| Pages:

1

2

3 |

markx

National Hazard

Posts: 645

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

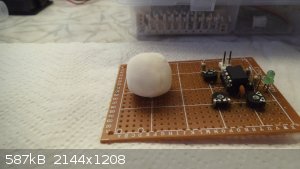

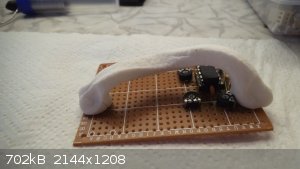

A simple yet effective mix for plasticizing actions:

80-90% low polymerisation degree PIB from rat glue

10-20% high polymerisation degree PIB from "self amalgamating" tape

Below is the example with 20% of the mentioned binder in action:

Judging by the excellent mechanical properties one can do with much less than 20% of this particular binder in the mix.

Exact science is a figment of imagination.......

|

|

|

Microtek

National Hazard

Posts: 827

Registered: 23-9-2002

Member Is Offline

Mood: No Mood

|

|

That does look very promising. What else is in it? Or alternately, how did you prepare it? I haven't had the opportunity to examine rat- or bird glue

myself, but I'm assuming there must be some plasticizers in it as well.

|

|

|

markx

National Hazard

Posts: 645

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

Quote: Originally posted by Microtek  | | That does look very promising. What else is in it? Or alternately, how did you prepare it? I haven't had the opportunity to examine rat- or bird glue

myself, but I'm assuming there must be some plasticizers in it as well. |

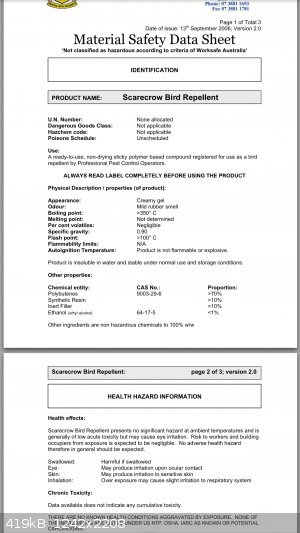

I really can't figure out if there are any plastifying additives in the rat glue composition...as far as the package label or sds card say it only

contains polybutene (copolymer of butylene and isobutylene). The tape might have some additives that leech into the extraction solvent together with

the pib mass, but again I have no information on what these additives might be. The fact is that either one of the PIB based binders used alone or in

conjuction with additional plastifiers (methyl riccinolate, different oils etc) do not produce a similar effect.

The composition on the pictures is as follows:

18% rat glue pib

2% tape pib

80% energetic of choice

The binder was dissolved in alkene mixture and added to the energetic in aforementioned proportions. The mass was mixed and kneaded manually until the

solvent evaporated (approximately 30min) resulting in a highly elastic mass that can be streched out very much like bubble gum without breaking apart.

The mass was not rolled, just kneaded and stretched manually.

Exact science is a figment of imagination.......

|

|

|

Microtek

National Hazard

Posts: 827

Registered: 23-9-2002

Member Is Offline

Mood: No Mood

|

|

| Quote: |

The binder was dissolved in alkene mixture

|

Do you mean alkane? using alkenes as solvents for polymers seem a little exotic and toxic...

As for the rat glue composition, I've been googling it a little, and found an msds that listed the following ingredients (the company name is SX

Environmental):

Butyl rubber 2-10%

PIB 10-20%

White mineral oils 30-50%

Polyethylene 1-5%

Oil resin 15-25%

The mineral oils and the "oil resin" (though I'm not quite sure what they mean by that) probably both have a plasticizing effect, and comprise 45-75 %

of the composition. The product may not be at all identical to yours, but I think it quite likely that yours also contain a lot of plasticizer.

|

|

|

markx

National Hazard

Posts: 645

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

Quote: Originally posted by Microtek  |

| Quote: |

The binder was dissolved in alkene mixture

|

Do you mean alkane? using alkenes as solvents for polymers seem a little exotic and toxic...

As for the rat glue composition, I've been googling it a little, and found an msds that listed the following ingredients (the company name is SX

Environmental):

Butyl rubber 2-10%

PIB 10-20%

White mineral oils 30-50%

Polyethylene 1-5%

Oil resin 15-25%

The mineral oils and the "oil resin" (though I'm not quite sure what they mean by that) probably both have a plasticizing effect, and comprise 45-75 %

of the composition. The product may not be at all identical to yours, but I think it quite likely that yours also contain a lot of plasticizer.

|

True that, alkanes are solvent media that I used (what a difference one letter can make!)  The glue that I used is from the company Kollant SRL and they only mention the polybutenes and 0-0,25% cyclohexane on the sds. But then

again the sds does rarely expose the true composition of a product and I'm sure that there are many different formulations out there... The glue that I used is from the company Kollant SRL and they only mention the polybutenes and 0-0,25% cyclohexane on the sds. But then

again the sds does rarely expose the true composition of a product and I'm sure that there are many different formulations out there...

