PLSHY

Hazard to Self

Posts: 96

Registered: 30-7-2023

Member Is Offline

|

|

Cast vs Plastic

I used 15 grams of plastic explosive and fused cast explosive to make two explosive pillars, and used them to blast steel plates of the same size.

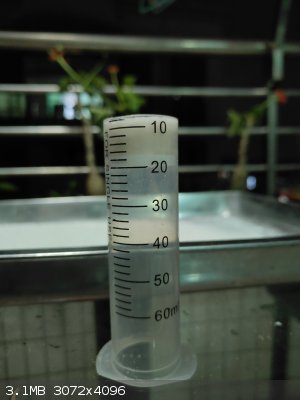

First weigh 15 grams of plastic explosive and melted explosive

|

|

|

PLSHY

Hazard to Self

Posts: 96

Registered: 30-7-2023

Member Is Offline

|

|

The red ones are plastic explosives and the white ones are molten explosives.

Next, shape the measured explosive into a cylinder in the syringe, then press in three grams of PETN to expand the explosion.

[Edited on 1-2-2024 by PLSHY]

|

|

|

PLSHY

Hazard to Self

Posts: 96

Registered: 30-7-2023

Member Is Offline

|

|

The size of the steel plate is 1.5cm*8cm*10cm. The steel plates used in both explosives are the same.

|

|

|

PLSHY

Hazard to Self

Posts: 96

Registered: 30-7-2023

Member Is Offline

|

|

Place the explosive on the steel plate and light the fuse...

|

|

|

PLSHY

Hazard to Self

Posts: 96

Registered: 30-7-2023

Member Is Offline

|

|

|

|

|

PLSHY

Hazard to Self

Posts: 96

Registered: 30-7-2023

Member Is Offline

|

|

Four pits appeared on the two steel plates!

Let’s compare and measure the size of the pit

First is plastic explosives.

This is the crater it made on the steel plate

The first picture is the front and the second is the back.

Hole depth 3.5mm

[Edited on 1-2-2024 by PLSHY]

|

|

|

PLSHY

Hazard to Self

Posts: 96

Registered: 30-7-2023

Member Is Offline

|

|

|

|

|

PLSHY

Hazard to Self

Posts: 96

Registered: 30-7-2023

Member Is Offline

|

|

Next comes the molten explosives.

This is the crater it made on the steel plate.

The first picture is the front and the second is the back. The depth of the pit is 6mm.

[Edited on 1-2-2024 by PLSHY]

|

|

|

PLSHY

Hazard to Self

Posts: 96

Registered: 30-7-2023

Member Is Offline

|

|

It can be found that the difference is really big, the melted explosive wins! I was amazed at its detonation performance! Cast explosives on the

bottom, plastic explosives on the top

|

|

|

fx-991ex

Hazard to Others

Posts: 109

Registered: 20-5-2023

Member Is Offline

|

|

Nice test with interesting result.

what did you use as a primary? I see some aluminum foil at the end of the fuse, is it ETN?.

So the main charge was also PETN or it was something else and only the 3g booster was PETN?

[Edited on 1-2-2024 by fx-991ex]

|

|

|

PLSHY

Hazard to Self

Posts: 96

Registered: 30-7-2023

Member Is Offline

|

|

Quote: Originally posted by fx-991ex  | Nice test with interesting result.

what did you use as a primary? I see some aluminum foil at the end of the fuse, is it ETN?.

So the main charge was also PETN or it was something else and only the 3g booster was PETN?

[Edited on 1-2-2024 by fx-991ex] |

I used 0.3 grams of lead azide

[Edited on 1-2-2024 by PLSHY]

|

|

|

PLSHY

Hazard to Self

Posts: 96

Registered: 30-7-2023

Member Is Offline

|

|

I forgot to give their ratio!

The composition of plastic explosives is 85 parts petn: 15 parts plasticizer

The composition of cast explosive is 1petn: 1etn

[Edited on 1-2-2024 by PLSHY]

|

|

|

DennyDevHE77

Hazard to Others

Posts: 168

Registered: 15-9-2014

Member Is Offline

Mood: No Mood

|

|

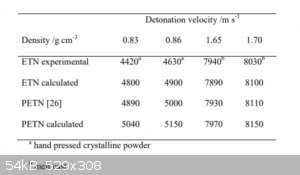

Thanks for the pictures. But all in all, nothing amazing. Cast ETH has a density of 1.65-1.7 and a detonation velocity of 7950-8000 m/s.

A quality high-density plastic explosive can also have similar parameters (C4 comes to mind), but it has to pulverize the inert component (binder)

during detonation, losing energy in the process. This affects the explosion temperature, energy release, explosive yield, and other parameters.

By the way, you did not specify the density of your plastic explosive. A quality PETN-based plastic can have >1.6 g/mL at 90/10 and two crystal

fractions.

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1447

Registered: 2-9-2014

Location: Tel Aviv University

Member Is Offline

Mood: old jew

|

|

Good job. Finally, after a long time, I see a quality measuring test. That hole on the opposite side is usually called a tear break.

Tear break can kill a tank crew under similar conditions. Without any hole in armor.....

