| Pages:

1

2 |

evil_lurker

National Hazard

Posts: 767

Registered: 12-3-2005

Location: United States of Elbonia

Member Is Offline

Mood: On the wagon again.

|

|

| Quote: | Originally posted by volfrahm

| Quote: | Originally posted by evil_lurker

In the mail today I got a Chemglass 350ml pressure vessel with #15 threaded teflon stopper that is supposedly good to 150psi.

Will have to try it out... will post results later. |

This caught my eye. Did you ever get a chance to try it out?

How easy would it be to modify the teflon stopper for hydrogenations? |

Yah I've used it for microwave solvent extractions. Works pretty darned good.

Last week I landed a Chemglass account thru my biz... they make the teflon stoppers (bushings as they call them) already pre-drilled for 1/8" or 1/4"

NPT.

The pressure vessels are pre-tested @150PSI at the factory, but they don't guarantee them in the lab due to safety reasons.

All it takes is a cross, pressure gauge, some nipples, needle valve, some hose and th necessary tank and ya gots yourself a small hydrogenator.

Not all chemicals are bad. Without chemicals such as hydrogen and oxygen, for example, there would be no way to make water, a vital ingredient in

beer.

|

|

|

Nicodem

Super Moderator

Posts: 4230

Registered: 28-12-2004

Member Is Offline

Mood: No Mood

|

|

| Quote: | Originally posted by madcease

Nicodem once one has constucted the press-like holder. What is best to use to seal the tube inside the rubber stopper? |

There is nothing beetween the rubber stopper and the polypropylene tube to seal the connection. In fact, the tube can be easily pulled out of the

stopper. The hermetic seal is created once you screw the press to push the stopper onto the flask. This defforms the elastic rubber stopper which in

its attempt to expand seals the gap around the tube (as well as the gap between the bottle neck and the rubber). It is a very simple design which

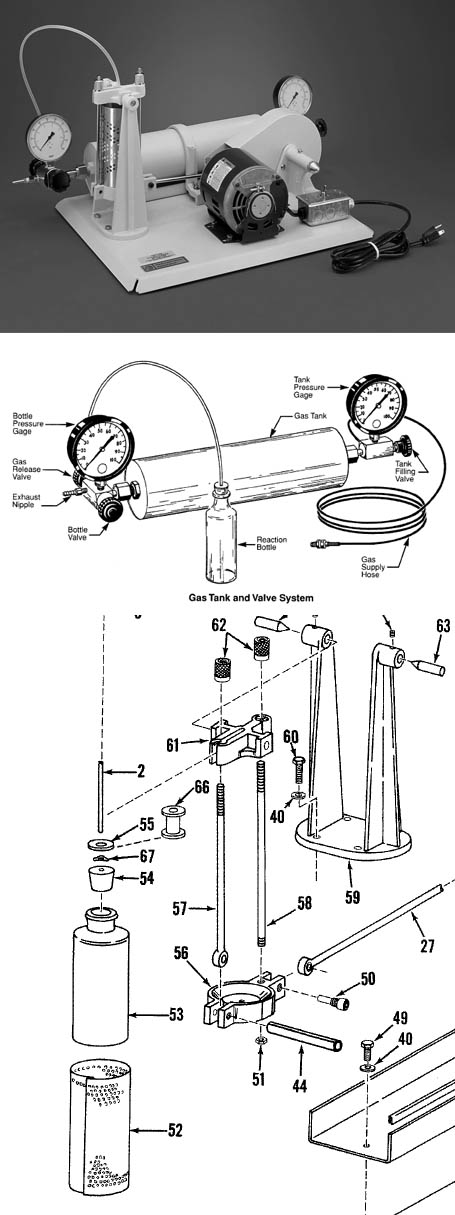

proved itself in more than 80 years of use. Here are some pictures copy/pasted from the manual:

…there is a human touch of the cultist “believer” in every theorist that he must struggle against as being

unworthy of the scientist. Some of the greatest men of science have publicly repudiated a theory which earlier they hotly defended. In this lies their

scientific temper, not in the scientific defense of the theory. - Weston La Barre (Ghost Dance, 1972)

Read the The ScienceMadness Guidelines!

|

|

|

madcease

Harmless

Posts: 48

Registered: 9-9-2005

Member Is Offline

Mood: No Mood

|

|

When using Platinum oxide or dioxide as catalyst what is better suited for hydrogenation a stirred setup or shaken? Does it matter? I have heard that

stirred is better but more opinions would be great.

And at what temps do these hydrogenations run at or does that depend on your pressures?

|

|

|

| Pages:

1

2 |