| Pages:

1

2

3

4

5 |

MrHomeScientist

International Hazard

Posts: 1806

Registered: 24-10-2010

Location: Flerovium

Member Is Offline

Mood: No Mood

|

|

I'll confirm what blogfast said above - I got my sodium bisulfate from Home Depot as a pool supply called "dry acid." It's only listed as 93%

bisulfate, but it's worked for my purposes so far. I just add a bit extra dry acid to make up the difference. I used mine to isolate bromine.

|

|

|

elementcollector1

International Hazard

Posts: 2684

Registered: 28-12-2011

Location: The Known Universe

Member Is Offline

Mood: Molten

|

|

Quote: Originally posted by blogfast25  |

I wouldn't worry too much about that colour change: it could be caused by all sorts of things like the last but of volatile contamination blowing off.

It's very hard to tell what it is precisely and colour is deceptive in any case, probably more so at high temperature. If it's nice and white it's

probably fairly pure. Iron would tinge it red to brown for instance.

[Edited on 14-4-2014 by blogfast25] |

Maybe. I've always heard of Nd2O3 being gray or grayish-blue, never white. Plus, it remains just as white when cooled...

A thought: Are neodymium's odd color-changing properties coming into play here? Looking at Google Images for neodymium oxide, there are two versions

of the same photo: One with my coloration, and one with what I consider the 'standard' blue-gray.

I'm going to try calcining it one more time - couldn't hurt, right?

After that, I'll try some acids to see if it really is neodymium.

As for the bisulfate, I'll take a look around.

Elements Collected:52/87

Latest Acquired: Cl

Next in Line: Nd

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

My own homemade neodymium (III) oxide was very light beige. I was sure it was at least 99 %. I'm not too worried about these slight differences...

|

|

|

Dan Vizine

National Hazard

Posts: 628

Registered: 4-4-2014

Location: Tonawanda, New York

Member Is Offline

Mood: High Resistance

|

|

Quote: Originally posted by 12AX7  | Regarding scandium, AFAIK, its use in aluminum alloys is as a modifier, similar to titanium. Titanium finds use as a grain refiner: it is present as

fine TiSix (TiSi2 comes to mind?) intermetallic grains, which have low solubility in molten aluminum and act as nucleation agents, resulting in a

finer, stronger crystalline structure on casting. The amount is usually < 0.1%. This is probably less important for rolled or wrought products.

My short understanding of odd Russian alloys is limited to this: they used lithium-aluminum alloys in rocket parts (skin, structural?). Whether these

(or any other military or special purpose) alloys contain Sc, I don't know.

Tim |

The lithium-aluminum alloys had strength similar to steel. Similar to the strength exhibited by stir-plates tops of aluminum with a little copper

(Dural, I think). Are these two basically the same thing, inappropriately sized impurity atoms screwing up the smooth slide of slip faults, teamed

with creating smaller grains, or is it deeper than that?

Re. Sc in Al, Wiki says:The positive effects of scandium on aluminum alloys were discovered in the 1970s, and its use in such alloys remains its only

major application. You could probably expect to see this in applications where cost is secondary, military or not.

[Edited on 14-4-2014 by Dan Vizine]

|

|

|

Brain&Force

Hazard to Lanthanides

Posts: 1302

Registered: 13-11-2013

Location: UW-Madison

Member Is Offline

Mood: Incommensurately modulated

|

|

MiG-29 components contain scandium-aluminum alloys.

One of the problems with scandium as a pure metal is that it splits water to form the hydroxide. This excluding its low concentration and high cost.

Scandium turnings are also highly flammable.

I'm interested as to what alloys one can form with lithium, magnesium, aluminum, scandium, titanium, and yttrium. All of which are light metals that

form strong alloys. The problem is making them and forming them - again, these alloys tend to burn instead of melt.

At the end of the day, simulating atoms doesn't beat working with the real things...

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

Quote: Originally posted by Dan Vizine  |

The lithium-aluminum alloys had strength similar to steel. Similar to the strength exhibited by stir-plates tops of aluminum with a little copper

(Dural, I think). Are these two basically the same thing, inappropriately sized impurity atoms screwing up the smooth slide of slip faults, teamed

with creating smaller grains, or is it deeper than that? |

Dunno. The phase diagram looks surprisingly typical (a thick intermetallic in the middle, usually suggesting a brittle, fairly strong phase, with

aluminum with solid solubility on one side, and more intermetallics towards the lithium side), so it would be precipitation hardening without a doubt,

like most aluminum alloys (Cu, Mg, Si and Zn among the most important).

AFAIK, interstitial (dissolved) atoms add a little strength, but as I recall, 6061-T0 (annealed) isn't too much stronger than most other non-hardening

alloys (1000 series, 3003, etc.). Which are still a lot stronger than pure aluminum (1199 I think?), which is just ridiculously soft (like lead), but

a long ways to go compared to 6061-T6 (worked, precipitation hardened and aged) or others.

