| Pages:

1

..

16

17

18 |

m1tanker78

National Hazard

Posts: 685

Registered: 5-1-2011

Member Is Offline

Mood: No Mood

|

|

Before you all get too carried away with the math...

Remember that chlorine, the product generated at the anode, is a gas and as such, impedes the reliable flow of current. Unfortunately, molten NaCl

whose temperature range falls anywhere above NaCl MP and below Na BP is considerably viscous. I suppose this isn't such a big problem if the bath is

heated externally in that the NaCl bath will remain molten regardless of the current density, etc.

In any case, once a certain anode current density is exceeded, a fearsome hiss will ensue and efficiency will go through the floor. This is actually

an equilibrium between chlorine gas generation (and NaCl displacement from the anode) and the electrolyte flowing back to the anode (as chlorine

bubbles off). The result is that the tip(s) of the anode(s) will carry more average current and will erode much faster than the superior part of the

anode(s).

When the current density is decreased below that bitter sweet spot, I get 'burbling' at the anode. Sodium and chlorine are red/ox'ed rapidly. This is

the Downs Cell sweet spot as far as I'm concerned.

Sorry, I got a bit off topic. Anyway, how does one account for gaseous product(s) when planning out electrode configuration, resistances, etc??

Surely the viscosity of the electrolyte must be taken into consideration??

Tank

Chemical CURIOSITY KILLED THE CATalyst.

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

What's "considerably viscous"? My experience with molten salt has been a very watery consistency. Of course, I'm not about to mix water with it for

a side-by-side test!

|

|

|

m1tanker78

National Hazard

Posts: 685

Registered: 5-1-2011

Member Is Offline

Mood: No Mood

|

|

I don't blame you! Anyway, I guess what I'm trying to say is that the residence time of chlorine on the anode must be taken into consideration when

drafting equations and so forth... Or am I wrong? Even electrolysis in aqueous electrolyte tends to produce bubbles on electrode(s) that don't

immediately rise to the surface. In most industrial settings where this is undesirable they usually incorporate vigorous stirring of some sort (as

with electroplating). Yes, molten NaCl is watery but still not as free-flowing as water.

Tank

Chemical CURIOSITY KILLED THE CATalyst.

|

|

|

WGTR

National Hazard

Posts: 971

Registered: 29-9-2013

Location: Online

Member Is Offline

Mood: Outline

|

|

Recently I did some experiments with molten salts, using my new electric furnace. This was basically just me "playing around"

with various salt mixtures, so sorry about being short on pictures this time around. I wanted to report these results, however,

because I thought some of them were interesting.

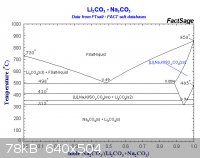

Using the information from this phase diagram here:

I made a 50/50 mole% Li2CO3/Na2CO3 melt of about 17 grams total. The crucible was mild steel. I actually just wanted to

watch it melt, but once it did I decided to try electrolyzing it to see what would happen.

I figured that no alkali metals would form at the cathode, because for one thing, lithium is so reactive at those temperatures

that it would immediately react with the electrolyte if it was formed at all. So I used a copper wire as a cathode, and a graphite

rod as an anode, and electrolyzed the melt at 0.5-1.0A.

After running the cell for ten minutes or so, the power was shut off and the electrodes removed. The anode showed noticeable

erosion, but it was a "clean" erosion; it wasn't disintegrating or spalling, but wearing smoothly. The cathode was encased in a

hard, black, material that looked like carbon sponge. It was quite hard, but voluminous considering the amount of energy

that had passed through the cell. Upon submerging this cooled material in water, no gas evolution was noted. The black material

was then crushed underwater with pliers, and still no gas was produced.

