| Pages:

1

2

3 |

Sauron

International Hazard

Posts: 5351

Registered: 22-12-2006

Location: Barad-Dur, Mordor

Member Is Offline

Mood: metastable

|

|

I do look in other places but many of them I find disappointing; many I have done business with and been disappointed by. Some like eBay I refuse to

deal with any longer. I could list the companies and individuals I have bought from but it would be a LONG list.

At the time Stong wrote that particular article I was 8 years old. I am most definitely an English speaking American scientist, but I was not a

regular reader of SA, so being such is not a sine qua non. I have no recollection at all of The Amatuer Scientist so if I ever saw it in the pages of

SA it made very little impression on me as a child, an adolescent or as an adult. I was busy reading JACS and JOC, science fiction, other literature,

my uncle's back file of ARRL magazines, etc etc and somehow SA just was not high on my agenda. I have not even touched on the gun journals, and later

the defense journals, I ended up as an editor for one of those and a contrinutor for many others.

In the immortal words of @Orgie: "Sorry, my bad."

[Edited on 25-2-2007 by Sauron]

|

|

|

hinz

Hazard to Others

Posts: 200

Registered: 29-10-2004

Member Is Offline

Mood: No Mood

|

|

I hope anyone can help me with the next problem with the FTIR.

Beginning is here:

http://www.sciencemadness.org/talk/viewthread.php?tid=7770

(WIN-IR is running properly, the problem was caused by a dongle in the printer port as copy protection for WIN-IR and I thought the copy protection

would be read from the FTIR's interface so I overlooked the dongle which looked rather like a printer adapter than a protection dongle, but after I

opened it and saw a chip everything was clear.)

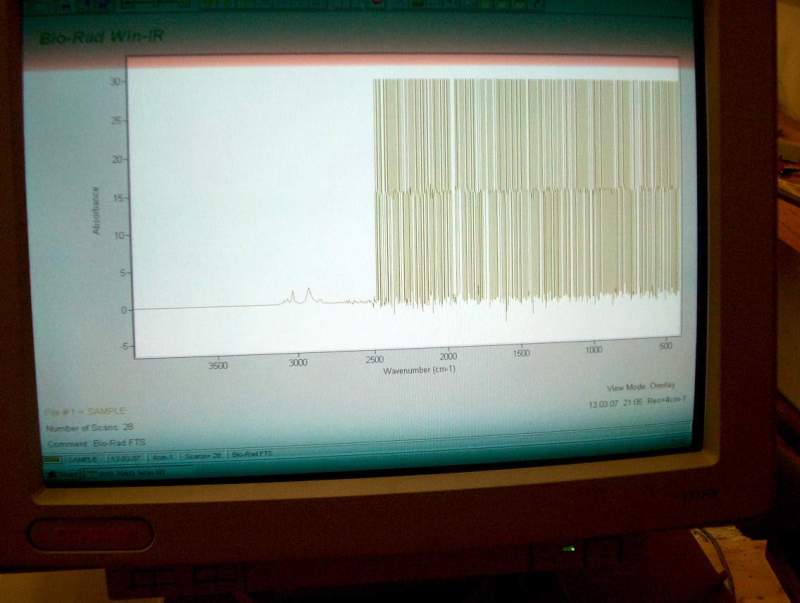

Now I tried to get a proper spectra of a polystyrene film which I got as testing sample for the FTIR, but the spectra starts suddenly to oscillate

wildly from 1/2500cm to the lower wavenumbers/higher wavelenght (photos I

uploaded), but between 1/4000cm and 1/2500cm are exactly the peaks you would expect of a polystyrene transmission sample like this one: (photos I

uploaded), but between 1/4000cm and 1/2500cm are exactly the peaks you would expect of a polystyrene transmission sample like this one:

http://animl.sourceforge.net/Minutes/2005/20050617%20Virtual...

There's one piezoelectrically cooled DTGS detector inside, but DTGS detectors are normally rated for the entire mid-IR range, so this couldn't be the

the reason.

It might be caused by the beamsplitter, I don't know from what it's made of (transparent in normal light,so maybe KBr or KRS-5) but can a opaque

beamsplitter (if not made from something mentioned above) cause such a sudden oszillating?

When I block the beam by placing a piece of wood into the sample cell, the oszillating is in the whole area from 4000-400cm^-1

Could the reference laser for the infernometer cause this, if you look close to the photo with the detector you can see the laser beam on the

detector, it's lasering through the sample cell, but I think it shouldn't do this.

I hope anyone with experience with FTIR's could help here, probably I've overlooked some settings in the software.

