| Pages:

1

2

3

..

10 |

Polverone

Now celebrating 21 years of madness

Posts: 3186

Registered: 19-5-2002

Location: The Sunny Pacific Northwest

Member Is Offline

Mood: Waiting for spring

|

|

picramic acid from picric

I know that sodium sulfide is used as a reducing agent for picric acid to form picramic acid, but to be honest I really don't like using sodium

sulfide. It stinks and H2S is none too good for your health. Reviewing the threads on DDNP production at the E&W Forum, it seems that a lot of people

have trouble at the stage where (according to KIBC or similar instructions) you reduce the TNP with homemade Na2S. But! When you mix NaOH and

elemental sulfur in solution, you aren't making pure Na2S. You're making mostly sodium polysulfide(s) and sodium thiosulfate, and even exposure to the

air will further oxidize the solution. I really don't know how the reducing power of this soup compares to a pure solution of Na2S.

Urbanski states:

| Quote: | | When mildly reduced, for example with sodium sulphide or hydrosulphite or with ferrous sulphate, picric acid is converted into picramic acid, a very

useful intermediate in the dystuffs industry and a starting material for the preparation of diazodinitrophenol, primary explosive (Vol. III). Stronger

reduction may lead to the formation of triaminophenol. |

Unfortunately, I don't have volume III handy so I can't look at his DDNP synthesis. But I am confident (overconfident?) that I won't have trouble with

the diazotization if I can produce picramic acid.

I used photo-grade sodium sulfide one time, added to an already-alkaline solution of sodium picrate, and obtained a dark red solution. I have been

able to produce similar dark red solutions with ascorbic acid and fructose as reducing agents, which are both readily available and more pleasant than

sulfides. But I don't know if I am in danger of over-reducing to triaminophenol. I can't even tell if I have triaminophenol. I don't

know anything about it. Chemfinder is ignorant of it. No web pages give any information. Lange's Handbook of Chemistry doesn't list it.

Even picramic acid itself seems a mysterious substance. I have seen its color described as brown, yellow-brown, and brilliant yellow. In alkaline

solution it (its salts?) are supposed to be red.

If any kind individuals have information to contribute about picramic acid, triaminophenol, or anything else mentioned here, it would be appreciated.

Note that right now I'm not interested in later stages of DDNP preparation: I just want to nail the reduction and do it without the nasty and variable

NaOH/sulfur mixture.

|

|

|

Polverone

Now celebrating 21 years of madness

Posts: 3186

Registered: 19-5-2002

Location: The Sunny Pacific Northwest

Member Is Offline

Mood: Waiting for spring

|

|

good information found!

I remembered that picramic acid has been used as a dye, so the other day when I saw Fundamental Processes of Dye Chemistry sitting on a shelf

I thought I would take a look inside. I found very detailed instructions on the preparation of picramic acid from picric acid.

It's a shame that I have such a big backlog of books I want to scan, because this book is full of interesting information. But since good results

producing picramic acid have been so hard to achieve, I scanned the couple of pages and have added them in a PDF to the sciencemadness library. I bet

you had forgotten we even had a library! Well we do, currently with an astounding seven items in it. I hope this helps those who have been questing

for DDNP. I plan to apply the instructions myself one of these days (weeks? months?).

http://www.sciencemadness.org/library/

|

|

|

Krypton

Hazard to Self

Posts: 90

Registered: 21-11-2002

Location: Spain

Member Is Offline

Mood: explosive 21

|

|

Question

Why making picramic-acid ?

You can make many picramate-salt`s

(f.i. potassium and ammonium picramate)

directly from picric-acid without the way over picramic-acid in a double-step-synthesis (double-substitution in one step).

Substitute the -OH group with the Metal and reduce one NO2 group.

And also, be careful, when i remember rightly,

picramic acid are highly toxic (< 35 mg/kg).

|

|

|

Polverone

Now celebrating 21 years of madness

Posts: 3186

Registered: 19-5-2002

Location: The Sunny Pacific Northwest

Member Is Offline

Mood: Waiting for spring

|

|

I was using "picramic acid" as shorthand for "picramic acid and its salts." But one reason to prepare the free acid instead of

just salts is lower water solubility, which would make it easier to purify.

Purification may not be strictly necessary, but poor results have been consistently reported by people trying to follow fringe-literature instructions

to produce DDNP. Eliminating extraneous variables by starting with pure materials seemed like a good idea for when I go to make my own attempt.

|

|

|

Krypton

Hazard to Self

Posts: 90

Registered: 21-11-2002

Location: Spain

Member Is Offline

Mood: explosive 21

|

|

Synthesis

The purification of picric-, picramic-acid... salt`s

conditional by high water-solublety is always not easy.

