| Pages:

1

2 |

PLSHY

Hazard to Self

Posts: 91

Registered: 30-7-2023

Member Is Offline

|

|

Help: Can ETN/PETN 4:6 be poured safely in a vacuum vibration environment?

I am planning to cast the shaped charge using an etn/petn 4:6 ratio which may come into contact with copper and mild steel when melted, as molten etn

is notoriously sensitive so I would like to know if there is any danger when casting using this ratio ? If it was dangerous, I would eliminate the

vacuum shock step and adjust the ratio to 1:1. I would add one percent diphenylamine as a stabilizer. Of course, the temperature throughout the

process will not exceed 80 degrees, and an intelligent temperature-controlled water bath is used to adjust it. Please judge whether there are any

dangers in this process? Because the amount of pouring is large (200~350gr), I want to avoid any risks. Or do you have any recommendations for

pouring charges that are more suitable for energy gathering and safer? Thank you very much for your answer!

|

|

|

PLSHY

Hazard to Self

Posts: 91

Registered: 30-7-2023

Member Is Offline

|

|

I have tried dozens of etn pours and several etn/petn pours before, but I have never touched metal when melting, and I have never tried vacuum

vibration pouring, so I am very worried.

|

|

|

Metacelsus

International Hazard

Posts: 2539

Registered: 26-12-2012

Location: Boston, MA

Member Is Offline

Mood: Double, double, toil and trouble

|

|

That sounds rather dangerous to me (especially the vibration). If you want to avoid risk you could make a machine to do it automatically, and retreat

to a safe distance.

|

|

|

OneEyedPyro

Hazard to Others

Posts: 280

Registered: 7-10-2015

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by PLSHY  | | I have tried dozens of etn pours and several etn/petn pours before, but I have never touched metal when melting, and I have never tried vacuum

vibration pouring, so I am very worried. |

The concept of 300 grams of very powerful high explosives detonating accidentally certainly should terrify you. I'd never physically manipulate that

much molten ETN unless my life depended on it.

If you insist on it, I'd do as Metacelsus said and figure out a way to maintain a safe distance. If your container or anything around it will produce

fragmentation ensure it's well shielded and not a danger to yourself or others if it does detonate.

Rather than pour it you could heat it in the container you intend to detonate it in.

Let us know before you try it so we can start a 'death after detonation' thread just in case something goes wrong and we never hear back from you.

[Edited on 23-9-2023 by OneEyedPyro]

|

|

|

PLSHY

Hazard to Self

Posts: 91

Registered: 30-7-2023

Member Is Offline

|

|

Quote: Originally posted by OneEyedPyro  | Quote: Originally posted by PLSHY  | | I have tried dozens of etn pours and several etn/petn pours before, but I have never touched metal when melting, and I have never tried vacuum

vibration pouring, so I am very worried. |

The concept of 300 grams of very powerful high explosives detonating accidentally certainly should terrify you. I'd never physically manipulate that

much molten ETN unless my life depended on it.

If you insist on it, I'd do as Metacelsus said and figure out a way to maintain a safe distance. If your container or anything around it will produce

fragmentation ensure it's well shielded and not a danger to yourself or others if it does detonate.

Rather than pour it you could heat it in the container you intend to detonate it in.

Let us know before you try it so we can start a 'death after detonation' thread just in case something goes wrong and we never hear back from you.

[Edited on 23-9-2023 by OneEyedPyro] |

What you said does make sense, maybe I can pour it in multiple times

(10 grams at a time) or give up this plan altogether, but the joke you made at the end made me a little uncomfortable, but thank you for your answer,

I may use tnt cast instead of etn or simply use egdn mixed with petn (but then I can't use partitions)

[Edited on 24-9-2023 by PLSHY]

|

|

|

EF2000

Hazard to Others

Posts: 153

Registered: 10-5-2023

Location: The Steppes

Member Is Offline

Mood: Taste testing the Tonka fuel

|

|

Does your mold conduct heat well? If yes, you can skip the pouring step and associated danger. Just fill mold with your mixture in powder form, then

heat it up to melt. While staying at the safe distance.

Of course, homogenicity of resulting explosive will suffer (though it can be compensated with vibration, right?). But accidental detonation of ~500 g

of TNTeq is too unpleasant way to join the host of heroes in Valhalla, visit Shangri-La and be reincarnated as unstoppable goddess of explosions in

some video game world.

I'd rather choose non-homogenous melt cast on that side than ideal cast and ticket to other side.