EDIT: Uploaded picture instead of .rar file

[Edited on 14-3-2007 by hinz]

|

|

|

unionised

International Hazard

Posts: 5123

Registered: 1-11-2003

Location: UK

Member Is Offline

Mood: No Mood

|

|

It's probably just my computer but I can't download that file. For the benfit of stupid people like me could you screen dump the image and copy it

into a post here please? I'm not saying I will be able to help but I'm curious about this problem.

|

|

|

hinz

Hazard to Others

Posts: 200

Registered: 29-10-2004

Member Is Offline

Mood: No Mood

|

|

Second picture, the detector with the laser beam on it.

Today I took a spectra without background and with the intensity of the beam at the Y-axis instead of absorbance, and the intensity gets down from a

high value at 1/4000cm to zero at 1/2500cm and if you look close at the spectra above, you can see an increase of noise between 1/2700 and 1/2500cm

(the wavy line). It's because the signal to noise ratio gets worse till the computer doesn't know how to handle the signal and thus makes an

oscillating line.

So either the beamsplitter or the detector isn't made for those wavelengths, but if you look at the detector you can clearly read "cooles TGS" which

stands for Triglycine sulfate and should handle at least IR light between 1/4000 and 1/400cm.

Do you think I could place something like a second IR source (a piece of electrically heated NiCr wire) in the sample compartment and look whether

the detector responds on it. Thereby I could bypass the infernometer and beamsplitters. Are you sure that this won't harm the detector if I only heat

it slightly and don't place it in front of the detector.

PS: Now I know why the nice analytic equipment is that cheap at E-bay, because you have a lot of trouble till it works how it should if it ever do

so

[Edited on 14-3-2007 by hinz]

|

|

|

unionised

International Hazard

Posts: 5123

Registered: 1-11-2003

Location: UK

Member Is Offline

Mood: No Mood

|

|

Thanks for the picture. I guess you are right and the beamsplitter or detector doesn't respond properly. That seems odd because a TGS detector should

be OK. Is there any way to check if the cooling is working?

Is there a setting in the software that controls the path length difference when the machine scans?

Unfortunately, I think you might be right about buying cheap stuff on ebay.

|

|

|

S.C. Wack

bibliomaster

Posts: 2419

Registered: 7-5-2004

Location: Cornworld, Central USA

Member Is Offline

Mood: Enhanced

|

|

That's your fault for using IE or some other crap browser. Looks fine on my monitor.

Stuff that appears on ebay often got there for good reason, or the people who put it there often put one part in one lot, and another essential part

in another lot, because they have no clue and often got it at the local auction the same way.

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

| Quote: | Originally posted by S.C. Wack

That's your fault for using IE or some other crap browser. Looks fine on my monitor. |

Well, no. IE works just fine, and besides that, I'm using Firefox and the previous page is stretched (slightly). I'm running 1280x1024 (this window

is not maximized). Do you also imply, then, that FF is a "crap browser"? I'm curious if any browser would count as anything other than

"crap" based on your reasoning.

Yes, that's right, I AM going to singe your asshairs, right here and right now, for generalizing about a Microsoft product. You have an IRRATIONAL

FEAR of IE (and likely, OE and other products) that reflects very poorly on you in deed!

Tim

|

|

|

not_important

International Hazard

Posts: 3873

Registered: 21-7-2006

Member Is Offline

Mood: No Mood

|

|

hinz

Your plotting the intensity was what I would have done. It sure looks like something is either absorbing the longer wavelengths, or the detector is

foobar.

Most pyroelectric detectors are very broadband, while not DC to x-ray them will work at least from in the visible on out to 50 microns.

Your detector is working in that it responds to the short wave stuff, so you know that it and the electronics work. This doesn't tell you if the

detector is damaged in some wave that affects its working band.

First thing I'd look for is any sign of a filter being added in. Also try to get the part number for the detector, see if it is stock or special.

It's also try your idea of another IR source, but put it so the light goes through the full path so you can get intensity readings vs wavelength off

it. Unless you've a way to measure the detector output, having it see the naked IR source won't tell you much, you don't know if it is responding to

the longer wavelengths or not.

Some examples of commercial detectors here

http://www.oss.goodrich.com/ThermalIRDetectors.shtml

|

|

|

S.C. Wack

bibliomaster

Posts: 2419

Registered: 7-5-2004

Location: Cornworld, Central USA

Member Is Offline

Mood: Enhanced

|

|

12AX7 - Yes! By all means, let's derail yet another thread with nonsense that could be PM'd if mentioned at all. Unfortunately I must participate in

this because I won't let that go. Sorry, hinz. As you can see here,

http://www.box.net/shared/3u5hqqfyh1

not only am I running Firefox, the only web browser that I use, but the page is not stretched at all.