As for scandium and other grain refiners, I guess you could figure those act to prepare the microstructure for what it's best at. Crystal boundaries

are weak, so having many of them means more strength (very crudely). The intergranular impurities also act as wedges, locking slip planes around and

between crystals. I expect this isn't as important for worked material (deformation elongates and refines the crystal structure already), but maybe

it's still fairly useful. And of course, precipitation hardening involves creating very fine particles (<1um IIRC) which lock slip planes within a

crystal.

That's about the extent of my knowledge on this... I've forgotten so much metallurgy since I last used any of it!

Tim

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

You have a reference for this?

|

|

|

Dan Vizine

National Hazard

Posts: 628

Registered: 4-4-2014

Location: Tonawanda, New York

Member Is Offline

Mood: High Resistance

|

|

Tim said "That's about the extent of my knowledge on this... I've forgotten so much metallurgy since I last used any of it!"

To which I reply....hmmm, someone who has forgotten more than I know...glad to make your acquaintance. I have an immense amount of respect for

matalurgists. Metal is the exact opposite of the flat, unchanging, static thing it appears. The levels of complexity under the surface are mind

blowing. Static it is not! I've been self-educating in this field for a decade, on and off, depending on my latest crazy fascination of the moment,

and I only know the surface. I'm humbled by the complexity.

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

On an old repeat of 'Cajun Pawn Stars' last night our pawners sold a 'scandium revolver'. It was a small hammerless revolver, quite futuristically

looking, but it wasn't clear at all what part was supposed to be scandium or whether there was a scandium minority or majority alloy in the gun or

what.

|

|

|

Dan Vizine

National Hazard

Posts: 628

Registered: 4-4-2014

Location: Tonawanda, New York

Member Is Offline

Mood: High Resistance

|

|

The positive effects of scandium on aluminum alloys were discovered in the 1970s, and its use in such alloys remains its only major application.--

Wiki

You could probably expect to see this in applications where cost is secondary, military or not.--Me

A few % Sc in Al is all that is needed. You get a gun light as aluminum but strong as steel. As I noted before, verry expensive. These guns set

records*. In bicycles they allowed the ultimate in weight reduction. I guess it maybe didn't catch on in bikes as I never hear about it, usually Ti/Al

is the thing I believe. Probably too pricey.

*not accuracy

[Edited on 15-4-2014 by Dan Vizine]

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Wait until someone finds a decent deposit, it's only a matter of time...

|

|

|

Zyklon-A

International Hazard

Posts: 1547

Registered: 26-11-2013

Member Is Offline

Mood: Fluorine radical

|

|

Not exactly a reference, but here is the FIRE AND EXPLOSION HAZARDS DATA for some Scandium:

| Quote: |

Flash Point: N/A

Autoignition Temperature: N/E

Flammable Limits: Upper: N/E Lower: N/E

Flammability: Highly flammable

Extinguishing Media: DO NOT USE WATER or halogenated extinguishers. Use special powder for metal fires.

Special Firefighting Procedures: Firefighters must wear full face, self-contained breathing apparatus with full protective clothing to prevent

contact with skin and eyes.

Unusual Fire & Explosion Hazard: Scandium dust is flammable when exposed to heat or flame or oxidizing agents. May react violently in air and to

halogens. Reacts slowly with water to liberate hydrogen gas. Thin foils can be ignited by spark or static electricity.

|

Here's the site I found this on:Site.

You might be able to buy some scandium here - I'm not sure.

|

|

|

elementcollector1

International Hazard

Posts: 2684

Registered: 28-12-2011

Location: The Known Universe

Member Is Offline

Mood: Molten

|

|

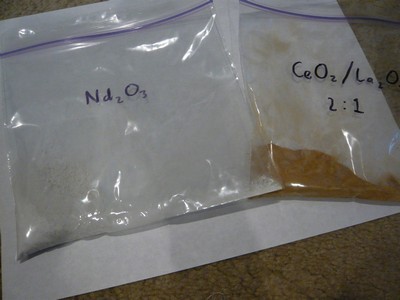

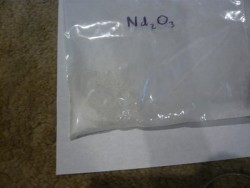

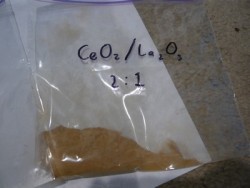

Some pictures of my 'mischmetal oxide' and neodymium oxide, made by calcining their oxalates via blowtorch:

The white neodymium oxide:

I swear, the cerium/lanthanum oxide isn't nearly this brown in reality - more of a dark tan.

