator, it hardly let more than a drop every few seconds).

The result is a deep yellow/orange solution, probably a mix of Cr VI something and sodium carbonate, which precipitated out in the Erlenmeyer.

|

|

|

j_sum1

Administrator

Posts: 6229

Registered: 4-10-2014

Location: Unmoved

Member Is Offline

Mood: Organised

|

|

Well done.

If you have some thiocyanate or potassium ferricyanide you can test for iron in your filtrate.

You should also test with acid and alkali to see if you get the chromate-dichromate change. You will soon notice if there are other transition metal

compounds in there.

The fun part now is separating your chromium compound from whatever else is there. As I said before, the sodium salts are very soluble so double

displacements are possible. The difficulty is that addition of potassium or ammonium salts risks precipitating something else with a similar

solubility to ammonium dichromate or potassium dichromate. I have not found easy solutions for the complicated mixtures I have ended up with. Right

now I have some rather impure calcium carbonate and some quite good potassium dichromate, both of which are dry. I also have a solution that I believe

is about 50:50 sodium hydroxide and sodium chromate.

|

|

|

Admagistr

Hazard to Others

Posts: 350

Registered: 4-11-2021

Location: Central Europe

Member Is Offline

Mood: The dreaming alchemist

|

|

I would use natural chromite: FeO.Cr2O3,it is sold as foundry sand in 25 kg bags and is very cheap.It will contain similar impurities as stainless

steel...Other impurities are Al,Mg,Zn...

|

|

|