Panache

International Hazard

Posts: 1290

Registered: 18-10-2007

Member Is Offline

Mood: Instead of being my deliverance, she had a resemblance to a Kat named Frankenstein

|

|

Desiccating a solid

Am i correct in assuming that, in general, when desiccating a solid in a desiccator the true dessicant is not the substance used to dry the air in the

vessel (eg CaCl2, P2O5, silica etc) but rather the dry air itself.

Thus dry air must be a superlative desiccant, which makes one wonder why dry air streams from a cylinder are not used rather than using solid

desiccants to dry air. It sure would cheapen and simplify things.

A steam partial pressure gradient exists between your wet solid and your desiccant. Provided the desiccant is not exhausted and your solid remains

wet, water will migrate from the solid to gaseous area between the two and move along the gradient, where it is ab/adsorbed by the desiccant, thus

maintaining the gradient and thus maintaining the flow of steam. It appears the gradient is the necessary instrument, not the desiccant, as it only

ensures the gradient remains. Why would a dry air stream not perform in the exact same way as it also satisfies the system, that is maintaining a

steam partial pressure gradient?

Where is my logic flawed?

Also is it correct to refer to gaseous water in air as steam?

[Edited on 4-9-2008 by Panache]

|

|

|

bfesser

Resident Wikipedian

Posts: 2114

Registered: 29-1-2008

Member Is Offline

Mood: No Mood

|

|

How would you dry the gas? It's easier to just use a solid desiccant and then heat it to drive out the water of hydration and reuse the solid.

There's also a lot less hardware to deal with if you're using a solid desiccant.

|

|

|

Klute

International Hazard

Posts: 1378

Registered: 18-10-2006

Location: France

Member Is Offline

Mood: No Mood

|

|

Well, when you use a hair dryer to dry a TLC plate fro example, you are only using dry air like you mention. Even a ventilate doven works like that.

But you need quite alot of hot, dry air, and using it from a cylinder really wouldn't be economically practical... Cost of presurizing the cylinder,

volumes occupied, etc

Most solid dessicants are cheap, and some recycleable, so really remain the bets option, after removing most volatil solvent traces under a lamp, or

vacuum.

\"You can battle with a demon, you can embrace a demon; what the hell can you do with a fucking spiritual computer?\"

-Alice Parr

|

|

|

Panache

International Hazard

Posts: 1290

Registered: 18-10-2007

Member Is Offline

Mood: Instead of being my deliverance, she had a resemblance to a Kat named Frankenstein

|

|

Simply by buying dry compressed air. On a bleed the cylinder would last a very long time. i need to check how dry the compressed air available is.

Why would it need to be hot klute it is not hot in a dessiccator?

Edit-The company is getting back to me on monday with the water ppm, then i can calculate.

[Edited on 4-9-2008 by Panache]

|

|

|

watson.fawkes

International Hazard

Posts: 2793

Registered: 16-8-2008

Member Is Offline

Mood: No Mood

|

|

| Quote: | | Originally posted by PanacheA steam partial pressure gradient exists between your wet solid and your desiccant. Provided the desiccant is not

exhausted and your solid remains wet, water will migrate from the solid to gaseous area between the two and move along the gradient

|

This is true for mass transfer of water vapor by diffusion, which is slow. In practice, moving fresh, dry

air across the wet material is far more efficient. The dominant process here is not diffusion, but kinetic flow. | Quote: | | Also is it correct to refer to gaseous water in air as steam? |

No. Gaseous water in air is water vapor. When

the amount of that vapor is higher that the equilibrium partial pressure of water at that temperature, then you have steam. In other words, steam is

a supersaturated solution, gas-in-gas, of water in air.

|

|

|

watson.fawkes

International Hazard

Posts: 2793

Registered: 16-8-2008

Member Is Offline

Mood: No Mood

|

|

| Quote: | | Originally posted by Panachei need to check how dry the compressed air available is. |

How did that

air get dry before it got in the bottle? Can you use that directly, and skip the bottling step entirely?

|

|

|

Panache

International Hazard

Posts: 1290

Registered: 18-10-2007

Member Is Offline

Mood: Instead of being my deliverance, she had a resemblance to a Kat named Frankenstein

|

|

| Quote: | Originally posted by watson.fawkes

| Quote: | | Originally posted by Panachei need to check how dry the compressed air available is. |

