| Pages:

1

2

3

4 |

Tacho

National Hazard

Posts: 582

Registered: 5-12-2003

Member Is Offline

Mood: No Mood

|

|

| Quote: | Originally posted by frogfot

Why is 20 torr "to good to be true"?!?! lol It's easy to get the pressure down to waters vapour pressure.. (I've measured

everything with digital lab monometer) |

In my previous attempts, my best vacuum was about 700 Torr (mmHg) so, to see that needle jump all the way down was a weird experience. I'm not

used to go from total failure to total success so easy.

| Quote: |

Gonna try it the normal way with measures you've suggested!! Didn't know that drilling/enlarging hole in brass nipples was that easy

|

Brass is relatively soft for drilling/machining. Just hold the piece with pliers; if it get stuck, you don't hurt your hand.

| Quote: | these pumps can be really massproduced  |

Exactly! I am trying new combinations of fittings and tubings to see what is the easiest way of making it and what does or does not matter.

I already built a new one, with a conical injector and a 7mm diameter, 20mm long exit tube (just a hose adapter with no copper tube soldered), it was

a failure! Only about 500 Torr! I'll be testing to see what's to blame, the larger diameter, the shorter length or the conical injector. I

have a hunch that the exit tube has to be longer. In fact, I believe the numbers given by HRH are THE numbers, but experiment is the king.

| Quote: | | Btw, is converging part on exit really necessary? |

Good question. Omitting it may save a lot of work. I hope to post my experimental results and pictures/drawings soon.

|

|

|

frogfot

Hazard to Others

Posts: 212

Registered: 30-11-2002

Location: Sweden

Member Is Offline

Mood: happy

|

|

Ok, now I understand the excitement, just misunderstood you

Tested it the normal way like in your shematic pic but simplified.

And now I see that converging part on nozzle is really important.. first I tested a straight pipe as the nozzle, with ID 3mm, this gave only about 200

torr. However when I changed it to a larger pipe ID 4mm hammered in one end like you've suggested, to ID 3mm (maby slightly larger), this gave 30

torr.. on further addjustement of distance between nozzle and throat it gave 18 torr with suction capacity of 90-100 ml/s (water). At the same time,

commercial pump gave 12 torr and ~71ml/s. So, yp, thats too good to be true..

Some measures on mentioned experiment:

Nozzle hole: ~3 mm

Throat ID: 5 mm

Throat length: 20 mm

Btw, any idea how to decrease the end of 10 mm pipe to 3 mm?? It's kinda hard with a hammer.. or maby one have to practice..

[Edited on 4-9-2004 by frogfot]

[Edited on 4-9-2004 by frogfot]

[Edited on 4-9-2004 by frogfot]

|

|

|

Tacho

National Hazard

Posts: 582

Registered: 5-12-2003

Member Is Offline

Mood: No Mood

|

|

| Quote: | Originally posted by frogfot

<snip>

Btw, any idea how to decrease the end of 10 mm pipe to 3 mm?? It's kinda hard with a hammer.. or maby one have to practice..

|

I doubt it can be done by hammering. It has to be some commercial standart piece. Or resin casting, or even metal casting. As I said, I used this

complicated rotating epoxy casting.

New things I learned:

1- The exit tube seems to be extremely important to the workings of the aspirator. No wonder you never see a picture of an aspirator with a short

tube. In my second aspirator, the Ø 7mm one, I could get no vacuum at all using the 20mm long fitting alone as the exit. When I added a 150mm

flexible plastic tube to its exit, internal Ø 7.5mm, boom, 360 Torr!

By bending this plastic tube with my fingers, I could make the vacuum go even beyond that. So, don’t underestimate this tube, a lot of the magic

happens inside it (forget Bernoilli), and I believe the gradual widening is of great help.

I think the straight part of the exit tube (before widening) has to be at least 50mm long

2- From the ones I tested, the best diameters for the injector-nozzle/exit-tube are 4mm/6.3mm. I also found out that the 5mm/7mm was quite better than

the 6.3mm/7mm. So a good ratio seems to be 0.6-0.7.

Frogfot, you mention 3-5, that's 0.6.

3- The highest vacuum is when the nozzle is just 1(maybe less) or 2 milimeters away from the throat, and, as frogfot noticed, the nozzle has to be

conical, even if just in the tip.

My system (the 1/4HP pump + bucket + my #1 aspirator), circulates 18 liters per minute. It’s a high consumption, but it’s a closed system, and I

can’t reduce the pump power (why should I?)

