| Pages:

1

2

3

4

5

..

7 |

JJay

International Hazard

Posts: 3440

Registered: 15-10-2015

Member Is Offline

|

|

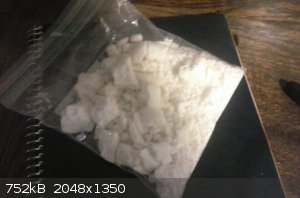

Oh and of course, here is a picture of the crude product.

|

|

|

JJay

International Hazard

Posts: 3440

Registered: 15-10-2015

Member Is Offline

|

|

It's definitely sodium ethyl sulfate, and I think 90% is a good estimate of the purity. I did another run, this time neutralizing to pH 8 (instead of

9) and filtering the solution at 500 mL. I got slightly less product, and it appears that slight decomposition took place, so the product is light tan

instead of nearly white. But after evaporation of the water, the product is crystalline (consistency of coarse sand). I don't know the purity, but I

am guessing that it is higher than 95%.

|

|

|

S.C. Wack

bibliomaster

Posts: 2419

Registered: 7-5-2004

Location: Cornworld, Central USA

Member Is Offline

Mood: Enhanced

|

|

What is this assessment based on? BTW barium chloride or recrystallization from alcohol would be a decent minimum effort...BTW2, old CRC Handbook says

the sodium salt is a monohydrate, solubility 164 g/100 ml water at 17C. No K hydrate is mentiored and no solubility for the K salt is either, except

it is soluble in water and alcohol.

|

|

|

JJay

International Hazard

Posts: 3440

Registered: 15-10-2015

Member Is Offline

|

|

I used an analysis that might be hard to reproduce, so I am looking into other methods of verification.... The melting point of the products have

obtained appear to be less than 100C, and I am not exactly sure why. If the substance is heated on a water bath, it will melt and harden as the water

is given off.

I am planning to do a recrystalization from methanol / ether.

[Edited on 16-4-2016 by JJay]

|

|

|

JJay

International Hazard

Posts: 3440

Registered: 15-10-2015

Member Is Offline

|

|

The crystaline substance was acidic, and the recrystallization was a disaster... I think it may have contained considerable sodium bisulfate....

It has appeared to me on multiple occasions that sodium ethyl sulfate decomposes in neutral pH solutions, but I have read a few places that it does

not, and I can't figure out what could be acidifying it unless it is picking up carbon dioxide from the air.... Anyway, I started another run, and

this time I'll aim for pH 9 and won't filter when the solution becomes saturated.

|

|

|

S.C. Wack

bibliomaster

Posts: 2419

Registered: 7-5-2004

Location: Cornworld, Central USA

Member Is Offline

Mood: Enhanced

|

|

Desseigne and Giral seem to have no problem with distilling off excess ethanol and some added water from their neutral to slightly alkaline solution.

Perhaps their simple procedure could be followed to dryness, if sodium sulfate all separates nicely first and why not throw in some vacuum too.

|

|

|

JJay

International Hazard

Posts: 3440

Registered: 15-10-2015

Member Is Offline

|

|

I wonder if there are impurities in my sulfuric acid that could be causing difficulties. It's one of the better-quality drain cleaners, but it's not

distilled and titrates to 95%... I've also observed that with NaEtSO4 created with sodium bisulfate, though....

[Edited on 17-4-2016 by JJay]

|

|

|

JJay

International Hazard

Posts: 3440

Registered: 15-10-2015

Member Is Offline

|

|

Quote: Originally posted by S.C. Wack  | | Desseigne and Giral seem to have no problem with distilling off excess ethanol and some added water from their neutral to slightly alkaline solution.

Perhaps their simple procedure could be followed to dryness, if sodium sulfate all separates nicely first and why not throw in some vacuum too.

|

Perhaps... I've tried very similar procedures before and found them disappointing, though. A large excess of ethanol could be used to chase the

unwanted mineral salts out of solution, but there is still the problem of hydrolosis if the sodium ethyl sulfate solution is not sufficiently

alkaline. Also, sources disagree on the temperature and duration of heating for forming ethylsulfuric acid, and I haven't found any sources that

specify different melting points for the monohydrate and anhydrous sodium ethyl sulfate.

|

|

|

chemrox

International Hazard

Posts: 2961

Registered: 18-1-2007

Location: UTM

Member Is Offline

Mood: LaGrangian

|

|

Two comments: 1) it's a worthwhile venture as sodium ethyl sulfate goes for $134/25g. 2) this isn't "organic chemistry"

"When you let the dumbasses vote you end up with populism followed by autocracy and getting back is a bitch." Plato (sort of)

|

|

|

clearly_not_atara

International Hazard

Posts: 2781

Registered: 3-11-2013

Member Is Offline

Mood: Big

|

|

I doubt that SES is actually worth $5/g. It's hardly useful for anything, other than selective ethylations of a few polyfunctional compounds. It

*costs* $5/g, but what you're really paying for is the ability to order a chemical that isn't produced in large quantities, i.e. you're paying because

it's special-made for you, the same way you would also pay (in terms of your time and energy) to make it yourself.

