| Pages:

1

..

17

18

19

20

21

..

27 |

roXefeller

Hazard to Others

Posts: 463

Registered: 9-9-2013

Location: 13 Colonies

Member Is Offline

Mood: 220 221 whatever it takes

|

|

The use of ED drugs is a contraindication for the administration of NG or nitrates. So if you are already getting black market viagra, don't go

dosing on NG for added effect.

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by The_Davster  |

What moisture addition issues? you are either washing with aq. bicarb or water. Why would you care about dry air when it is under water?

[Edited on 8-2-14 by The_Davster] |

I was referring to using air to agitate the nitration mixture in that case, not the bicarb solution. A lot of old texts describe using compressed air

to agitate NG nitration mixtures.

[Edited on 8-2-2014 by Hennig Brand]

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

Peroksit

Harmless

Posts: 49

Registered: 5-4-2012

Member Is Offline

Mood: No Mood

|

|

Hennig Brand what do you use for mixing of nitration acid ? mechanic mixer or hand mixing or air ?

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Hennig Brand  | | When I first started, during nitration, I used to stir with a glass laboratory thermometer very carefully (trying not to hit the sides or bottom of

the vessel). I quickly decided that swirling would be a lot safer and from then on I tried to use vessels that allowed easy swirling.

|

The rocker would work, but some sort of three dimensional rocker or swirling type machine would probably be better. The rocker I built works in only

two dimensions. I was also thinking of a small overhead stirrer, with a teflon or teflon coated paddle rod. One could easily be built, with a shield

and maybe a small (loosely stuffed) stuffing box to keep acid vapors from destroying the electric stirrer motor. A dc motor would make stirrer speed

control easy. The top part below the neck (funnel shaped) of some plastic bottles could easily function as the shield and the neck and screw cap could

easily be converted into the stuffing box. A little cotton or flax with some wax or grease (Vaseline maybe) worked in could be used as packing for the

stuffing box. This would keep the acid vapors from getting at the motor and electrical connections and still allow the stirring rod to turn mostly

unimpeded. Most support for the stirring rod would need to come from some sort of bearing between the stuffing box and the motor. A simple sleeve

bearing would probably be fine for this low speed and low duty application. A makeshift sleeve bearing could be made from a bit of metal tubing or

even a smooth hole through a bit of hardwood (well lubricated) would probably suffice.

A stuffing box is a very old and ingenious way of sealing a rotating shaft. It serves as a barrier preventing leakage of liquids and/or gases.

[Edited on 13-2-2014 by Hennig Brand]

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

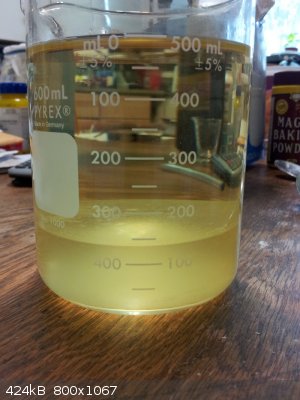

I used 230mL of the nitric acid that was made with the home made distillation apparatus to nitrate some glycerine. The following link should take you

to where production of the nitric acid was discussed.

http://www.sciencemadness.org/talk/viewthread.php?tid=15676&...

A round, glass coffee pot was used to perform the nitration. About 230mL of nitric acid which titrated as 82% was used. About 460mL of sulfuric acid

which titrated as 91% was used. About 115mL of glycerine was used. The flask/coffee pot with mixed acid had a plastic wrap cover put over it. The

plastic cover is in my opinion a wonderful addition, because it keeps water out and the unpleasant vapors in. A liquid medication 10mL syringe was

used to add the glycerine. A small hole was poked in the plastic wrap cover so that the plastic tip of the syringe could be put through and the

glycerine could be added. About 2-3mL of glycerine was added at a time followed by a few swirls. During swirling one hand was supporting the flask

from underneath (temperature sensor and support) and one hand was on the handle. A few times during the addition the flask started to warm up above

room temperature so it was placed in a large bowl of ice and water and swirling continued which quickly brought the temperature back down. The

addition of the 115mL of glycerine took about an hour. A piece of plastic wrap, without a hole, was then placed over the coffee pot and the flask left

to sit in the dark at room temperature for about an hour and a half. The NG was removed using a separatory funnel and the nitration mixture recovered

and put back in the dark. The next morning another crop of NG (about 20-25mL) was removed from the acid mixture.

