| Pages:

1

..

35

36

37

38

39

..

48 |

bbartlog

International Hazard

Posts: 1139

Registered: 27-8-2009

Location: Unmoored in time

Member Is Offline

Mood: No Mood

|

|

The theory he was referring to was this:

| Quote: | | A way around this is to use a second Pt-plated electrode as a cathode. |

...as you would acknowledge if you weren't being deliberately obtuse.

|

|

|

hissingnoise

International Hazard

Posts: 3940

Registered: 26-12-2002

Member Is Offline

Mood: Pulverulescent!

|

|

Well, he did say this. . .

| Quote: |

I have tried the platinum cathode and I can tell you that it is a very bad thing to do. I completely destroyed, (turned to powder), one of the 4

electrodes I bought, which leads me to believe that your idea of the platinum plating onto the cathode in normal operation is incorrect. It

seems the plating goes from negative to positive, this is why, it seems, my platinum cathode completely dissolved in about 150 hours.

|

Everyone knows that Pt is resistant to everything except Aqua Regia and how many people are there who think that electroplating works by migration of

metal from the cathode to the anode?

|

|

|

white rabbit

Harmless

Posts: 33

Registered: 29-11-2009

Member Is Offline

Mood: Groovy

|

|

My point was simply, if the platinum is plating across, it is certainly not plating on the platinum cathode as you stated and Pt is certainly not

electrochemical resistant as a cathode. So your statement that, "Pt is resistant to everything", is also incorrect.

|

|

|

hissingnoise

International Hazard

Posts: 3940

Registered: 26-12-2002

Member Is Offline

Mood: Pulverulescent!

|

|

It's hot - I'm lazy!

Tim knows what I. . .

|

|

|

white rabbit

Harmless

Posts: 33

Registered: 29-11-2009

Member Is Offline

Mood: Groovy

|

|

I will concede that platinum is indeed resistant but not impervious to electro/chemical attack. I really don't know what exactly happened to the

platinum cathode but it really doesn't like to be negative in the electrolyte solution of the chlorate/ perchlorate cells.

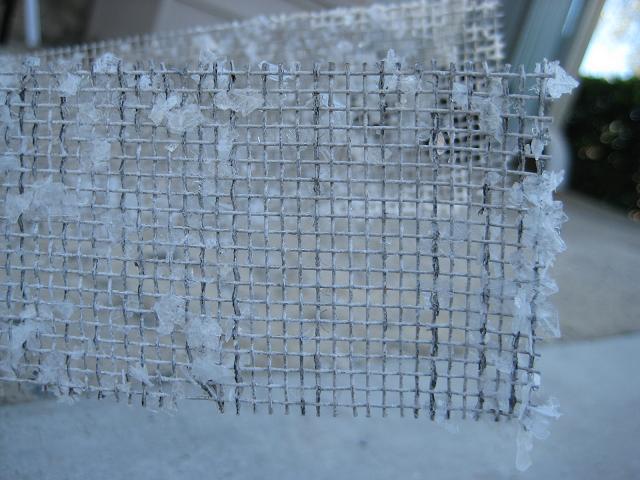

This was my first usage of the platinum electrodes, both anode and cathode at ~70 hours at 6.5 volts / 25 amps. The anode appears to be completely

unaffected and continued to look this way run after run with a stainless cathode.

This was the beginning of the cathode corrosion, and quickly continued, until after removing the electrode from solution, and leaving it exposed to

the air overnight, it crumbled to dust.

|

|

|

hissingnoise

International Hazard

Posts: 3940

Registered: 26-12-2002

Member Is Offline

Mood: Pulverulescent!

|

|

| Quote: | | I really don't know what exactly happened to the platinum cathode but it really doesn't like to be negative in the electrolyte solution of the

chlorate/ perchlorate cells. |

White rabbit, as you know, platinum is famous for its inertness to acidic and alkaline environments.

It certainly shouldn't noticeably corrode when used as cathode or anode in a chloride cell.

Perhaps the electrode was defective in some way. . .

| Quote: |

This was the beginning of the cathode corrosion, and quickly continued, until after removing the electrode from solution, and leaving it exposed to

the air overnight, it crumbled to dust. |

If the Pt plating was not continuous enough to fully protect the electrode, corrosion and hydrogen embrittlement of the substrate metal? could

possibly account for what happened. . .

It's certainly curious and at the price of the electrode, the experience must have been pretty devastating.

|

|

|

white rabbit

Harmless

Posts: 33

Registered: 29-11-2009

Member Is Offline

Mood: Groovy

|

|

You may have a good point there. That one electrode was never used as a anode. I have used three of the four electrodes so far and the two used as

anodes still look like the day I first started using them. (The crusty residue washes of with water) The substrate material is niobium and is supposed

to have an exceptional chemical resistance.

