Quince

National Hazard

Posts: 773

Registered: 31-1-2005

Location: Vancouver, BC

Member Is Offline

Mood: No Mood

|

|

Alumina

This is more materials science than chemistry, but I thought I'd try here.

Is it possible to make your own alumina ceramic? I need sub-millimeter thick wafers of a high temperature, high electrical breakdown material, and

mica didn't work as it is physically too weak. I'm having trouble finding any place to buy thin alumina wafers in small amount for a

reasonable price, so I'm wondering if I could make my own.

Another thing is, other than tungsten, is there any conductor that can withstand high temperatures, and not erode (this is in atmospheric air)?

Again, I need sub-millimeter thick pieces.

Finally, I need to figure out a way to drill sub-millimeter diameter holes in both, and the hole walls must be smooth, not ragged.

\"One of the surest signs of Conrad\'s genius is that women dislike his books.\" --George Orwell

|

|

|

chemoleo

Biochemicus Energeticus

Posts: 3005

Registered: 23-7-2003

Location: England Germany

Member Is Offline

Mood: crystalline

|

|

I don't think it'd be easy. Although alumina cements can be made at home of course, making sub-millimeter thickness wafers should be very

hard. The only way I can see this to work is to pressure the alumina composition into correct molds, and then to harden it at high heat.

Plus you'd have to work out the optimal composition so that the wafers don't crumble at the slightest touch.

A lot of work.

I am tempted to merge this with a thread on a similar subject...hmmm.

Never Stop to Begin, and Never Begin to Stop...

Tolerance is good. But not with the intolerant! (Wilhelm Busch)

|

|

|

Quince

National Hazard

Posts: 773

Registered: 31-1-2005

Location: Vancouver, BC

Member Is Offline

Mood: No Mood

|

|

I need to make MHCD (microhollow cathodes). Pendulum electrons in the hole between the two conductive wafers (insulator sandwitched in between)

create a glow discharge. This discharge can then be used as a cathode for a much larger discharge. As opposed to using simple electrodes, this

avoids cathode fall instabilities causing a GAT (glow-to-arc transition) and allow stable large discharges in plain air. There are some papers I can

cite for references, but the idea is old.

I'm applying this to make versions of Dr Hill's Plasmatronics speakers without the need for helium (he used it due to low breakdown).

Replacing a helium tank every few months is what made these impractical. But plasma is by far the lowest distorting driver. Hill's patent is

4,219,705, and I got some details of the actual implementation from an owner (there were few units sold). The amplifier is essentially a voltage

controlled current sink at the cathodes (plasma anodes go to power supply).

The complication with using MHCD cathodes is that the discharge is no longer 'normal' (that is, constant voltage). Well, that's at

least for DC characteristics; I've not found any data on AC characteristics of glow discharges during my research. I can't do

experimentation yet, as I've yet to make chimneys for my output devices, Eimac 4X150 tetrodes I got brand new off eBay for next to nothing (the

sockets cost me more than the tubes, but I got them used as new sockets for ceramic tubes can be a couple of hundred or more).

\"One of the surest signs of Conrad\'s genius is that women dislike his books.\" --George Orwell

|

|

|

Eclectic

National Hazard

Posts: 899

Registered: 14-11-2004

Member Is Offline

Mood: Obsessive

|

|

Alumina wafers occasionally show up on Ebay .010-.040 thick as electronics substrates. The same guy that sold these: http://cgi.ebay.com/ws/eBayISAPI.dll?ViewItem&category=2...

You can drill a smooth hole with copper rod or tube and diamond grit/dust from lapidary supply.

|

|

|

Mr. Wizard

International Hazard

Posts: 1042

Registered: 30-3-2003

Member Is Offline

Mood: No Mood

|

|

BTW these thin Alumina plates make great dielectric separators for DIY Ozone generators. I converted a small 'Bug Zapper' to an Ozone room

deodorizer with two similar plates and some aluminum window screen between them. The HV source and the fan in the bug zapper did the job very well,

and it still gets an occasional bug ;-)

This will take food and pet odors out of a room , but don't leave it on all the time unless you want a headache or worse. It is toxic.

