RogueRose

International Hazard

Posts: 1585

Registered: 16-6-2014

Member Is Offline

|

|

Wood ash leaching - results of ~2 gal hardwood - is this normal?

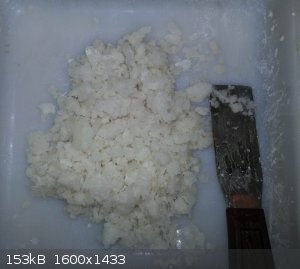

I've never seen K2CO3 before and I have heard that is the main component of leaching hardwood ash. I had about 2-3 gallons of oak ash (had a lot of

nails so there may be rust as well) and distilled water or rain water was used to slowly leach through the ash. It took about about 7-10 days for 4

gallons of water to filter through and it was the color of a light lager beer.

After evaporation this is the result and what the water looks like at total saturation point. This stuff seems more difficult than other solutions to

evaporate as it is boiling at ~175-180F which I find strange. It's also very difficult to get this last little bit to evaporate - I'll have to try a

slow oven evap process.

Here is what the product looks like. Is this normal and any suggestions on cleaning up the product?

|

|

|

Maroboduus

Hazard to Others

Posts: 257

Registered: 14-9-2016

Location: 26 Ancho Street

Member Is Offline

Mood: vacant

|

|

That's how it looks when I've done that in the past, but it would have been a good idea to screen out any metal of other non-ashy stuff before the

leaching.

Potassium carbonate just doesn't dry out very well. I would stir it in a stainless steel over a gas stove until it started to form a paste. When the

paste starts getting thick as toothpaste turn the heat off and continue to stir and scrape the bottom as it cools and hardens. You could dry it in an

oven, but you'll need a HOT oven to get it done.

Then It needs a real cooking. heat it in a high temp crucible. I use the top cut off of a used oil filter as it's free, steel, and isn't soldered

together. One will survive several uses. You could use a kiln if you've got one, but I just put the crucible in the red-hot coals of a large fire.

Much boiling and destructive distillation will take place, so don't fill the container more that 1/4 full at first. As the foaming dies down you can

feed in more stuff.

This high temp firing is to burn off organic contaminants. When you're done dissolve whatever is left in the crucible in water and filter. This is

tough because there's usually a lot of very fine carbon in there which will pass through some filters and clog others. Decantation of the clear

supernatant liquor to filter first saves time. It should come out fairly clear, but often has a bluish tint to it. That's pure enough for many

technical uses, but if you boil it down to a nearly saturated state and let it sit for a few days there should be a crystallizing out of sulfates

which can then be filtered.

I'm not sure what you do if you want really high purity. I think high grade stuff is made from potassium tartrate or something like that instead of

wood. Purification is a problem because potassium carbonate just doesn't crystallize well.

It might be possible to purify the wood ash derived product to some extent by converting it to the bicarbonate, purify that, and then roast it to get

the carbonate back.

|

|

|

violet sin

International Hazard

Posts: 1475

Registered: 2-9-2012

Location: Daydreaming of uraninite...

Member Is Offline

Mood: Good

|

|

Hydrogen peroxide cleaned up the liquid from leaching burnt bannana peels for me. Got it nice and clear. Reminds me, I need to check that petridish.

Last time I looked there wer nice big crystals and only a little water left.

Remember, there is more than potassium in there. I never got around to trying a more complete separation. The bannana peel experiment already took a

lot of time with all the eating, drying, burning, leaching, filtering, clarification, reduction, crystilization, recrystilization. Clear cystals from

bannana's was good enough for the learning experience here. Though a complete workup would have been nice, I lacked materials and equipement to make

it easy at the time.

|

|

|

RogueRose

International Hazard

Posts: 1585

Registered: 16-6-2014

Member Is Offline

|

|

Thanks for the replies! I did sift the ash first with window screen before leaching so the nails were only present during burning which I suspect

left some iron oxide in the ash (as they were rusty when the wood was burnt).

All in all I am kind of impressed with the amount of product recovered. I am curious if I would have gotten more had I used 2x the water for the

leaching or how much more could be extracted from the remains.

Maybe mixing a little 35% H2O2 into the slurry and then heating in a wood fire will clean it up some

|

|

|

Maroboduus

Hazard to Others

Posts: 257

Registered: 14-9-2016

Location: 26 Ancho Street

Member Is Offline

Mood: vacant

|

|

I don't doubt that the peroxide treatment will do the trick instead of roasting it. I just wanted to do it without buying chemicals, so I did it the

old-fashioned way.