Similarly, McDonald's fries aren't worth what they charge for them -- you can buy frozen French fries a the store for way less. McDonald's fries cost

what they do because of how and when they're given to you; you pay for the service of being handed a box of freshly-fried French fries,

similar to paying for the service of making a small amount of a useless chemical just for you.

That's why, if you're a professional chemist, you're probably gonna just buy diethyl sulfate for $50/kg and partially hydrolyse it (I bet bicarbonate

works). Much easier.

[Edited on 18-4-2016 by clearly_not_atara]

|

|

|

JJay

International Hazard

Posts: 3440

Registered: 15-10-2015

Member Is Offline

|

|

High-grade sodium ethyl sulfate actually is in demand and fetches a premium price since it is used for calibrating some equipment that monitors

alcohol consumption... of course, the stuff that the home hobbyist produces in a garage isn't worth as much, but I'm pretty darn sure there is a

market for tech grade NaEtSO4.

Also, not everyone wants to handle diethyl sulfate... and it's really not that much easier to make sodium ethyl sulfate from diethyl sulfate as it is

from ethanol and sulfuric acid.

[Edited on 18-4-2016 by JJay]

|

|

|

JJay

International Hazard

Posts: 3440

Registered: 15-10-2015

Member Is Offline

|

|

Quote: Originally posted by chemrox  | | Two comments: 1) it's a worthwhile venture as sodium ethyl sulfate goes for $134/25g. 2) this isn't "organic chemistry" |

This is a pretty long-running thread... it's a pretty simple organic compound, but I would have to say that Organic Chemistry is the best forum for

it.

Oh and I just found the melting point of the monohydrate! It's 86 C, according to Commercial Organic Analysis.

[Edited on 18-4-2016 by JJay]

|

|

|

JJay

International Hazard

Posts: 3440

Registered: 15-10-2015

Member Is Offline

|

|

I just did another run that yielded 288 grams. pH 9 seems to be a safe level of alkalinity for NaEtSO4. If anyone wants some - it is a fairly crude

tech grade but should work well in most synthetic reactions - feel free to message me. I can't say I'll let it go for a super cheap price, and I'm not

interested in supplying chemicals to people who are making illegal drugs, but if you have a legitimate use for it, I'm sure I can quote a better price

than you are likely to find elsewhere online.

The standardized solution markets for this stuff have completely unreal prices....

|

|

|

JJay

International Hazard

Posts: 3440

Registered: 15-10-2015

Member Is Offline

|

|

I revisited this a couple of months ago, attempting a larger batch, and discovered that upon repeated heating on a water bath with filtering,

eventually, it will become much harder to concentrate the solution further, and evaporation at 100 C will not cause the precipitation of further

salts. Upon cooling, a very slightly alkaline crystaline substance, melting at 86 C, will form on the sides and bottom of the flask and across the top

of the solution. It's hard to know exactly when to stop removing the water... evaporating the water until the solution solidifies completely on

cooling produces a similar product that visibly contains impurities in the form of a crust.

[Edited on 30-12-2016 by JJay]

|

|

|

sulfuric acid is the king

Hazard to Self

Posts: 94

Registered: 11-1-2017

Member Is Offline

|

|

No,you are not!

I am ultra inerested in this topic such a long time...

I tried to make NaEtSO4 many many times but i always failed at the major fact - it is soluble in ethanol/EtSO4,right?

I noticed when i neutralize acid with bicarbonate there was feezing,but i always thought that unsoluble part was NaEtSO4.

It was very suspicious that molar mass was very near,there was less product,and it reacted with weak acids like bicarbonate.

Now i know why...couse it was bicarbonate!!!

|

|

|

JJay

International Hazard

Posts: 3440

Registered: 15-10-2015

Member Is Offline

|

|

I'm not exactly sure how soluble it is offhand, but sodium ethyl sulfate is most definitely soluble in ethanol. I had little difficulty dissolving one

part of sodium ethyl sulfate in ten parts methanol. If you're trying to prepare it from calcium ethyl sulfate, it's best to neutralize with saturated

sodium carbonate solution and go slow so that you have less bicarbonate in solution at the end of the neutralization. Removing excess bicarbonate

causes mechanical losses. Also, the carbon dioxide released by neutralizing with bicarbonate greatly increases the solubility of the calcium

carbonate.

Although I'm not aware of it being mentioned in any ancient alchemical texts, it is a substance that was undoubtedly researched by alchemists... I

think the alchemical term is something like "crystallized soda of wine oil."