Exact science is a figment of imagination.......

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

The MSDSs for the few bird repellent products I have looked at stated as low as 88% to as high as 98% polybutenes, I always figured there was probably

some plasticizer(s) added as well, but it was (or they were) never listed in the MSDSs. Nice looking putty by the way!

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

NeonPulse

Hazard to Others

Posts: 417

Registered: 29-6-2013

Location: The other end of the internet.

Member Is Offline

Mood: Isolated from Reality! For Real this time....

|

|

Here's the one I use and it works great although it is not 100% pure. The MSDS said only 70% + polybutene, but not sure what the inert fillers could

be and what the synthetic resins comprise of. It is preferable to the rat traps or fly paper since all you need is a caulking gun. Very little mess.

And easy to work with, but if you get it on stuff it is a real pain in the ass to clean up.

[Edited on 29-2-2016 by NeonPulse]

[Edited on 29-2-2016 by NeonPulse]

|

|

|

XeonTheMGPony

International Hazard

Posts: 1636

Registered: 5-1-2016

Member Is Offline

Mood: No Mood

|

|

http://www.ebay.com/itm/The-glue-is-non-toxic-from-rodents-a...

Well searching for sources of PIB I found this, all the chararistics they discribe sounds exactly like streight up un modified pib! of the right

weight. Thoughts?

|

|

|

magicchemist

Harmless

Posts: 6

Registered: 24-1-2016

Member Is Offline

Mood: No Mood

|

|

markx what the brand of your ratglue ?

|

|

|

deadpool

Harmless

Posts: 21

Registered: 13-3-2014

Member Is Offline

Mood: No Mood

|

|

Well I know this is an old topic, but I was trying to binding ETN using the best products and related work here

used :

(per wiki c4)

5.3% dioctyl sebacate

1.6% mineral oil

2.1% Pib from "bird repellent"

The results were extremely poor, the product was brittle and woudn't adhere, I ad to keep increasing the quanity of the PIb to get some final product

which was still poor and ended up containing large quantities of inert compounds. I think the problem is the bird repellent, it's nasty stuff and not

very rubber like, just a sticky mess. perhaps the trick is getting longer chains, next Ill try the amazing results w/ glue traps and tape as

mentioned by markx

|

|

|

XeonTheMGPony

International Hazard

Posts: 1636

Registered: 5-1-2016

Member Is Offline

Mood: No Mood

|

|

Bike inner tube glue I have found to work very well.

|

|

|

twelti

Hazard to Others

Posts: 217

Registered: 20-2-2019

Member Is Offline

|

|

Is this of any interest:

https://www.ebay.com/itm/2-oz-Pro-Grade-Styrene-Butadiene-Ru...

|

|

|

deadpool

Harmless

Posts: 21

Registered: 13-3-2014

Member Is Offline

Mood: No Mood

|

|

Thanks Xeon!

I'll give that a try, currently working with scapa 2504 tape (also claims to be pib) not sure what the difference is between the 2501 & 2504

(think just the dimensions)

|

|

|

wessonsmith

Hazard to Others

Posts: 203

Registered: 15-2-2018

Location: elsewhere

Member Is Offline

|

|

HTPB Binder

Very quick and easy method. Let the machine do all the work.

https://youtu.be/1BCsG84-rIo

|

|

|

Microtek

National Hazard

Posts: 827

Registered: 23-9-2002

Member Is Offline

Mood: No Mood

|

|

I'm a little uneasy about the prospect of machine tumbling a material as sensitive as ETN. IIRC, TNT based composites such as cyclotol have

occasionally been initiated in very similar mixing machines. Granted, the temperature must have been around 90C, but given the lower sensitivity of

RDX and TNT I still find it a little unsettling.

|

|

|

wessonsmith

Hazard to Others

Posts: 203

Registered: 15-2-2018

Location: elsewhere

Member Is Offline

|

|

Quote: Originally posted by Microtek  | | I'm a little uneasy about the prospect of machine tumbling a material as sensitive as ETN. IIRC, TNT based composites such as cyclotol have

occasionally been initiated in very similar mixing machines. Granted, the temperature must have been around 90C, but given the lower sensitivity of

RDX and TNT I still find it a little unsettling. |

First, the blades of the mixer don't touch each other or the surface of the bowl. Secondly, you add the ETN in batches so that the HTPB has a chance

to coat the crystals. You do this at low speed first. Once the crystals are covered, the sensitivity goes WAY down — no chance of detonation.