It can also be cleaned somewhat in an oven at 200C or more (more is better). The brown lumps you'll get from drying it will gradually turn back then

grey because organic impurities are being oxidized. After the baking you'd want to dissolve in water, filter out any newly generated ash or carbon,

and re-dry.

The hydrogen peroxide treatment, if you go that way, probably wont require high temperatures, just time to do its trick.

But I'm just guessing about that.

Roasting the way I do it probably removes some extraneous salts of metals by turning them into metal their oxides which are often poorly soluble (

magnesium and stuff like that), but Re-crystallizing would remove those anyway.

I never went as far as repeated re-crystallizations because I was happy with some fairly crude stuff for another project I was working on.

EDIT: I've never heard what happens when you put 35% H2O2 in a crucible and heat it. That might be either very dangerous, or very messy.

With that high a concentration I bet it'd work wonders at room temp.

[Edited on 18-10-2016 by Maroboduus]

|

|

|

RogueRose

International Hazard

Posts: 1585

Registered: 16-6-2014

Member Is Offline

|

|

I didn't really mean use the same volume of 35% as I would if I used 3% but that I would add 35% and water to make whatever concentration needed for

oxidizing what is in the material. Maybe a nice 5-6% solution and then either slowly evap in an oven then move it to the fire for a high temp heating.

What I have always wondered about in high temp oxidations is how to get air into the powder when it is in a crucible. The heat will make the gases

rise and I would think most gases around the crucible in the flame would have almost no O2 left as it has burnt up in the flames. Does this make

sense?

Would it be better to use some kind of hollow stainless steel stir rod connected to a low pressure air compressor or blower to blow O2 into the

mixture

|

|

|

Maroboduus

Hazard to Others

Posts: 257

Registered: 14-9-2016

Location: 26 Ancho Street

Member Is Offline

Mood: vacant

|

|

Cool. I just wanted to be sure you weren't gonna put 35% in a crucible and stick it in hot coals!

When I fire the crude carbonate, I think most of the impurities actually either get distilled out (aren't many organics that don't vaporize at the the

heat of red hot steel, and my crucible gets red hot), or are broken down into smaller organics which also vaporize.(pyrolysis)

When most of the volatiles have been driven off, there's more room above the hot carbonate for air to get at it. And don't forget that with all that

heat there's considerable air flow. As the combustion gasses rise cool air is constantly drawn into the fireplace, and the mixture of the cool air

and hot gasses probably makes some turbulence in there. Also the red hot, or nearly red-hot, upper rim of the crucible helps make the gasses circulate

by making its own mini-draft.

I don't think the air flow is much of a problem. I've tried this with an open crucible and with a cover on it, and the results seem pretty similar.

The cover was a loose-fitting one made from sheet metal(basically a circle of metal with 3 or 4 flanges bent down at the edges to hold it in place),

so there were still gaps at the edges.

Even when I do it without the cover, there wasn't much flame in the crucible. It would light a few times, but only for a few seconds. And when you're

done, there's still considerable un-burned carbon left in the crucible. I suppose a more complete combustion than I was getting might have meant less

fine carbon powder left to clog up my filters though. Your idea of blowing air into the crucible could be a way to do this. A man named Kelly in the

US used this set-up to convert pig iron to wrought iron back a few years before the Bessemer converter was invented in England.

|

|

|

violet sin

International Hazard

Posts: 1475

Registered: 2-9-2012

Location: Daydreaming of uraninite...

Member Is Offline

Mood: Good

|

|

With the bannana peels, it was hard to get complete combustion to white/grey ash. Used a blow pipe and patients. Anyhow, after I was done leaching

the sol was straw colored to light beer colored. Adding a little 3% H2O2 to warm solution was enough. Pretty sure I microwaved

my leachings a few sec then added peroxide. After a few min waiting and adding more, repeat, it was clear. No excessive heat or high strength

peroxide was needed. It was also somewhere in the neighborhood of 150ml before addition. Yours being darker, might appreciate more oxygen for sure.

Not saying it was a better route to go; just that it worked and we just got a new bottle of peroxide for the medicine cabinet. So it was an easy

first shot at cleaning the raw rinse solution. Have to say, I admire the toasting it to save a few bucks. It is a pain to go back to the store and

grab more xxx for some project as often as it seems to happen. This hobby can devour $ if you let it

Subscripts are a bitch on my phone, manually entering brackets and what not.. Pardon the use of "peroxide" to generally refer to

H2O2

|

|

|

RogueRose

International Hazard

Posts: 1585

Registered: 16-6-2014

Member Is Offline

|

|

Well I tried adding some 35% H2O2 diluted 6:1 with hot water and continued adding water as it foamed. The mixture foamed over the top of the jar as I

stirred and the smell of H2O2 was noticable. I'm guessing the foaming was CO2 from the carbon mixing with the O2??

