| Pages:

1

..

34

35

36

37

38

..

43 |

Waffles SS

Fighter

Posts: 998

Registered: 7-12-2009

Member Is Offline

|

|

Thanks byko3y.that is great information

|

|

|

clearly_not_atara

International Hazard

Posts: 2696

Registered: 3-11-2013

Member Is Offline

Mood: Big

|

|

This study, which describes the formation of a compound I suspect chlorinates acids, is attached. However, the 2:3 adduct, which contains the crucial

alpha,alpha-dichloro moiety, appears to be unstable. It may form transiently during the acetonitrile method, but it may not be feasible to isolate it.

Attachment: phpkMmtNR (1.1MB)

This file has been downloaded 558 times

[Edited on 04-20-1969 by clearly_not_atara]

|

|

|

CuReUS

National Hazard

Posts: 928

Registered: 9-9-2014

Member Is Offline

Mood: No Mood

|

|

why not do a baeyer-villiger on diacetyl to get AA ? -https://books.google.co.in/books?id=AcpPyv0HWRsC&lpg=PP1...

diacetyl is available as butter flavour

anyways,if you want AA only for acetylation ,you can do it using acetic acid/TCT instead

|

|

|

Waffles SS

Fighter

Posts: 998

Registered: 7-12-2009

Member Is Offline

|

|

| Quote: |

5,4 g Diacetyl (63 Millimole) wurden in 500 cm3 Ather gegossen, die 14,1 g Perphtalsaure(77,5 Millimole) gelost enthielten. Nach wenigen Stunden war

die einem Mol. entsprechende Menge Perphtalsaure verbraucht. Unter Ruhren haben wir hierauf wahrend

einer Stunde trockenes NH3-Gas eingeleitet, hierauf die Flussigkeit von dem entstandenen Niederschlag abdekantiert und sie auf 20 cm3 eingeengt. Uber

Nacht krystallisierte daraus Acetamid aus, das nach Umkrystallisieren aus Benzol bei 81 schmolz und mit Acetamid keine Schmelzpunktsdepression zeigte.

Ausbeute 0,87 g, d. h. 24% der Theorie.

Zur Oxydation von α‐Diketonen und einigen Derivaten von solchen mit Phtalpersäurev

Karrer; Hohl - Helvetica Chimica Acta, 1949, vol. 32, p. 1933

|

[Edited on 11-8-2018 by Waffles SS]

Chemistry = Chem + is + Try

|

|

|

GrayGhost-

Hazard to Self

Posts: 61

Registered: 31-10-2017

Location: Argentina

Member Is Offline

Mood: No Mood

|

|

sincerely I dont read the 36 page of this thread.

In the patent of 1933 number 42573 preparate acetic anhydride with sodium pirosulfate ( from SO4HNa calcinated ) and ammonium acetate.

[Edited on 11-8-2018 by GrayGhost-]

|

|

|

Waffles SS

Fighter

Posts: 998

Registered: 7-12-2009

Member Is Offline

|

|

Quote: Originally posted by GrayGhost-  | sincerely I dont read the 36 page of this thread.

In the patent of 1933 number 42573 preparate acetic anhydride with sodium pirosulfate ( from SO4HNa calcinated ) and ammonium acetate.

[Edited on 11-8-2018 by GrayGhost-] |

Maybe you have to read or search some pages of this topic.this method and similar method tested many times without any success.

Chemistry = Chem + is + Try

|

|

|

CuReUS

National Hazard

Posts: 928

Registered: 9-9-2014

Member Is Offline

Mood: No Mood

|

|

Oxone would be a better,cheaper and more OTC choice than perpthalic acid -https://www.organic-chemistry.org/abstracts/lit4/052.shtm

|

|

|

Waffles SS

Fighter

Posts: 998

Registered: 7-12-2009

Member Is Offline

|

|

Of course

[Edited on 12-8-2018 by Waffles SS]

Chemistry = Chem + is + Try

|

|

|

clearly_not_atara

International Hazard

Posts: 2696

Registered: 3-11-2013

Member Is Offline

Mood: Big

|

|

It appears that in the BV oxidation of diacetyl, the AA needs to be trapped in situ, because it reacts with nucleophiles which are present. But maybe

the trapping reagent could be something which gives an activated acetyl, such as imidazole or N-hydroxysuccinimide.

[Edited on 04-20-1969 by clearly_not_atara]

|

|

|

GrayGhost-

Hazard to Self

Posts: 61

Registered: 31-10-2017

Location: Argentina

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Waffles SS  | Quote: Originally posted by GrayGhost-  | sincerely I dont read the 36 page of this thread.

In the patent of 1933 number 42573 preparate acetic anhydride with sodium pirosulfate ( from SO4HNa calcinated ) and ammonium acetate.

[Edited on 11-8-2018 by GrayGhost-] |

Maybe you have to read or search some pages of this topic.this method and similar method tested many times without any success.

|

I dont tempt make , but i sure what this reaction should be in strictly anhydrous conditions like Grignard and Friedel-Craft.

|

|

|

Waffles SS

Fighter

Posts: 998

Registered: 7-12-2009

Member Is Offline

|

|

Quote: Originally posted by GrayGhost-  |

I dont tempt make , but i sure what this reaction should be in strictly anhydrous conditions like Grignard and Friedel-Craft.

|

Please read more pages !