The nitroglycerine was washed twice in water and then left in 4-5% sodium bicarbonate solution for several days with occasional swirling. Yield was a

bit better than 1mL NG per mL of glycerine. I was also thinking that a rocker/washer vessel should have a corrugated bottom, which should facilitate

washing much better than a flat bottom (see posts above).

A bit of 10% NG, starch, ammonia dynamite was made and used on a green maple stump. The tree was healthy and cut just days before the blast. About a

300g charge was used. A blasting cap, with 1g of ETN, 0.1g of undextrinated lead azide and a bit of basic lead picrate, was used for initiation and

was fired electrically. The charge was placed in a 1 3/4" inch hole that was bored below ground level into the stump with a hand auger. Boring was

difficult and the hole ended up being slightly off center. It is difficult to see from the pictures taken, but half of the stump below the ground was

blown away and the rest is damaged because the stump can be wiggled easily by hand. Before the blast an available farm tractor couldn't budge the

stump, but now a tractor or a set of come alongs should be able to remove it easily. A larger quantity of explosive was not used, and another blast

was not considered because of the proximity to a house. It was quite risky as it was. Several other stumps were removed completely the same afternoon,

in safer locations farther from structures and vehicles.

[Edited on 28-7-2014 by Hennig Brand]

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

Turner

Hazard to Others

Posts: 197

Registered: 2-12-2013

Member Is Offline

Mood: No Mood

|

|

That is very close to a house!!

What did your neighbors have to say of the 300 grams of HE exploding right there?

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

Well, it wasn't my neighbors, but even so it was a very rural location (farm land, etc). The owner is a friend and understood and accepted the risk.

Blasting stumps is not loud like an air blast above ground, for a similar weight and type of explosive. Actually, usually when I blast a stump it is

more of a big thump kind of sound rather than a bang (not hard on the ears at all). The exception would be if a stump, or other target, was severely

overcharged (too much explosive). Then you can experience a significant air blast. The earth, wood, etc, normally do a very good job of deadening the

sound from an explosion, especially if the blaster isn't being wasteful of explosives.

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

Bert

Super Administrator

Posts: 2821

Registered: 12-3-2004

Member Is Offline

Mood: " I think we are all going to die. I think that love is an illusion. We are flawed, my darling".

|

|

Did you stem the bore hole? That is, tamp sand, dirt or clay into any empty space over the charge-

Rapopart’s Rules for critical commentary:

1. Attempt to re-express your target’s position so clearly, vividly and fairly that your target says: “Thanks, I wish I’d thought of putting it

that way.”

2. List any points of agreement (especially if they are not matters of general or widespread agreement).

3. Mention anything you have learned from your target.

4. Only then are you permitted to say so much as a word of rebuttal or criticism.

Anatol Rapoport was a Russian-born American mathematical psychologist (1911-2007).

|

|

|

NeonPulse

Hazard to Others

Posts: 417

Registered: 29-6-2013

Location: The other end of the internet.

Member Is Offline

Mood: Isolated from Reality! For Real this time....

|

|

Pretty close there. I wouldn't personally have let 300g off so close to my house though,but if the owner understood the risk and was still willing

then why not? Great to see a practical use for the NG. Seems to have done what NG does best! Good pictures and story to go along with it too.