Just for fun, I decided to add NaCl to the melt. After doing so, the molar composition of the molten bath was split evenly three

ways between NaCl, Li2CO3, and Na2CO3. Upon applying the same amount of current as before for about the same amount

of time, I noticed small "fireflys" appearing around the cathode. Tiny little orange flames would appear from time to time on

the surface of the electrolyte. No chlorine production was noted, although there was quite a bit of gas coming out from around

the anode. When the cathode was removed, the same hard black solid was present around the wire, but this time it reacted with

water, vigorously gassing for a couple of seconds. Every time the gas evolution slowed down, it could be restored by slightly

crushing the solid with pliers underwater. One time I had trouble breaking open a particularly hard piece, so I lifted it out of

water to crush it. Upon breaking open, the moist solid erupted into a 2cm yellow fireball, with a whisp of white smoke curling

away.

I tried the same experiment again, but this time with a copper anode that I had electroplated with nickel. The nickel was

suspended in the furnace exposed to the air for about an hour before it was submerged in the electrolyte. The results

at the cathode were the same. I was hoping that the anode erosion would be less, but it was inconclusive this time. The nickel

plating appearing to be loosening up, and I probably need to use a solid piece of nickel for this.

Afterward I was hunting around online to see if I could find some information that would corroborate what I had just done.

I think this is a relevant resource here, complete with pictures:

Attachment: 1209.3512.pdf (636kB)

This file has been downloaded 1378 times

In one case the electrolysis of molten Na2CO3/K2CO3 was noted as not leaving a coating of carbon on the cathode. Upon

adding Li2CO3, or CaCO3, a hard carbon deposit would begin to form at the cathode. As far as I know, no mention was made of

the presence or absence of alkali metals formed in any of their experiments.

As a result of my few tests, I'm not sure of the temperature at which Sodium reacts with a carbonate, but it appears that it can

coexist in the molten carbonate bath at about 650C....or at least it can when it is co-deposited into a solid conglomeration with

carbon.

|

|

|

m1tanker78

National Hazard

Posts: 685

Registered: 5-1-2011

Member Is Offline

Mood: No Mood

|

|

WGTR:

There are a ton of side reactions that can (and do) take place in a cell of molten salt(s). Some of these are undocumented afaik. For me, the

real fun was what I called 'garbage time'. When it came time to discard the fused salt mixtures, I always performed at least one experiment

before shutting down the power.

Adding metal carbonates in almost any proportion drastically changes the cell reactions. You already observed the first and most obvious -- no (or

very little) free chlorine gas is evolved. Your black sponge is sort of a glass-carbon-electrolyte-metal matrix. If you let it sit in air, it will

develop some white spots that will become goop and then runny. Under some coercive conditions, one can make an intercalated solid this way.

Tank

Chemical CURIOSITY KILLED THE CATalyst.

|

|

|

WGTR

National Hazard

Posts: 971

Registered: 29-9-2013

Location: Online

Member Is Offline

Mood: Outline

|

|

In a way this is what I'm going for: Intercalating (or alloying) alkali metals under cell conditions into a solid at the cathode.

This solid in turn will (hopefully) have similar reactivity to the pure alkali metal itself, while making it easier to collect the product.

The carbonate has a much lower decomposition potential at high temperatures than the equivalent chloride does. The oxide

requires even less. So really, no chlorine is formed unless one blasts the snot out of the anode.

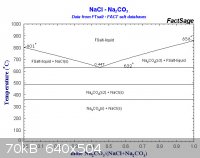

The next experiment will probably start from this system:

with Li2CO3 added incrementally until I begin obtaining an adherent deposit of carbon at the cathode. The current density was

probably too high for that little piece of wire last time, so I'll adjust it downward until sodium stops floating to the top of the bath.

Over time more carbonate will have to be added. In a way, CO2 is being co-electrolyzed using lithium as a catalyst

of sorts. According to the reference mentioned previously CaCO3 can be used to add CO2 back into the system, as CaCO3

is soluble in the melt, but the resulting CaO precipitates out.