|

|

|

Quince

National Hazard

Posts: 773

Registered: 31-1-2005

Location: Vancouver, BC

Member Is Offline

Mood: No Mood

|

|

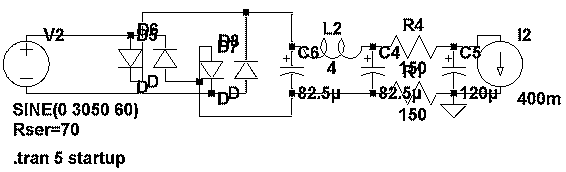

Attached to this post is my power supply (this has already been built). I'm planning to add a regulator, though it should be OK without it. The

current source at the end of the schematic represents the load, obviously, not part of the supply. Diodes are 8 x 1N4007 in series. Works with no

problems, even though I've mixed from different manufacturers. First two caps are series-parallel chains of electrolytics and equalizing

resistors. Final is 3 x 3 kV, 40 uF film in oil huge cans I got off eBay. Resistors are 2 x 75R, 22 W. Choke was handwound. Transformer is rebuilt

and heavily modified large microwave oven transformer. More details I've written in another thread here, about igniting thermite if I remember

correctly.

\"One of the surest signs of Conrad\'s genius is that women dislike his books.\" --George Orwell

|

|

|

Quince

National Hazard

Posts: 773

Registered: 31-1-2005

Location: Vancouver, BC

Member Is Offline

Mood: No Mood

|

|

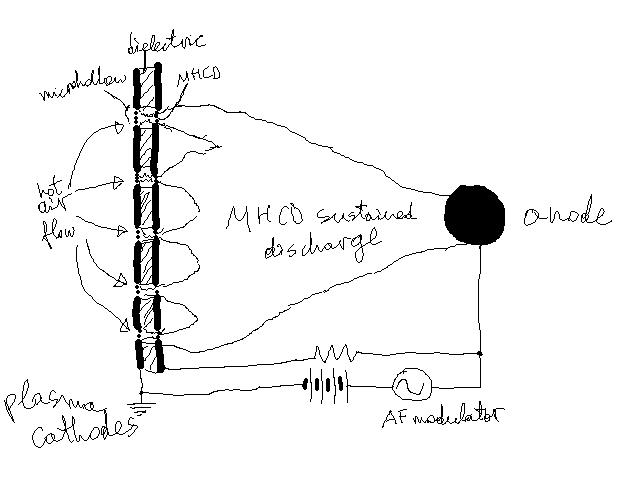

Detail showing the complex cathodes is attached. Thickness of wafers is under 1 mm, as are hole diameters.

\"One of the surest signs of Conrad\'s genius is that women dislike his books.\" --George Orwell

|

|

|

Quince

National Hazard

Posts: 773

Registered: 31-1-2005

Location: Vancouver, BC

Member Is Offline

Mood: No Mood

|

|

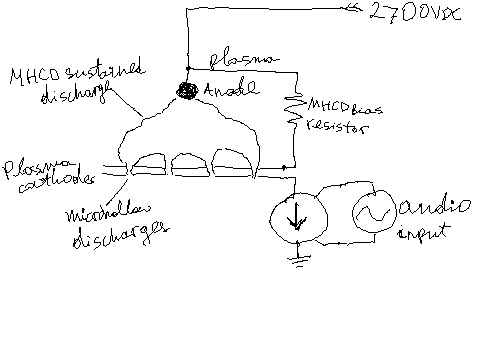

High level overview of the setup is attached. The triangular shape of the plasma is necessary, as each discrete region along the vertical axis has a

different peak in the frequency response; this is a way to get a fairly flat frequency response for the whole thing. The patent elaborates. The

discharge is maybe a couple of cm in size, and is situated in the groove of a heatsink, which also regulates the thermal relaxation constant. Again,

patent explains this.

(I say again, what's different about what I'm doing from the patent is that I plan to avoid using helium for the discharge by using MHCD to

sustain the discharge in atmosheric air; NOx and O3 may become a problem, but I have ways around that).

[Edited on 10-2-2005 by Quince]

\"One of the surest signs of Conrad\'s genius is that women dislike his books.\" --George Orwell

|

|

|

JohnWW

International Hazard

Posts: 2849

Registered: 27-7-2004

Location: New Zealand

Member Is Offline

Mood: No Mood

|

|

Large ruby and sapphire crystals, which are crystalline alumina (corundum) with some of the Al atoms replaced by Cr(III) or Ti(III) plus Fe(III)

respectively, are grown commercially in the form of large cylindrical single crystals by slow crystallization from the molten state. The artificial

rubies are used to make red lasers. The melting-point of corundum is given as between 1,999ºC and 2032ºC, which is the temperature required. The

equipment needed is fairly expensive, but the production is quite lucrative.

[Edited on 11-2-2005 by JohnWW]

|

|

|