The price of the electrode was of no consequence, but I certainly didn't do the dance of joy.

|

|

|

Lambda-Eyde

National Hazard

Posts: 857

Registered: 20-11-2008

Location: Norway

Member Is Offline

Mood: Cleaved

|

|

Quote: Originally posted by hissingnoise  |

Everyone knows that Pt is resistant to everything except Aqua Regia and how many people are there who think that electroplating works by migration of

metal from the cathode to the anode?

|

Quote: Originally posted by hissingnoise  |

It certainly shouldn't noticeably corrode when used as cathode or anode in a chloride cell.

Perhaps the electrode was defective in some way. . .

|

Platinum metal may dissolve if free chlorine is liberated at the anode.

Ref: Kvantitativ Analyse ("Quantitative Analysis"), Katrine Seip Førland, Tapir Academic Press (1984)

|

|

|

jpsmith123

National Hazard

Posts: 764

Registered: 24-6-2005

Member Is Offline

Mood: No Mood

|

|

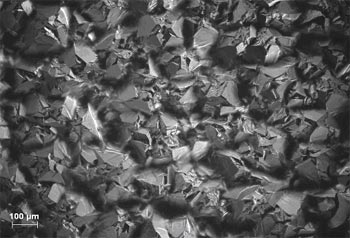

BDD Makes Perchlorate

I recently came across the following interesting abstract. I've been loosely following the development of BDD anodes for a while now, looking for

experimental confirmation that they will in fact make perchlorate. The results stated here seem to verify it, and it sounds promising, IMO.

The other important question, still unanswered AFAIK, is: How well would a BDD anode hold up in a perchlorate cell?

In any case, it seems to me that it might now be worth buying that small BDD slab available from e6 corp. to do some testing. The main issue there is:

How do you make an electrical connection to it?

Electrochimica Acta

Volume 54, Issue 7, 28 February 2009, Pages 2102-2107

ELECTROCHEMISTRY FOR A HEALTHY PLANETENVIRONMENTAL ANALYTICAL AND ENGINEERING ASPECTS Selection of papers from the 6th ISE

Spring Meeting 16-19 March 2008, Foz do Iguacu, Brazil

doi:10.1016/j.electacta.2008.09.040

Copyright © 2008 Elsevier Ltd All rights reserved

The occurrence of perchlorate during drinking water electrolysis using BDD anodes

M.E. Henry Bergmann, Johanna Rollina and Tatiana Iourtchouka

Anhalt University, FB 6/7, Bernburger Str. 55, 06366 Koethen, Germany

Received 30 April 2008; revised 15 September 2008; accepted 17 September 2008. Available online 27 September 2008.

Abstract

Electrochemical studies were carried out to estimate the risks of perchlorate formation in drinking water disinfected by

direct electrolysis. Boron Doped Diamond (BDD) anodes were used in laboratory and commercially available cells at 20 °C. The current density was

changed between 50 and 500 A m−2. For comparison, other anode materials such as platinum and mixed oxide were also tested. It was found that BDD

anodes have a thousandfold higher perchlorate formation potential compared with the other electrode materials that were tested. In long-term

discontinuous experiments all the chloride finally reacted to form

perchlorate. The same result was obtained when probable oxychlorine intermediates (OCl, ClO2, ClO3) were electrolysed in synthetic waters in the ppm

range of concentrations. The tendency to form perchlorate was confirmed when the flow rate of drinking water was varied between 100 and 300 L

h−1 and the temperature increased to 30 °C. In a continuous flow mode of operation a higher chloride concentration in the water resulted in a

lower perchlorate formation. This can be explained by

reaction competition of species near and on the anode surface for experiments both with synthetic and local drinking waters. It is concluded that the

use of electrodes producing highly reactive species must be more carefully controlled in hygienically and environmentally oriented applications.

|

|

|

dann2

International Hazard

Posts: 1523

Registered: 31-1-2007

Member Is Offline

Mood: No Mood

|

|

Hello JP,

Good to see you posting again.

I have not been doing much lately in the Chlorate/Perchlorate line.

The BDD sounds like a great Anode.

Dann2

|

|

|

jpsmith123

National Hazard

Posts: 764

Registered: 24-6-2005

Member Is Offline

Mood: No Mood

|

|

Hi Dann2,

I've been tinkering with electrical stuff and putzing around with a mini-lathe, but seeing the above abstract has re-ignited my interest in BDD

anodes.

I was following this thread for a while, but now it seems most of the participants have moved on to other things.