I'm considering leaching the ashes from this winters fires as I got more product than I expected from the ash. My main concern is that of not knowing

what wood was burned. I know I have oak, cherry, mulberry and elm in a wood pile and maybe a little spruce mixed in. I've heard that woods other

than oak can give "bad" ashes but this doesn't make a lot of sense as it seems potassium (and maybe phosphorus) would be the main mineral in any ash

as they are the macro nutrients. Can anyone explain the ash mineral contents of different woods?

|

|

|

RogueRose

International Hazard

Posts: 1585

Registered: 16-6-2014

Member Is Offline

|

|

Well after drying at 400F and crushing to a powderish form, I have 260g of material (from about 2-2.5 gal of ash) - IDK if that is a good yield or

not. It seems pretty good to me.

As I said, 50g of 35% H2O2 and 300g hot water was added and mixed then dried. The material is still not as pure as I would like so I am planning on

doing at least 2 different purification processes. One is heating in a forge to at least 1400F (it can go to > 2000F but my crucible is SS and it

will get weak. K2CO3 melts at 1,636F and decomposes at boiling point which I'm trying to find out. I'm concerned about removing the solidified/cooled

K2CO3 after heating to such a high temp. I suspect dissolving it and filtering would be a good next step so that is an option.

Finally the solubility difference between 20C and 100C is 111g to 155.6g respectively - good enough to do solubility crystallization followed by

filtering to remove crystals. I've never worked with K2CO3 before so I'm not sure how this will work.

I'm still wondering about the content of different wood ashes and if leaching any fireplace ash will work or if it has to be strictly hardwood. Any

info here, especially anecdotal is appreciated!

*edit - I searched and found on wiki that some have reported that CaCO3 as a major constituent of some wood ash as well as iron oxide. K2CO3 is

reported at about 10% of ash and phosphate at about 1%. I would think that leaching would largely eliminate any CaCO3 and iron oxides passing through

as their solubility is minimal in water. I find it odd that Fe2O3 would be found in "percentage" quantities in wood ash that doesn't have foreign

materials present. Do trees use iron in cellular construction and "life"?

[Edited on 20-10-2016 by RogueRose]

|

|

|

Pumukli

National Hazard

Posts: 686

Registered: 2-3-2014

Location: EU

Member Is Offline

Mood: No Mood

|

|

If you like anecdotal "references" then here's mine: I read somewhere that straw ash contains higher percentages of K2CO3 than

hard/soft wood ashes.

If you take into account that intensive farming use fertilizers (among them K too) then it may make sense.

|

|

|

RogueRose

International Hazard

Posts: 1585

Registered: 16-6-2014

Member Is Offline

|

|

Quote: Originally posted by Pumukli  | If you like anecdotal "references" then here's mine: I read somewhere that straw ash contains higher percentages of K2CO3 than

hard/soft wood ashes.

If you take into account that intensive farming use fertilizers (among them K too) then it may make sense. |

Well that is something to look into! It does make sense in some manner.

I did do the heating step over a wood fire. It was windy so it got pretty hot very fast. I noticed melting around the edges and it turned into a

black glossy liquid. It finally melted completely and then when I took it off the heat within about 3-4 seconds it turned completely brown and

started making "pinging" noises as it crystallized. It finally solidified to a glass-like texture and breaks like glass.

|

|

|

Maroboduus

Hazard to Others

Posts: 257

Registered: 14-9-2016

Location: 26 Ancho Street

Member Is Offline

Mood: vacant

|

|

That sounds like a great yield to me. I'd get about 1/2 that.

I don't know if you've got better ashes, or if your slow leaching just did a much better job of extracting.

I never did it that way, I'd just mix the ash with hot water, let it cool down, and filter it through a t-shirt I didn't care about.

This meant a lot of the liquid was left behind in the ashes. And probably a lot of the carbonate along with it.

I'm surprised the stuff was brown after the fire treatment. I'd leave it in for hours, and when it cooled off and I took it out it would be jet

black. Then when I dissolved it in water and filtered out the carbon it would be a slightly bluish solution, which would dry out to make crystals

which looked pretty white.