Development of primarily - secondary substances: CHP (2015) neutral CHP and Lithex (2022) Brightelite (2023) Nitrocelite and KC primer (2024) Diper

60 (2025)

|

|

|

PLSHY

Hazard to Self

Posts: 96

Registered: 30-7-2023

Member Is Offline

|

|

Quote: Originally posted by DennyDevHE77  | Thanks for the pictures. But all in all, nothing amazing. Cast ETH has a density of 1.65-1.7 and a detonation velocity of 7950-8000 m/s.

A quality high-density plastic explosive can also have similar parameters (C4 comes to mind), but it has to pulverize the inert component (binder)

during detonation, losing energy in the process. This affects the explosion temperature, energy release, explosive yield, and other parameters.

By the way, you did not specify the density of your plastic explosive. A quality PETN-based plastic can have >1.6 g/mL at 90/10 and two crystal

fractions. |

I've measured it before. The density of plastic explosives is above 1.5, and the density of cast explosives is above 1.7

I used a formula to calculate that the detonation velocity of melted explosive reaches 8300 at a density of 1.7

This is actually a very high explosion speed, because it is not a molten-cast explosive with tnt as a carrier, but a molten-cast explosive with etn as

a carrier! Since etn has similar performance to petn (about 5% weaker than petn), even if the melt-cast explosive has the same density as plastic

explosive, the explosive speed will only be higher! In contrast, pure petn or rdx only has an explosion speed of 8400 when pressed to a density of

1.7. It does not matter whether the maximum density of plastic explosives can reach 1.7 (the plasticizer density is usually only about 0.9, so the

maximum density of plastic explosives is generally not will exceed 1.65 (for example, the maximum density of C4 explosive is 1.65), but even if it

reaches the maximum density, its performance will definitely not exceed that of pure PETN or RDX of the same density, so this melt-cast explosive

cannot be used by any PETN or RDX-based plastic explosives. Beyond!

|

|

|

PLSHY

Hazard to Self

Posts: 96

Registered: 30-7-2023

Member Is Offline

|

|

But I did a test before.

That is comparing three different plastic explosives.

The red one is called No. 1 plastic explosive, the pink one is called No. 2 plastic explosive, and the white one is called No. 3 plastic explosive.

From left to right they are numbers one, two and three

The depths of the pits of the steel plates are 10mm, 11mm, and 14mm respectively.

The steel plate is a 1cm steel plate made of two 0.5cm channel steels.

The plastic explosive compared with melt-cast explosive this time is No. 1 plastic explosive. I believe it would be better if the No. 3 plastic

explosive with more advanced technology is used, but it cannot exceed 5mm.

|

|

|

PLSHY

Hazard to Self

Posts: 96

Registered: 30-7-2023

Member Is Offline

|

|

This picture shows the front of the steel plate. From left to right, they are No. 3, No. 2, and No. 1.

[Edited on 2-2-2024 by PLSHY]

|

|

|

PLSHY

Hazard to Self

Posts: 96

Registered: 30-7-2023

Member Is Offline

|

|

And pictures of the explosives used in the test

|

|

|

DennyDevHE77

Hazard to Others

Posts: 168

Registered: 15-9-2014

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by PLSHY  | | I used a formula to calculate that the detonation velocity of melted explosive reaches 8300 at a density of 1.7 |

Formulas are good of course, but if there is practical material it is better to use it, I used this document. According to it, the detonation velocity

is about 8 km/s.

Quote: Originally posted by PLSHY  | | so the maximum density of plastic explosives is generally not will exceed 1.65 (for example, the maximum density of C4 explosive is 1.65), but even if

it reaches the maximum density, its performance will definitely not exceed that of pure PETN or RDX of the same density, so this melt-cast explosive

cannot be used by any PETN or RDX-based plastic explosives |

That's my point above. That even with the same density, the plastic explosive would need to pulverize the bundle, losing some energy in the process.

Attachment: ETN&PETN.pdf (4.8MB)

This file has been downloaded 259 times

[Edited on 2-2-2024 by DennyDevHE77]

|

|

|

PLSHY

Hazard to Self

Posts: 96

Registered: 30-7-2023

Member Is Offline

|

|

Quote: Originally posted by DennyDevHE77  | Quote: Originally posted by PLSHY  | | I used a formula to calculate that the detonation velocity of melted explosive reaches 8300 at a density of 1.7 |

Formulas are good of course, but if there is practical material it is better to use it, I used this document. According to it, the detonation velocity

is about 8 km/s.

Quote: Originally posted by PLSHY  | | so the maximum density of plastic explosives is generally not will exceed 1.65 (for example, the maximum density of C4 explosive is 1.65), but even if

it reaches the maximum density, its performance will definitely not exceed that of pure PETN or RDX of the same density, so this melt-cast explosive

cannot be used by any PETN or RDX-based plastic explosives |

That's my point above. That even with the same density, the plastic explosive would need to pulverize the bundle, losing some energy in the process.

