Anthraquinone by oxidation of 9-bromoanthracene

While the preparation of anthraquinone from 9-bromoanthracene might seem like a waste of a valuable raw material I have rather a lot of it and very

little use for it, while I have very little anthracene. So, this conversion is in my case a matter of necessity. My original plan was to reductively

de-halogenate the bromoanthracene to anthracene and then oxidize this by one of the many possible procedures. However, a brief note in von Richter's

Chemistry of Organic Compounds under the description of 9,10-dichloroanthracene states that when this compound is oxidised it yields anthraquinone

with the loss of its chlorine. This raised the possibility that oxidation of 9-bromoanthraquinone would similarly yield anthraquinone. The only risk

that I foresaw was the possibility of bromination of the resulting anthraquinone but it turns out that direct halogenation of anthraquinone is very

difficult.

The following preliminary experiment was based on the experimental procedure for the oxidation of anthracene to anthraquinone presented in Cain and

Thorpe(1).

Experiment 1

14.401g of 9-Bromoanthracene was dissolved in 100ml of boiling glacial acetic acid under a reflux condenser in a 500ml flask equipped with a magnetic

stir-bar. The chromic acid oxidising solution was prepared by dissolving 20.0g of chromium trioxide in 15ml of water and then diluting with 75ml of

glacial acetic acid. The chromic acid solution was added slowly from a dropping funnel through the reflux condenser and such a rate as to maintain a

steady reflux. After the addition of about 35-40ml of the chromic acid solution the separation of anthraquinone requires additional external heat to

be applied to maintain a vigorous reflux or the reaction mixture becomes hard to stir. Once most of the chromic acid solution had been added much

bromine vapour began to reflux. Addition took about 40 minutes. When all of the chromic acid solution had been added the dark green solution was

cooled a little until reflux ceased and then the condenser rearranged for simple distillation into a vented receiver, the vent having a pipe to an

inverted funnel in a beaker of dilute sodium hydroxide to absorb bromine and other vapours. The bromine was then distilled off until the distilled

vapour was practically colourless acetic acid, about 20ml were distilled off. The contents of the flask were cooled a little and then poured into

400ml of cold water and a further 100ml of water used to rinse the flask. The diluted suspension was allowed to cool to room temperature (c 10°C) and

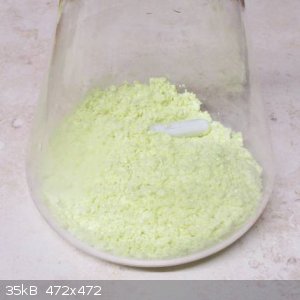

filtered. The pale-yellow solid was washed repeatedly on the filter until the washings were neutral and clear. The cake was dried at 40-45°C for 14

hours to give 11.319g of crude anthraquinone, about 97% of theory.

Comments

This procedure was adapted from an experiment to oxidise an equivalent molar quantity of anthracene (10.0g) and if anthracene is used the bromine

distillation may be dispensed with. An attempt was made to recover the chromium from the residue without first neutralising the large amount of acetic

acid by the addition of a large amount of potassium sulphate with the intension of causing the crystallisation of chrome alum but this did not work.

Even after evaporation to about 300ml only a green basic chrome salt or hydroxide precipitated.

The bromine distillate was neutralised with a mixture of sodium hydroxide and sodium sulphite then discarded. In a larger scale preparation, it may be

possible to utilise the bromine-acetic acid mixture as this is a common brominating mixture.

Experiment 2.

28.835g of 9-bromoanthracene were placed in a 1 l conical flask equipped with a large stir-bar. 200ml of glacial acetic acid were added and the flask

warmed and stirred to disperse the bromoanthracene most of which dissolves. The flask was equipped with a reflux condenser at the top of which was

placed a side vent and then a dropping funnel.

Chromic acid in acetic acid ..................................... 9-bromoanthracene charge ....................................... Solution in acetic

acid almost complete

The dropping funnel was charged with a solution of chromic acid prepared by dissolving 40g of chromium trioxide in 30ml of water and when dissolved

diluting with 150ml of glacial acetic acid.

General set-up for chromic acid addition

When the contents of the flask had almost reached boiling point and most of the bromoanthracene had dissolved the chromic acid solution was added

through the reflux condenser at such a rate that the mixture refluxed gently. It was found necessary to keep the hotplate on at about 120°C in order

to keep the reflux going, particularly towards the end of the reaction. Addition took about 50 minutes but could usefully be shortened. Towards the

end of the chromic acid addition the flask is filled with bromine vapour and bromine starts to reflux with the acetic acid. It was necessary at this

point to add a hose with a gas trap containing dilute sodium hydroxide to the vent at the top of the reflux condenser.

Dark green colour quickly forms on chromic acid addition ....... Anthraquinone starting to precipitate

Bromine vapour starting to reflux with the acetic acid ...... Detail of bromine absorption set-up

The flask was allowed to cool a little and then the condenser rearranged for distillation into a vented flask with the gas trap attached to the vent.

The contents of the flask were then distilled until the vapour in the conical flask was almost colourless, about 35-40ml of acetic acid plus bromine

were distilled off. When no significant amount of bromine was passing over the distillation was stopped, the flask allowed to cool a little and then

the contents poured into a 2 l beaker. The flask was rinsed with 100ml of water and the washings added with good stirring to the beaker. The dark

green slurry was allowed to stand overnight and cool to ambient temperature, about 7-8°C.

Bromine distillation starting ............................................... Bromine distillation practically complete

The cold suspension was filtered using a large Buchner funnel (11cm with Whatman 541 acid hardened paper, but a large sintered glass Buchner funnel

could be used.) The greenish crystalline cake was washed on the filter and then sluiced back into the beaker, dispersed into 500-600ml of fresh water

and filtered again. Water was drawn through the solid until it ran completely clear and then the cake was drained for 10 minutes. The cake was dried

for 24 hours at 45-50°C to give 22.186g of pale-yellow crystalline powder, about 95% of theory.

Vacuum filtration using 11cm Buchner funnel ................... Final washed and dried anthraquinone cake

Comment

Pure anthracene may be used in place of bromoanthracene in which case 20g are required to replace the 28.3g of bromoanthracene used here.

(1) Book: The Synthetic dyestuffs and intermediate products, J.C. Cain and J.F. Thorpe, 7th edition, [1933], page 349. (Or Practical Organic

Chemistry, Cohen, [1926], p287 (also in downloadable digital 1910 edition) to which Cain and Thorpe give credit as the source of the preparation.)

|