Just don't try fusing with it with potash and phlogisticated nitre in a boiling bath of clarified spruce pitch and redistilling the heavy ethers...

you might summon a demon or something.

[Edited on 11-1-2017 by JJay]

|

|

|

sulfuric acid is the king

Hazard to Self

Posts: 94

Registered: 11-1-2017

Member Is Offline

|

|

I willl make it by neutralizing mix of ethanol/ethylsulfuric acid,then filter off unreacted bicarbonate,and evaporate liquid mix.

Will thermal decomposition occur?

|

|

|

JJay

International Hazard

Posts: 3440

Registered: 15-10-2015

Member Is Offline

|

|

I think so.

|

|

|

sulfuric acid is the king

Hazard to Self

Posts: 94

Registered: 11-1-2017

Member Is Offline

|

|

Hmm...So i will need to use vacuum,or some recrystallization...

But i don't have any data on NaEtSO4,solubility table,some physical properties like boiling point etc... etc... It is very difficult to think what to

do without some essential data.

|

|

|

JJay

International Hazard

Posts: 3440

Registered: 15-10-2015

Member Is Offline

|

|

The monohydrate melts at 86 C. I'm not sure about the anhydrous salt; while I have seen actual crystals of it, they melted in my filter funnel and

then decomposed under heating in neutral conditions.

My observations are that heat and neutral conditions will destroy it in the presence of water, causing it to revert to sodium bisulfate and ethanol.

It's very highly soluble in water... I don't have the exact numbers in front of me, but it takes less than 100 mL of water to dissolve 100 grams of

it. Crystals of the pure (or at least very nearly pure) substance will register very slight alkalinity when placed against damp pH paper. It's been

stated that the pure monohydrate salt resembles cauliflower; that is a pretty accurate description.

I've attempted to produce it by similarly reacting ethylsulfuric acid with sodium carbonate but wasn't really sure how to recover all of the product

or purify it. You could probably extract it with ethanol and then remove it under vacuum, but that's messier than it sounds without a rotovap,

especially if you are trying to make more than a tiny quantity.

|

|

|

alking

Hazard to Others

Posts: 252

Registered: 11-3-2016

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by JJay  | | The monohydrate melts at 86 C. I'm not sure about the anhydrous salt; while I have seen actual crystals of it, they melted in my filter funnel and

then decomposed under heating in neutral conditions. |

Did you put your filter into the freezer? Maybe reduce it further if you're not getting many crystals to begin with.

| Quote: |

I've attempted to produce it by similarly reacting ethylsulfuric acid with sodium carbonate but wasn't really sure how to recover all of the product

or purify it. You could probably extract it with ethanol and then remove it under vacuum, but that's messier than it sounds without a rotovap,

especially if you are trying to make more than a tiny quantity.

|

Wouldn't that basically be the same as the bisulfate route? You could probably put it in a dessicant chamber I would think, no need for a rotovape.

|

|

|

JJay

International Hazard

Posts: 3440

Registered: 15-10-2015

Member Is Offline

|

|

Quote: Originally posted by alking  | Quote: Originally posted by JJay  | | The monohydrate melts at 86 C. I'm not sure about the anhydrous salt; while I have seen actual crystals of it, they melted in my filter funnel and

then decomposed under heating in neutral conditions. |

Did you put your filter into the freezer? Maybe reduce it further if you're not getting many crystals to begin with.

|

The problem was that the ether was evaporating much faster than the methanol in my filter funnel. Cooling the funnel is an interesting idea, but I

think if I'd used a more concentrated solution containing less ether, I would have had an easier time.

| Quote: |

Wouldn't that basically be the same as the bisulfate route? You could probably put it in a dessicant chamber I would think, no need for a rotovape.

|

In my experience, the bisulfate route works but doesn't work nearly as well as advertised.

[Edited on 12-1-2017 by JJay]

|

|

|

alking

Hazard to Others

Posts: 252

Registered: 11-3-2016

Member Is Offline

Mood: No Mood

|

|

What kind of yields did you get with the bisulfate route? Or do you not know since the product is impure? Sorry if you mentioned it already, I don't

want to read the whole thread.

|

|

|

JJay

International Hazard

Posts: 3440

Registered: 15-10-2015

Member Is Offline

|

|

I'm not really sure... I haven't tried it in quite some time, but the yield was nowhere close to the quantitative yield claimed in the patent... maybe

20%?

|

|

|

alking

Hazard to Others

Posts: 252

Registered: 11-3-2016

Member Is Offline

Mood: No Mood

|

|

Oh, that is pretty bad. Did you try the sulfuric acid route?

|

|

|

| Pages:

1

2

3

4

5

..

7 |