[Edited on 2-2-2024 by DennyDevHE77] |

I refer to the book written by Urbanski, which says that petn has an explosion speed of 8300 at 1.7 density, and 8500 at 1.72 density (there is also

data that says it has an explosion speed of 7750 at 1.75 density, which is obviously a mistake). I found a lot of books (mostly Chinese books), and

the explosion speed at 1.7 density is around 8400.

[Edited on 2-2-2024 by PLSHY]

|

|

|

PLSHY

Hazard to Self

Posts: 96

Registered: 30-7-2023

Member Is Offline

|

|

PETN-based plastic explosives can reach a detonation velocity of 8000 at a density of 1.6, while pure PETN has the same detonation velocity at a

density of 1.7 as a plastic explosive containing inert ingredients at a density of 1.6? it's out of the question. Therefore, the burst speed of petn

at 1.7 density is definitely more than 8000. The only possibility is that the test method in the literature you referenced is not standard.

|

|

|

DennyDevHE77

Hazard to Others

Posts: 168

Registered: 15-9-2014

Member Is Offline

Mood: No Mood

|

|

Well, so it exceeds, in the screenshot that I dropped above, it can be seen that its detonation velocity is 8110 m/s. In other sources, I found speeds

of 8350 at 1.72, which is quite consistent with 8110 at 1.7

As for the detonation rate in plastic explosives, it may well be even higher than in powder ones. Because of the greater continuity. Exactly the same

works for watered-down explosives. Urbanski wrote about that, too. And I even remember, I think the Japanese, in some study "accelerated" tetryl

thickened with water with dissolved ammonium nitrate to 8500 m/s instead of 7600 characteristic for it

There was such a plastic explosive.

"Performex -79P" PETN– 79%, dibutyl phthalate — 13%, nitrocellulose – 8% Detonation rate

7850 m/s at 1.50 g/cm3. It is used for explosive hardening of metal and repair of blast

furnaces.

Pure pressed PETN at 1.51 g/ml yields 7520 m/s.

In fact, the biggest problem is that different sources from the beginning of the twentieth century to the present used different measuring equipment

and different measurement conditions. So the exact detonation speeds can easily differ by 300-500 m/s. In such old books as Stetbacher or

Khmelnitsky's reference books, they indicate 8400 m/s at 1.6, which is obviously not the case.

[Edited on 2-2-2024 by DennyDevHE77]

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1447

Registered: 2-9-2014

Location: Tel Aviv University

Member Is Offline

Mood: old jew

|

|

Denny is right. Literature and tables are interesting. But it's just a guide and a number in the table. Nothing more than approx value.

The most important are the own tests. Because each test contains many variable values. From the own tests, it is quite clear which substance is the

most brisantive. Even if the opposite was written in some literature. Most important (decisive) are results itself of researcher. In his conditions.

Bigger hole = bigger brisance.... .....(at same exact conditions of course) .....(at same exact conditions of course)

Development of primarily - secondary substances: CHP (2015) neutral CHP and Lithex (2022) Brightelite (2023) Nitrocelite and KC primer (2024) Diper

60 (2025)

|

|

|

PLSHY

Hazard to Self

Posts: 96

Registered: 30-7-2023

Member Is Offline

|

|

Quote: Originally posted by DennyDevHE77  | Well, so it exceeds, in the screenshot that I dropped above, it can be seen that its detonation velocity is 8110 m/s. In other sources, I found speeds

of 8350 at 1.72, which is quite consistent with 8110 at 1.7

As for the detonation rate in plastic explosives, it may well be even higher than in powder ones. Because of the greater continuity. Exactly the same

works for watered-down explosives. Urbanski wrote about that, too. And I even remember, I think the Japanese, in some study "accelerated" tetryl

thickened with water with dissolved ammonium nitrate to 8500 m/s instead of 7600 characteristic for it

There was such a plastic explosive.

"Performex -79P" PETN– 79%, dibutyl phthalate — 13%, nitrocellulose – 8% Detonation rate

7850 m/s at 1.50 g/cm3. It is used for explosive hardening of metal and repair of blast

furnaces.

Pure pressed PETN at 1.51 g/ml yields 7520 m/s.

In fact, the biggest problem is that different sources from the beginning of the twentieth century to the present used different measuring equipment

and different measurement conditions. So the exact detonation speeds can easily differ by 300-500 m/s. In such old books as Stetbacher or

Khmelnitsky's reference books, they indicate 8400 m/s at 1.6, which is obviously not the case.

[Edited on 2-2-2024 by DennyDevHE77] |

I must admit, you are right. Because part of the air in the explosive is replaced by a plasticizer with a higher sonic velocity, it can indeed bring

about a higher detonation velocity. I was wrong about this part, an explosive containing a certain inert substance at the same density may have a

higher detonation velocity.

|

|

|

Microtek

National Hazard

Posts: 920

Registered: 23-9-2002

Member Is Offline

Mood: No Mood

|

|

Also, remember that the dimensions and containment of the charge matters greatly, as alluded to above. Charges of small diameter will have lower VOD

than ones with larger diameter of course, but short charges may not have time to accelerate to the highest possible VOD. I question whether the

syringe charges pictured were long enough to accelerate sufficiently.

|

|

|