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Bert  | | Did you stem the bore hole? That is, tamp sand, dirt or clay into any empty space over the charge- |

Yes indeed, crushed rock was used to fill the borehole over the charge and then a wheelbarrow load of very wet, heavy earth from a nearby stream bank

was packed in over that whole side of the stump (over the bore hole). I learned a while back that crushed rock makes excellent stemming when rock

blasting. It tends to bridge or lock together in the hole and makes a very solid blockage. It may not work quite as well in a wood hole though, I

don't know. Very wet and heavy sandy earth with high clay content was chosen as tamping material (it also happened to be close). It is mostly the high

water content which makes that tamping material so effective.

As stumps go it was a fairly tough target. Green maple is pretty tough stuff. The dynamite used was a very low velocity type as well.

@NeonPulse

Thanks, I hesitate to post things of this nature, but for the most part I think I was being responsible. Of course, the professionals would probably

never consider blasting anything that close to a house, especially in modern times. Insurance is the big thing nowadays.

[Edited on 28-7-2014 by Hennig Brand]

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

I realize that the results of that last blast didn't look all that impressive, so I took some pictures of another blast that should be a little more

interesting. The first picture is of the last stump with a Pepsi can beside it for scale.

This stump was very large, but it was cut at least a few years ago and was softwood not hardwood to begin with. This charge was of the same type but

slightly heavier, at 350g, than what was used for the stump from the last post (ca. 300g). The same materials and quantities were used for the

detonator.

[Edited on 30-7-2014 by Hennig Brand]

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

Bert

Super Administrator

Posts: 2821

Registered: 12-3-2004

Member Is Offline

Mood: " I think we are all going to die. I think that love is an illusion. We are flawed, my darling".

|

|

I can't fault the performance-

I'd suggest that a charge placed in a shaft augered into the earth next to, and angled under the stump to loosen the earth and allow a tractor or 4WD

truck to snatch the stump out with a log chain would be easier than trying to drill the stump itself below ground level? Such drilling is quite

awkward, and the inevitable dulling of auger bits by sand & etc. from the soil slows the process even more.

An ammonia dynamite of less than 15-20% nitroglycerin content is essentially an ammonium nitrate explosive with an active sensitizer... For such uses,

my taste would be to use a very thin jelly of around 98% NG:2% NC, and as dense a fuel/absorbent as possible to allow a somewhat plastic and more

easily rammed to fit bore composition. Naoum in "Nitroglycerin and Nitroglycerin Explosives" suggests rye flour as a suitably dense absorbent/fuel for

such very low NG variants of ammonia gelignite. Plus, you can make a nice pumpernickel with any leftover rye flour?

For close in to valuable structure blasts, blasting mats are the thing. These may be approximated by placeing disposeable scraps of plywood over the

backfill/tamping materials, and then covering the blast zone and over laying plywood with burlap potato sacks filled with sand. You want the gasses to

be able to escape fairly easily once they break the surface, without offering up any large, hard, dense objects that could fly beyond your safety

perimeter.

Safe & efficient stump blasting is an art, and "reading" both the soil & the stump is a vital skill to be learned. I'm barely a beginner.

Rapopart’s Rules for critical commentary:

1. Attempt to re-express your target’s position so clearly, vividly and fairly that your target says: “Thanks, I wish I’d thought of putting it

that way.”

2. List any points of agreement (especially if they are not matters of general or widespread agreement).

3. Mention anything you have learned from your target.

4. Only then are you permitted to say so much as a word of rebuttal or criticism.

Anatol Rapoport was a Russian-born American mathematical psychologist (1911-2007).

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

You have some good points there. It isn't really clear from the above pictures, but that maple stump is more than half cut off below ground level now

and the half remaining appears to be severely crushed, because the stump can be wiggled by hand now. I think a tractor could now pull it out easily.