So as someone running XP, I'm not qualified to diss IE? Even though you're right, it does not stretch the page. Opinion is now irrational fear? Again

I concede the last word, because I'm not going to shit here more than necessary. The point was - in response to Sauron's now deleted post, previously

immediately above mine; saying that the pictures should be resized because they stretch the page - there was not a size problem.

|

|

|

unionised

International Hazard

Posts: 5123

Registered: 1-11-2003

Location: UK

Member Is Offline

Mood: No Mood

|

|

Just to contribute more pointless junk to this "debate" I couldn't load it as a .rar file but it works fine since it got changed.

It works on this machine in firefox and IE.

SCW, did you actually try to load the original file, it seems unlikely since you only commented on it after it was changed to one that works fine?

|

|

|

Ozone

International Hazard

Posts: 1269

Registered: 28-7-2005

Location: Good Olde USA

Member Is Offline

Mood: Integrated

|

|

I have seen this sort of noise before (albeit on UV-VIS scanning instruments). The result was a faulty (out-of-calibration) monochromator which had

the instrument thinking it was seeing one wavelength when it wasn't. This resulted in "insufficient signal" and noise was returned. Running a

wavelength calibration solved the problem. is there an autocal or wavelength calibration option in your software (it might be under something like

"user maintenance" or somesuch.

Cheers,

O3

-Anyone who never made a mistake never tried anything new.

--Albert Einstein

|

|

|

len1

National Hazard

Posts: 595

Registered: 1-3-2007

Member Is Offline

Mood: NZ 1 (goal) - Italy 1 (dive)

|

|

I got an FTIR off eBay to work recently so Ill hazard a guess at your problem. Mine took two months work of my spare time and I had to reverse

engineer just about every part of the instrument since PE said they 'dont sell service manuals'. However I expected quite a bit of work, since there

had to be a reason why the instrument was cheap. Your instrument looks newer, and its problem not as severe as mine, so I suspect you got a better

deal.

First, I presume your instrument is running in ratio mode, as otherwise its most likely an electronics fault.

If so, it could be that a deterioration in either the detector or IR source has meant that your signal, which is not too good at short wavelengths

either, has dipped below the noise level at long wavelengths. However the most frequent cause of FTIR failure is the beamsplitter. (This would

be easiest to diagnose if you ran the instrument in the inteferrogram mode, ie gathered the raw data. We need to see the reason for the oscillations

(if there is one) at the FFT level) In that case all you have to do is up the overall throughput, so the signal does not fall below the noise at

large wavelengths as well as the short. To up the power you can

1) Align the adjustable fixed mirror azimuthally and elevation wise - these alignments normally require removal of purge cover, so have a dry

environment before you do this. This would attone for beamsplitter deterioration in angular performance

2) Up the electronic gain. My FTIR had a varibale pot for this on the analog board.

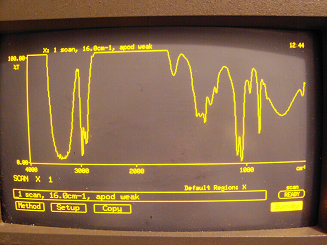

Heres a spectrum of a thin ethanol film I took yesterday - as good as on a new FTIR, (compare: http://www.800mainstreet.com/irsp/eir.html) (shows that a dumped FTIR with enough attention can clearly still perform)

As a question: does anyone have any detailed reference to 'catastrophic beamsplitter failure'? This is the warning on the purge cover of my

instrument should you fail to change the dessicant at regular intervals. Yet my instrument looked like it was kept inside a shower (90% humidity

outside cover, 50% inside), but was able to be coaxed to work. Has anyone seen what a beamsplitter that has undergone catastrophic failure looks

like?? I notice that a replacement beamsplitter from PE costs 1/2 the price of the original instrument. Maybe this has something to do with it, ie

PE want you to think that the beamsplitter has 'catastrophically failed' so you would not be tempted to adjust the instrument but instead buy a new

beamsplitter (or even better a new FTIR).