Now, for a bit of fun with calcium I picked up some fluorspar (CaF2) from the pottery shop, and some CaCl2 from the grocery

store. The minimum melting point of this system is about 650C, which is much better than pure CaCl2 alone (772C). At 650C it

turns out that CaO is quite soluble in this melt, so this should allow me to avoid halogen gas production, as well as to use

a nickel/nickel oxide anode. Calcium metal is a solid at those temperatures, so its collection--especially at the lower melt

temperature--shouldn't be too difficult. I think at the melting point of CaCl2, calcium dissolves quite readily into the molten salt.

Anyway, if i get around to that, I'll post it in one of the "calcium" threads.

|

|

|

m1tanker78

National Hazard

Posts: 685

Registered: 5-1-2011

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by WGTR  |

The carbonate has a much lower decomposition potential at high temperatures than the equivalent chloride does. The oxide requires even less. So

really, no chlorine is formed unless one blasts the snot out of the anode.

The next experiment will probably start from this system:

with Li2CO3 added incrementally until I begin obtaining an adherent deposit of carbon at the cathode.

[...]

Over time more carbonate will have to be added. In a way, CO2 is being co-electrolyzed using lithium as a catalyst

of sorts. According to the reference mentioned previously CaCO3 can be used to add CO2 back into the system, as CaCO3

is soluble in the melt, but the resulting CaO precipitates out.

Now, for a bit of fun with calcium I picked up some fluorspar (CaF2) from the pottery shop, and some CaCl2 from the grocery

store. The minimum melting point of this system is about 650C, which is much better than pure CaCl2 alone (772C). At 650C it

turns out that CaO is quite soluble in this melt, so this should allow me to avoid halogen gas production, as well as to use

a nickel/nickel oxide anode. Calcium metal is a solid at those temperatures, so its collection--especially at the lower melt

temperature--shouldn't be too difficult. I think at the melting point of CaCl2, calcium dissolves quite readily into the molten salt.

Anyway, if i get around to that, I'll post it in one of the "calcium" threads. |

Perhaps a 'molten salt experiments' thread should be opened?

If you want to recover your alkali metal(s) then forget about trying to form oxides. Oxide of any alkali/alkaline earth metal will spoil your

experiment (the melt will freeze). With that in mind, carbonates are to be avoided as much as possible because they eventually decompose to oxide and

greatly increase the needed heat input/current to keep the electrolyte molten. I've melted(!) a few carbon steel and stainless steel cathodes trying

to 'fight the freeze' in the past.

Also, beware that a molten salt electrolyte that employs carbonate does produce some CO. I imagine highly toxic nickel carbonyl could easily

form if one uses a nickel cathode under certain conditions.

A few 'typical' observations I made when sodium carbonate was included in the recipe:

One interesting side reaction I've observed is the formation of Fe3(CO)12 in a certain temperature range while the solid electrolyte is cooling. IIRC,

I posted a pic in the 'pretty pictures' thread.

Warm sodium puts off an eerie blue flame in a CO2 atmosphere (i.e. decomposing sodium carbonate/bicarbonate). Sodium reduces CO2 to CO which in turn

burns in air to produce a lovely blue flame. In slightly harsher conditions, sodium will reduce CO2 to carbon. Under very harsh conditions, sodium

will reduce CO2 and form diamonds from the resultant carbon. I don't have the equipment to personally confirm that last one but I suppose you

could just start with graphite.

Sodium formate??? Affirmative.

Sodium hydride??? Maybe. Hard to prove and impossible for me to isolate from other salts. Evidence gives a nod but who knows?

A few scars and scares can be summed up with the following:

Safety should go beyond potential thermal burns and mass ejections of molten salt and alkali metal (been there!)  I strongly recommend doubling up on eye protection. Goggles AND face mask should

be worn even with small quantities. Some conditions favor emissions of toxic gasses and/or corrosive dust. I strongly recommend doubling up on eye protection. Goggles AND face mask should

be worn even with small quantities. Some conditions favor emissions of toxic gasses and/or corrosive dust.