[Edited on 25-9-2023 by EF2000]

|

|

|

ManyInterests

National Hazard

Posts: 924

Registered: 19-5-2019

Member Is Offline

|

|

The most molten ETN I ever put was around 1g. And I did do it in a steel blasting cap as the main charge to a detonator. I wasn't aware that molten

ETN became super sensitive in mild steel. Good thing I handled it with the care it deserved. But amount of melt-cast anything is... really powerful.

Like 250/300g going off is like a bundle of grenades exploding all at once. Others have mentioned life after detonation, but here there will be no

life after that.

I am curious as to what you wish to do with the shaped charge? Like legitimately so. That is also quite a lot of energetic material. I made a few

hundred grams of stuff myself, but I never intended to make it into a charge. Even if I set it off in the middle of nowhere it will still be extremely

loud and I highly doubt that people wouldn't hear it for kilometers around.

| Quote: | | Does your mold conduct heat well? If yes, you can skip the pouring step and associated danger. Just fill mold with your mixture in powder form, then

heat it up to melt. While staying at the safe distance. |

I do concur this for safety. Melt-cast ETN is no joke. I only melt-casted my stuff within the container (and again, not more than 1 or 1.2g) When I

did it, I immersed my blasting cap in a hot water bath no more than 70C for 7 minutes before VERY carefully removing it and putting it in a foam block

that I made a hole in specifically for holding detonators in place.

so hypothetically, if I had a cardboard tube (sealed on end with epoxy and covered in aluminum foil to protect from water) immersed the same way,

would that safely allow a few hundred grams of ETN to be melt cast at once? I'm just curious here. I did end up accidentally melt-casting a few dozen

grams in hot water when I was trying to rewash my ETN. Nothing happened, but that was a scary moment.

|

|

|

dettoo456

Hazard to Others

Posts: 238

Registered: 12-9-2021

Member Is Offline

|

|

I’d first mix the EM with wax just as a handling precaution (it won’t affect the performance too much anyways), then maybe try to make a copy of

the shaped charge liner out of something like HDPE and then cast the EM in/onto that. You’d need to find a suitable mold release to pull the ETN

puck off, then you can just plunk it onto the actual metal liner face. Also though, for stability’s sake, maybe try to coat the metal (Cu or steel)

with a spray coat or non-reactive lacquer to prevent the ETN from metal contact under storage conditions. I don’t know if it’d be a big issue but

PETN does degrade in the presence of Fe so you could run into similar issues with Cu and steel.

|

|

|

PLSHY

Hazard to Self

Posts: 91

Registered: 30-7-2023

Member Is Offline

|

|

Quote: Originally posted by EF2000  | Does your mold conduct heat well? If yes, you can skip the pouring step and associated danger. Just fill mold with your mixture in powder form, then

heat it up to melt. While staying at the safe distance.

Of course, homogenicity of resulting explosive will suffer (though it can be compensated with vibration, right?). But accidental detonation of ~500 g

of TNTeq is too unpleasant way to join the host of heroes in Valhalla, visit Shangri-La and be reincarnated as unstoppable goddess of explosions in

some video game world.

I'd rather choose non-homogenous melt cast on that side than ideal cast and ticket to other side.

[Edited on 25-9-2023 by EF2000] |

It's a nice method, maybe I could just put it in scalding hot water and

leave so I don't have the risk of stirring it, but there's a good chance it could blow up my apartment if it starts accidentally, so I thought I'd add

A part of DNT or TNT reduces the sensitivity. I found that both substances can be miscible with etn in a certain proportion and lower the melting

point (40 degrees Celsius). This may reduce the performance to a certain extent, but it is still enough. This is a good Method?

|

|

|

PLSHY

Hazard to Self

Posts: 91

Registered: 30-7-2023

Member Is Offline

|

|

Quote: Originally posted by ManyInterests  | The most molten ETN I ever put was around 1g. And I did do it in a steel blasting cap as the main charge to a detonator. I wasn't aware that molten

ETN became super sensitive in mild steel. Good thing I handled it with the care it deserved. But amount of melt-cast anything is... really powerful.

Like 250/300g going off is like a bundle of grenades exploding all at once. Others have mentioned life after detonation, but here there will be no

life after that.