It don`t say, you get a bad product when not produced

by picramic acid.

Here a example for potassium-picramate.

Potassium-picramate are very long beautiful brown needles

which are somewhat sensitive to friction and shock

and which can be easy detonated by flame.

It`s a strong eplosive which have no real practical

significance.

I think it`s not nessesary to purificate the crude product

which have a good quality as well as don`t produced by picramic-acid.

The disadvantage is a bit lower yield, but the

expenditure is lower.

In convention with my ancestor.

|

|

|

Polverone

Now celebrating 21 years of madness

Posts: 3186

Registered: 19-5-2002

Location: The Sunny Pacific Northwest

Member Is Offline

Mood: Waiting for spring

|

|

I was somewhat worried by the accounts I've read of people who have prepared picramic acid (or its salts) by improvised methods and found it

burns poorly, with the smell of SO2. But I think I realize what that's from now: the polysulfides (perhaps even sulfides?) that you form by

reacting sulfur and NaOH will yield extremely fine sulfur particles when acted upon by acid. There is probably very fine precipitated sulfur mixed in

with the picramic acid/picramate.

That picture that you posted: is it of material that you have made yourself? It looks pretty clean.

[Edited on 21-2-2003 by Polverone]

|

|

|

Boob Raider

Harmless

Posts: 33

Registered: 15-10-2002

Location: Canada

Member Is Offline

Mood: Picros

|

|

What about

using SnCl2 or FeCl2 in acidic solns to reduce the -NO2 on TNP to Picramic acid. It is used to reduce -NO2 to -NH2 in other reactions.

\"Go down in a Blaze of Glory\"

|

|

|

Microtek

National Hazard

Posts: 827

Registered: 23-9-2002

Member Is Offline

Mood: No Mood

|

|

But it is not a partial reduction. You will likely get triaminophenol with Fe/HCl. Of course you could perhaps mononitrate phenol ( though you would

get both o- and p-nitrophenol ), reduce with Fe/HCl, and nitrate further.

|

|

|

Boob Raider

Harmless

Posts: 33

Registered: 15-10-2002

Location: Canada

Member Is Offline

Mood: Picros

|

|

Lets say

we get triamino phenol, If we treat it with NaNO2 we should get the Diazo 4,6-diaminophenol. After this is seperated .... is it possible to oxidize

the -NH2, back to -NO2 with say HNO3 or a persulfate etc. The only reason I am trying to eleminate the sulfide is ... some say it is -HS and some -2S.

Then homemade NaSx contains all sorts of stuff in it. It is hard enough for me to accquire NaNO2, sulfides .... not a chance as they don't have

much regular consumer application.

\"Go down in a Blaze of Glory\"

|

|

|

Boob Raider

Harmless

Posts: 33

Registered: 15-10-2002

Location: Canada

Member Is Offline

Mood: Picros

|

|

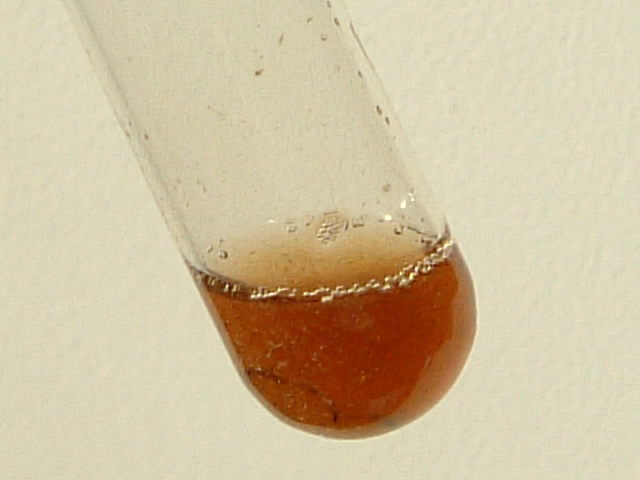

Is this the color of Picramic acid. This was made by the addition of a soln of FeCl2 and HCl in Picric acid soln (made from ASA)

\"Go down in a Blaze of Glory\"

|

|

|

PHILOU Zrealone

International Hazard

Posts: 2893

Registered: 20-5-2002

Location: Brussel

Member Is Offline

Mood: Bis-diazo-dinitro-hydroquinonic

|

|

Reduction of TNP with Fe/HCl or with SnCl2/HCl will attack all NO2's of the ring no mather they are ortho or para; you will end up with 2,4,6

Triaminophenol!