Just to clarify, we were careful to dig down on that side of the maple stump and remove the earth before drilling into the stump. It was just wood

(not rock or earth) that was drilled, which was a bit lucky. The hole was drilled down at an angle as well, probably around 30-40 degrees from

horizontal. It didn't occur to me to take pictures until after the charge was placed, which is a bit of a shame. What I have noticed is that very

often hardwoods can be very difficult to dig under and make a hole large enough and in the right place (center of stump) for the charge. I blasted a

large green elm stump a couple of months ago and after about an hour of picking away with a large crowbar and a garden trowel I did manage to get a

small hole under it, but the charge was made to fit the hole not the other way around. Big soft wood stumps on the other hand, like the last blast

posted about, have a much less complicated root system, and generally no tap root, and it is usually very easy to dig a hole underneath and place the

charge.

The explosive type was chosen because it stretched the supply of NG, not because it was necessarily the best explosive for the job. I sometimes go as

low as 7-8% NG even, which is still cap sensitive, but yes, it really isn't dynamite and is called nitroglycerin powder IIRC.

I like the improvised blasting mat idea. I made do by being very careful of charge placement and charge size, etc, but blasting mats would have been a

good idea.

I am still a beginner too. I think I have 20-25 stumps under my belt and about 20-25 boulders as well. Now that I have a bit of experience I should

probably hit the books again. The bit of experience should make absorbing the theory easier now.

[Edited on 31-7-2014 by Hennig Brand]

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

Jimbo Jones

Hazard to Others

Posts: 102

Registered: 15-10-2009

Member Is Offline

Mood: No Mood

|

|

Ordinary flour is superior to starch in terms of absorption, so there is no need to gel the nitroglycerin. Just dry the flour in oven before use, mix

it with the AN and then add the nitroglycerin. Heavy duty nylon bag is OK for this purpose. It allow you to form the mixture in the shape of stick and

actually tape it to real stick, which is handy when it’s come the time to put the charge in the bore hole. I have made excellent ammonium dynamites

with 15 % NG and even better with EGDN and flour.

Always bore the holes in the earth deep beneath the roots and close to the center of the stump. These will allow you to use more explosives because

the earth will confine the blast where it’s needed and will act as natural tamping material. Putting the charge near the roots will shatter the wood

instead to “remove it”. Consider them as a week spot.

[Edited on 31-7-2014 by Jimbo Jones]

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

According to "anval.net" corn starch has the highest bulk density of the three fuels/absorbents mentioned. Attached is a pdf of the bulk density table

where the figures came from. I suppose bulk density can vary as well. With only 10% NG, the ammonium nitrate & starch mixture still basically

looks and feels dry. Once you get up around 30 to 40% NG it is nice to add a little nitrocellulose though.

Corn Starch: 689 kg/m^3

Rye Flour: 673 kg/m^3

Wheat Flour: 673 kg/m^3

I have found that by using cardboard or wooden forms that waxed paper tubes can be quickly and easily rolled. This allows me to make the charges or

sticks just under the diameter of the borehole in the case of rocks and stumps that have been drilled. It is best if the charge fits snuggly in the

borehole. The powdered explosive is simply spooned into the tube in increments and then tamped with a wooden dowel (I actually used a large drill bit

the other day (the shaft end) because a dowel wasn't close by).

Attachment: Bulk Density Table.pdf (255kB)

This file has been downloaded 1123 times

[Edited on 1-8-2014 by Hennig Brand]

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

Jimbo Jones

Hazard to Others

Posts: 102

Registered: 15-10-2009

Member Is Offline

Mood: No Mood

|

|

Yes, indeed, you are right. When I made my tests I judged by the look and the feel of the mixtures and have not search for any further information.

With 15 % my mixtures also looks barely wet. Sorry for the confusion.

Try the flour version if you wish and have the time & NG to do it. After all it’s all about the funny things.