Another question: is there any sense in buying an FTIR instrument without the computer and software? Is PE FTIR computer control generic? If so

can the software be readily obtained (I presume not from PE seeing they dont even want to sell the service manual)

[Edited on 19-4-2007 by len1]

|

|

|

chemrox

International Hazard

Posts: 2961

Registered: 18-1-2007

Location: UTM

Member Is Offline

Mood: LaGrangian

|

|

This is all very nice .. I love the idea of building a magnetic resonance spectrometer. I like the idea of building a polarimeter better. The latter

would be useful the homemade nmr is just a curiosity. I mean how could you possibly use it?

|

|

|

hinz

Hazard to Others

Posts: 200

Registered: 29-10-2004

Member Is Offline

Mood: No Mood

|

|

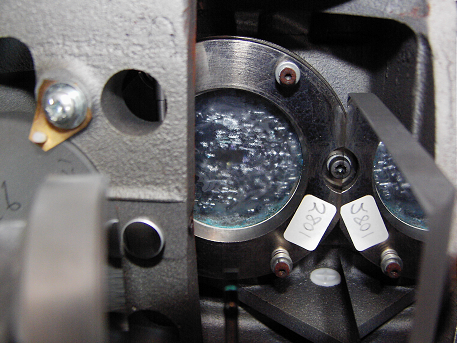

Hello len1, you thin film spectra looks nice, I hope I'll get mine to work as well as your's. I've found the error in my FTIR quite some time ago, it

was the beam splitter and not the detector as I supposed. The beamsplitter which was mounted was made of quartz and it is only translucent up to 4um /

1/2500cm so the oscillations is noise which is amplified till it fills the whole screen.

Here is a absorption spectra of quartz:

http://www.korth.de/transmiss/sio2.htm

Inside the beamsplitter compartment was another beamsplitter, I realised afterwards that this one was made form KBr, because I wondered for what the

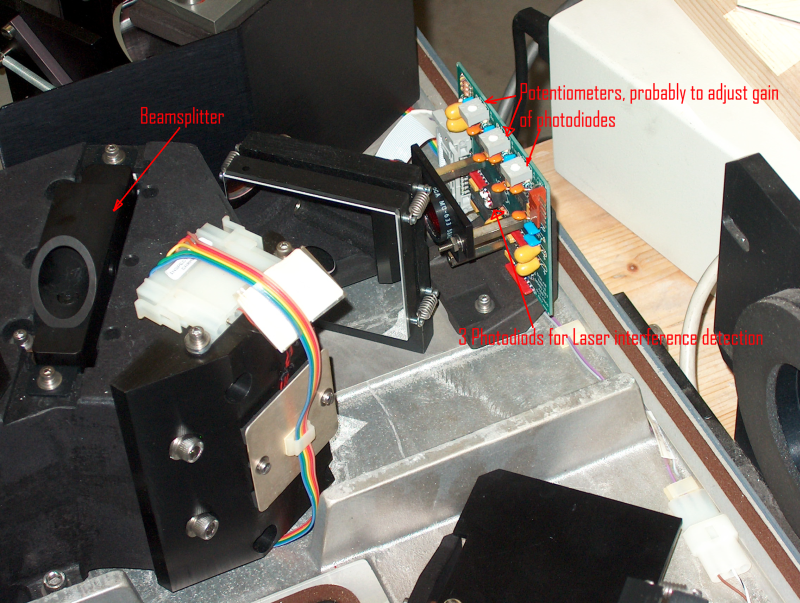

hole in the middle of the beamsplitter was and why the FTIR didn't found the reference laser beam with it. At first I thought it would be some kind of

aperture due the hole in the middle (the quartz beamplitter is half transparent mirrored entirely).

As I opened the cover I saw that the laser beam passes through the hole in the middle of the beamsplitter on 3 photodiodes. Now it was clear to me

that the hole is for the laser beam, but it doesn't still find the reference laser. I think it's because the KBr disks aren't really translucent by

visible light and the mirror in the middle for the laser has drawn some water and isn't 50% reflective any more.

At the photodiodes are 3 variable resistors, probably to adjust the gain of each photodiode, but I'm not sure about this. It's strange, but wouldn't 1

photodiode be enough to measure the interferences?

I was at a local universitylast week and there I asked someone if he could get me a new beamsplitter or if he would know from where I could get a new

beamsplitter and he replid that it would be difficult, because chemical IR strucure analysis of chemical compounds is dying out and thus the

university doesn't have a lot of FTIR's any more.

How much costs a beamsplitter for your instrument ecactly len1, I suppose from the screen on the picture it's a PE 1600. Probably I have to buy a new

one from Biorad.

BTW: The beamsplitter construction is bad. Why couldn't they place the half translucent laser mirror coaxial to the KBr mirror, So they could make the

laser mirror from glas and you could just order a half germanium mirrored KBr disk from one of those various supppliers which also sell output mirrors

made of KBr for CO2 lasers.