As to your question about different kinds of wood, I know somebody who tried this with ashes from a bunch of old shingles which he burned just to get

ashes, and he said the yield was awful. Back when I first read about this procedure I saw some info about the ash content of different woods, but that

was an awfully long time ago, and I'm not sure where I saw it.

I'll poke around in some of my old books, I might have it.

|

|

|

RogueRose

International Hazard

Posts: 1585

Registered: 16-6-2014

Member Is Offline

|

|

Well the wood was all old (60-80 yr old) white or red oak that had gotten dry rot. IDK if that makes any difference with the yield.

I was totally amazed at how quickly the K2CO3 melted with a plain wood fire (no blower or anything). It was kind of windy (5-8 mph) so that helped

get it hotter, but reaching the 1636F temp seemed unlikely without a blower. Could contamination drop the melting point somehow?

I have another post about NaNO3 turning dark brown/blackish when heated to 400F in an oven and some mentioned it may be organic contamination.

In both cases the starting materials were whiteish to tanish/white and I didn't notice any organics. How does the heat get rid of the contamination?

I would think that Carbon + O2 would yield CO2 and this the black contamination would disappear as gas, but that isn't the case with the carbonate.

It does seem to settle nicely and I'm in the process of filtering but there is a good bit passing though - will need to do multiple filterings.

As far as filtering goes - when material passes through but larger particles are retained, I often pass the filtrate back through the same dirty

filter and the larger particles often block the previously passed particles giving a purer filtrate. I repeat this as many times as needed as each

time it gets a little (or considerably) clearer. Does anyone know of a faster method for this as passing the same material through 3-5 times is a

little time intensive.

|

|

|

wg48

National Hazard

Posts: 821

Registered: 21-11-2015

Member Is Offline

Mood: No Mood

|

|

You can use a filter aid to coat the filter first.

See: http://www.filteraid.com/how_filteraid_works.html

|

|

|

RogueRose

International Hazard

Posts: 1585

Registered: 16-6-2014

Member Is Offline

|

|

Awesome! Thanks for posting this. I didn't know that diatomaceous Earth (DE) could be used as a filter. I know it was used to filter/clean oil but

never thought about using it for other stuff. Now that I think about it, I believe it is used in swimming pools and such. I'm thinking about making

an activated carbon filter followed by the DE to remove any of the super find AC particles.

|

|

|

RogueRose

International Hazard

Posts: 1585

Registered: 16-6-2014

Member Is Offline

|

|

Well after filtering then passing back through the same filter again, the solution was crystal clear! I boiled then evaped last 30% or so in the

oven. The "crystals" looked a lot like KOH as it make flat flakes. I've never seen K2CO3 so I don't know if that is how it looks as well. So do I

have carbonate or hydroxide? the temp when heated got to > 1,636F but I don't know what decomp point is.

I haven't weighed it yet but I know I lost some when heating as it was liquid and spilled.

Overall I'm REALLY impressed with how this process worked out and and going to do it with wood ash from this winter. I didn't think I would get it

this clean after seeing it turn BLACK when liquid then black/dark brown when cooled.

I used water captured from a dehumidifier but may not have enough this winter. Does the type of water matter? I was told rain water is good as well.

This is a chunk of the solidified material. The last pic is of it almost completely dried.

|

|

|

Maroboduus

Hazard to Others

Posts: 257

Registered: 14-9-2016

Location: 26 Ancho Street

Member Is Offline

Mood: vacant

|

|

I think making it decompose takes some REALLY high heat. But for a quick test as to whether it's carbonate, weigh some and see how much acid it will

neutralize.

I've started collecting extract of ashes to make more myself as this thread was nostalgic for me.

I like the fact that the process uses nothing but water and ashes and gives somewhat clean carbonate. I think almost any water low in non-volatile

dissolved salts will do.

When I get a good stockpile I may see about making it into KOH with lime. Be nice to be able to make my own.

Might be interesting to try making glass with it, but I'd want to find some good quality sand for that.

Then there's always that 18th century recipe for Potash Biscuits on You Tube. They probably taste rotten, but there's something pretty cool about a

biscuit recipe that starts with fireplace ashes and a red-hot crucible

|

|

|

RogueRose

International Hazard

Posts: 1585

Registered: 16-6-2014

Member Is Offline

|

|

Quote: Originally posted by Maroboduus  | I think making it decompose takes some REALLY high heat. But for a quick test as to whether it's carbonate, weigh some and see how much acid it will

neutralize.

I've started collecting extract of ashes to make more myself as this thread was nostalgic for me.