Anyway, I'm going to start seriously looking again to see if I can buy some niobium/BDD anode material somewhere at a reasonable price. I'll post here

if I have any luck.

|

|

|

watson.fawkes

International Hazard

Posts: 2793

Registered: 16-8-2008

Member Is Offline

Mood: No Mood

|

|

Think about using vacuum

deposition. Given that the technology was invented by Thomas Edison (yes, really, it surprised me), it's certainly achievable in a home lab,

particularly now that refrigeration service pumps are so common.

|

|

|

jpsmith123

National Hazard

Posts: 764

Registered: 24-6-2005

Member Is Offline

Mood: No Mood

|

|

Being that the diamond is doped with boron, it's an electrical conductor (although not a very good one according to the specs), so it might be

possible to metallize it by simple electroplating, for that matter, and then something could be soldered or brazed to it.

I think the main problem is that the metal-to-diamond joint will be exposed to the environment of the chlorate/perchlorate cell, so most common

materials would probably not last very long.

I remember seeing a patent from 50 or 60 years ago wherein diamond powder was metallized and attached to the metal core of a grinding wheel using a

paste of TiH2. The assembly was then fired to 400 or 500 degrees C in a furnace.

That's probably something like what you'd have to do to make a reliable connection to it, i.e., a direct diamond to valve metal bond.

In any case, another disadvantage of trying to use bulk BDD slab material available from e6, is that the conductivity of the material is rather low,

so, depending to a certain extent on how you connect to it and use it, the current you could put through it would probably be limited to a few amps.

Quote: Originally posted by watson.fawkes  | | Think about using vacuum

deposition. Given that the technology was invented by Thomas Edison (yes, really, it surprised me), it's certainly achievable in a home lab,

particularly now that refrigeration service pumps are so common. |

[Edited on 24-7-2010 by jpsmith123]

|

|

|

dann2

International Hazard

Posts: 1523

Registered: 31-1-2007

Member Is Offline

Mood: No Mood

|

|

Hello Folks,

Have a look at:

http://www.advoxi.com/products

These things may be available in the dumpsters soon. (like the MMO)

Still getting around to the SnO2/Bismuth doped Anode to see if it's any good. Perhaps next month.

Dann2

[Edited on 28-7-2010 by dann2]

|

|

|

jpsmith123

National Hazard

Posts: 764

Registered: 24-6-2005

Member Is Offline

Mood: No Mood

|

|

Thanks for that link Dann2.

I'm going to email them and find out what's available and at what price.

|

|

|

jpsmith123

National Hazard

Posts: 764

Registered: 24-6-2005

Member Is Offline

Mood: No Mood

|

|

Unfortunately, I found out that they won't sell just BDD anodes, but only the whole electrolytic cell. Even more unfortunate is the price...they want

over $5000 US dollars for a small cell for swimming pools (if I've converted the currency correctly).

So it looks like that company is out. Rats. We need to keep looking I guess.

|

|

|

dann2

International Hazard

Posts: 1523

Registered: 31-1-2007

Member Is Offline

Mood: No Mood

|

|

Thats bad news!

If you Google

homemade boron doped diamond

some interesting looking links appear. I did not read them yet though. They seem to suggest that it may be possible to do it in an Amateur setting.

Also De Beers BDD Electrodes are distributed by Windsor Scientific, Slough, UK

http://www.windsorscientific.co.uk/index.php?main_id=92&...

240 pounds sterling for a disk 3mm in diameter. (ouch). The damm thing is hardly much bigger that a good sized full stop!

If it made an everlasting Perchlorate Anode though.........

Perhaps someone who is a bit flush with cash could stand into the breech.

Cheers,

Dann2 (holding on tightly to his hard earned cash  ) )

[Edited on 4-8-2010 by dann2]

|

|

|

white rabbit

Harmless

Posts: 33

Registered: 29-11-2009

Member Is Offline

Mood: Groovy

|

|

Buy the platinum anode and you're done. It saves 100's of hours of your precious time looking for alternatives.

|

|

|

jpsmith123

National Hazard

Posts: 764

Registered: 24-6-2005

Member Is Offline

Mood: No Mood

|

|

No doubt platinum is great anode material, but it seems BDD has the potential to be much better: more efficient at making perchlorate, more robust and

longer lasting, and hopefully, someday, significantly cheaper.

BDD may even be able to do things that, AFAIK, other anode materials can't, e.g., directly convert HCl onto HClO4.

I thought by now somebody would be doing something with "poly(hydridocarbyne)", i.e., applying diamond films to substrates by thermolysis of a

precursor solution, similar to how MMO anodes are made.

I thought the patent holders (the processes to make the poly(hydridocarbyne) are patented) would have an interest in developing applications like this

for their invention. Apparently not.

|

|

|

jpsmith123

National Hazard

Posts: 764

Registered: 24-6-2005

Member Is Offline

Mood: No Mood

|

|

Well it seems it'll be awhile before BDD anodes compete with Pt or PbO2, for our purposes at least.