Picture of the beamsplitter:

[Edited on 19-4-2007 by hinz]

|

|

|

hinz

Hazard to Others

Posts: 200

Registered: 29-10-2004

Member Is Offline

Mood: No Mood

|

|

The 3 potentiometers and photodiodes for detection of the laser beam:

EDIT: better photo

[Edited on 19-4-2007 by hinz]

|

|

|

len1

National Hazard

Posts: 595

Registered: 1-3-2007

Member Is Offline

Mood: NZ 1 (goal) - Italy 1 (dive)

|

|

Hi Hinz

Of course, the solution to the problem was right on the screen, the fact that the transition to noise occured at 2500cm-1 just where quartz stops

transmitting. I should have thought of that. Mind you I have not encountered quartz beamsplitters before, Im mainly interested in organic analysis,

where quartz blocks half the region of interest.

I did not quite understand your second paragraph (I presume you are German speaking right?) so please excuse if my response is not to what you were

asking.

KBr transmits visible perfectly, it looks just like glass and has a similar index. The KBr is normally coated with a film to protect the KBr from

mjoisture and reduce reflection at the first surface, and a half mirror at the main interface. This coating while good for IR scatters visible light,

and hence the coating is absent where the laser beam is to pass through. My PE 1600 (your guess was spot on, obviously are familiar with IR's) has a

small notch in the coating on the side of the beamsplitter (not in the middle like yours) for the laser.

I got well below 50% laser reflection at the half mirror - its only about 16%, yet the FTIR can still be got to work in those circumstances.

I dont know if I understood you correctly: you do get laser signal detected properly on the quartz (else you could not have produced the absorbance

diagram above) but it is failing with the second splitter you have shown? If it is failing what is the error message?

Ill wait for a reply before saying any more, but I do note that the half-mirror surface appears much darker than that on my FTIR. Mine you can

actually see through visibly. I dont know if this appearance is due to oxidation, or whether indeed some metal coating like that are used. If so, I

have not previoysly seen them. Maybe someone else can correct me. In any case the laser beam should have no problem passing the KBr - that is not a

coating problem.

To answer your question, a new beamsplitter from PE costs $US4400. Far too much for me. As I said I think its a deliberate rip-off by PE, and most

FTIR could be got to work as is. Len

PS Can you take a better picture, I have problems in seeing the path from beamsplitter to laser detector (and its very dark and low resolution)

[Edited on 19-4-2007 by len1]

|

|

|

hinz

Hazard to Others

Posts: 200

Registered: 29-10-2004

Member Is Offline

Mood: No Mood

|

|

The quartz beamsplitter is working properly, but I'm also interested in organic structure analysis thus I want to get the FTIR work with the KBr

beamsplitter. But when I mount the KBr beamsp. in the FTIR, I always get a "No laser detected" error.

I think this is because the mirror in the middle for the laser is damaged by moisture. The outer surface (Ge-mirror is between the two disks) is also

slightly etched by water so if I try to look trough it, I see everything blurred, like if you look trough a glass plate you once drpped in HF. I

wonder if there was once a moisture protection on it.

The mirror of the beamsp. is completly intransparent in visible light, you can't look trough it, but I think this is normal, because germanium becomes

transparent in the IR-region. Here is a spectra of germanium: http://korth.de/transmiss/ge.htm

I think I'll contact Biorad sometimes in the near future and ask them how much a new KBr beamsplitter costs, I hope they don't rip you off like PE

does it. Then I could also ask them for a service manual, maybe there is written for what the three potentiometers at the laser interference detection

circuit board are.

Thanks for your help with my FTIR and you guessed right, I'm German speaking

|

|

|

len1

National Hazard

Posts: 595

Registered: 1-3-2007

Member Is Offline

Mood: NZ 1 (goal) - Italy 1 (dive)

|

|

Hi Hinz,

The new picture is much better I can see whats going on now. After the beamsplitter there is a germanium mirror with a hole in it to allow the laser

beam to pass through a filter and then to photodiodes behind it, while the IR ir reflected at 90 degrees to a detector. The PE 1600 is arranged

differently, the laser passes through a visible transparent region in a notch on the side of the mirror, and is stopped by a single photodetector a

few centimeters behind the notch.

You've also explained better what your problem is. Next question: do you see the laser beam strike any of the photodiodes? As I said the KBr is

transparent to visible, you can see right through it, so the laser must pass through as well. You said the surface at the beamsplitter center appears

fogged, but in the picture you posted you still can see the pattern in the paper underneath through it, so its not bad enough to completely scatter

the laser signal.