I can dig up some references if anyone is interested..

Tank

Chemical CURIOSITY KILLED THE CATalyst.

|

|

|

WGTR

National Hazard

Posts: 971

Registered: 29-9-2013

Location: Online

Member Is Offline

Mood: Outline

|

|

I might move to a different thread if things really get off-topic, but not just yet.

I think that sodium will react with Na2CO3, I'm just not sure what temperature is required for that to happen. Lithium obviously

reacts with great vigor in the presence of carbonates at 650C. The melt consisting of Li2CO3 and Na2CO3 produced no

free alkali metal that I could notice. When NaCl was added, what I think happened is that the added concentration of Na+ in the

melt allowed sodium to start being reduced along with lithium at the cathode. The lithium reacted away, leaving some sodium

mixed in with the carbon. At least that's what I think, I could be wrong.

Certain oxides are actually soluble if the supporting electrolyte is compatible with them. Li2O and Na2O are fairly soluble in

this particular molten bath. CaO is much less so, but still soluble to a few percent or so. But yes, the way that I'm running this

bath will soon cause the electrolyte to solidify, due to depletion of carbonate, and the buildup of oxides. If CaCO3 is used

initially instead of Li2CO3, then the bath consists of CaCO3, Na2CO3, and NaCl. All of those salts are very cheap and easy to

find, so I don't think it would be a big deal to change out the electrolyte periodically.

In the case of the calcium system, the supporting electrolyte would be CaCl2/CaF2. The composition of that solvent shouldn't

change, since it wouldn't be electrolyzed. It would simply serve to dissolve a few percent of CaO, which would then be

electrolyzed. Extra CaO could be added as needed.

Certainly, if you have some references to share, I'd be happy to read through them. And I appreciate the discussion.

|

|

|

Zyklon-A

International Hazard

Posts: 1547

Registered: 26-11-2013

Member Is Offline

Mood: Fluorine radical

|

|

If considering chlorides, I suggest KCl, as it has a lower melting point, and potassium is more desired in my opinion.

|

|

|

bfesser

|

Thread Pruned

26-11-2013 at 19:40 |

Metacelsus

International Hazard

Posts: 2531

Registered: 26-12-2012

Location: Boston, MA

Member Is Offline

Mood: Double, double, toil and trouble

|

|

NaK alloy production; shielding with wax

30g NaOH and 30g KOH were melted together in a 100 mL Ni crucible, then ~10A of current were passed through (voltage controlled with variac and

rectifier to keep current more or less constant). Unfortunately, the metal burned off as soon as it formed.

Then, I realized that, because the temperature wasn't too high, I could melt paraffin wax on top of the hydroxide to exclude air. In this way, I

obtained a pea-sized amount of NaK alloy, liquid at room temperature.

[Edited on 12-7-2015 by Cheddite Cheese]

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Nice focus on your arm there, CC!

|

|

|

Metacelsus

International Hazard

Posts: 2531

Registered: 26-12-2012

Location: Boston, MA

Member Is Offline

Mood: Double, double, toil and trouble

|

|

https://youtu.be/anYM4eiJ6P8

A video of the electrolysis with no shielding. Note the sparks by the cathode.

|

|

|

WGTR

National Hazard

Posts: 971

Registered: 29-9-2013

Location: Online

Member Is Offline

Mood: Outline

|

|

Quote: Originally posted by Cheddite Cheese  |

Then, I realized that, because the temperature wasn't too high, I could melt paraffin wax on top of the hydroxide to exclude air. In this way, I

obtained a pea-sized amount of NaK alloy, liquid at room temperature. |

Very good job! That's an innovative and cheap solution to a difficult problem in lab-scale alkali metal production. If you

make another video using the paraffin approach, it would go right to my "download" folder.

|

|

|

Metacelsus

International Hazard

Posts: 2531

Registered: 26-12-2012

Location: Boston, MA

Member Is Offline

Mood: Double, double, toil and trouble

|

|

Caution: wax is flammable!