I hope to mount two aspirators in parallel to optimize the use of the pump.

In the average, my pump could bring a 1,64 liter PVC tube “bomb” to 360 Torr in 17 seconds. My math brought me to 4,3 l/s. Thanks for that formula

HRH.

EDIT: Oops , make that 4.3 l/minute.

I had an incident when a flake of epoxy clogged the exit tube. Water started to squirt from the vacuum connection. After I cleaned and remounted it, I

could not get any vacuum higher than 160 Torr. Some fine tuning may be required, but I won’t bother, this vacuum is more than enough to my purposes.

Unfortunately this happened before I installed the new gauge, so I cannot confirm the 20 Torr vacuum.

[Edited on 5-9-2004 by Tacho]

|

|

|

Tacho

National Hazard

Posts: 582

Registered: 5-12-2003

Member Is Offline

Mood: No Mood

|

|

Using mouse balls in one-way valves.

Don't castrate you pet yet.

The picture shows (in 2, 3 and 4) how to use your computer's old mouse's ball to make a one-way valve. The O-ring makes it even better,

although I believe it may work without it. The fittings are PVC. One 1" connection (I don't know their name in english, a short tube with

threads inside) and 2 reductions from 1" to 1/2".

An interesting warning: be careful testing this valve with your mouth, the ball seems to jump and can easily go to your thraquea.

About exit tubes of aspirators:

I've changed my 2 aspirator so that it's now identical to my #1 except that it doesn’t have the long external exit tube. I noticed that it

could provide as much vacuum as #1, but it had a slow pumping speed. But, if you add a 10cm piece of flexible plastic tube (internal diameter of

7.7mm) to the copper exit tube (picture 1), it gets as good as #1.

So this may be an option to gradual widening: widening in one or more steps using concentrical tubes.

Also, as I suspected, the initial exit tube (6.3mm, copper) has to be long. Mine is 70mm.

In the picture (5 & 6) I also show how I managed to easily center the injector tube in the nipple adaptor using electric tape and epoxy resin.

Wind the tape in the tube until it fits tight(5) in the nipple and fill both sides with epoxy.

Frogfot,

I'll add some net or filter to my system. It seem that anything inside the aspirator, even a hair, can change its performace greatly. I have

cloggins all the time. 40 Torr is easy to get.

|

|

|

Hermes_Trismegistus

National Hazard

Posts: 602

Registered: 27-11-2003

Location: Greece, Ancient

Member Is Offline

Mood: conformation:ga

|

|

| Quote: | Originally posted by Tacho

I'll add some net or filter to my system. It seem that anything inside the aspirator, even a hair, can change its performace greatly.

|

strange....almost like hydrodynamics are complex eh? stilll, I admire your enthusiasm and hopefully, when you're done, I'll get to copy your

design.

Arguing on the internet is like running in the special olympics; even if you win: you\'re still retarded.

|

|

|

HRH_Prince_Charles

Hazard to Self

Posts: 92

Registered: 29-6-2004

Location: Clarence House, London

Member Is Offline

Mood: Bombastic

|

|

Interesting Posts

Thanks for providing such detail Tacho. You shall certainly go to heaven.

I calculate your pumping speed as approx. 0.1 L/s or 6 L/min. (Better than the commercial models).

S = V/t * ln(P0/P1)

= 1.64/17 * ln(1000/360)

= 1.64/17 * 1.02

= 0.099 L/s

~ 100 mL/s

~ 6 L/minute

Loather of monstrous carbuncles, lover of organic melons and servant girls.

|

|

|

Tacho

National Hazard

Posts: 582

Registered: 5-12-2003

Member Is Offline

Mood: No Mood

|

|

| Quote: | Originally posted by Hermes_Trismegistus

strange....almost like hydrodynamics are complex eh? |

Lol! That's EXACTLY what I tought! Lol! That's EXACTLY what I tought!

HRH,

There is something wrong with the pressure ratio in your math. I don't think units are important, since its a ratio, but if my final pressure is

360 in Torr (or mmHG), I can't see why the initial pressure should be 1000 instead of 760.

|

|

|

HRH_Prince_Charles

Hazard to Self

Posts: 92

Registered: 29-6-2004

Location: Clarence House, London

Member Is Offline

Mood: Bombastic

|

|

My mistake

I was thinking in millibar.