Lets assume the laser beam (in actual fact two strong beams should exit the interferrometer) passes thru but doesnt strike any of the photodiodes.

That was one of the problems in my spectrometer. Slight alterations in the refractive index of coatings of the beamsplitter with time are then at

fault. The laser beam is refleted onto the beamsplitter from the laser via an adjustable mirror, adjust the two degrees of freedom of this mirror so

the beam strikes the diodes.

Second case: the beam does strike one of the photodiodes. That could still give you a laser fault message. Thats because the electronics looks for

beats between the laser beams traversing the two paths of the interferrometer. In this case you must adjust the fixed mirror at the back of the

beamsplitter to make sure both beams strike the photodiodes head on. They must do this to interferre. If the computer sees no interference it still

reckons theres no laser signal.

Now as to why there are 3 photodiodes. Without having the spectrometer in front of me I cant tell you 100%, but there are really only these

possibilities I believe

1) The spectrometer changes the detector diode in response to changed settings. For instance when you change beamsplitters, the slightly different

refraction index of the KBr channels the signal to a different diode than for the quartz.

2) Your spectrometer has attachments for an external detector, which would result in the laser beam following a slightly different course

3) There are facilities for different lasers/positionings.

If (1) is the case, then thats a possible source of the problem responsible for your fault. Unless you have switched the software from quartz to KBr,

the electronics will still be trying to read the quartz diode, and not see a signal.

I did not understand what you mean by "mirror in the middle for the laser is damaged by moisture", which mirror? The half mirror in the beamsplitter?

All other Ge coated mirrors are not KBr and so should not be attacked by moisture. The laser mirror should be just glass. If you mean the

half-mirror in the beamsplitter, then that is not so important as the laser signal is very strong, I found even a KBr interface with no coating still

has enough reflective properties (in addition to refractive) to allow lock-on to the laser beat signal. In theory the reflective property of uncoated

KBr is (1.52-1)/(1.52+1) or about 20% at normal incidence. Please show me what exactly you are referring to.

Ge is opaque to visible as you say. But

1) Ge is silver white, not brown as it appears in the photo. My beamsplitter and mirror surface all appear this way.

2) The coating is only a 50% mirror, and some visible light still gets through, at least in my case.

I had enquired the cost of beamsplitters from various manufacturers, when I was trying to substitute mine for anything available (this is before I

knew that it could be restored) They all charge in the order US$3000-US$5000 for a new splitter. This is why FTIR's come cheap once the original

(clueless) owners find their splitter has deteriorated. Because the equipment manufacturer has arranged the economics so as to entice the to acquire

a new one.

I was interested to hear that FTIR's are dying out in Germany. Not here as far as Im aware. What is being used instead? (surely MS and NMR are too

bulky, and the latter also expensive).

Another question: can you help with IR libraries, does your software come with them? Len

[Edited on 20-4-2007 by len1]

|

|

|

Matchheads

Harmless

Posts: 21

Registered: 19-4-2007

Member Is Offline

Mood: No Mood

|

|

We had a FTIR from the other company besides Nicolette, based in Madison, WI, and they flew us out there, but this was 1988. I was being paid $8 per

hour, and they wanted formulas broken, but we should have had other lab eqpt besides that. You can run a spectrum easily, but I never trusted the

library to accurately tell us what it was. It seemed like you had to superimpose the two spectra and slide one into position along the ordinate to

get a match. The commands were in DOS. If they aren't lined up in the computer's view, the "closest" thing to your spectrum would be a false

positive. So, did they cure that? Second, when they gave us a sample, it would often be a product which was mostly water. You couldn't dry out

samples using the same method on each one. It seemed like there was no telling how dry the library sample would have been. Some ingredients are

hydrates. What do you do about that (drying samples). Somebody is into instrument building, not analytical chem. That is hinz, and the guy chatting

with him is len1. You must work in a lab with a budget.

|

|

|

len1

National Hazard

Posts: 595

Registered: 1-3-2007

Member Is Offline

Mood: NZ 1 (goal) - Italy 1 (dive)

|

|

To answer your question, the FTIR is my own not the labs. I prefer to do something else with my $20K. In the lab it doesnt matter since its the

customers money. Its interesting to hear about your experience. What was in the samples? Some things FTIRs are just not designed for, and MS would

have been better (such as the VS plasma) Len

|

|

|

len1

National Hazard

Posts: 595

Registered: 1-3-2007

Member Is Offline

Mood: NZ 1 (goal) - Italy 1 (dive)

|

|

Hinz, if you can see the laser beam hitting one of the photodiodes, and the beam is single - that is its not split into two spots, then its a matter

of uping the gain using the potentiometer corresponding to that particular diode. You can find out which it is by tracing the electronics on the back

of the card.

