ziqquratu

Hazard to Others

Posts: 385

Registered: 15-11-2002

Member Is Offline

Mood: No Mood

|

|

Designing an incubator

Howdy all! Not entirely sure where this should live, so If mods feel it would be better relocated to another home, please feel free!

Alright, so, I want to build an incubator to culture some bacteria and fungi (no, not THAT fungus!). There's not a huge amount of suitable info

around (despite days of googling, I'm still drawing blanks on real details, although lots of inspiration!). See, the main issue is that, in my area,

temperature can vary quite a bit day to night, and is certainly massively variable between summer and winter. As such, it's no good to me to simply

have a device which heats or cools, it needs to do both!

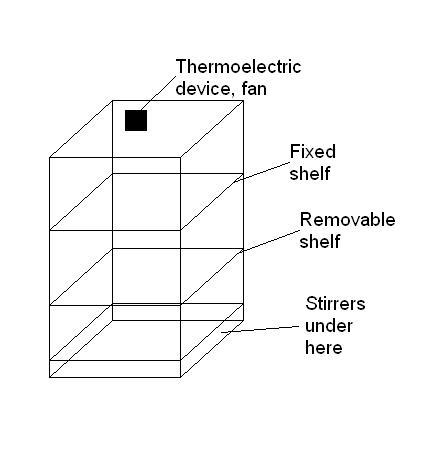

Basic idea I have so far is a wooden box, with some sort of insulation lining it (polystyrene, perhaps, or some other sort of foam), with a plastic

internal chamber (acrylic, polycarbonate, polypropylene, whatever's cheap!). The chamber is heated/cooled by a thermoelectric device, which has a

good-sized heatsink and fan attached to both sides.

In this thing, I want the option of culturing from both petri dishes/McCartney-type bottles as well as erlenmeyer flasks (up to say 500mL). Also, I

intend to incorporate magnetic stirrers to stir the flasks. As such, I have an idea of having one upper fixed shelf (with suitable clearance for

bottles and dishes), and then a lower section which is high enough to fit the flasks - a set of mag stirrers, made from PC fans, will be placed on the

"floor" of the unit, under a second layer of plastic. I also think that it'd be nice to have a removable shelf that divides this lower area in two,

so if I'm not in the mood for flasks, I can have extra room for dishes and vials. Have a look at the attatched paint sketch of how I envisage the

internal chamber to get an idea, if you're interested. Also, the two internal shelves will have plenty of holes in them, to allow efficient air

movement and thus temperature stability within the chamber.

Overall, I think internal dimensions will be roughly 30cm deep and wide, and maybe a couple of feet high. I'm guessing this should accomodate 4x500mL

erlenmeyers on the base, with enough height for them and the upper shelf. Temperature should ideally be controllable between 20-40C, with stability

being maybe +/- 1C about the set point (since it'll be fan-forced, this shouldnt be too difficult). I envisage the power supply, temperature and mag

stirrer controls being housed in a box on top of the unit, with an LCD showing both the set and actual temperatures, and ultimately a datalogger to

keep an eye on the temp over time (although the datalogger in particular can wait - LCD would be nice, though!). Most of the circuitry I've already

got lined up in my head (cheap and efficient PWM controls for the stirrer, and a design for a datalogger).

So, most of this stuff I have essentially worked out. My main problem is controlling a Peltier for this job. Does anyone know how to use one of

these beasts for thermostatic control, rather than all-out cooling/heating? How do you control the power output? Also, I've read that switching the

polarity of the device (so that the hot side becomes the cold side) can damage them if you dont turn the thing off for a time in between - anyone know

the deal about this? Also, as I mentioned, I'd like a way to interface an LCD with this (just a small one line one, or two at most, which says

something along the lines of "Set: XX.XC; Actual:YY.YC"). But if that's not possible, well, life goes on *shrugs*.

Any input at all would be most appreciated.

|

|

|

chemoleo

Biochemicus Energeticus

Posts: 3005

Registered: 23-7-2003

Location: England Germany

Member Is Offline

Mood: crystalline

|

|

Although I am not going to go through your post point by point, since I lack some of the electronic knowledge-

* please do not make an incubator that is so high. All those I have seen are flat and squat, probably for a good reason - to prevent temperature

gradients with height. 30 cm high ('a foot') is what I see in professional incubators. This could naturally be avoided by including a heavy duty fan

to avoid these gradients. However - growth flasks are normally open lidded- in that the lid sits on the flask lightly. This is ok for sterility, and

reasonable O2/CO2 exchange. However, with massive air currents circulating in a high incubator, you WILL compromise sterility. Hence the design is

such that the incubator is flat, where little fan power is required to maintain temperature.