Corrected:

S = 1.64/17 * ln(760/360)

= 1.64/17 * 0.747

= 0.072 L/s

= 72 mL/s

= 4.3 L/minute

Loather of monstrous carbuncles, lover of organic melons and servant girls.

|

|

|

trilobite

Hazard to Others

Posts: 152

Registered: 25-2-2004

Location: The Palaeozoic Ocean

Member Is Offline

Mood: lonely

|

|

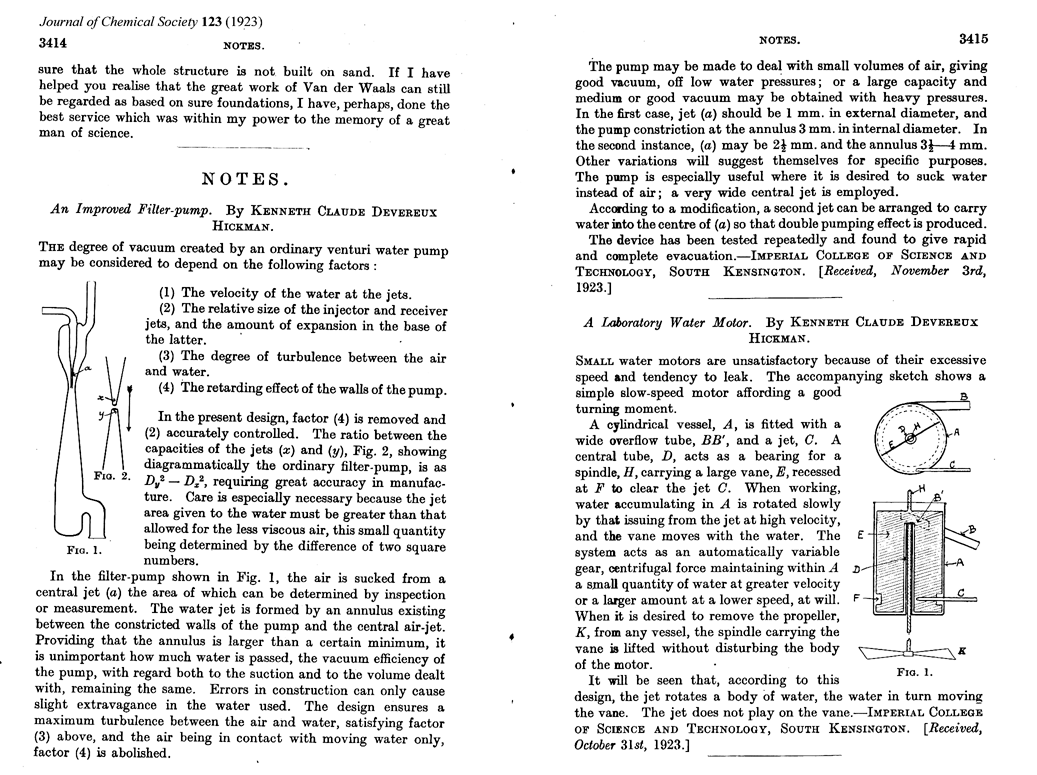

An improved Filter-pump

A few weeks ago I got inspired by this thread, even as there were no practical designs posted, and looked around a bit and found an article describing

a bit different water jet pump design. It's from Journal of Chemical Society 123, 3414-3415 (1923) and there is also a design for a laboratory

water motor included. both by a guy named Kenneth Claude Devereux Hickman.

|

|

|

HRH_Prince_Charles

Hazard to Self

Posts: 92

Registered: 29-6-2004

Location: Clarence House, London

Member Is Offline

Mood: Bombastic

|

|

Vacuum Hose

Just some thoughts on vacuum hose. Ideally, the gas conductance of the tubing should be much greater than the pumping speed of the water-jet pump,

otherwise it will limit the performance of the pump. Conductance increases with the 4th power of diameter: double the internal diameter and the

conductance increases 16 times!

For air at 15 C and 5 mbar pressure and 1 m length hose:

Bore (mm) Conductance (L/s)

5------------------0.043

9------------------0.45

15----------------3.44

Typical water-jet pump pumping speed = 0.075 L/s

For those wishing to get down to 5 mbar with iced water, the hose bore should be at least 9 mm. At higher pressures, conductance increases and

narrower bore can be used.

Loather of monstrous carbuncles, lover of organic melons and servant girls.

|

|

|

frogfot

Hazard to Others

Posts: 212

Registered: 30-11-2002

Location: Sweden

Member Is Offline

Mood: happy

|

|

Nice pics tacho.