In the contrary Na2S, (NH4)2S, Na2S2 reduction is very much specific and almost only reduce one ortho NO2!

You can kill a fly with a nuclear bomb or with pyrethrine; both methods work but difference is specificity and efficiency!

Also you seem to review your organic chemistry basics!

HNO2 will make diazotation of all NH2's from triaminophenol; it is also non specific/surgical reactant! Thus oxydation back to NO2 is impossible!

PH Z (PHILOU Zrealone)

"Physic is all what never works; Chemistry is all what stinks and explodes!"-"Life that deadly disease, sexually transmitted."(W.Allen)

|

|

|

PHILOU Zrealone

International Hazard

Posts: 2893

Registered: 20-5-2002

Location: Brussel

Member Is Offline

Mood: Bis-diazo-dinitro-hydroquinonic

|

|

Seem like I was tirred!

"Also you seem to NEED TO review your organic chemistry basics!HNO2 will make diazotation of all NH2's from triaminophenol; it is also non

specific/surgical reactant AND IT WILL ATTACK EVERYWHERE! Thus oxydation back to NO2 is impossible!(POSSIBLE BUT NEED MUCH MORE PERACETIC ACID AND

HEAT CONTROL)"

PH Z (PHILOU Zrealone)

"Physic is all what never works; Chemistry is all what stinks and explodes!"-"Life that deadly disease, sexually transmitted."(W.Allen)

|

|

|

fritz

Harmless

Posts: 49

Registered: 29-11-2003

Member Is Offline

Mood: No Mood

|

|

it´s possible to reduce one nitro-group of TNP with glucose. I never tried this but this reaction is used in physiological chemistry for testing the

content of sugar in blood. So it should work.

1ml glucose sln. (8%)

4ml TNP sln. (1%)

1ml 3M NaOH

shaking and gentle heating. the solution should change its colour to red.

Equation:

3NaOH + 3CH2-(CHOH)4-CHO + NaTNP => Na-picramate + 2H2O +3Na[CH2OH-(CHOH)4-COO]

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

Vitamin C should do the trick as a reducing agent

I too have been looking for alternative reducing agents for the reduction of picric acid to picramic acid .

Urbanski mentions that Ferrous Sulfate will reduce picric acid to picramic acid , but no details are provided .

Also it is likely that Ascorbic Acid , Vitamin C , is a good bet for the reduction , actually being a slightly stronger reducing agent than the

Ferrous Sulfate . Solutions

of Ferrous Sulfate are green because of the Ferrous ion when freshly made but after exposure to the air , gradually are oxidized to the brown or rust

colored Ferric oxidation state . Gradually adding some Ascorbic Acid solution will reportedly

reduce the brown Ferric solution right back to the green Ferrous solution , showing that Ascorbic Acid is the stronger

reducing agent than the Ferrous Sulfate .

I have not verified this yet by experiment ,

but read about it . Perhaps other of the dietary " anti-oxidants " may also be candidate reducing agents , for reducing picric acid to

picramic acid .

Ferrous Sulfate is cheap as a garden supply item , so in terms of economy it may be the best reducing agent . It would be interesting to experiment

with these alternatives to the sodium polysulfide , and see what sort of yields

and what purity of product improvements

may be achieved , to see what works best .

Sodium Bisulfite is another possibility .

[Edited on 2-4-2005 by Rosco Bodine]

|

|

|

UhhKaipShaltaBlet

Harmless

Posts: 11

Registered: 23-1-2005

Member Is Offline

Mood: Shalta Blet ...

|

|

This is sodium salt of picramic acid. Made by reducing TNP with Sodium Polysulfide.(SP prepared by dry method with NaOH and S.) No H2S after about 5

attempts was noticed. From 18.5g Picric acid prepared from phenol yield is 14.3g of high purity Sodium Picramate precipicated from water.

<img src="http://www.scimad.org/scipics2/SoPic.jpg" width="600" />

<!-- bfesser_edit_tag -->[<a href="u2u.php?action=send&username=bfesser">bfesser</a>: reduced

image size(s); hosted image(s) at scimad.org/scipics2/]

[Edited on 18.12.13 by bfesser]

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

In terms of simplicity and economy the method using the " polysulfide " reagent

made from the dry mixing and exothermic

melt reaction of S and NaOH is definitely

practical , and worth experimentation .

The experiments with that method were

not numerous to an extent for finding what exact proportions and conditions were optimum . The experiments were

only sufficient for identifying a general

method which would give worthwhile yields , by a few trial and error comparisons intended to improve upon

some of the earlier published black book

methods which give poor results .