The accidents that you refer to are not the heating and mixing but when they allowed the TNT to harden and left it in the mixer overnight. When they

restarted those powerful mixers, which broke free of the TNT, it was enough energy to detonate.

I am employing simple math with my method. There isn't enough friction or force generated against the ETN crystals to cause any problems.

Once the ETN is completely coated, you can hit it with a hammer against steel and it won't detonate.

[Edited on 10-7-2019 by wessonsmith]

|

|

|

MineMan

National Hazard

Posts: 996

Registered: 29-3-2015

Member Is Offline

Mood: No Mood

|

|

What is the math, I would like to learn this?

|

|

|

twelti

Hazard to Others

Posts: 217

Registered: 20-2-2019

Member Is Offline

|

|

I'm also curious. It seems that trying to equate sensitivity values measured in one very specific way to this different situation would be tricky. I

mean, I'm guessing that one could calculate the total energy being imparted to the "dough" by the mixer, and try to compare to the minimum energy

required for initiation or something on that order. But, I would think that the actual frictional energy, shear and stress etc. is not evenly

applied throughout the mass. If it is a distribution of energy levels, then some small parts could have much higher energies and initiate the rest.

At the very least, it doesn't sound simple.

|

|

|

Microtek

National Hazard

Posts: 827

Registered: 23-9-2002

Member Is Offline

Mood: No Mood

|

|

I agree that the probability of initiation is likely very low, but many things behave in a non-ideal manner (eg. mix is not completely homogenous or

forces are not applied evenly). Also, sometimes you discover a phenomenon that hadn't occurred to you before, like adiabatic heating from liquid

sloshing (has been known to initiate nitromethane). NM can be fired upon with 12.7 mm HMG rounds and not go off, so on the face of it, you wouldn't

think there would be any problems driving it around in tanker cars. It turns out that if the tank isn't completely full, it can actually detonate from

sudden stops.

Things like this can be hard to predict, so who's to say that there isn't some other phenomenon that could be of relevance in this instance? If I were

you I would at least place the kneading machine far from buildings and people, and switch it on remotely.

|

|

|

Microtek

National Hazard

Posts: 827

Registered: 23-9-2002

Member Is Offline

Mood: No Mood

|

|

Some years ago, I (like several other members here) frequented the Explosives and weapons Forum. One of the members there was someone who called

himself NBK2000. He was not a pleasant person, but he posted something he called the RTPB (Rules To Prosper By). One of these rules was to "Plan for

failure", and I have since found that to be sound advice indeed (though obviously not invented by this person - I was taught the same thing at

technical university), especially in relation to energetics.

So, to play devils advocate: What would happen if your mixing machine failed in some manner? Maybe the blades are warped, or maybe there is an

electrical malfunction possibly due to overheating (I'm guessing the machine isn't designed for making plastique, so maybe this places a higher than

designed load on the components). A warped blade could result in metal on metal grinding, an electrical problem could possibly result in a fire.

I realize that you can't eliminate all risk (we'd never get anything done that way, and we'd still not live forever), and you are of course free to do

things in whichever way you please.

|

|

|

twelti

Hazard to Others

Posts: 217

Registered: 20-2-2019

Member Is Offline

|

|

Quote: Originally posted by wessonsmith  | | Quote: |

"Plan for failure", and I have since found that to be sound advice indeed (though obviously not invented by this person - I was taught the same thing

at technical university), especially in relation to energetics. So, to play devils advocate: What would happen if your mixing machine failed in some

manner? Maybe the blades are warped, or maybe there is an electrical malfunction possibly due to overheating (I'm guessing the machine isn't designed

for making plastique, so maybe this places a higher than designed load on the components). A warped blade could result in metal on metal grinding, an

electrical problem could possibly result in a fire.

|

I agree, I always plan for failure, that is what I meant by using common sense. For example, I chose a mixer that was powerful

enough to handle the job of mixing my composition. I also stand there the entire time that the mixer is on. If for some reason there was a problem,