I was doing another run, trying to make a good video (so I had my camera with me). A little bit of NaK must have come into contact with air despite

the wax. It set the wax, which was heated past its flash point, on fire. I put it out by covering up the cell with a metal lid and waiting a few

minutes for it to cool down.

|

|

|

tsathoggua1

Hazard to Others

Posts: 335

Registered: 8-1-2017

Location: Beyond the pale

Member Is Offline

Mood: Phosphorescent

|

|

A couple of questions, if I may,

Of late, my father decided for some unfathomable reason to order some carbon crucibles. Why? I really don't know. Said he just wanted to play around

with them, only, he's shown not the slightest sign of doing anything of the sort. Actually my suspicion is that he bought them expecting that I'd be

the one using them (which he gave pernission to do) having realized that currently (pun intended) one of my latest projects is having yet another

crack (or quite a lot of cracks, would be more like it, one after another after another after another, accompanied by plenty of flying molten sodium

metal)

I have currently a power supply that will deliver either 14A@15V or 35A@5v and I've managed to make some Na and Na/Ca alloy with this, primarily using

the higher amperage terminal of the power supply.

I've been concentrating on hydroxides as the melt, because of the reactivity issues with Cl2 salts, although adding a small amount of anhydrous CaCl2

to lower the melting point has been of use. And of course there is the issue of the intermetallic compound formed by fused hydroxide dissolving Na

into it.

Now, the crucibles my old man ordered are of the black carbon type material, amorphous carbon AFAIK, I invested myself in some more crucibles of

various kinds, steel/iron ones for plating in chromium or in nickel, I did treat myself to an all nickel crucible with lid through which a short

length of glass or ceramic tubing will be inserted through the top as an insulating ring, not contacting the melt itself directly, but serving to

merely insulate the incoming electrode wire(s) from the metal crucible body and lid.

The ones my old man bought are of the black, dense, quite hard carbon allotrope/polymorph, whilst one of the carbon ones I myself ordered is actual

graphite, softer, silvery and unlike the black carbon type, which are reasonably difficult although not challengingly so to scratch with metal

implements, the graphite ones are much softer, although the one that arrived today is perhaps a quarter inch thick.

Metal electrodes being used are either copper, or made out of a nickel alloy, the kind used for making guitar frets, since there is a large bucket

chock full of fret-wire offcuts about 2'' long, and this alloy, whatever the composition, seems to stand up to fused NaOH very well, even when a blob

of caustic is allowed to set on the end of one and that end, holding the other in pliers, is subjected to a roaring flame from a propane torch.

And whilst the black solid carbon (same stuff as is in battery carbon rods) crucibles seems to stand up to a fair lot of abuse, is there a significant

difference in the resistance of this allotrope of carbon and of actual bona fide graphite per se, the true, softer (against indentation/scratching

mechanically with hard metal or carbide tipped cutterss etc.) to fused alkali hydroxide melts at an equal degree of heat and time course, equal

current/voltage and other variables, the variable changing being solely that of graphite vs black (non-vitreous) carbon?

And lastly, I seem to remember that a melt of NaOH and KOH, when fused, acts as an eutectic and in the right proportions, can result in the lowering

of melting point of the mixed melt bath to as little as 200 degrees 'C.

Going to have a shot at preparing some NaK tonight now that today, Mr.Postie dropped off not only that large, thick graphite crucible but a nicely

weighty sack of KOH, a few kg at least

What is the ideal eutectic proportion in an NaOH/KOH melt? and can it be further lowered with addition of a little anhydrous carbonate or bicarbonate?

