testimento

Hazard to Others

Posts: 351

Registered: 10-6-2013

Member Is Offline

Mood: No Mood

|

|

Methods for producing at least 900C temps in fume hood?

Some sources(wiki - propane torch) cite that uncompressed, unoxygenated air propane burners scarcely generate flames over 1000C. Electric heater

circuits could be an option. A problem is that one would need a heater element capable of heating few kg's or liters' masses of different materials up

to 1000C within reasonable time. Any ideas? One possible method for utilizing a 6kW propane burner is to use air pump and ejector(that is internally

built already into the burner and with that to inject excess air directly into the burner and actually feed the propane gas from the ejector port so

the air flow sucks it in. This could generate much purer burning flame.

|

|

|

bfesser

|

Thread Moved

26-9-2013 at 09:07 |

Gooferking Science

Hazard to Self

Posts: 97

Registered: 17-7-2013

Location: Somewhere in Kansas, USA...

Member Is Offline

Mood: Halogenated

|

|

An oxygen/propane torch reaches temperatures over 2000 degrees centigrade. Unfortunately rigging up and maintaining an oxy/propane torch can be very

expensive.

|

|

|

sonogashira

National Hazard

Posts: 555

Registered: 10-9-2006

Member Is Offline

Mood: No Mood

|

|

Bunsen burner?!

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

If you only need a short duration, improperly stored ether will do the trick. . .

A few kgs sounds more like a kiln, or at least a reasonable sized muffle.

Gas burners have all the heat you could want, but you have to contain it inside insulating refractory, or you'll just have bigger problems on your

hands (like, the ensuing lack of a fume hood on hand..). Even with insulation, you have to handle the exhaust gasses properly: they're leaving at or

above the temperature inside. Pump more than a few liters/min of hot gasses through your furnace and see just how sweaty it gets in there.

Tim

|

|

|

testimento

Hazard to Others

Posts: 351

Registered: 10-6-2013

Member Is Offline

Mood: No Mood

|

|

I've decided to go through all the trouble of making an electric kiln which I was gonna make earlier already. I searched through my stuff and found a

decent 20-meter coil of 0.5mm nichrome wire, a 2kW potentiometer, 5L SS kettle and a good lot of CaCO3 powder. The steel containers withstand

continuous temperatures from 870 to 1000C quite well according to sources ( http://www.azom.com/article.aspx?ArticleID=1175 ) and since having the container made of steel, it eases the removal of the products mechanically

very substantially: where a porcelain vessel could easily crack.

The plan is next: I'm gonna stuff some Al2O3 paste over the outer SS pot for maybe 5mm thick, and then coil the nichrome all around the pot and apply

another layer of Al paste and then I'll roll a centimeter thick layer of clay and place the whole thing into a steel bucket and fill the middler with

free flowing CaCO3 (better than Al2O3) with 50-70mm thick layer. The top lid I will use 3mm steel plate which I will force into a slight conical form

to make it stand tightly against the corners of the pot and cast a cake of clay or something else over it. I'll weld a tube on the lid so I can

collect possible fumes and stuff with it. The whole thing could still be wrapped with ceramic wool.

I've done several processes inside involving a 6kW and 12kW propane burners and some electric heaters, and yes, they heat up the room quite a bit, but

not a wonderous ventilation is required to remove the heat. I actually have a 1000m3 line fan in my fume hood which I can vent the fumes through a

water scrubber made in a barrel, activated carbon filter or directly outside.

With the propane burner, the trouble comes excatly with the need of pressurized air or pure oxygen, which are quite hard to come by.

If one wants an easy solution, there are ovens made for heat treating and ceramic making that can reach 1300C no problem and have volumes from 5 to

500 liters and cost anywhere from 500 from astronomics. I might actually give a hit for the smaller scale oven.

[Edited on 27-9-2013 by testimento]

[Edited on 27-9-2013 by testimento]

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

Ah, tons of ventilation then... go nuts!

I'll be surprised if you can get clay or alumina (or other refractories, like furnace cement) to stick to a stainless pot without cracking. I guess

as long as it doesn't crack directly beneath the nichrome, it won't be a big shorting hazard.

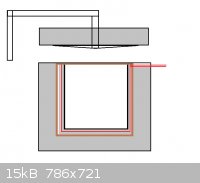

Propane-air will get a furnace up to 1600C no problem. I like this design: http://www.abymc.com/tmoranwms/Casting_Propane3.html Don't have drawings of it, it would seem, but I could make some -- it's very simple, and

pleasingly effective. All you need otherwise is a propane tank, regulator, hoses and valves.

Tim

|

|

|