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

Flour probably works just fine, maybe even better than starch I don't know. I imagine the result would be pretty similar though. Here is a link to an

interesting site which gives descriptions of what looks like most of the available techniques for removing stumps. Blasting was one of the methods

mentioned, but it was obvious that they didn't plan on very many people being able to use that method.

http://www.dumbstump.com/Decisions-Decisions

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

Bert

Super Administrator

Posts: 2821

Registered: 12-3-2004

Member Is Offline

Mood: " I think we are all going to die. I think that love is an illusion. We are flawed, my darling".

|

|

With such a low amount of liquid nitroglycerin, curious as to the use of a LIQUID fuel to get the mix with ammonium nitrate back to a "putty"

consistency that would be easy to cartridge and later to tamp out the cartridges so as to contact the walls of a bore hole- I've seen these types of

extremely dry appearing low NG mixes, they are either powdery or chunky when handled. I like something closer to modeling clay.

Say, real turpentine in sufficient quantity to make an OB mix. Or diesel fuel cetane booster additive. Or other liquid dual purpose sensitizer/fuels,

ideally ones that won't interfere with forming gelatin...

It's late at night, perhaps do a search in the morning.

(Edit)

Yup! Reinventing the wheel again...

http://www.google.com/patents/US3450584

| Quote: |

United States Patent US. Cl. 149-50 16 Claims ABSTRACT OF THE DISCLOSURE A gelatinized dynamite in which the nitroglycerin content is reduced to about

8 to 16% by weight by blending a gel of polyvinyl butyral resin in a solvent, such as caster oil, dibutyl phthalate or dioctyl phthalate, and

polyoxyethylene stearate, with a known constituent, such as nitroglycerin or nitrocellulose, and which nevertheless has excellent detonation ability

plasticity and extrudability The present invention relates to gelatinized dynamites in which the content of nitroglycerin (or a mixture of the same

with nitroglycol, which will hereinafter be referred to as nitroglycerin for simplicity) is reduced to about 8 to 16% by weight and which nevertheless

have an excellent detonation ability and are sufiiciently shapable into cartridge by conventional extruder type or rollentype cartridging machine, and

a process for the production thereof. The plasticity and extrudability of conventional gelatin dynamites depended upon the amount of nitro gel

consisting of nitroglycerin and nitrocotton, and the minimum amount of the nitro gel, which provides for extruding of the resultant gelatin dynamites,

has been about 30% by weight. However, there has been a desire for reducing the amount of nitroglycerin blended in gelatin dynamites to a minimum, due

to the facts that it is expensive and that nitroglycol admixed in nitroglycerin is poisonous for human body. Recently, an auxiliary plasticizer, such

as aromatic nitro compound, surface active agent or synthetic resin, have been used for the purpose of reducing the amount of nitroglycerin to below

the aforementioned minimum limit, but even in this case an amount of nitroglycerin as much as 18% by weight is the practical minimum limit. The amount

below the said limit results in drastic deterioration of the plasticity and extrudability of dynamites. Even if the product dynamite is shapable, it

tends to be hardened with the passage of time, with the result that the detonation ability thereof is deteriorated, making the dynamite unserviceable

for practical applications. The use of such auxiliary plasticizer in a large amount to avoid such undesirable effect, however, will cause various

drawbacks. That is, the use of an aromatic nitro compound in a large amount will result in lowering the sensitivity of explosive and also in

separation of and exuding a liquid substance, whereas the use of a surface active agent in a large amount will render the explosive excessively soft,

so that the explosive cannot retain its shape and therefore handling of the explosive, during production, storage and use, becomes inconvenient. On

the other hand, when a synthetic resin is used in an excessively large amount, the detonation property of the explosive is extremely deteriorated and

the capability of sympathetic detonation of the explosive is lowered remarkably. Due to the foregoing reasons, only the use of auxiliary plasticizer

in a large amount has not been very much effective in reducing the amount of nitroglycerin. The object of the present invention is to provide a

gelatinized dynamite in which the amount of nitroglycerin is reduced to about 8 to 16% by weight by blending a gel of polyvinyl butyral resin in such

a solvent as castor oil, dibutyl phthalate (hereinafter referred to as DBP) or dioctyl phthalate (hereinafter referred to as DOP), and poyloxyethylene

stearate, a non-ionic surface active agent, with a conventional constituent, such as nitroglycerin or nitrocellulose, and which nevertheless has a

good detonation ability, plasticity and extrudability stands up satisfactory in long storage.

|

[Edited on 1-8-2014 by Bert]

Rapopart’s Rules for critical commentary:

1. Attempt to re-express your target’s position so clearly, vividly and fairly that your target says: “Thanks, I wish I’d thought of putting it

that way.”