Chemistry = Chem + is + Try

|

|

|

CuReUS

National Hazard

Posts: 928

Registered: 9-9-2014

Member Is Offline

Mood: No Mood

|

|

I don't see any potential nucleophiles in the oxone paper I linked above | Quote: | | But maybe the trapping reagent could be something which gives an activated acetyl, such as imidazole or N-hydroxysuccinimide. |

won't imidazole or NHS themselves get oxidised under BV conditions ?

Isn't there any other way of isolating the AA,either by using a biphasic medium or nucleophile scavengers ?

|

|

|

professsormuddyhutty

Harmless

Posts: 4

Registered: 18-3-2017

Member Is Offline

Mood: No Mood

|

|

Can distilling zinc acetate and condensing the vapors manufacture AA?

|

|

|

clearly_not_atara

International Hazard

Posts: 2696

Registered: 3-11-2013

Member Is Offline

Mood: Big

|

|

One thing I am kind of curious about is the reaction (if any) of anhydrous copper (II) acetate with SO2. It seems like SO2 might be oxidized under

this condition. If so, the net reaction should look like:

2Cu(OAc)2 + SO2 >> Cu2SO4 + 2 Ac2O

Since SO2 has a high solubility in acetic acid, the reaction might be performed effectively in acetic acid as solvent. There are a lot of methods that

try to produce acetic anhydride by oxidation, but this is the first one that uses reduction, to my knowledge. Ensuring all reagents are anhydrous will

be a challenge. If Cu2SO4 is produced, it is light green. Possibly, dithionate will be formed instead:

2 Cu(OAc)2 + 2 SO2 >> Cu2S2O6 + 2 Ac2O

http://en.wikipedia.org/wiki/Dithionate

The paper which claimed Ac2O release from Zn(OAc)2 was criticized by byok3y for inferring the presence of Ac2O using an NMR spectrum

that didn't actually seem to show any Ac2O present.

In a related method, which is known to work, silver acetate does decompose to release acetic anhydride. However, if there is any water present, it

catalyzes the decomposition of acetic anhydride like this:

Ac2O >> Me2CO + CO2

In order to achieve a reasonable yield of acetic anhydride, the AgOAc had to be dried carefully and carried out under an inert atmosphere. Therefore,

even if silver is available, the reaction may not be very practical.

The short answer is that distilling acetates is a dead end for all practical purposes.

[Edited on 10-10-2018 by clearly_not_atara]

[Edited on 04-20-1969 by clearly_not_atara]

|

|

|

Waffles SS

Fighter

Posts: 998

Registered: 7-12-2009

Member Is Offline

|

|

Quote: Originally posted by clearly_not_atara  | One thing I am kind of curious about is the reaction (if any) of anhydrous copper (II) acetate with SO2. It seems like SO2 might be oxidized under

this condition. If so, the net reaction should look like:

2Cu(OAc)2 + SO2 >> Cu2SO4 + 2 Ac2O

|

Possible but you will get copper sulfite instead of sulfate

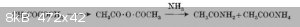

(below reaction of ammonium acetate with SO2)

[Edited on 11-10-2018 by Waffles SS]

Chemistry = Chem + is + Try

|

|

|

Jackson

Hazard to Others

Posts: 189

Registered: 22-5-2018

Location: U S of A

Member Is Offline

Mood:  Happy about new glassware

|

|

https://patents.google.com/patent/US3281462A/en

This patent uses oxalic acid and boric acid as catalysists for formation of Ac2O under pressure of 10 to 70 PSIG at 20° to 80° C

Because it is not to much pressure, it could probably be carried out relatively easily at the labratory scale.

|

|

|

NZniceguy

Harmless

Posts: 48

Registered: 16-9-2017

Member Is Offline

Mood: No Mood

|

|

I was recently given the following and was curious as to what you guys thoughts were......

take some GAA fill a “pipe bomb” ie threaded and capped pipe, add an excess amount of ground up dry ceramic wrench that cap on like it’s never

coming off (though it is) and through in a hot fire like a brick oven with good O2 flow ie accordion type thing and cook the fuck out of it for a few

hours. If tight enough and anywhere near hot enough lots of wiggle room it won’t pop and the brick oven would protect shrapnel anyway the ceramic

will absorb water as it is removed and cools (water produced from the condensation) pour off the crude as fuck AA fractionally distill off anything

boiling at 100 or less and collect only that coming over above 135-140 IIRC. That’s your clear clean highly pure AA. I’m not gonna describe

fractional distillation if one is to undertake this is will work but for safety and other reasons one needs dedication and some basic lab knowledge ie

what bps are and what a fractional distillation is. If not one shouldn’t even bother. The pressures generated in that pipe will be very high

numerous atmospheres as you are going way above it normal bp in a static volume. For thermodynamic reasons with the absorption of water produced and

the decrease in molar amounts of free substance in the product direction it becomes favorable for it to go to completion. Do not even bother thinking

this will ever work at normal pressure or normal temp. You need the energy of heat and the pressure effects. Pressure will nearly always drive a rxn

in closed volume towards whatever produces the least gases (or at least with the higher bps) and in direction where there is overall less molecules.