How did that

air get dry before it got in the bottle? Can you use that directly, and skip the bottling step entirely? |

The theory is that a huge gas plant can dry air very efficiently and cheaply, much more so than i can on a small scale, by using their economies of

scale one could desiccate much more easily and cheaply than by using solid desiccants in a sealed environment. However it all depends on how dry their

air is. Their N2 is 10ppm H2O.

|

|

|

watson.fawkes

International Hazard

Posts: 2793

Registered: 16-8-2008

Member Is Offline

Mood: No Mood

|

|

| Quote: | Originally posted by Panache

The theory is that a huge gas plant can dry air very efficiently and cheaply, much more so than i can on a small scale[...] |

That theory is wrong. The machinery used to dry air in not expensive because it dessicates, it's expensive because it regenerates

its dessicant internally. For you, a bottle of calcium sulfate with indicator (such as Drierite) works just fine for drying air. It's exactly the

same basic technique as used industrially. The main difference is that you will have to regenerate your dessicant manually. The big equipment uses

dual cartridges, cut-over valves, and a built-in regenerator. That's where the money is. You can replace that money with some of your time.

You can also use silica gel. And if you gang two of these in sequence, you only need an indicating dessicant in the second stage.

|

|

|

Tsjerk

International Hazard

Posts: 3022

Registered: 20-4-2005

Location: Netherlands

Member Is Offline

Mood: Mood

|

|

With a dessicant in a desiccator you lose less of your product if it has a vapor pressure, because when that vappor pressure is reached in the

dessicator your product stops evaporating.

With a continuous stream of air the vappor pressure is never reached and thus more product will be lost.

|

|

|

Klute

International Hazard

Posts: 1378

Registered: 18-10-2006

Location: France

Member Is Offline

Mood: No Mood

|

|

Good point. Also, there will surely be some losses from small particules flying off.

I considered using hot air as to have a lower relative humidity, which would be much more efficient than RT air. This can also be attained by applying

vacuum, hence the use of vacuum dessicator to improve the drying.

But honestly, I don't really understand your point here. Unless you are aiming for some semi-industrial setup for drying kilo's of wet solids, at a

lab scale nothing beats a vacuum dessicator IMHO.

I dunno, I just picture you trying to use hydroelectric electricity to charge batteries to be used on a water pump to have cold water in your

condenser, while directly pluging in a aquarium pump would be more than suitable.

In practice, you have to buy the cylinder, the regulator, the tubing, install a setup and an exit, check with leaks, bear with the noise to dry a few

grams of solids, while a 1E/kg bag of CaCl2 in a tuperware would be more than enough.

But of course, if this is just a theoritical consideration, and more applied to industrial considerations, indeed most of th etime the industrials use

super-heated air to dry solids in essoring devices, most of the time taking advantage of the hot, dry air comming out of a reactor for example, or

passing the air under high pressures in an heat exchangor (sp?) to condense the water, using a streamof liquid that is going to be vaporized: by

condensing the water present in the air, it absorbs a little amount of heat, reducing the relative humidity.

Most of the times, the air doesn't need to be extremely dry, just enough to cause partial drying, as you just need to use more air, and most the time

the water will be condensed at one point, after a compression for example, and used as cooling or cleaning water. But industrial applications like

this are no way close to lab-scale considerations, as they can play with high/low pressures and extrem temp gradients.

\"You can battle with a demon, you can embrace a demon; what the hell can you do with a fucking spiritual computer?\"

-Alice Parr

|

|

|

vulture

Forum Gatekeeper

Posts: 3330

Registered: 25-5-2002

Location: France

Member Is Offline

Mood: No Mood

|

|

If you use pressurized air, this will become cold when expanding to 1 atm. Also, forcing water evaporation in this way will rapidly cool down whatever

you're drying, seriously decreasing the efficiency.

|

|

|

Panache

International Hazard

Posts: 1290

Registered: 18-10-2007

Member Is Offline

Mood: Instead of being my deliverance, she had a resemblance to a Kat named Frankenstein

|

|

the thought for the thread came up not because i'm considering doing it but i was considering the notion that i mentioned in the first post. Namely

that although we can use expensive desiccants, really the desiccant we are all using is actually dry air, what we use to dry the air is like a

secondary desiccant. Thus if one didn't have access to P2O5, it would not matter for complete drying a solid provided they had a dry air source. I

believe CaCl2 works as effectively as P2O5 albeit more slowly.