2. List any points of agreement (especially if they are not matters of general or widespread agreement).

3. Mention anything you have learned from your target.

4. Only then are you permitted to say so much as a word of rebuttal or criticism.

Anatol Rapoport was a Russian-born American mathematical psychologist (1911-2007).

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

Good find. I see more now the significance of what you are talking about. That would be an improvement. Starch and flour do have the advantage of

being easily accessible to pretty much everyone though. I suppose there could be some commonly available liquid fuels/sensitizers that could work

well.

Yeah, what I need is a good auger for drilling under stumps, through earth and roots, etc. The hand auger we used was really designed for wood

working.

[Edited on 1-8-2014 by Hennig Brand]

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

Just making a note that there are several cheaper easier to make ammonia dynamite compositions that have good heaving power that would make them

suitable for stump blasting and breaking up earth, where there isn't much need for the shattering of rock that would require higher velocity

explosives. Also urea nitrate is in this category of explosive intermediate between ANFO and nitroglycerin sensitized ammonia dynamite. Some of the

double salt / adduct dry granular composiitions of ammonium nitrate sensitized by hexamine or glycine, or nitronaphthalene sensitized ammonium nitrate

could be applicable also to such uses which is generally earth moving, ditching, clearing beaver dams, soft rock blasting, cratering ground for

drainage or making an instant waterhole with larger charges, loosening ground for excavation for holding tanks, preparation for drilling or digging

water wells, clearing tough spots for laying pipe or installing junction boxes, ect. Even reactive target mixes like tannerite would work for these

kind of low-medium velocity blasting chores that are less demanding than hard rock blasting. Low water content "formite" type or "Tovex" type water

gels and emulsions that are cap sensitive could also be good choices as cheaper alternatives to a nitroglycerin sensitized ammonia dynamite.

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

I have tried using urea nitrate for stumping several times in the past couple of years and the results were generally pretty poor. I experienced low

order detonations with low power for the most part and even incomplete detonations sometimes. The material seems to often take a very substantial kick

to get it into high gear and/or some extra confinement. Out of the 5 or 6 times I have attempted detonation only once have I had a result which was

similar to low velocity dynamite. That time the material was dried very well (and carefully to avoid decomposition), and funneled into an old propane

torch canister and left loose. Initiation was accomplished with a 2 or 3g PETN base charge (can't remember which since it was a few years ago). The

urea nitrate charge in this instance was buried in the ground and I remember being impressed by how much earth it threw. I find the material very

reluctant to go high order, especially if not perfectly dry. I would imagine a small booster charge would result in urea nitrate more reliably going

high order. Urea nitrate sounds like a good material for larger charges, but I have found that nitroglycerin or nitroglycol dynamites are about the

most reliable explosive materials there are, especially for small charges and small scale blasting.

[Edited on 3-8-2014 by Hennig Brand]

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

Urea Nitrate is a good test material for detonators because if a detonator will cause high order detonation of urea nitrate, then it will likely also

be good for any other energetic material that could reasonably be called cap sensitive.

