| Pages:

1

2

3 |

roXefeller

Hazard to Others

Posts: 463

Registered: 9-9-2013

Location: 13 Colonies

Member Is Offline

Mood: 220 221 whatever it takes

|

|

I just finished my ball mill today while hanging out with the kids during their snow day. I used the drive from a frozen-bowl ice cream maker. It

essentially turns a bowl slowly to push the product against a stationary agitator. It comes with two reductions to slow the motor to reasonable

speeds. I tore it apart and mounted the motor/gears parallel to two rolling dowels and connected it with a wide gum band.

|

|

|

Trotsky

Hazard to Others

Posts: 166

Registered: 6-2-2013

Location: US

Member Is Offline

Mood: No Mood

|

|

That's a good idea, but I use my ice cream maker. Home made gelato is wonderful

|

|

|

roXefeller

Hazard to Others

Posts: 463

Registered: 9-9-2013

Location: 13 Colonies

Member Is Offline

Mood: 220 221 whatever it takes

|

|

Eh, I can buy ice cream from the local creamery. They won't sell me pyrotechnic compositions though.

|

|

|

Refinery

Hazard to Others

Posts: 371

Registered: 17-2-2014

Member Is Offline

Mood: Still

|

|

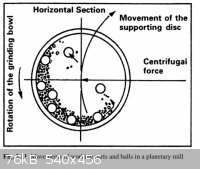

I was thinking of making a planetary ball mill.

https://www.youtube.com/watch?v=0H0stoFw3DY

The idea is to make two different gears rotate around the center to balance out each other between to plates and bring up the rotational speed up to

300RPM.

|

|

|

roXefeller

Hazard to Others

Posts: 463

Registered: 9-9-2013

Location: 13 Colonies

Member Is Offline

Mood: 220 221 whatever it takes

|

|

300 seems fast, light it might throw everything to the circumference without tumbling.

|

|

|

hyfalcon

International Hazard

Posts: 1003

Registered: 29-3-2012

Member Is Offline

Mood: No Mood

|

|

I run an 8" ball mill at 50 rpm. You don't want fast, that will glue your media to the sides of the mill jar.

|

|

|

Refinery

Hazard to Others

Posts: 371

Registered: 17-2-2014

Member Is Offline

Mood: Still

|

|

Please note: planetary mill. There high speeds are must. I have 6" ball mill on me and I run it at about 90RPM. The critical speed is around 120RPM

and I can easily hear it when the rumbling sound stops because all media is stuck to the walls because of centrifugal forces.

My idea is to use one inbound gear and align two inner hears with bearings around an axle so when they rotate, they turn counter-clockwise 2-3 times

per each revolution. Planetary mill idea is to rotate the media and material by the walls, and when the vessel turns, the media and material is

ejected directly on the other wall, creating very high impact energy. Planetary mills are supposed to get 1mm particles below 10um 6-8 times faster

than ordinary mills, so one could grind foil aluminium into dark pyro within 24 hours.

http://openi.nlm.nih.gov/imgs/512/358/3180689/3180689_1752-1...

If you can get the idea from this picture. The small pots contain the grinded stuff and the whole thing spins around 400RPM. The sub-gear rotation

within the pot can reach even as high as 800-1600RPM.

[Edited on 5-3-2014 by Refinery]

|

|

|

Refinery

Hazard to Others

Posts: 371

Registered: 17-2-2014

Member Is Offline

Mood: Still

|

|

For those who understand more physics, is there any reasonable upper limits for plantary ball mill for critical speeds? For the reference picture I

understand that the planetary flasks must be in critical revolution phase in order to work, but would the supporting disk have any upper limit?

|

|

|

Refinery

Hazard to Others

Posts: 371

Registered: 17-2-2014

Member Is Offline

Mood: Still

|

|

For you to know, I am currently working on a planetary ball mill project. I have constructed a two-vessel structure with wooden gears and ran it for

total of 2 hours now. Because I dont have lathe and other high level metalworking tools, I have hand-made the parts and therefore the tolerances are

what they are. I dont have pics on hand because I forgot my camera to my workshop, but will post later. I did a 5-minute test with ballasts(I dont

currently have the SS vessels, they are waiting for welding) using two plastic TCCA containers which fit into the rotating basket quite well, and the

sheer centrifugal forces grinded the TCCA tablets down to powder during this time. I had to stop it because the containers were able to move few

millimeters so that the metallic baskets began to grind through the walls of the baskets and there were a cloud of TCCA in the mill when I opened it.