I could pull the plug. Even if somehow the blade bent at lower speeds no big deal. Once I transition to the higher rates, the ETN has been

thoroughly coated and can withstand direct blows from a hammer on steel without detonating. (Yes I have thoroughly tested my plastic

The bottom line my method is the safest way for ((( ME ))) to mix explosives. With the blender, I eliminate my fatigue, which can cause accidents,

and the mixer also ensures consistency of the process. |

I haven't been around long, but I get the impression that sensitivity can go up for larger amount of energetic material. For example, my tests of ETN

with a hammer have been using very small amounts, since when heating in foil, it detonates easily and loudly. It is insensitive in those amounts, but

I have been told that if using a larger amount, it should detonate with hammer easily. I'm going to try that soon. But that, and other various

things I have heard or read, makes me wonder if larger amounts can be more sensitive than the small amounts normally tested. The amounts you deal in

are very large by my standards. Also wondering if the trapped air in the mixture is a factor. Does that increase sensitivity? Finally, you are

using large and small crystals to start with. Will that optimal mixture still be intact after the shaving resulting from the mixing process?

|

|

|

twelti

Hazard to Others

Posts: 217

Registered: 20-2-2019

Member Is Offline

|

|

Quote: Originally posted by wessonsmith  |

| Quote: |

I haven't been around long, but I get the impression that sensitivity can go up for larger amount of energetic material. For example, my tests of ETN

with a hammer have been using very small amounts, since when heating in foil, it detonates easily and loudly. It is insensitive in those amounts, but

I have been told that if using a larger amount, it should detonate with hammer easily. I'm going to try that soon. But that, and other various things

I have heard or read, makes me wonder if larger amounts can be more sensitive than the small amounts normally tested. The amounts you deal in are very

large by my standards. Also wondering if the trapped air in the mixture is a factor. Does that increase sensitivity? Finally, you are using large and

small crystals to start with. Will that optimal mixture still be intact after the shaving resulting from the mixing process?

|

A crystal explosives sensitivity doesn't change with the amount used. The situation you were having was that you were missing the ETN with the hammer

due to the small amount used. His suggestion for you to use more ETN was intended to increase the probability of hitting the ETN inside the foil.

FYI, 50mg of ETN in foil is hazardous if you are not wearing eye and ear protection.

Trapped air decreases the density of the plastic explosive; that is why I always use a vacuum chamber once I am done mixing. Low density means less

brisance and power.

I use a mixture of small and large particle sizes, 31.5% small, and 68.5% large. Using the two different particle sizes is crucial in getting the

most ETN possible into the HTPB matrix.

|

I don't think I am missing the ETN. I mean the foil is flattened and then some! Even if so, that just illustrates the point: the larger the amount,

the more probability of an (improbable) event that can result in detonation.

Doesn't air spaces increase sensitivity? Hotspots, cavitation and all...

I just wondered if after all that mixing the larger crystals get reduced in size. Maybe both the large and small get reduced the same amount?

|

|

|

MineMan

National Hazard

Posts: 996

Registered: 29-3-2015

Member Is Offline

Mood: No Mood

|

|

Wesson, we appreciate how much you have researched this, and your confidence.

But what makes us nervous is it’s ETN...you could do this a 1000 more times and not have an incident..

But, ETN is rather sensitive. This would make me nervous with PETN... but with ETN I would say your quite brave. I wouldn’t recommend this procedure

with anything less than RDX.

When quanity goes up. So does uncertainty... you say crystal sensitivity doesn’t change with the amount, but you have a higher chance of having a

crystal with more internal stress...

Wesson. This just makes me uneasy. Wish Bert and some of the others that know industry better were here to comment.

[Edited on 12-7-2019 by MineMan]

|

|

|

wessonsmith

Hazard to Others

Posts: 203

Registered: 15-2-2018

Location: elsewhere

Member Is Offline

|

|

Probably best if I just delete my posts. My intention wasn’t to make people uneasy.

[Edited on 12-7-2019 by wessonsmith]

|

|

|

Microtek

National Hazard

Posts: 827

Registered: 23-9-2002

Member Is Offline

Mood: No Mood

|

|

My own hypothesis about the Al-foil bias is that the soft aluminum deforms around the individual crystals with the first few hammer blows, and then

cushions them against the subsequent strikes. This would also explain why a slightly larger amount responds more reliably (since there would be more

crystal on crystal interfaces), and gives a more accurate impression of the sensitivity.

|

|

|

| Pages:

1

2

3 |