I am curious as to what you wish to do with the shaped charge? Like legitimately so. That is also quite a lot of energetic material. I made a few

hundred grams of stuff myself, but I never intended to make it into a charge. Even if I set it off in the middle of nowhere it will still be extremely

loud and I highly doubt that people wouldn't hear it for kilometers around.

| Quote: | | Does your mold conduct heat well? If yes, you can skip the pouring step and associated danger. Just fill mold with your mixture in powder form, then

heat it up to melt. While staying at the safe distance. |

I do concur this for safety. Melt-cast ETN is no joke. I only melt-casted my stuff within the container (and again, not more than 1 or 1.2g) When I

did it, I immersed my blasting cap in a hot water bath no more than 70C for 7 minutes before VERY carefully removing it and putting it in a foam block

that I made a hole in specifically for holding detonators in place.

so hypothetically, if I had a cardboard tube (sealed on end with epoxy and covered in aluminum foil to protect from water) immersed the same way,

would that safely allow a few hundred grams of ETN to be melt cast at once? I'm just curious here. I did end up accidentally melt-casting a few dozen

grams in hot water when I was trying to rewash my ETN. Nothing happened, but that was a scary moment. |

I'm

going to use it to penetrate steel columns, which is apparently legal in our country, and I need to design a low-cost, high-power perforating charge.

|

|

|

Microtek

National Hazard

Posts: 865

Registered: 23-9-2002

Member Is Offline

Mood: No Mood

|

|

| Quote: |

blow up my apartment

|

Please don't work with that amount of very sensitive HE in an appartment. You will definitely be endangering the people living around you.

|

|

|

EF2000

Hazard to Others

Posts: 153

Registered: 10-5-2023

Location: The Steppes

Member Is Offline

Mood: Taste testing the Tonka fuel

|

|

Really now, don't do it in apartment, in house or even in garage. It can do a lot of damage, like collapsing ceiling or rupturing gas tubes.

If I would be doing such project, I'll go to the steppe, dig a hole and heat the mold in water bath with something like portable stove (maybe there

are electric ones, working from something like car battery, didn't check) or low-temperature flame (hexamine fuel tablets).

About adding TNT, pentolite was used for HEAT charges and small explosive shells (like HEFI for anti-air) with no issues. Penetration performance of

old HEAT shells sounds puny today (~130 mm for 105 mm howitzer shell). But that's because they were rotating, not because pentolite is weak or

something.

[Edited on 26-9-2023 by EF2000]

|

|

|

PLSHY

Hazard to Self

Posts: 91

Registered: 30-7-2023

Member Is Offline

|

|

Of course I am not doing this in a building, but in a bungalow in the village with few people around...Thank you for your concern

|

|

|

Tsjerk

International Hazard

Posts: 3031

Registered: 20-4-2005

Location: Netherlands

Member Is Offline

Mood: Mood

|

|

If you don't care about the absolute best performance, then why would you melt cast to begin with? Powdered PETN or ETN works just fine for shaped

charges.

Quote: Originally posted by PLSHY  | | Of course I am not doing this in a building, but in a bungalow in the village with few people around. |

Right... And a bungalow is not a building and a few people are not people?

[Edited on 26-9-2023 by Tsjerk]

|

|

|

PLSHY

Hazard to Self

Posts: 91

Registered: 30-7-2023

Member Is Offline

|

|

Quote: Originally posted by Tsjerk  | If you don't care about the absolute best performance, then why would you melt cast to begin with? Powdered PETN or ETN works just fine for shaped

charges.

Quote: Originally posted by PLSHY  | | Of course I am not doing this in a building, but in a bungalow in the village with few people around. |

Right... And a bungalow is not a building and a few people are not people?

[Edited on 26-9-2023 by Tsjerk] |

Only I can enter this house, and it has only one floor (about 70 square

meters), so it is called a bungalow,and sparsely populated means that there are not many people living around it. This house is our old house, but

I don't want anything to explode inside, so I asked the question "Can it be cast safely? Because the volume is large, I want to avoid any accidents

and use pressed pbx is also a good method, but the density of the pressed grain is too low. Since the penetration depth of the homogenized target

plate is directly proportional to the square of the explosion velocity, I want to increase the density as much as possible, so using tnt casting will

also The effect is much better than simply suppressing it. I agree that adding a part of dnt is a compromise on sensitivity, but it does not mean

that I don’t care about power at all.