The biggest problem so far is the noise. It's not just like rumbling of an ordinary ball mill, but imagine two 3-kg cylinders fixed at planetary gears

to rotate at 900RPM around the planetary axis rotating about 300RPM powered by 1.2kW electric motor.  The noise is so horrible that even when the mill is empty, I must wear protectors in my workshop. The noise is so horrible that even when the mill is empty, I must wear protectors in my workshop.  So sad my shop is too close to living compartments I could not leave the mill run

there, so I must make some special arrangements. Well, I made a wooden coffin and simply buried the mill half-way to the ground and covered it with

sandbags and installed some soundproof ventilation shaft and a fan, and now it is all quitet by 10 meters away and close it sounds like large but

quiet diesel engine. So sad my shop is too close to living compartments I could not leave the mill run

there, so I must make some special arrangements. Well, I made a wooden coffin and simply buried the mill half-way to the ground and covered it with

sandbags and installed some soundproof ventilation shaft and a fan, and now it is all quitet by 10 meters away and close it sounds like large but

quiet diesel engine.

Waiting for some Al milling tests. Planetary mills should do the job in less than 24 hours what normal mills take weeks to do and they can't even get

down to sub-micron level!

|

|

|

roXefeller

Hazard to Others

Posts: 463

Registered: 9-9-2013

Location: 13 Colonies

Member Is Offline

Mood: 220 221 whatever it takes

|

|

I imagine most of your noise is coming from gear tooth profiles and tolerances. Did you cut straight teeth or helical? Did you say that you powdered

tablets in five minutes?

|

|

|

TheAlchemistPirate

Hazard to Others

Posts: 151

Registered: 25-3-2014

Location: The point of no return

Member Is Offline

Mood: Enigmatic

|

|

I found a very reasonably priced professional ball mill at cannonfuse.com, I would check there.

"Is this even science anymore?!"

|

|

|

Amos

International Hazard

Posts: 1406

Registered: 25-3-2014

Location: Yes

Member Is Offline

Mood: No

|

|

If you continue having trouble with your ball mill, your grinding media may be lining up in a way that disrupts the grinding process. Upon adding a

plastic bar along the inside diameter of my canister; this kept the balls from lining up and greatly sped up the process.

|

|

|

davidmichaud

Harmless

Posts: 2

Registered: 18-2-2016

Member Is Offline

Mood: No Mood

|

|

Here is another critical speed calculator for wanna be metallurgists and a ball size calculator https://www.911metallurgist.com/blog/top-ball-size-grinding-... and more https://www.911metallurgist.com/blog/EQ

|

|

|

JJay

International Hazard

Posts: 3440

Registered: 15-10-2015

Member Is Offline

|

|

Will something like this work as a ball mill if I use alumina balls: http://www.ebay.com/itm/ROLLING-STONES-MODEL-635-ROCK-TUMBLE...

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

I had the exact same rock tumbler, when I started milling things, which I got at a yard sale for $3 IIRC. I used it to make 10-15g of flake aluminum

powder at a time suitable for flash powder for small firecrackers in 4 days or so from aluminum sandings. Stainless Steel sling shot ammo was used as

grinding media. Used to make small batches of black powder with it too. Eventually (after about 10-12 batches) the drive wheel got worn down to the

point that it wouldn't drive the drum anymore (I assume all the aluminum dust on the drum and wheel accelerated the wearing). I assume the rubber

drive wheel could have been replaced, but it wasn't a great setup anyway. It was too small and the drum couldn't be sealed well at all; there was a

big gap where the two pieces of the drum fit together which I sealed with tape as best I could and ran the mill on an incline so the powder was less

likely to escape. I built a mill with a PVC drain pipe drum after that which was much better in every way.

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

NedsHead

Hazard to Others

Posts: 409

Registered: 9-12-2014

Location: South Australia

Member Is Offline

Mood: No Mood

|

|

I would be concerned that alumina may not have the mass to grind much in such a small ball mill, +1 for building your own ball mill to the

specifications you need

|

|

|

Bert

Super Administrator

Posts: 2821

Registered: 12-3-2004

Member Is Offline

Mood: " I think we are all going to die. I think that love is an illusion. We are flawed, my darling".

|

|

If you are going to re purpose a rock polisher, larger diameter is always better. 6" ID and up drums will make for much shorter working times when

grinding Al powders.

Alumina works, given a large enough Dia. mill jar and larger pieces of media, but heavy media like ball bearings works much faster.

Rapopart’s Rules for critical commentary:

1. Attempt to re-express your target’s position so clearly, vividly and fairly that your target says: “Thanks, I wish I’d thought of putting it

that way.”