The reducing agent which is produced by the high temperature melt reaction between S and NaOH is likely a mixture which is mainly two different sodium

sulfur compounds , sodium hydrosulfide NaHS , and sodium polysulfide Na2S4 ? or Na ? S_(x) .

It is evident that the high temperature rapid reaction of the melt and lowered exposure to the air gives a product which

has more reducing properties than the product obtained by diluted solutions and boiling .

A patent US4156656 has compared the different compositions of the mixture which results for the reactions of alkali and sulfur under differing

conditions of temperature and exposure to air . From the charted results it is evident that high temperature and minimized exposure to air results in

a product much higher in the hydrosulfide which is the probable reducing reagent responsible for the conversion of picrates to picramates .

The " polysulfide " is probably a secondary

participant which may contribute to the reduction , although it is likely the polysulfide reagent could be more accurately named " hydrosulfide /

polysulfide " reagent , when analysis of

its actual composition may be done .

The reaction is interesting because of the unknown nature of the stoichiometry for both the formation of the reagent , the reduction of the picrate to

picramate ,

and the byproducts of the reduction .

I still do not understand exactly the reactions involved . I'll be damned if I can explain it to myself much less to anyone else how it works ,

only that it does work

For purification of the sodium picramate ,

I have read that the crude material

is dissolved in boiling water and filtered ,

and then dripped while still hot into a warm well stirred dilute HCl , which should result in the precipitation of the

only slightly soluble pure picramic acid

which is filtered out after cooling . The isolated pure picramic acid can then be used to produce whatever pure picramate

is desired by neutralizing with the base

for the desired salt .

Attached in this post will be the patent .

In the two following posts will be attached related files which shed more light on the soluble sulfide reducing reagents and reactions .

[Edited on 28-4-2005 by Rosco Bodine]

Attachment: US4156656 Preparation of Hydrosulfides.pdf (150kB)

This file has been downloaded 1925 times

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

alkali-polysulfides

Attachment: alkali-polysulfides.pdf (574kB)

This file has been downloaded 3705 times

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

polysulfide-aromatic-reduce

Attachment: polysulfide-aromatic-reduce.pdf (440kB)

This file has been downloaded 2998 times

|

|

|

chemoleo

Biochemicus Energeticus

Posts: 3005

Registered: 23-7-2003

Location: England Germany

Member Is Offline

Mood: crystalline

|

|

Hmm, although very interesting, I am not sure how far I should let these off-topic discussions go. Isn't there a sulphide thread somewhere?

Wouldnt it be better to post there and link to this topic stating its use?

Anyway. As I said, it's interesting that this in fact has been studied. We discussed this before, in the What was this substance thread! There are some pretty pics to look at, too. I still haven't gotten to the bottom of the mystery. The

conditions the patent people employ are nearly identical to ours, so this should help (90 deg C, for 1 hour, no pressure, with NaOH/H2O/S).

Never Stop to Begin, and Never Begin to Stop...

Tolerance is good. But not with the intolerant! (Wilhelm Busch)

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

Hmmm , Here's what happened .

About 3 weeks after this topic was

posted by Polverone more than two years ago , I was not yet registered here

but anonymously e-mailed a reply to the subject in discussion in this thread .

The " dry method " for the unknown composition soluble sulfide reducing agent

was posted originally in the thread where

all of Mr. A's first messages appeared .

About a third of the way down the following page , is the dry method first described

for this experimental variation on the Zinin reaction .

www.sciencemadness.org/talk/viewthread.php?tid=470&*

Anyway , the post above in this thread two years later is the first feedback confirmation

by anyone else experimenting with the "dry method " so it seemed pertinent to reply here since the feedback was posted here .

At the time I was experimenting with the dry method of making the polysulfide reagent ,

the improved results were evident . However experiments remain to be done to determine what precise ratio of NaOH to S , and what quantity of the

prepared reagent is optimum ,

for reduction of each mole of sodium picrate .

At the time of the experiments with the dry method , I did not have the references

above , which could have bearing on future experiments at optimizing the method .

The direction of the experiments was to increase the ratio of NaOH to S

in preparing the " polysulfide " reagent ,

until a point of diminishing yield would help to estimate the best ratio . And then

working with that best ratio , to first try using decreased amounts of the polysulfide ,

to a point of diminishing yields , in order to chart and identify the quantities

which would represent an optimized synthesis .

The next experiment which I have contemplated , but have yet to perform ,

is to use 16 grams of NaOH to 10 grams S , in the same reaction as otherwise described . My time for such experiments is often unhappily diverted to

other business ,

so I simply wished to provide what information I had on the incompleted work in case anybody else wished to go further with that line of experiments

which was producing improved yields of picramate .