If hose diameter limits pumping speed, than would volume of pump do the same? With volume I mean insides of the pump thats filled with air..

| Quote: |

Frogfot, you mention 3-5, that's 0.6

|

I always count by area

It took some time to to post since I were waiting for silicone in my finall pump to dry.. it did, and after operating for some time darn silicone

loosened  seems like it doesn't like pressure.. or maby i degreased poorly.. seems like it doesn't like pressure.. or maby i degreased poorly..

Gonna use epoxy next time, but I don't think it's that waterresistant..

Anyway, pump fluctuated at 16-18 torr  This fluctuation may depend (guessing)

on the form of the nozzle. I think nozzle should be symmetrical (kinda hard to make this with a hammer) This fluctuation may depend (guessing)

on the form of the nozzle. I think nozzle should be symmetrical (kinda hard to make this with a hammer)

The specifications of this pump are nearly the same as the one I made before. Only changed pipe to 4 mm ID, hammered to 3 mm in one end.

Tacho, I dunno why you said that throat must be 5 cm long.. Commercial (glass) pump I've got, have ~2,5 cm throat...

Btw, when you refer to HRH, is it "Performance of low-cost ejectors" pdf? well I always assumed it was that file..

Gotta write another text on this pump

|

|

|

HRH_Prince_Charles

Hazard to Self

Posts: 92

Registered: 29-6-2004

Location: Clarence House, London

Member Is Offline

Mood: Bombastic

|

|

Dimensions

Frogfot, according to the ejector design pdf, the ratio of nozzle to throat diameters should be 0.59. This ratio is critical: throat too small and

poor pumping speed; too large and poor vacuum. Kanske possible to compensate for too large a throat by making it longer. Mine is 50 mm length and I

don't need a divergent section or hose on the end for it to work well.

In my pump, I have a 6.1 mm bore throat and a 3.5 mm bore nozzle. I fabricated the nozzle from a fine cake decorating nozzle, which was drilled out to

3.5 mm and sawn off. This was epoxied onto some 8.1 mm bore brass tubing. The nozzle has around a 20 degree taper and gives a nice jet. The main

housing is a 1/2" BSP female brass T. 1/4" BSP brass reducers are used in each end. I used a countersink drill bit to add a 45 degree flare

to the throat (easily cuts soft brass).

When the pump is running, I can pull the nozzle right back from the throat and still get a good vacuum.

Model shops are a good source of brass tubing. My local has 1-10 mm in 1 mm increments.

Don't have a digital camera. I'll see if I can borrow one. Will try and get an accurate vacuum measurement this weekend.

Edit: pumping speed - the hose and the pump chamber will add to the total volume to be evacuated. 1 m of 9 mm bore hose has a volume of 66 cm^3; my

pump has an internal volume of around 30 cm^3. So, you have to add 100 cm^3 to the volume of the apparatus.

[Edited on 11-9-2004 by HRH_Prince_Charles]

Loather of monstrous carbuncles, lover of organic melons and servant girls.

|

|

|

Tacho

National Hazard

Posts: 582

Registered: 5-12-2003

Member Is Offline

Mood: No Mood

|

|

| Quote: | Originally posted by frogfot

If hose diameter limits pumping speed, than would volume of pump do the same? With volume I mean insides of the pump thats filled with air..

|

Good question. I don't think so, it's already quite large compared with the hose, but I may be wrong.

| Quote: |

Gonna use epoxy next time, but I don't think it's that waterresistant..

|

It's very waterresistant, don't worry.

| Quote: |

Tacho, I dunno why you said that throat must be 5 cm long.. Commercial (glass) pump I've got, have ~2,5 cm throat...

|

I mentioned somewhere above that I had much better results when I made that 2cm throat longer. I refer to the tube after the 45° cone, where water

exits, before the widening area, is that what you are talking about? maybe we have a misunderstanding and you are talking about the cone itself.

| Quote: |

Btw, when you refer to HRH, is it "Performance of low-cost ejectors" pdf? well I always assumed it was that file..

|

HRH is "HRH Prince Charles" our friend here at sciencemadness forum, who choose a user name that's very hard to quote.

By the way, HRH, I use air conditioning copper tubes because they are soft and thick enough to be hammered to shape. I have those model shops brass

tubes and they are quite harder to shape.

[Edited on 12-9-2004 by Tacho]

|

|

|

HRH_Prince_Charles

Hazard to Self

Posts: 92

Registered: 29-6-2004

Location: Clarence House, London

Member Is Offline

Mood: Bombastic

|

|

Tubing

Yes, I've found brass modelling tube to be quite hard to form too. I don't need to form the tube in my configuration - I used a cake

decorating nozzle.