The neodymium was purified from magnets using HCl, then oxalic acid. The lanthanum/cerium mix was purified from mischmetal rods (those from magnesium

firestarting blocks) using the same method.

Elements Collected:52/87

Latest Acquired: Cl

Next in Line: Nd

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Did you mean "lanthanides/cerium mix"? Real mischmetal is supposed to be a mixture of more than just La and Ce... Did your rods come with a

specification?

|

|

|

elementcollector1

International Hazard

Posts: 2684

Registered: 28-12-2011

Location: The Known Universe

Member Is Offline

Mood: Molten

|

|

Quote: Originally posted by blogfast25  |

Did you mean "lanthanides/cerium mix"? Real mischmetal is supposed to be a mixture of more than just La and Ce... Did your rods come with a

specification? |

No... but I remember a while back that the composition was 25% La, 50% Ce, bal. Fe and MgO, as well as small amounts of other RE's (<1%).

Curiously, Encyclopedia Britannica lists 50% Ce, 25% La, 15% Nd (???), 10% other RE's + iron.

Elements Collected:52/87

Latest Acquired: Cl

Next in Line: Nd

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Curiously? This is closer to what most chemists would expect from misch metal: mostly light REs with traces of the heavier ones... even though the EB

is hardly an authority on these things.

|

|

|

Subcomputer

Harmless

Posts: 15

Registered: 23-3-2013

Member Is Offline

Mood: No Mood

|

|

There is no defined mix at all for mischmetal, even the majority lanthanum/cerium mix is up in the air. It really is the mix that came out of the mine

that day, once it it no longer cost effective to separate out the other REs. Essentially a waste product that has found a new life. The Fe (and Fe

compounds) come from making additives for hardening it up at which point it becomes "ferrocerium", again with no particular formula as far as REs go,

although there are guidelines as far as how much Fe. Mg is getting into the survival strikers, where there might be a particular breakdown for a

particular brand or product, but that's about it.

|

|

|

Brain&Force

Hazard to Lanthanides

Posts: 1302

Registered: 13-11-2013

Location: UW-Madison

Member Is Offline

Mood: Incommensurately modulated

|

|

Scandium turnings burning: http://youtu.be/s1i90S0vsW8

I haven't got a clue about the bulk metal.

ESPI metals requires two trade references to order from. Try Metallium instead.

As for mischmetal and ferrocerium, it's economical now to remove the last traces of praseodymium and neodymium, so a lot of the firestarter products

on the market today only contain these two lanthanides. Also note that mischmetal shouldn't contain much (if any) iron or magnesium. However, it's

harder to get than the ferrocerium used in most firestarting products.

Try looking for "Rare Earth Chloride" if you want a mixture of the lanthanides - but at this point I would just order the metals online.

At the end of the day, simulating atoms doesn't beat working with the real things...

|

|

|

Dan Vizine

National Hazard

Posts: 628

Registered: 4-4-2014

Location: Tonawanda, New York

Member Is Offline

Mood: High Resistance

|

|

Once I bought a block of Lanthanum to section for preparing samples. I used my horizontal metal-cutting band saw and a continuous stream of sparks

about an 1/2" diameter sprayed out of the cut continuously until the cut finished.

Scandium metal is frequently on e-Bay. It is simple to acquire although costly. Most "real" companies look at you and me and see zero commercial

potential, unless they are hobbyist oriented. They just see liability, only to make peanuts on a sale.

There are a few people on eBay who specialize on RE's from China and Poland.

[Edited on 17-4-2014 by Dan Vizine]

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Thanks, B&F.

Dan: I hope to be one of them, 'shortly'.

|

|

|

IrC

International Hazard

Posts: 2710

Registered: 7-3-2005

Location: Eureka

Member Is Offline

Mood: Discovering

|

|

Quote: Originally posted by Subcomputer  | | There is no defined mix at all for mischmetal, even the majority lanthanum/cerium mix is up in the air. It really is the mix that came out of the mine

that day, once it it no longer cost effective to separate out the other REs. Essentially a waste product that has found a new life. The Fe (and Fe

compounds) come from making additives for hardening it up at which point it becomes "ferrocerium", again with no particular formula as far as REs go,

although there are guidelines as far as how much Fe. Mg is getting into the survival strikers, where there might be a particular breakdown for a

particular brand or product, but that's about it. |

This is lacking in chemistry knowledge and misleading in so many ways. Merely reading the wiki page would point this out.

http://en.wikipedia.org/wiki/Mischmetal

Neither Mischmetal nor Lanthanides (in the form of the pure metals alloyed into Mischmetal with metal oxides mixed in for hardness) 'come out of the

mine' in any sense of the term. As to Fe or Mg they are added as their oxides "an alloy of only rare-earth elements would be too soft to give good

sparks. For this purpose, it is blended with iron oxide and magnesium oxide to form a harder material known as ferrocerium". I think you will learn on

SCM a higher level of technical competency is desired before posting anything as a 'fact' or 'facts'.