I have found another interesting effect with the 1600. Any shock to the instrument produces a pronounced change in the background. Not just in the

amplitude, but in the shape as well, meaning the instrument has to be realighned. The design of the 1600 is quite shoddy, by my expectations anyway.

The beamsplitter and all interferrometer mirrors are held in place by two metal prongs, rather than a solid all-round fit. The moving mirrors are

freely pivoted in a v-groove. I noticed that misalignment of the fixed mirror manifests itself in an unexpected way. As I said above any

misalignment reduces background transmission, that is expected, BUT it also leads to a characteristic modulation of the interferrometer throughput.

The background, rather than being humpback-shaped develops deep undulations. These are periodic, so if theres a minimum transmission at 800cm-1,

there will also be at 1600cm-1 and 2400cm-1. These are quite broad (sinusoidal in fact) and so there is little chance of mistaking them for

absorption peaks (except if they occur in the hydrogen-bonding region). Nonetheless the background needs be as flat as possible for maximum

sensitivity. I had not heard of the undulation effect of misalignment before, but have now convinced myself that theoretically that is what you would

expect.

The interferrometer works by inteferring a multitude of light beams, travelling along two paths. In the simple model one normally uses, one

interferres just two beams whose path difference is dL giving sin(om dL) as the interference phase. Integrating over all emited wavelengths gives the

usual Fourier transform of the incident spectrum. However if one approximates the adjustable beam by two light rays each travelling length dL1 and

dL2 with respect to the fixed beam then we have

sin(om dL1) + sin(om dL2) = 2 sin(om (dL1+dL2)/2) sin(om (dL1-dL2)/2)

The second term modulates the output and is independent of position since dL1-dL2 is fixed. This then forms the sinusoidal filter I noted above. The

filter in reality is not as sharp as above (it doesnt have zero transmission troughs) because a multitude of rays (instead of two) need to be

integrated, rather than summed, above. This gives a filter of finite depth.

|

|

|

Matchheads

Harmless

Posts: 21

Registered: 19-4-2007

Member Is Offline

Mood: No Mood

|

|

I have worked for a few employers, but the timeframe was 1978-1989. As I examine these companies in the intervening years, I try to take note of

which ones survived and prospered and/or went out of business or changed their names, or, worst of all, had their name splashed all over the

newspapers due to an industrial accident. Because, when you work there, you can see them headed for these various ends. I am not really serious

about chemistry since my boss's idea of hard work may include me chipping out the last bit of CrO3 from a drum with rubber gloves and a hammer and

screwdriver, but no respirator as that would cause alarm among the rest of the employees.

This particular company was named "Custom Chemical Formulators" of Cudahy, CA. It is where the 5 and 605 freeways cross in LA. Other towns around

there include Bell and there is a lot you can do there you can't do elsewhere. The cities of Southgate, Carson, or Santa Fe Springs are not garden

spots.

In chemistry, there are often whole yards where you can just have the chemicals. An industry exists in which you can charge $600 per drum to take

drums away, but you better document what happens to them, and they are manifested with the word WASTE before the chemical name. You need to know what

is in them. Many are intact. Out of a hundred, there may be only 20 with no label and being penetrated by rainwater, a classic chemical problem.

They hired me and my boss, a marijuana grower who had his 4-year degree from Cal State Fullerton, name of Bob Stone, to work in the lab together in

1988. I was just wondering why it went the way it did, since I had my UCSD degree by then, but, it went that way because our contact downstairs hired

me to work with him. If he had been given the power to hire and fire, he would have gotten a girl without a degree to spend the days with.

As it was, they depended on me to do things like ride a forklift to the ceiling with a portable pH meter and adjust a batch, in a shop where the

workers could not be taught to do that. They did not speak English. Thus, Bob was able to get me fired when I took time to attend a lab auction. It

was worth it. I got two 12s and a 22-L boiling flask, a mantle, a Hot Shot, from Tauber Auctioneers. I could smell the phenylacetic acid in the

equipment. Some other cooks beat me out of some good stuff, too. I registered as a Mr. Davidson, as in Harley-Davidson. This auction was in North

Hollywood. It was a Goldilocks auction. One that was too big was Occidental Petroleum in Irvine. They always put things in lots, an auctioneer's

trick; you either buy 15 Variacs or gas regulators (just to get Hydrogen), or you budget and get very little. An old glassblower is a good source.