Two grams of picric acid as a base charge will usually do the job on urea nitrate that is dry and loose crystals at only a slightly settled bulk

density as would occur from gently tapping a plastic container to settle the contents. Dry and untamped urea nitrate should go high order if it

detonates, and if it doesn't completely detonate then the detonator is inadequate and may have to be increased to 2.5-3 gram range......depending on

the quality of the detonator it will high order detonate urea nitrate in that 2-3 gram range of base charge for picric acid, and this test is a good

followup to plate testing of detonators, since urea nitrate is only barely cap sensitive and requires a strong cap, it provides a good proof test for

a detonator. There is a kind of parallel about the technical difficulty of getting good output from a picric acid base charge and the difficulty for

initiation of urea nitrate as a secondary main charge. So urea nitrate will function as a kind of "truth test" material by which you can polygraph

your work and gauge its performance.

|

|

|

deadpool

Harmless

Posts: 21

Registered: 13-3-2014

Member Is Offline

Mood: No Mood

|

|

Safety & Pointers

@ Henning Brand. First good job on your success; however, I have serious safety and lab concerns with your coffee pot! The top of the “pot”

looks to be plastic, and I’m quite certain this would react to the nitro/sulfuric acids making a mess (how did you even get the acids out?). The

picture of your mix acid/glycerin solution almost appears the same color as the plastic, which makes me wonder if this was due to plastic

contamination or nitrogen dioxide in the nitric acid. Also please use a sealable container and not plastic wrap! The plastics wrap can react to

nitric acid, not to mention just being in proximity to nitroglycerine can cause serious headaches, and a drop in blood pressure. Safety note worth

mentioning: Do not use latex gloves they combust when in contact with nitric acid (seriously violent awesome to see), nitrile gloves are poor

protection, vinyl is best. Here are some pointers to follow that might help, if you used a fuming acid solution, this will increase your yield

because it will facilitate water as a leaving group from the glycerin during nitration. Have you considered nitrocellulose as binder? Keep in mind,

this will be a high detonation velocity depending of the nitrogen content of the nitrocellulose. In cold climates, substitute the glycerin for ethyl

glycol, end product has much lower freezing point.

[Edited on 8-8-2014 by deadpool]

|

|

|

roXefeller

Hazard to Others

Posts: 463

Registered: 9-9-2013

Location: 13 Colonies

Member Is Offline

Mood: 220 221 whatever it takes

|

|

Quote: Originally posted by Rosco Bodine  | Urea Nitrate is a good test material for detonators because if a detonator will cause high order detonation of urea nitrate, then it will likely also

be good for any other energetic material that could reasonably be called cap sensitive.

Two grams of picric acid as a base charge will usually do the job on urea nitrate that is dry and loose crystals at only a slightly settled bulk

density as would occur from gently tapping a plastic container to settle the contents. Dry and untamped urea nitrate should go high order if it

detonates, and if it doesn't completely detonate then the detonator is inadequate and may have to be increased to 2.5-3 gram range......depending on

the quality of the detonator it will high order detonate urea nitrate in that 2-3 gram range of base charge for picric acid, and this test is a good

followup to plate testing of detonators, since urea nitrate is only barely cap sensitive and requires a strong cap, it provides a good proof test for

a detonator. There is a kind of parallel about the technical difficulty of getting good output from a picric acid base charge and the difficulty for

initiation of urea nitrate as a secondary main charge. So urea nitrate will function as a kind of "truth test" material by which you can polygraph

your work and gauge its performance. |

We should quote this difficulty in initiation the next time somebody tries to claim terrorist explosives are readily available from urine. Assuming

someone is so short on resources that they turn to 'urine explosives' then a strong cap probably isn't going to be acquired.

|

|

|

Ral123

National Hazard

Posts: 735

Registered: 31-12-2011

Member Is Offline

Mood: No Mood

|

|

UN has very low energy but I've heard it can be set off with 2g HMTD. Also I'm not sure if it's easy to tell when the UN is completely dry, but still

hasn't lost HNO3. I believe UN+NG/EGDN can make cheap dynamite with decent brisance and density(may be densities that are too high for ammonium

dynamite).

|

|

|

| Pages:

1

..

17

18

19

20

21

..

27 |