Tinkering today, I found that length of the outlet pipe is important for best vacuum. I have a 6.1 mm bore throat, 55 mm long. Unless it is immersed

in water, I need to add a 20 cm tube to the end to ensure good vacuum.

Loather of monstrous carbuncles, lover of organic melons and servant girls.

|

|

|

frogfot

Hazard to Others

Posts: 212

Registered: 30-11-2002

Location: Sweden

Member Is Offline

Mood: happy

|

|

Haha, oops, sorry HRH

I've tried hammer aluminium tubes. They're easy to form, but it's hard to make nozzle symmetrical..

| Quote: |

I refer to the tube after the 45° cone, where water exits, before the widening area, is that what you are talking about?

|

Yp, we're on the same thing..

|

|

|

cavgdad

Harmless

Posts: 22

Registered: 27-4-2004

Member Is Offline

Mood: No Mood

|

|

piece of shit aspirator

i bout this from macnanbio on ebay

http://cgi.ebay.com/ws/eBayISAPI.dll?ViewItem&category=2...

it states that it does 38 mmHg, but when i use it on distilling equiptment it only boils H2O at 80C thats somewhere around 350mmHg right. so is there

anything I can do to make it work or should I send it back?

|

|

|

HRH_Prince_Charles

Hazard to Self

Posts: 92

Registered: 29-6-2004

Location: Clarence House, London

Member Is Offline

Mood: Bombastic

|

|

Crap aspirator

cavgdad, just checked out the ebay page. It specifies 38.25 inches mercury (negative gauge pressure) - this is impossible - maybe it is a typo for

28.25 inches Hg negative gauge = 5.6 mbar absolute. This is the vapour pressure of water at zero degrees Celsius, so they are saying the pump reaches

water vapour pressure, as it should.

Your water is probably warmer than this, but you should get down to 25 mbar or so.

First thing: is your water pressure high enough? If you don't get high enough water speed through the pump, its minimum pressure won't be as

good.

Secondly, try it with the aspirator outlet under water, or stick a hose on it - this works for me.

Thirdly, keep the water as cool as possible. Best is to recirculate ice water with a pump. You'll need a high pressure pump though (50 foot head

or better in US units).

Hope this helps.

Loather of monstrous carbuncles, lover of organic melons and servant girls.

|

|

|

Tacho

National Hazard

Posts: 582

Registered: 5-12-2003

Member Is Offline

Mood: No Mood

|

|

| Quote: | Originally posted by HRH_Prince_Charles

<snip>

Secondly, try it with the aspirator outlet under water, or stick a hose on it - this works for me.

Thirdly, keep the water as cool as possible. Best is to recirculate ice water with a pump. You'll need a high pressure pump though (50 foot head

or better in US units).

Hope this helps. |

If you put the aspirator outlet under water, remember to use some sort of protection agaist suckback or, when you turn off the water source, your

sistem will suck water until pressures equalize or you water reservoir reaches the outlet level.

My 1/4hp pump is rated 15 meters, that's about 50 feet. It works perfectly, confirming what HRH said.

|

|

|

HRH_Prince_Charles

Hazard to Self

Posts: 92

Registered: 29-6-2004

Location: Clarence House, London

Member Is Offline

Mood: Bombastic

|

|

Pump Size

That 1/4 hp pump sounds almost perfect Tacho. I've looked everywhere, and the best I could get was a 370 W model. It does give 25 L/min at 15 m

head, so I could run a pair of water jet pumps.

A typical water-jet pump only requires around 30 W of power to run! (calculate from pressure drop x flowrate). However, a typical pump is only 20%

efficient at driving the water - the other 80% goes into heating the water in the pump. So, to get 30 W of water power for the water jet, you need a

pump of

100/20 x 30 W = 150 W (0.2 HP)

Note also that the maximum head for a pump is at zero flowrate. In use, the head will be lower. My pump is 35 m max. head but only 15 m head at 25

L/min.

Loather of monstrous carbuncles, lover of organic melons and servant girls.

|

|

|

frogfot

Hazard to Others

Posts: 212

Registered: 30-11-2002

Location: Sweden

Member Is Offline

Mood: happy

|

|

I'm currently looking for a cheap water pump to make a recirculating station too.. but I'm worrying about sound. Which pumps make less

sound, usual or "immerseable"?