The best price I've got so far is 960 Euro for a BDD over Nb plate anode of dimensions about 7.5"x3.25"x0.1" with a 5 micron BDD coating on both

sides.

The recommended current density for this anode is 100 ma/cm^2.

The manufacturer says it is suitable for perchlorate electrosynthesis, which again confirms what we've already concluded.

As I understand it, BDD does slowly wear away, supposedly as OH attacks and damages it where there are defects in the crystal structure, or something

like that. But it will nevertheless last a long time, maybe 10,000 hours or more of continuous use under harsh conditions.

I had hoped that, by now, conductive (boron doped) diamond powder would be commercially available...alas it isn't, as far as I know. Which is

unfortunate as it seems to me that an electrophoretically coated platinum or MMO anode would be the easiest way to make a BDD anode at home.

Another method might be thermolysis of "poly(hydridocarbyne), with the addition of some boron compound as a dopant.

And I'm really surprised that nothing seems to be happening with this stuff.

Lastly, it may be possible to rig up a homemade cvd apparatus and make BDD at home, but I certainly don't have the resources to even try right now.

Luckily, it's been shown possible to make high quality BDD using alcohol vapor instead of methane and hydrogen gasses, and it's been shown that boric

acid can be added to the alcohol as a boron dopant.

Also, luckily, the vacuum requirements are lax, so a simple water aspirator might suffice instead of a rotary vane vacuum pump.

The two remaining technical hardships would be (1) keeping the substrate temperature between 700 and 900 degrees C (or something like that); and (2)

creating the plasma with which to dissociate the vapor into the active species.

It's possible that a dielectric barrier discharge can be used instead of a hot filament or a microwave (or RF) plasma, but I couldn't find any

specific examples in the literature where a DBD was used (although I didn't look very thoroughly). If DBD will suffice for this purpose, I can see the

apparatus being greatly simplified...with the major PITA being finding the optimum combination of pressure, discharge power, electrode spacing, etc.

|

|

|

dann2

International Hazard

Posts: 1523

Registered: 31-1-2007

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by jpsmith123  |

The best price I've got so far is 960 Euro for a BDD over Nb plate anode of dimensions about 7.5"x3.25"x0.1" with a 5 micron BDD coating on both

sides.

The recommended current density for this anode is 100 ma/cm^2.

|

Thats not too far off from the price of Pt.

Dann2

|

|

|

jpsmith123

National Hazard

Posts: 764

Registered: 24-6-2005

Member Is Offline

Mood: No Mood

|

|

I think e6 has convinced me that, with regard to presently available commercial technology, bulk BDD, rather than BDD coated substrates, is the way to

go for diamond anodes. (Although I think it's possible someday that thick, electrophoretically applied coatings over the right substrate might be an

exception).

Apparently e6 experimented with both BDD coatings and bulk material, and decided the latter was best. It seems that the coatings can develop pinholes

which ultimately result in delamination of the coating. This is apparently why manufacturers of coated anodes recommend limiting the current density

to 100 mA/cm^2, whereas the bulk BDD anodes can run from 0.5 to 1.0 Amp/cm^2.

Their literature predicts a life expectancy of >45,000 hours, when running at 0.5 A/cm^2.

A piece of BDD that's 20 x 20 x 0.6 mm would cost around $200 USD.

|

|

|

densest

Hazard to Others

Posts: 359

Registered: 1-10-2005

Location: in the lehr

Member Is Offline

Mood: slowly warming to strain point

|

|

Anyone in the UK have a moment to talk to these people?

Advanced Oxidation Limited

Unit 1

Homelands Business Centre

Burrington

Umberleigh

North Devon

EX37 9JG

United Kingdom

Telephone:

Alan +44 (0)7811 541339

Paul +44 (0)7702 707228

They say they sell wastewater treatment units containing BDD anodes including ones for spa/hot tub/pools.

|

|

|

metalresearcher

National Hazard

Posts: 731

Registered: 7-9-2010

Member Is Offline

Mood: Reactive

|

|

Where can I get platinum metal sheet or wire ?

Jewelry supply shops like cooksongold.com sell only jewelry grade Pt which is Pt alloyed with 5% Cu which is unsuitable for anodes as the copper is

dissolved (AFAIK).

On Ebay I cannot find pure platinum for the 'normal' day price of $1600/oz or only slightly above which is 1600/0.031= EUR 51200/kg only for MUCH

higher.

|

|

|

hissingnoise

International Hazard

Posts: 3940

Registered: 26-12-2002

Member Is Offline

Mood: Pulverulescent!

|

|

The biggest suppliers of PGMs are Johnson Matthey and Degussa - check them or their subsidiaries out first!

|

|

|

| Pages:

1

..

35

36

37

38

39

..

48 |