2. List any points of agreement (especially if they are not matters of general or widespread agreement).

3. Mention anything you have learned from your target.

4. Only then are you permitted to say so much as a word of rebuttal or criticism.

Anatol Rapoport was a Russian-born American mathematical psychologist (1911-2007).

|

|

|

JJay

International Hazard

Posts: 3440

Registered: 15-10-2015

Member Is Offline

|

|

Hmm... looks like I might have to build a ball mill.

I am very curious about United Nuclear's, but every time I check, they are sold out.

|

|

|

ecos

Hazard to Others

Posts: 464

Registered: 6-3-2014

Member Is Offline

Mood: Learning !

|

|

I built home made ball mill and I used washing machine motor.

the motor was overheated after few days of running however I used a fan to cool it down.

I think washing machines motors are not suitable to work for continues operation!!

any better suggestions ?

[Edited on 1-3-2016 by ecos]

|

|

|

James Ikanov

Hazard to Self

Posts: 81

Registered: 12-7-2015

Location: Alaska

Member Is Offline

Mood: Zen

|

|

Perhaps the motor from a dryer?

I might be off, but I would consider the work load more comparable between a ball mill and a dryer than a washing machine and a ball mill.

If nothing else works, then perhaps you could consider putting your motor on a timer, so it has enough time to cool down occasionally? Even one of

those "I'm going on vacation but want the lights to flick on/off for a few hours" type deals that plug into the wall could probably be had fairly

cheap, if you're using out the wall current.

“To do good work one must eat well, be well housed, have one's fling from time to time, smoke one's pipe, and drink one's coffee in peace” -

Vincent Van Gogh

|

|

|

ecos

Hazard to Others

Posts: 464

Registered: 6-3-2014

Member Is Offline

Mood: Learning !

|

|

the washing and dryer motors are "universal motors"

from wiki:

| Quote: |

negative aspect is that these motors may only be used where mostly-clean air is present at all times. Due to the dramatically increased risk of

overheating, totally-enclosed fan cooled universal motors would be impractical, though some have been made. Such a motor would need a large fan to

circulate enough air, decreasing efficiency since the motor must use more energy to cool itself. The impracticality comes from the resulting size,

weight, and thermal management issues which open motors have none of. |

It is a headache to reduce the speed of the universal motor using pulleys since it has average speed of 10,000 RPM. Mine has 16,000 RPM

I am thinking to use fan motor (induction motor), I am not sure yet if it is the right choice or not !!!

at least induction motors has better power efficiency but I am not sure about overheating.

|

|

|

Great

Harmless

Posts: 34

Registered: 8-2-2016

Member Is Offline

Mood: No Mood

|

|

Trotsky: If you ever scale your ball mill up, here are some great materials I use that you might like too. The belt would be the rubber inner tube

from a child's bicycle, with a diameter of 20 inches. One roller would be a PVC tube coated in this rubber too, and the other would just be inverted

wheels from scrapped furniture. (The wheeled type used for patios and workshops)

|

|

|

wg48

National Hazard

Posts: 821

Registered: 21-11-2015

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by ecos  | the washing and dryer motors are "universal motors"

Snip

It is a headache to reduce the speed of the universal motor using pulleys since it has average speed of 10,000 RPM. Mine has 16,000 RPM

I am thinking to use fan motor (induction motor), I am not sure yet if it is the right choice or not !!!

at least induction motors has better power efficiency but I am not sure about overheating. |

Most dryers have an induction motor. See the one I extracted a few days ago. Unfortunately one of its bearings is worn out. Its a pity as its a nice

size (smaller than than many I see) for a mill.

Yes getting the rpm geared down is pain. I prefer a belt reduction system as its more tolerant of build tolerances.

With a universal motor you can probably use a triac phase controller to adjust the rpm or even better an adjustable dc power supply.

|

|

|

Great

Harmless

Posts: 34

Registered: 8-2-2016

Member Is Offline

Mood: No Mood

|

|

I have the weirdest old electric stirrer from the 60s or older, which has a controllable rpm. Pretty big score, also considering how durable and

strong the motor is.

|

|

|

ecos

Hazard to Others

Posts: 464

Registered: 6-3-2014

Member Is Offline

Mood: Learning !

|

|

I think dryers and washing machines motors are not designed to work for 11 days continuously without stop!

in their work , they run for certain point then stop again and so on, this is not as stressful as running for days without stop.

I am thinking that a fan motor or air pump motor will be the best solution since their normal work is to run for long time !

I am still thinking about better solution !

|

|

|

| Pages:

1

2

3 |