* Most bacteria require temperatures above 20 deg C to grow properly. Depending on your climate, I'd seriously consider just including a heating

element, that heats when required by circulating air into the system through the fan. To argue that you have seasonal variation - well, undoubtedly,

but if the incubator is off during a few months in summer wouldnt be too devastating right? Unless of course you run your incubators in the middle of

the Sahara. In that case I suggest Peltier's only  . Essentially the simpler the

better. Unless you enjoy building a homemade incubator more than the actual usefulness of it.... . Essentially the simpler the

better. Unless you enjoy building a homemade incubator more than the actual usefulness of it....

* From experience with other set-value programming, I might suggest simply hooking up the temperature readout, and the power fed into the heater in

front of the inlet fan, by a simple computer program. These can be found on the net. Essentially, if the temp drops below a certain level, the heater

is turned on for a set interval. Another set time is allowed to evolve to allow temperature to equilibrate. If still below, then the heater is turned

on for another interval, which is adjusted for the temp differential. Et cetera. There are serial (and probably USB these days) elements whcih allow

you to simply address input/output of these functions.

* at last, i'd rather get PP boards (5 mm strength), and use that as internal coating. You can even fuse it with silicone inside, or use PP welding

(don't know how that works though, but I've seen it). This way, if there is spillage, or if you require (which is likely) thorough sterilisation of

the incubator, you can simply fume the whole thing with chlorine, UV lamp, or whatever nasties take your fancy  Most labequipment I've seen works this way, or has internal stainless steel lining, which is probably more difficult

for you... Most labequipment I've seen works this way, or has internal stainless steel lining, which is probably more difficult

for you...

May I ask what you are going to use the incubator for?

[Edited on 16-7-2006 by chemoleo]

Never Stop to Begin, and Never Begin to Stop...

Tolerance is good. But not with the intolerant! (Wilhelm Busch)

|

|

|

ziqquratu

Hazard to Others

Posts: 385

Registered: 15-11-2002

Member Is Offline

Mood: No Mood

|

|

Hi chemoleo, thanks for the reply.

At the moment, the only real ideas I have are to try growing a variety of yeast strains for brewing purposes (my housemate has a thing for

homebrewing, and myself a thing for microbiology, thus...!). Other than that, I guess we'll see what inspires me down the track!

The height issue: did think of that, but wasnt sure how much of a problem it would be. My design is loosely inspired by commercial units such as the

one seen here:

http://www.tritechresearch.com/cgi-bin/shop/incub.html

(the second one, the 68L black one, is approximately the dimensions I gave).

Realistically, though, the option of tall-and-narrow was conceived due simply to space restrictions. Ultimately, if it's short-and-fat, I dont really

mind. I'd really like to include room for flasks and dishes, though...

As to heating/cooling, the reason I want this is because I have tentative plans to do some long-term "selective breeding" experiments down the track,

with some biosynthetic organisms, in order to develop optimally-producing strains (god only knows of what... maybe I can play with the mold that's

started growing in my bathroom :s). In any case, I'd like to be able to perpetuate strains, which is easily enough done by storing them on slopes

under parafin in the incubator. Thus, I'd need the thing to be stable in summer, too...

I thought about a computer program, too, and it looks like the easiest option... But if someone knew a (relatively) simple microprocessor controlled

design, i could have a lot of fun with that, too  . I have some ideas, but am

still looking into it. . I have some ideas, but am

still looking into it.

Also, i like the idea of stainless, and thought perhaps aluminium would be a suitable substitute, but at this point they're both out (for price and

weight). And as to choice of plastic, PP would of course be ideal - chemically resistant, easy to clean, and (i think) reasonably easy to work with.

Anyways, we'll see about the in the future.

|

|

|

methyl_ethyl

Harmless

Posts: 13

Registered: 21-5-2006

Location: Estonia

Member Is Offline

Mood: No Mood

|

|

Since temperature stability is of concern, it would not hurt to put the extra time in, and design a water jacket for your incubator. This may help

to maintain a stable temperature, and may lessen the load on your heating/cooling method of choice.

just a thought,

On the other hand if your heating/cooling system is sub-par and goes haywire, it would insure that whatever you have growing up, has no chance of

survival

regards,

m_e

Unipolar Mania.... it\'s good for life

|

|

|

|