I like the fact that the process uses nothing but water and ashes and gives somewhat clean carbonate. I think almost any water low in non-volatile

dissolved salts will do.

When I get a good stockpile I may see about making it into KOH with lime. Be nice to be able to make my own.

Might be interesting to try making glass with it, but I'd want to find some good quality sand for that.

Then there's always that 18th century recipe for Potash Biscuits on You Tube. They probably taste rotten, but there's something pretty cool about a

biscuit recipe that starts with fireplace ashes and a red-hot crucible |

I'd like to see the biscuit recipe if you have it or a link! Glass would be really cool as I was thinking of that too. I want to get into glass

blowing. I make soap as well and might try making some with this as well. Might be good for drying EtOH as well  . I actually could use about as much as I can get so I'm wondering how I can get more ashes from others this winter. . I actually could use about as much as I can get so I'm wondering how I can get more ashes from others this winter.

Well I just got a good bit more ash from a forge/smelter session so I'm going to try again with a known amount of ash, probably like 2-3 lbs. I know

that 99%+ of it is old white oak and the rest is 2x4 spruce (man that stuff burns hot and fast b/c it is so dry and I guess relatively high sap

content - VOC's??)

I think I made a mistake today. I was cleaning my sodium acetate crystals by adding a little vinegar to make sure no carbonate was left. When I

added them to one jar it fizzed as expected but then I noticed the smell of smoke/ashes so I stopped adding vinegar. I'm wondering if I mis-labeled

the first batch of K2CO3 filtered & evap'd from the same batch of acid. If this is the case, my yield is SOOO much better than originally thought

as it weighed ~ 400g (+ 260g already processed - from 2-2.5 gal's ash).

The mean weight of ash is .827g/cc and max weight is about 1.376g/cc. (figures from reference below) I would suspect mind was around 1.2-1.3 as it

sank quite readily - I'll use 1.25g/cc. at 2.25 gallons that's about 10.898kg. At 10% K2CO3 I should get 1100g from this batch. Had I known this I

would have used more water when leaching.

K2O content can be between 4-16% in trees and various parts of trees. I found that pine needles average 11-16.5% K2O so I am planning of collecting

those and testing that. I'm also curious about pine cones.

WOOD ASH: A NEW SOURCE OF POZZOLANIC MATERIAL

| Quote: | | 3 All wood ashes tested were first oven - dried at 210 °F ± 10 °F and then tested for gradation in accordance with ASTM C 136

using standard sieve sizes (one inch through #100). Gradation of wood ashes tested is reported in Table 1. The av erage amount of wood

fly ash and bottom ash passing sieve #200 (75 μ m) after washing (ASTM C 117) was 59.9 % (ranged from 10.5% to 98.8%) and 8%

(ranged from 1.2% to 18.5%), respectively. The average amount of wood fly ash retained on No. 325 sieve (ASTM C 430) was 46%, which varied

between 3.6 and 98.3 percent. Typical particle size distribution (combined ASTM C 136 and ASTM C 422) for wood fly ash is shown in Fig. 1. The

above test results indicate that wood bottom ash may be acceptable as a substitute for sand replacement in ready - mixed concrete

and/or as both coarse and fine aggregate replacements in dry - cast concrete products such as bricks, blocks, and paving stones

because of its coarse gradation. Wood fly ash can be used as a partial replacement of cement and fine aggregates in the manufacture of concrete

and other cement - based products. Test results for unit weight or bulk density (ASTM C 29) for wood fly ash exhibited average

density value of 548 kg/m 3 (34.2 lb/ft 3 ). It ranged from 162 to 1376 kg/m 3 (10.1 lb/ft 3 to 85.6 lb/ft 3 ). For wood

bottom ash the average was 827 kg/m 3 (51.6 lb/ft 3 ). It ranged from 663 to 977 kg/m 3 (41.4 lb/ft 3 to 61 lb/ft 3 ). |

|

|

|

Maroboduus

Hazard to Others

Posts: 257

Registered: 14-9-2016

Location: 26 Ancho Street

Member Is Offline

Mood: vacant

|

|

17th century potash cakes

see: https://www.youtube.com/watch?v=hD7mNUAj9MA

I found this guy when looking in to making suet. I wanted to try a short crust for my steak and kidney pie.

The item about ash products in concrete was interesting. I'd wondered about the leftovers after I extracted the potash. It sure does seem a little

cement-like.

If you're worried at all about the acetate in your other ash sample, you can always re-fire it. The acetate should just decompose to carbonate (I

think).

|

|

|