[Edited on 26-9-2023 by PLSHY]

|

|

|

PLSHY

Hazard to Self

Posts: 91

Registered: 30-7-2023

Member Is Offline

|

|

Forget about the house, I'm pretty sure I'm the only one who would be hurt if anything less than 1kg of tnt exploded inside (or the termites that live

there). What I prefer is that there is no possibility of explosion, rather than reducing losses when there is a possibility of explosion, because I

don’t want to be exposed to the risk of losing my life at any time. If you tell me that using melted ETN is likely to explode at any time, then I

will give up this immediately plan! I am now considering adding a certain proportion of dnt or tnt to reduce the sensitivity or simply using tnt for

casting. For safe casting, I added diphenylamine, used stainless steel for the casing, and tinned the copper shroud. In fact, the sensitivity of

melted etn is very complicated. The sensitivity of liquid nitrate seems to be proportional to the viscosity (only for NG homologues, such as etn,

egdn). I checked the relevant information and found that the drop weight sensitivity of methyl nitrate is 40 cm, ethylene glycol dinitrate increases

to 20 cm, while nitroglycerin is 5 cm, melted etn is 1 cm +-0.6 cm. This is also almost directly proportional to their viscosity and inversely

proportional to the difficulty of low-speed detonation. This seems to be related to the way they detonate: the bubbles in the liquid are subject to

external impact, causing the bubbles to be sharply compressed, increasing a large amount of internal energy, and eventually causing the explosive to

be detonated. I read in a book that the impact sensitivity of nitroglycerin with bubbles and without bubbles is about 20 times different. The

viscosity of a liquid is also related to the number of bubbles contained within it.

|

|

|

PLSHY

Hazard to Self

Posts: 91

Registered: 30-7-2023

Member Is Offline

|

|

Therefore, the high sensitivity of ETN does not come from itself, but from the bubbles trapped by its high viscosity, so the melted ETN that has been

eliminated by vacuum should have a lower sensitivity. (We all know that semi-crystalline NG is the most sensitive due to the friction between the

internal sensitive crystal and the liquid). Will petn and melted etn have such friction? After all, petn has a certain solubility in etn, so it is

also very There may be crystallization, and petn will increase the viscosity and bubbles of melted etn, so it stands to reason that petn will

increase the sensitivity of etn, but experiments tell us that petn will reduce the sensitivity of etn, which is really interesting. In addition, the

impact sensitivity of NG with bubbles removed is twice as low as that of petn. This means that the sensitivity of melted etn without bubbles is likely

to be more insensitive than that of unmelted etn! Has anyone had any experience or experience with this? I think I’d love to explore!

|

|

|

OneEyedPyro

Hazard to Others

Posts: 280

Registered: 7-10-2015

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by PLSHY  | | Therefore, the high sensitivity of ETN does not come from itself, but from the bubbles trapped by its high viscosity, so the melted ETN that has been

eliminated by vacuum should have a lower sensitivity. (We all know that semi-crystalline NG is the most sensitive due to the friction between the

internal sensitive crystal and the liquid). Will petn and melted etn have such friction? After all, petn has a certain solubility in etn, so it is

also very There may be crystallization, and petn will increase the viscosity and bubbles of melted etn, so it stands to reason that petn will

increase the sensitivity of etn, but experiments tell us that petn will reduce the sensitivity of etn, which is really interesting. In addition, the

impact sensitivity of NG with bubbles removed is twice as low as that of petn. This means that the sensitivity of melted etn without bubbles is likely

to be more insensitive than that of unmelted etn! Has anyone had any experience or experience with this? I think I’d love to explore!

|

It might be possible to use a solvent like acetone to create a hot saturated solution essentially making it unable to detonate while pouring then

remotely pull a vacuum under vibration and heating allowing you to get back while the acetone evaporates and the ETN/PETN reaches its natural melting

point.

This would obviously bring extremely flammable vapors into the equation possibly causing a fire leading to an accidental detonation. You'd at least be

a safe distance away. Keeping air out of the system and eliminating all possible ignition sources nearby would be necessary.

|

|

|

Microtek

National Hazard

Posts: 865

Registered: 23-9-2002

Member Is Offline

Mood: No Mood

|

|

| Quote: |

Therefore, the high sensitivity of ETN does not come from itself, but from the bubbles trapped by its high viscosity

|

Correlation does not imply causation, meaning, this conclusion is a logical fallacy. It is entirely possible that the increased sensitivity of molten

ETN is caused by the increased energy of the molecules (which will lower the required activation enrgy) rather than any trapped bubbles. This would

make your assumption of increased safety from vacuum vibration false, which would lead to an increased risk of accident.

If your question is "is it safe to melt cast ETN" then the answer is a definite no. There are steps you can take to mitigate the consequences of

accidental detonation, but with larger amounts of HE this becomes more difficult.