And klute i would use evian water, in the smallest bottles available, air freighted to australia, from here the evian and i would canoe to Antarctica

to cool the evian before canoeing back and using the evian in my condenser to distil some water to drink.

actually that does bring up one further question, whenever breaking the vacuum on a vac distil or other vac work you essentially allow a rush of 'lab

air' into your sample, to avoid this I was thinking of having a dry line that would be used to break the vacuum, does any one else do this, is it

practical?

|

|

|

Klute

International Hazard

Posts: 1378

Registered: 18-10-2006

Location: France

Member Is Offline

Mood: No Mood

|

|

| Quote: |

And klute i would use evian water, in the smallest bottles available, air freighted to australia, from here the evian and i would canoe to Antarctica

to cool the evian before canoeing back and using the evian in my condenser to distil some water to drink.

|

LOL! I'm sure that would be even more efficient!  I'll start collecting bottles

if you want I'll start collecting bottles

if you want

That vacuum distn issu has been bothering me sometimes, especially when removing solvent traces from a distn residu, using max vacuum, and

disconnecting it once in a while, it gets' flushed with often humid air.... So for the delicate products I use a schlenk as the still and break the

vacuum with a stream of argon, so that even when I disconnect the vacuum inlet the setup is already flushed with argon. But even with amine freebases

etc I don't think the stream of atmospher is that detrimental, if the product is air-sensitive, you should be working under inert atmospher all the

way along I guess.

\"You can battle with a demon, you can embrace a demon; what the hell can you do with a fucking spiritual computer?\"

-Alice Parr

|

|

|

vulture

Forum Gatekeeper

Posts: 3330

Registered: 25-5-2002

Location: France

Member Is Offline

Mood: No Mood

|

|

A balloon filled with inert gas and a three way valve between your setup and the vacuum source is a cheap but effective substitute for a Schlenk line.

|

|

|

Ephoton

Hazard to Others

Posts: 463

Registered: 21-7-2005

Member Is Offline

Mood: trying to figure out why I need a dark room retreat when I live in a forest of wattle.

|

|

some compounds evaporate to an extent and will leave with your dry air as you exit it from your desicator.

if you use a drying agent the amount of air that the wet compound can evaporate into is limited and so are your losses.

[Edited on 6-9-2008 by Ephoton]

e3500 console login: root

bash-2.05#

|

|

|

Panache

International Hazard

Posts: 1290

Registered: 18-10-2007

Member Is Offline

Mood: Instead of being my deliverance, she had a resemblance to a Kat named Frankenstein

|

|

| Quote: | Originally posted by Ephoton

some compounds evaporate to an extent and will leave with your dry air as you exit it from your desicator.

if you use a drying agent the amount of air that the wet compound can evaporate into is limited and so are your losses.

[Edited on 6-9-2008 by Ephoton] |

and there is the error in my theory!! NICE ONE!!

|

|

|

tapira1

Hazard to Others

Posts: 168

Registered: 9-10-2006

Location: Here!!!

Member Is Offline

Mood:

|

|

drying solids

There is an equilibrium shifted to the right. The drying agent dries the air; because the air has less vapor pressure than your sample to be dried,

some water goes from your sample to the air (and from it to the drying agent, until either your sample is dried or the drying agent is exhausted,

...or you interrupt the process...).

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

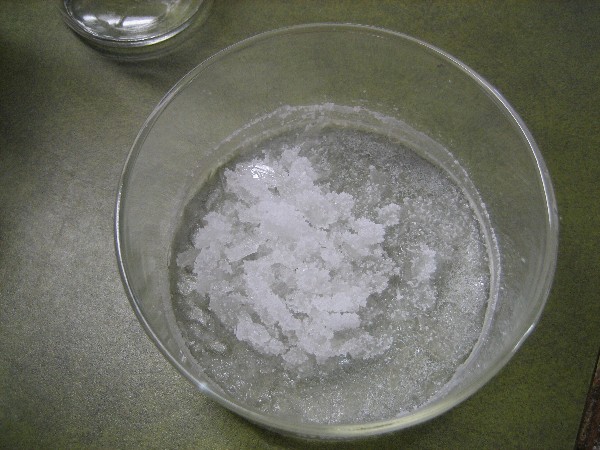

I have some wet MgCl2 that I made using 6N HCl and MgCO3 (gym chalk). I'm trying to dry it to MgCl2*6H20.