Btw, finally wrote some specifications on my little respirator.

It gives about 3 torr higher than commercial pump, but on the bright side it sucks 1,39 times faster with only 1,02 times greater water consumption

|

|

|

HRH_Prince_Charles

Hazard to Self

Posts: 92

Registered: 29-6-2004

Location: Clarence House, London

Member Is Offline

Mood: Bombastic

|

|

Excellent Details Frogfot

Your pressures seem as close as to make no difference. I've noticed the pump pressure seems to increase slightly after running for a short

period.

From a heating point of view, external pumps are better: waste heat from the motor doesn't heat the water. Considering that most pumps are so

inefficient, this doesn't make that much difference: it would be better to get an ideally rated pump.

Anyway, this time of year, what does a viking have to worry about? Snart comes the snow and then shall you have unlimited cooling. Can't you just

pick up a bargain from Clas Ohlson or something? You boys are spoilt for choice.

Edit: I mean pump pressure falls slightly after a while running.

[Edited on 16-9-2004 by HRH_Prince_Charles]

Edit again: oh yeh, as to noise - can't see it makes any difference. Placing my external pump on foam certainly cut down vibration.

[Edited on 16-9-2004 by HRH_Prince_Charles]

Loather of monstrous carbuncles, lover of organic melons and servant girls.

|

|

|

frogfot

Hazard to Others

Posts: 212

Registered: 30-11-2002

Location: Sweden

Member Is Offline

Mood: happy

|

|

Ok, then external pump it will be

| Quote: |

Can't you just pick up a bargain from Clas Ohlson or something? You boys are spoilt for choice.

|

Hehe, there are a large choice, but not with prices

I had my eye on one of the cheapest pumps which is 0,5hk, 40litre/min(max), 35m(max height). Thats for 60$, but I hope there will come up something on

second-hand market..

|

|

|

Tacho

National Hazard

Posts: 582

Registered: 5-12-2003

Member Is Offline

Mood: No Mood

|

|

Congratulations frogfot, your (beautifull) page will certaily become a reference for those willing to built their own aspirators! Great work! Fell

free to use any information or pictures I posted, although your work is more than comprehensive.

About pumps and silence: Before I bought this pump, I had another one that's very popular here because it's very cheap, even being 1/2hp.

It's a "vibratory" submersible pump. I could not use it, because it's tremendously noisy. Good for wells or underground

reservoirs, but nothing else. My new pump is very silent.

Another note: my water is above 20ºC 99% of the year, that's a good reason for my higher pressure readings.

|

|

|

Centimeter

Harmless

Posts: 28

Registered: 19-5-2004

Member Is Offline

Mood: No Mood

|

|

I wish I had seen this bit about pumps before I whent and purchased one. I purchased this one http://cgi.ebay.com/ws/eBayISAPI.dll?ViewItem&rd=1&i...

It says its maximum height is 6.5 feat, so I am guessing it will not be good enough. Is there some way I can render this pump usable or do I just have

to get another one? What kind of pump has the desirable specifications? I don't think any gardening or aquarium pump is going to have 50meter

head capability. How much money are we talking here? I only need the pump to pull about 200 torr but I sure would love to be able to experiment with

ones that can pull less than 20 torr.

Edit- I have this thing that attaches to my faucet and it is sapost to be used to run water from the tap to my fish tanks. However when the water is

allowed to flow through the system it acts exactly like an aspirator. I decided to try and measure its abilties. I found that it was able to easily

lift water up ~7ft. The ID of the toob was 3/8" thus I calculate that it drew up about 152ml of water at 15*C. The internet says the local

pressure is 1017hPa. Now using this information I know that I should be able to figure out how many torr the aspirator is capable of pulling, however

I don't remeber how and my notes are entirely confusing. My school chem book is no help either. Can someone please show me how to calculate the

vacuum's pressure? I suspect it is around 500 torr as it is able to pull about the same as I am with my mouth and I found a site that said the

human mouth can pull a vacuum of 20 inches of mercury.

[Edited on 17-9-2004 by Centimeter]

|

|

|

neutrino

International Hazard

Posts: 1583

Registered: 20-8-2004

Location: USA

Member Is Offline

Mood: oscillating

|

|

The diameter of the tube doesn't matter. Convert that to mm and divide by the density of mercury (13.6) and yeu get 157mm. 763mm (your air

pressure)-157 = 606mm Hg. Not really that good.

|

|

|

| Pages:

1

2

3

4 |