Part of the idea is that it is somewhat driving the whole system into a supercritical semiliquid semigas phase which is impossible to label as one or

the other. It is the oldest low tech way to make anhydrides for over 130 years I believe.

|

|

|

froot

Hazard to Others

Posts: 347

Registered: 23-10-2003

Location: South Africa

Member Is Offline

Mood: refluxed

|

|

Crude method crudely written.

" the ceramic will absorb water as it is removed and cools (water produced from the condensation)"

Will it? Don't hydrated ceramics lose their water at high temps?

We salute the improvement of the human genome by honoring those who remove themselves from it.

Of necessity, this honor is generally bestowed posthumously. - www.darwinawards.com |

|

|

clearly_not_atara

International Hazard

Posts: 2696

Registered: 3-11-2013

Member Is Offline

Mood: Big

|

|

Sounds pretty made-up to me. Author doesn't even know what the composition of the "catalyst" is supposed to be.

[Edited on 04-20-1969 by clearly_not_atara]

|

|

|

NZniceguy

Harmless

Posts: 48

Registered: 16-9-2017

Member Is Offline

Mood: No Mood

|

|

I dont see a catalyst mentioned....or are you referring to the ceramic pieces?

|

|

|

hissingnoise

International Hazard

Posts: 3940

Registered: 26-12-2002

Member Is Offline

Mood: Pulverulescent!

|

|

What you were 'given' sounds like some idiot ineptly trying to describe the cracking of acetic acid to produce ketene?

|

|

|

Waffles SS

Fighter

Posts: 998

Registered: 7-12-2009

Member Is Offline

|

|

I think yes,

There are so many patents and articles about making Ac2O by this method with different catalyst

US2045718(silica gel and Al2O3 at 700-750c)

US2006787(CuCl and CuCO3 at ~700c)

US1915572(calcium tungstate at 550-650c)

Compardou; Seon - [Comptes Rendus Hebdomadaires des Seances de l'Academie des Sciences, 1928, vol. 186, p. 592] (TiO2 at 300c)

DE410363( α-Al2O3*H2O; phosphoric acid; pumice stone at 600c)

DE475885( phosphoric acid at 680℃ , I think this happen with different route and not with ketene)

DE408715(with NaCl at 550c and with pumice stone at 650c)

and so many ...

[Edited on 9-11-2018 by Waffles SS]

Chemistry = Chem + is + Try

|

|

|

BakingBrownies

Harmless

Posts: 4

Registered: 14-11-2018

Member Is Offline

|

|

the best way to get it is to pass acetone vapor over a hot coil and then pass the gas through a condenser and then through the water. do it until the

water is saturated.

|

|

|

hissingnoise

International Hazard

Posts: 3940

Registered: 26-12-2002

Member Is Offline

Mood: Pulverulescent!

|

|

| Quote: | | the best way to get it is to pass acetone vapor over a hot coil and then pass the gas through a condenser and then through the water. do it until the

water is saturated. |

It worked well for you, then?

Tell us more?

|

|

|

clearly_not_atara

International Hazard

Posts: 2696

Registered: 3-11-2013

Member Is Offline

Mood: Big

|

|

All these shitty makeshift ketene generators scare me. It's a toxic, flammable, explosive gas; it's one thing if you're following a known procedure,

but just generating shitloads of ketene "over a hot coil" sounds like a recipe for disaster.

| Quote: | | Possible but you will get copper sulfite instead of sulfate |

I'm not sure you correctly interpreted? I was expecting that Cu2+ would oxidize SO2. In particular I had considered a mechanism like this:

AcOSO2- (acetyl sulfite) + Cu2+ >> AcOSO2* (radical)

2 AcOSO2* >> (AcO)2S2O4 (diacetyl dithionate)

(AcO)2S2O4 + 2 OAc- >> 2 Ac2O + S2O52-

http://en.wikipedia.org/wiki/Dithionate

So that would give you copper (I) dithionate, at least in theory. The compound acetyl sulfite, AcOSO2H, is known in the solid phase:

https://pubs.acs.org/doi/abs/10.1021/ja01233a507

(Note: there is no need to access the article; the preview contains the whole thing!)

However, the potential for Cu2+ to oxidize this compound is unclear. Cu2+ has a similar redox potential to bisulfate in aqueous

solution, but it may be a stronger oxidizer without aqua ligands.

Fe(OAc)3 may be a somewhat stronger oxidizer, but it is much harder to dry. AgOAc is easy to dry, but expensive and probably insoluble. Pb(OAc)4 is

cheaper but toxic. Perhaps Fe2(SO4)3 could be used?

[Edited on 15-11-2018 by clearly_not_atara]

[Edited on 04-20-1969 by clearly_not_atara]

|

|

|

| Pages:

1

..

34

35

36

37

38

..

43 |