I first let it dry in an open crystallizing dish inside the house (RH=28-29%) until it wasn't losing water anymore. At this point it was a wet slush.

It is now in a desiccator loaded with CaCl2 prills. After a week or so in the desiccator it doesn't appear to be drying any further. There's not

much free liquid but it is still a slush.

I don't have access to P2O5 but do have 93% H2SO4. I suppose if all else fails I could try heating it in an evaporating dish. Does anyone have a

suggestion for drying this MgCl2 to the hexahydrate, or even the anhydride?

[Edited on 6-1-2009 by Magpie]

|

|

|

not_important

International Hazard

Posts: 3873

Registered: 21-7-2006

Member Is Offline

Mood: No Mood

|

|

you might be getting close to the equilibrium for the RH vs saturated salt solution:

http://www.omega.com/temperature/z/pdf/z103.pdf

http://nvl.nist.gov/pub/nistpubs/jres/081/1/V81.N01.A06.pdf

Simple heating the chloride very much is likely to lead to oxychloride formation. Blowing filtered air across it while warming to 40-50 C might work.

You also may want some excess HCl in with the MgCl2.

Or you could try pulling a vacuum on it, and then slowly warming to the same temperature range.

Calcium sulfate is a decent desiccant although not of high capacity, which means you need a lot relative to the stuff being dried.

SFAIK the best way to get anhydrous MgCl2 at home is to mix the hexahydrate with a slight molar excess of NH4Cl, and the heat that to drive of water

followed by NH4Cl

with the second step often done under reduced pressure.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Thank you, not_important, for posting those links. According to the NIST document I should be able to dehydrate the MgCl2 using KOH. I do happen to

have a fair amount of it.

|

|

|

not_important

International Hazard

Posts: 3873

Registered: 21-7-2006

Member Is Offline

Mood: No Mood

|

|

One more thing, unless you are positive your gym chalk is pure MgCO3 and you hydrochloric acid only contains HCl and H2O, you should not evaporate to

dryness but rather filter off the liquid and discard or save for later workup (not really useful for Mg salts). Crystallisation is used to purify,

but to do so the impurities need someplace to go and that is the solvent.

Also, old time prep for MgCl2

[Edited on 6-1-2009 by not_important]

Attachment: MgCl2.pdf (707kB)

This file has been downloaded 717 times

|

|

|

garage chemist

chemical wizard

Posts: 1803

Registered: 16-8-2004

Location: Germany

Member Is Offline

Mood: No Mood

|

|

Anhydrous MgCl2 is produced by mixing the aqueous solution with two times its own stochiometric amount of NH4Cl, drying this solution with weak heat

(must become absolutely dry!) and then decomposing the double salt magnesium-ammonium chloride by strong heat in crucibles with lid, to sublimate away

the NH4Cl and prevent ingress of moisture at the same time.

The alternative is to dry the MgCl2 by heating it in a gas stream of dry HCl.

You will never get anhydrous MgCl2 from its solution by any other desiccation process.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

| Quote: |

One more thing, unless you are positive your gym chalk is pure MgCO3...

|

I'm sure that my gym chalk (Frank Endo brand) is not pure MgCO3. As I was titrating the HCl (muriatic acid) with the powdered chalk the product

solution had a faint yellow color. As the endpoint was reached (pH~6) it turned turbid and a salmon color. I speculated that this was due to iron

contamination. This turbid color was cleanly removed by filtration.

I really only need to know the concentration of MgCl2 in my aqueous slush. I thought that taking it to the hexahydrate crystal would be a good way to

do this.

[Edited on 6-1-2009 by Magpie]

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Here's a picture of the MgCl2 after exposure to KOH flakes in a desiccator for over a week. The white effloresced material I assume is MgCl2*6H2O.

However, in the bottom the MgCl2 is still syrupy. I bottled most of the white crystals. They will have to do.

|

|

|