[Edited on 29-4-2005 by Rosco Bodine]

|

|

|

pdb

Hazard to Self

Posts: 70

Registered: 8-4-2004

Member Is Offline

Mood: No Mood

|

|

Preparation from "Fundamental processes in dyes..."

For those among you who have followed the preparation procedure recalled below:

In a glass or iron container of at least 2.5-liter capacity, a solution of 10 grams of picric acid and 10 grams of 35 per cent sodium hydroxide in

600 cc. water is heated to 55°C., and to this is added, with vigorous

stirring over a period of 10 minutes, a solution of crystalline sodium sulfide in 100 cc. water. When this addition is completed, an additional 127.5

grams of pulverized picric acid is added in teaspoon portions, and simultaneously a solution of 220 grams of sodium sulfide in 400 cc. water is

introduced, the additions of the two reagents being completed at the same time (within about 10 minutes in all).

It doesn't tell what is the concentration of the first addition of sulfide... I am tempted to computerize it according to the proportions of PA

and sulfide in the next additions, but if this is wrong, I fear to reduce excessively PA and lower the yield.

Can you bring any precision to this process ?

|

|

|

Axt

National Hazard

Posts: 778

Registered: 28-1-2003

Member Is Offline

Mood: No Mood

|

|

"Lyons & Smith (Ref 5) prepd PAA in good yields by reducing PA with iron turnings in a very dil soln of Fe or Na chloride at 80-85°."

PATR 2700 vol. 1, A241.

Ref 5: R. E. Lyons & L.T. Smith, Ber 60, 180(1927) [attached]

Attachment: reduction-of-nitroaromatics.pdf (600kB)

This file has been downloaded 2043 times

|

|

|

pdb

Hazard to Self

Posts: 70

Registered: 8-4-2004

Member Is Offline

Mood: No Mood

|

|

Rosco, in an earlier post (24Apr05), you mentionned a procedure to purify sodium picramate. Could you, by chance, recall where you found it ?

Also, sodium picramate solubility in water is about 1.2 g per liter at 20°C. Does anyone know the figure for sodium picramate ? Thx

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

It was only a sentence or two in Urbanski or one of the journals maybe Industrial and Engineering Chemistry , I don't remember exactly but it was

a recent reading when I had posted that bit of information . It is straightforward though

to isolate picramic acid from a boiling hot solution of sodum picramate by acidification with HCl or H2SO4 , which leaves the sodium chloride or

sulfate in solution and precipitates the free picramic acid . There is a distinct color change from the very deep red sodium picramate to an orange

yellow precipitate of free picramic acid in a very pale tinted supernatant . The precipitate is extremely fine small particles as is typical of a low

solubility precipitate when rapidly precipitated , so it would aid getting a coarser more easily filtered product to do the precipitation at near the

BP and add the acid dropwise slowly , to give the crystals some time to grow in the hot solution during the precipitation . IIRC , the color change

is very pronounced , so the sodium picramate reactant actually acts as a built in color dye indicator for the progress of the acidification ,

providing a visual endpoint . You can actually work with fairly dilute solutions and not lose much in the supernatant over the free picramic acid ,

because the solubility is very very low especially after cooling , much lower than for picric acid for comparison . The solubility would seem to be

about comparable to calcium sulfate or carbonate for example , very small . I don't have the exact solubility ,

but it is a low number .

|

|

|

pdb

Hazard to Self

Posts: 70

Registered: 8-4-2004

Member Is Offline

Mood: No Mood

|

|

I reduced PA to sodium picramate using the first method of Fundamental Processes of Dye Chemistry, which is a bit fastidious (11 portions of 1.16g PA

to be added “simultaneously” with fractions of 5ml of commercial grade Na2S, 9H2O solution, while keeping temperature in a 57-62°C range). The

process states to leave the solution rest for 10 hours after the last addition: I left it over for 24 hours (couldn’t do otherwise), and the once

crystalline, dark-reddish precipitate of sodium picramate turned over time into a mud-like slurry, much more difficult to wash with cold salted water

once filtered… I will nevertheless attempt to diazotize it into DDNP. However, in the case this extended rest period proves to have ruined my

efforts (hydrolysis ? further reaction involving Na2S2O3 and/or NaOH ?), I am wondering how compulsory it is to closely follow the process, especially

in the simultaneity of the addition of the reactants. I am aware that NaOH generated during the reaction may alter the picramate produced if in

excess, and thus I am tempted to add Na sulfide dropwise to a PA slurry in water instead of adding PA to a sulfide solution.

|

|

|

| Pages:

1

2

3

..

10 |