Lanthanides come primarily from Monzanite sands (and from ores mined), separated and reduced to pure metals through a very complex series of chemical

procedures. Never pure metals in their natural state, the statement "It really is the mix that came out of the mine that day" just makes no sense from

a technically accurate view. The metals after being refined are mixed. You do not find Ce or La metal pure in nature ever. Far too reactive.

Mischmetal quite simply never 'came out of the mine that day' in any sense of the term. Being more precise and accurate in technical descriptions is

to be desired over blanket statements not thought through as to scientific accuracy. Maybe some will think I am picking at details, so be it. I think

it is important to point out the flaws in the statements.

[Edited on 4-17-2014 by IrC]

"Science is the belief in the ignorance of the experts" Richard Feynman

|

|

|

unionised

International Hazard

Posts: 5102

Registered: 1-11-2003

Location: UK

Member Is Offline

Mood: No Mood

|

|

The metal never came out of the mine, but the mixture of ores did.

And, if all you want to do is make sparks, there's no point going to the expense of refining the individual metals so, the stuff in lighter flints is

a mixture that contains the oxides in the same proportions as the elements were present in the ore that came out of the mine.

It's reduced to the metal and some iron and Mg thrown in.

The point being made was that nobody is likely to have analysed the stuff for the proportions of the RE metals before turning it into flints so the

statement "There is no defined mix at all for mischmetal" is true- it will, for example, vary with different mines.

It is the "mix that came out of the mine" in the sense that nobody bothered to un-mix them (OK there' may have been some partial separation to get

some of the more valuable ones)

|

|

|

Brain&Force

Hazard to Lanthanides

Posts: 1302

Registered: 13-11-2013

Location: UW-Madison

Member Is Offline

Mood: Incommensurately modulated

|

|

And it is "the mix that came out of the mine" because depending on the production site, the composition may vary. (Of course, as mentioned earlier,

some places remove all other rare earths except lanthanum and cerium because it's cost effective.) The only important thing is that cerium is included

to allow sparking.

However, this pure LaCe alloy (you know, lace would be a good name for it) is extremely soft and unstable in air. That's why other metals are added,

especially Mg to allow some passivation and Fe to improve hardness and sparking. Thus you get ferrocerium. It is possible to buy pure mischmetal

online - it is used in some different types of strikers because it's soft and produces huge globs of burning metal rather than sparks.

I would like to get ahold of cerium and determine whether the pure metal can spark significantly.

At the end of the day, simulating atoms doesn't beat working with the real things...

|

|

|

IrC

International Hazard

Posts: 2710

Registered: 7-3-2005

Location: Eureka

Member Is Offline

Mood: Discovering

|

|

I never disputed the variables in proportions, merely the sloppy way the creation of mischmetal was stated. I know as I have several pounds of

mischmetal, also of Ce, La, Nd, Eu, and most other Lanthanides. Except Tm, Tb, Lu, only tens of grams each of those. Expensive. All actually except

for the unobtainable Pm. I know what they all look like, act like, and so on. They look like the metals they are not rocks dug out of the ground as

was implied by the wording I was complaining about. By the way do not hacksaw Ce, once it starts burning not easy to put out. I do have some nice

oxides though. Mischmetal you can hacksaw but do it where you will not be setting your lab on fire as the sparks are thick. I also have lighter flint

metal and the composition is not identical to my ingots of mischmetal. You can lay cleanly cut flint metal on a table for months and it does not

oxidize all that much. However mischmetal does. Best to keep it well sealed in plastic or under oil. It degrades very slowly but I always have various

oxide powders of differing colors when I unwrap a bar of mischmetal. Actually chemically separating the oxides should be one way to find percentages.

While I have no assay on my mischmetal I can say I see no irreducible transition oxides left after long oxidation of slices of the ingots which has

lead me to believe mischmetal is used to make flint metal but I do not think flint metal is exclusively raw mischmetal. I have long thought the Fe and

Mg oxides were combined with mischmetal to create flint metal but am not positive. Just guessing from toying with large quantities of each over years.

"Science is the belief in the ignorance of the experts" Richard Feynman

|

|

|

Subcomputer

Harmless

Posts: 15

Registered: 23-3-2013

Member Is Offline

Mood: No Mood

|

|

I definitely could have said it better, but my main point was that there is no defined, nor way to predict the composition of mischmetal without

having your specific piece tested. Are they processing a monazite or bastnäsite load, which RE did that load lean toward, are they set up to pull out

neodymium, was neodymium judged economically worth pulling out that day, etc. Plus the question of if you're getting "true" cheap (from the original

source...) mischmetal end product, or "purified" RE-only ingots ready for separation.

|

|

|

| Pages:

1

2

3

4

5 |