I don't know if any rigorous experiments with ETN/PETN sensitivity in the molten state have been done, though Roscoe seemed to have some experience

with compositions along these lines.

[Edited on 27-9-2023 by Microtek]

|

|

|

PLSHY

Hazard to Self

Posts: 91

Registered: 30-7-2023

Member Is Offline

|

|

Quote: Originally posted by Microtek  |

| Quote: |

Therefore, the high sensitivity of ETN does not come from itself, but from the bubbles trapped by its high viscosity

|

Correlation does not imply causation, meaning, this conclusion is a logical fallacy. It is entirely possible that the increased sensitivity of molten

ETN is caused by the increased energy of the molecules (which will lower the required activation enrgy) rather than any trapped bubbles. This would

make your assumption of increased safety from vacuum vibration false, which would lead to an increased risk of accident.

If your question is "is it safe to melt cast ETN" then the answer is a definite no. There are steps you can take to mitigate the consequences of

accidental detonation, but with larger amounts of HE this becomes more difficult.

I don't know if any rigorous experiments with ETN/PETN sensitivity in the molten state have been done, though Roscoe seemed to have some experience

with compositions along these lines.

[Edited on 27-9-2023 by Microtek] |

I am not completely sure about this conclusion, but it is very possible

based on speculation. In C.H. Johnson's book "Detonation of Explosives", the detonation process of liquid nitrate explosives and the relationship

between bubbles and sensitivity are explained in great detail. Of course, I may be wrong. The low activation energy caused by high temperature may

also be the reason for the high sensitivity of melting etn.

|

|

|

PLSHY

Hazard to Self

Posts: 91

Registered: 30-7-2023

Member Is Offline

|

|

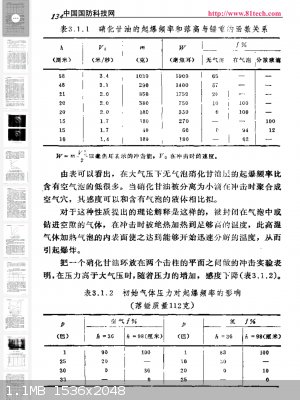

However, there is another point worthy of our attention, that is, the sensitivity changes drastically from solid to liquid. The sensitivity of almost

all explosive liquids will be much higher than that of solids. Even TMETN, which is famous for its insensitivity, or PETN, which is famous for its

stability, are still mainstream. This is true for TNT. This is obtained through experiments. However, the small increase in internal energy brought by

the slowly rising temperature cannot well explain the drastic change in sensitivity from solid to liquid. Therefore, CH Johnson proposed a special

detonation method for liquid explosives. way (as shown in the figure). This is most likely a common property of all explosives with two phases. Note

that it is all explosives with two phases, not just liquid or nitrate explosives.

|

|

|

PLSHY

Hazard to Self

Posts: 91

Registered: 30-7-2023

Member Is Offline

|

|

The sensitivity of the NG with bubbles removed is nearly 20 times lower than that of the normal tested NG! This speaks volumes! And there is a good

way to remove bubbles in liquid explosives, which is to replace the bubbles with water and melt the explosives with water to obtain molten etn without

bubbles.

|

|

|

Microtek

National Hazard

Posts: 865

Registered: 23-9-2002

Member Is Offline

Mood: No Mood

|

|

Nevertheless, making assumptions regarding sensitive high explosives in large amounts is a good way to not grow old. I urge you to err on the side of

caution, and assume that molten, vacuum treated ETN is as sensitive as the non-vacuumed version. That way, you won't be killed if the assumption turns

out to be wrong.

|

|

|

OneEyedPyro

Hazard to Others

Posts: 280

Registered: 7-10-2015

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by PLSHY  | | The sensitivity of the NG with bubbles removed is nearly 20 times lower than that of the normal tested NG! This speaks volumes! And there is a good

way to remove bubbles in liquid explosives, which is to replace the bubbles with water and melt the explosives with water to obtain molten etn without

bubbles. |

Regardless of air pockets the ETN will be in a more shock sensitive state as temperatures go up. At room temperature it's already considered to have

near primary levels of sensitivity.

|

|

|

PLSHY

Hazard to Self

Posts: 91

Registered: 30-7-2023

Member Is Offline

|

|

I would experiment with small ones (like 5 grams) before larger experiments, and take any explosives seriously!

|

|

|

| Pages:

1

2 |