Lastly, I have also potassium hydrogen phosphate. Two questions I have regarding this. Has it any role it may serve in the formulation of molten salt

eutectics, and also, whether fused, or in aqueous solution, be reduced to phosphorous acid or hypophosphite salts? or for that matter, H3PO4 to these

acids as is, without presence of counterion, since the presence of the hydrogen ion species should be sufficient to permit conductivity.

|

|

|

Novichok

Harmless

Posts: 3

Registered: 15-7-2017

Member Is Offline

Mood: No Mood

|

|

Making sodium metal from sodium hidroxide

This process uses electrolysis as a means of synthesizing sodium metal. . . Using a heat-resistant vessel that does not conduct electricity, place

sodium hydroxide in it and heat it to 320 degrees Celsius. When it reaches such temperature the compound will be liquid and therein place the positive

and negative poles of the electrolysis cell and begin the process Of decomposition of the element, soon after a few hours will see white balls in one

of the poles, this is the metal sodium, remove it from the container and put in a bowl with mineral oil and store, hopefully have helped. . . You may

be confused by what I said, well I do not speak fluent English.

|

|

|

Jstuyfzand

Hazard to Others

Posts: 166

Registered: 16-1-2016

Location: Netherlands

Member Is Offline

Mood: Learning, Sorta.

|

|

Congratulations! You just described the Castner process.

Although in practise it's a little more difficult.

[Edited on 15-7-2017 by Jstuyfzand]

|

|

|

Novichok

Harmless

Posts: 3

Registered: 15-7-2017

Member Is Offline

Mood: No Mood

|

|

Making sodium metal from sodium chloride

This medium uses sodium chloride electrolysis. . . In a divided, heat-resistant container (between 1000 ° C) and that does not conduct electricity,

place Sodium Chloride and warm the container above 800 degrees Celsius and below 850 Celsius, when heated place the positive and negative poles and

when Once the electrolysis process is started, after a few hours there will be a chlorine smell, keep the place ventilated, the negative pole will

have metallic sodium balls, separate them at the end of the process and place them in a pot with mineral oil

Attachment: phpOSLjs6 (33kB)

This file has been downloaded 1477 times

[Edited on 15-7-2017 by Novichok]

|

|

|

gdflp

|

Threads Merged

15-7-2017 at 06:26 |

gdflp

|

Threads Merged

15-7-2017 at 06:26 |

Jstuyfzand

Hazard to Others

Posts: 166

Registered: 16-1-2016

Location: Netherlands

Member Is Offline

Mood: Learning, Sorta.

|

|

Would a mixture of NaOH and NaCl have a lower melting point than NaOH?

I could not find any papers or write ups about such mixture, which leaves me with low expectations, but it isnt disproven either.

If this mixture would have a lower temperature, it could be promising for Sodium production at home.

|

|

|

metalresearcher

National Hazard

Posts: 731

Registered: 7-9-2010

Member Is Offline

Mood: Reactive

|

|

Add CaCl2 to the NaCl and the mp will lower to 640 C.

|

|

|

Jstuyfzand

Hazard to Others

Posts: 166

Registered: 16-1-2016

Location: Netherlands

Member Is Offline

Mood: Learning, Sorta.

|

|

I am aware of that, but 640 is still a bit high and unpractical.

A eutectic made with NaOH would be sub 330°C, so I was wondering whether a NaOH NaCl mixture would reach these lower temperatures.

|

|

|

Bezaleel

Hazard to Others

Posts: 444

Registered: 28-2-2009

Member Is Offline

Mood: transitional

|

|

Quote: Originally posted by Jstuyfzand  |

I am aware of that, but 640 is still a bit high and unpractical.

A eutectic made with NaOH would be sub 330°C, so I was wondering whether a NaOH NaCl mixture would reach these lower temperatures.

|

If you can tolerate the presence of potassium in your mixture, then consider the eutectic of NaCl, KCl, and CaCl2, which has a MP of 465 C. Check an

earlier post here.

|

|

|

| Pages:

1

..

16

17

18 |

|