There was even a guy in Fullerton with a daughter who specialized in IR, but she's old now. Much of it used to be recorders that would stop working

or you'd "just" have to find the chart paper for it, like computer printers are now.

People were interested in gold recovery, Kyocera has the best solution. It is not cyanide. By now they must have a good way to recycle catalytic

converters from cars.

Bob told me I could "have" whatever I wanted from a lot of glassware that came in; it was from before standard taper. I should have believed him, but

I just picked up a crucible with the bottom coming out and told the big boss, "Dude, this is platinum. I shouldn't take it. I guess it could be

nickel, but I doubt it." He comes back and says somebody gave him $600 for it. I was getting $8 per hour. He was from the salesman end of it. He

was buying iodine for making teat dip. I never even took the samples of HI they had. It wasn't "stabilized". But, we went through nothing but

iodine. The lab was stained with iodine. We washed it off with hypo. There's only a limited amount of iodine they can buy from South America. It's

"wet process". Another location which deals in drums of 57%HI and makes it is Deepwater Chemical across from Cal State Northridge. They are wise.

To answer your question Len I know. There is even a little drying tube for GCMS samples. These guys did not have what you would call professional

courtesy with say, an environmental lab. What they mainly do is whenever a big company (Micrographics, I think, needs potassium dichromate to be

opened up in someone else's facility), farms out hazardous operations, they do it. So, there are lots of one-time substances. i learned a lot. What

you want if you have to do it all by hand is a GOOD wet chemistry book. They had to have that to begin making soaps, during the phosphate stage and

before the ionic surfactant time. Rohm and Haas is good in anionic surfactants; they also have an ephedrine synthesis which goes through pyruvate.

what confused me about old books was the use of something you titrated to and calked out to a "NaO" equivalent, or some phosphate number where I

really wanted it to register as greater than 100%. It's hard to make soap go liquid so it will pump out of the mixer, or to get a high cleaning

power, if somebody else's product has it. What is "polyphosphoric acid"? I never found out.

What was in the samples I remember was ethyl acetate. I solved that one. We had ODCB in that shop, which is "orthodichlorobenzene". If they come in

the lab with an open sample of that you just scream at them what it is, and tell them to get it the hell out. We liked to say the initials, though.

Another good one is bromoacetone. You could say it made P2P in a one-pot, no catalyst, quantitative yield.

|

|

|

Matchheads

Harmless

Posts: 21

Registered: 19-4-2007

Member Is Offline

Mood: No Mood

|

|

Yeah, Len1, before I leave, I see your sample is swamped out with water. Also, you ran an ethanol film, so, you meant "ATTENUATION" when you used the

word 'attention', huh?

|

|

|

len1

National Hazard

Posts: 595

Registered: 1-3-2007

Member Is Offline

Mood: NZ 1 (goal) - Italy 1 (dive)

|

|

The alcohol I used is not really that, its just some meths I had at hand, which contains 5% water.

I dont know why Im continuing this, but for completness sakes, Ive now found out what is meant by catastrophic beamsplitter failure, a question I

posed before. That actually is the reason for the profusion of cheap second hand FTIR on the market. A replacement beamsplitter costs about half the

price of the instrument for most models which is why owners (and of course manufacturers) prefer to upgrade.

Heres a picture of the failure:

KBr base is stable to humidity, it can not handle condensation. when that happens a thin surface layer dissolves, and the IR reflective coating on it

crumples as seen in the pic. Whats more it cant be restored.

My point is that the spectrometer can still be made to work. Clean of the coating repolish the beamsplitter. At a 1.52 to 1.0 index difference the

beamsplitter surface still refelects 1.51-1/1.52+1^2 of the incident radiation. So a retruned FTIR will still function though with reduced

sensitivity.

My first FTIR the owner simply gave up on thinking the beamsplitter was fut, whereas in fact he couldnt tune it. I found that after desiccation for a

few weeks, not only did it function well as per diagram, but the throughput is 100% restored Len

|

|

|

benzylchloride1

Hazard to Others

Posts: 299

Registered: 16-3-2007

Member Is Offline

Mood: Pushing the envelope of synthetic chemistry in one's basement

|

|

Does anyone know where to obtain a pyroelectric detector for a Perkin Elmer 1310 infrared spectrophotometer? I recently bought one of these and the

detector failed.

Amateur NMR spectroscopist

|

|

|

| Pages:

1

2

3 |

|